TIM Dispensing Automation For Volume Production: Equipment And Process Controls

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TIM Dispensing Technology Background and Objectives

Thermal Interface Materials (TIM) dispensing technology has evolved significantly over the past two decades, transitioning from manual application methods to increasingly automated solutions. This evolution has been driven by the growing demands of electronics manufacturing, particularly in high-performance computing, automotive electronics, and consumer devices where thermal management has become critical for product reliability and performance.

The historical trajectory of TIM dispensing began with simple manual syringe applications, progressing through semi-automated systems in the early 2000s, to today's fully automated high-precision dispensing equipment. This technological progression has been necessitated by the miniaturization of electronic components, increasing power densities, and the need for more efficient heat dissipation in modern electronic devices.

Current industry trends indicate a clear movement toward dispensing systems that can achieve higher precision, faster cycle times, and improved consistency across high-volume production environments. The integration of advanced sensors, machine vision systems, and real-time feedback mechanisms represents the cutting edge of this technology, enabling unprecedented levels of control and repeatability.

The primary objective of modern TIM dispensing automation is to optimize the balance between speed, precision, and reliability in volume production environments. This includes achieving consistent material application with minimal waste, accommodating various TIM formulations (from traditional greases to phase-change materials and liquid metal compounds), and maintaining quality across millions of units.

Technical goals in this field include reducing cycle times below 10 seconds per unit while maintaining positional accuracy within ±0.05mm and dispensed volume consistency within ±3%. Additionally, there is a push toward systems that can automatically adjust parameters based on material viscosity changes and environmental conditions, ensuring consistent results despite variables in the production environment.

Another critical objective is the development of closed-loop control systems that can monitor and adjust the dispensing process in real-time, reducing the need for manual inspection and rework. This includes advanced vision systems for pre- and post-dispensing inspection, weight or volume verification technologies, and automated pattern recognition for quality assurance.

The industry also aims to create more flexible dispensing platforms that can quickly adapt to different product configurations, material types, and production volumes without significant retooling or downtime. This adaptability is essential for contract manufacturers and OEMs dealing with diverse product portfolios and frequent design iterations.

The historical trajectory of TIM dispensing began with simple manual syringe applications, progressing through semi-automated systems in the early 2000s, to today's fully automated high-precision dispensing equipment. This technological progression has been necessitated by the miniaturization of electronic components, increasing power densities, and the need for more efficient heat dissipation in modern electronic devices.

Current industry trends indicate a clear movement toward dispensing systems that can achieve higher precision, faster cycle times, and improved consistency across high-volume production environments. The integration of advanced sensors, machine vision systems, and real-time feedback mechanisms represents the cutting edge of this technology, enabling unprecedented levels of control and repeatability.

The primary objective of modern TIM dispensing automation is to optimize the balance between speed, precision, and reliability in volume production environments. This includes achieving consistent material application with minimal waste, accommodating various TIM formulations (from traditional greases to phase-change materials and liquid metal compounds), and maintaining quality across millions of units.

Technical goals in this field include reducing cycle times below 10 seconds per unit while maintaining positional accuracy within ±0.05mm and dispensed volume consistency within ±3%. Additionally, there is a push toward systems that can automatically adjust parameters based on material viscosity changes and environmental conditions, ensuring consistent results despite variables in the production environment.

Another critical objective is the development of closed-loop control systems that can monitor and adjust the dispensing process in real-time, reducing the need for manual inspection and rework. This includes advanced vision systems for pre- and post-dispensing inspection, weight or volume verification technologies, and automated pattern recognition for quality assurance.

The industry also aims to create more flexible dispensing platforms that can quickly adapt to different product configurations, material types, and production volumes without significant retooling or downtime. This adaptability is essential for contract manufacturers and OEMs dealing with diverse product portfolios and frequent design iterations.

Market Analysis for Automated TIM Dispensing Solutions

The global market for automated Thermal Interface Material (TIM) dispensing solutions is experiencing robust growth, driven by increasing demand for thermal management in electronics manufacturing. The market size for automated dispensing equipment is estimated to reach $2.5 billion by 2025, with TIM-specific dispensing solutions representing approximately 15% of this segment. This growth trajectory is supported by a compound annual growth rate (CAGR) of 7.8% from 2020 to 2025, outpacing the broader electronics manufacturing equipment market.

Key market drivers include the miniaturization of electronic components, which necessitates more precise TIM application, and the growing complexity of semiconductor packages requiring advanced thermal management solutions. The automotive electronics sector, particularly electric vehicles with their high-performance computing needs, represents the fastest-growing segment with a projected 12.3% CAGR through 2025.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for over 60% of global demand, with China, Taiwan, and South Korea leading in adoption rates. North America follows with approximately 20% market share, driven primarily by high-end computing and telecommunications applications. Europe represents about 15% of the market, with Germany and the Netherlands showing the strongest growth in the region.

By industry vertical, consumer electronics manufacturers remain the largest end-users, constituting 35% of the market. However, automotive electronics is rapidly gaining share, currently at 25% and expected to reach parity with consumer electronics by 2027. Telecommunications equipment and data center hardware collectively represent another 30% of the market.

The customer segmentation reveals three distinct tiers: high-volume manufacturers seeking fully integrated automation solutions (40% of market value), mid-tier manufacturers requiring flexible, reconfigurable systems (35%), and smaller specialty manufacturers focusing on semi-automated solutions (25%). This segmentation is reshaping product development strategies among equipment suppliers.

Market challenges include the high initial capital investment required for fully automated systems, which creates barriers for small and medium enterprises. Additionally, the rapid evolution of TIM materials necessitates continuous equipment adaptation, creating technical challenges for equipment manufacturers and potential obsolescence risks for end-users.

Future market trends point toward increased integration of real-time quality monitoring systems, AI-driven process optimization, and compatibility with Industry 4.0 frameworks. The market is also witnessing a shift toward equipment-as-a-service business models, which may reduce capital barriers and accelerate adoption rates among smaller manufacturers.

Key market drivers include the miniaturization of electronic components, which necessitates more precise TIM application, and the growing complexity of semiconductor packages requiring advanced thermal management solutions. The automotive electronics sector, particularly electric vehicles with their high-performance computing needs, represents the fastest-growing segment with a projected 12.3% CAGR through 2025.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for over 60% of global demand, with China, Taiwan, and South Korea leading in adoption rates. North America follows with approximately 20% market share, driven primarily by high-end computing and telecommunications applications. Europe represents about 15% of the market, with Germany and the Netherlands showing the strongest growth in the region.

By industry vertical, consumer electronics manufacturers remain the largest end-users, constituting 35% of the market. However, automotive electronics is rapidly gaining share, currently at 25% and expected to reach parity with consumer electronics by 2027. Telecommunications equipment and data center hardware collectively represent another 30% of the market.

The customer segmentation reveals three distinct tiers: high-volume manufacturers seeking fully integrated automation solutions (40% of market value), mid-tier manufacturers requiring flexible, reconfigurable systems (35%), and smaller specialty manufacturers focusing on semi-automated solutions (25%). This segmentation is reshaping product development strategies among equipment suppliers.

Market challenges include the high initial capital investment required for fully automated systems, which creates barriers for small and medium enterprises. Additionally, the rapid evolution of TIM materials necessitates continuous equipment adaptation, creating technical challenges for equipment manufacturers and potential obsolescence risks for end-users.

Future market trends point toward increased integration of real-time quality monitoring systems, AI-driven process optimization, and compatibility with Industry 4.0 frameworks. The market is also witnessing a shift toward equipment-as-a-service business models, which may reduce capital barriers and accelerate adoption rates among smaller manufacturers.

Current Challenges in TIM Dispensing Automation

Despite significant advancements in thermal interface material (TIM) dispensing automation, several critical challenges persist that impede optimal volume production efficiency. Material inconsistency remains a primary concern, as TIM properties can vary between batches and even within the same batch due to storage conditions, temperature fluctuations, and aging effects. These variations directly impact dispensing precision and ultimately thermal performance of the final product.

Equipment calibration presents another significant hurdle. Current dispensing systems require frequent recalibration to maintain accuracy, resulting in production downtime and increased operational costs. The calibration process itself is often complex, requiring specialized knowledge and skills that may not be readily available in all manufacturing environments.

Process parameter optimization continues to challenge manufacturers. The relationship between dispensing parameters (pressure, temperature, speed) and dispensing outcomes is highly complex and material-specific. Finding the optimal parameter combination for each TIM formulation requires extensive experimentation and can be difficult to translate across different production lines or facilities.

Real-time monitoring capabilities remain insufficient in many existing systems. Current technologies often lack the ability to detect dispensing anomalies as they occur, leading to waste and quality issues that are only discovered during post-process inspection. This reactive approach results in material waste and production inefficiencies.

Integration with existing manufacturing lines presents compatibility challenges. Many TIM dispensing solutions function as standalone systems rather than seamlessly integrating with broader production processes. This disconnection creates workflow bottlenecks and complicates data collection for process improvement initiatives.

Environmental control during dispensing represents another persistent challenge. TIM dispensing outcomes are highly sensitive to ambient conditions including temperature, humidity, and air quality. Maintaining consistent environmental parameters across large production facilities is technically difficult and resource-intensive.

Scalability limitations affect manufacturers attempting to increase production volumes. Many current dispensing solutions that perform well at moderate production rates struggle to maintain the same precision and reliability when scaled to high-volume manufacturing requirements. This creates a significant barrier to production expansion.

Cleaning and maintenance requirements for dispensing equipment remain labor-intensive and time-consuming. Material residue buildup in dispensing systems can affect accuracy over time, necessitating regular cleaning cycles that interrupt production and require specialized maintenance procedures.

Equipment calibration presents another significant hurdle. Current dispensing systems require frequent recalibration to maintain accuracy, resulting in production downtime and increased operational costs. The calibration process itself is often complex, requiring specialized knowledge and skills that may not be readily available in all manufacturing environments.

Process parameter optimization continues to challenge manufacturers. The relationship between dispensing parameters (pressure, temperature, speed) and dispensing outcomes is highly complex and material-specific. Finding the optimal parameter combination for each TIM formulation requires extensive experimentation and can be difficult to translate across different production lines or facilities.

Real-time monitoring capabilities remain insufficient in many existing systems. Current technologies often lack the ability to detect dispensing anomalies as they occur, leading to waste and quality issues that are only discovered during post-process inspection. This reactive approach results in material waste and production inefficiencies.

Integration with existing manufacturing lines presents compatibility challenges. Many TIM dispensing solutions function as standalone systems rather than seamlessly integrating with broader production processes. This disconnection creates workflow bottlenecks and complicates data collection for process improvement initiatives.

Environmental control during dispensing represents another persistent challenge. TIM dispensing outcomes are highly sensitive to ambient conditions including temperature, humidity, and air quality. Maintaining consistent environmental parameters across large production facilities is technically difficult and resource-intensive.

Scalability limitations affect manufacturers attempting to increase production volumes. Many current dispensing solutions that perform well at moderate production rates struggle to maintain the same precision and reliability when scaled to high-volume manufacturing requirements. This creates a significant barrier to production expansion.

Cleaning and maintenance requirements for dispensing equipment remain labor-intensive and time-consuming. Material residue buildup in dispensing systems can affect accuracy over time, necessitating regular cleaning cycles that interrupt production and require specialized maintenance procedures.

Current Automation Solutions for Volume Production

01 Automated TIM dispensing control systems

Automated systems for controlling the dispensing of Thermal Interface Material (TIM) utilize advanced process controls to ensure precise application. These systems incorporate sensors, feedback mechanisms, and real-time monitoring to adjust dispensing parameters such as volume, pressure, and flow rate. The automation helps maintain consistency in TIM application, which is critical for thermal management in electronic components and semiconductor manufacturing.- Automated TIM dispensing control systems: Automated control systems for thermal interface material (TIM) dispensing processes that utilize sensors, feedback mechanisms, and precision controllers to ensure accurate material application. These systems monitor parameters such as temperature, pressure, and flow rate in real-time to maintain consistent TIM dispensing quality. Advanced algorithms adjust dispensing parameters automatically based on environmental conditions and material properties.

- Quality monitoring and verification in TIM dispensing: Systems and methods for monitoring and verifying the quality of thermal interface material application during the dispensing process. These include vision systems for pattern recognition, weight measurement techniques, and thickness verification tools that ensure proper TIM coverage and distribution. Real-time inspection capabilities detect defects such as voids, excess material, or insufficient coverage, allowing for immediate process adjustments.

- Process optimization for TIM dispensing automation: Methods for optimizing the automated TIM dispensing process through data analytics, machine learning algorithms, and simulation tools. These approaches analyze historical process data to identify optimal dispensing parameters for different material types and application scenarios. Predictive models help anticipate material behavior under various conditions, enabling proactive adjustments to dispensing parameters for improved efficiency and reduced waste.

- Integration of TIM dispensing with manufacturing systems: Technologies for integrating TIM dispensing automation with broader manufacturing execution systems and production lines. These solutions enable seamless coordination between dispensing operations and other assembly processes through standardized communication protocols and interfaces. Integrated systems allow for centralized control, tracking of materials throughout the production process, and synchronized operation with upstream and downstream manufacturing steps.

- Material handling and preparation for TIM dispensing: Specialized systems for the handling, preparation, and conditioning of thermal interface materials prior to and during the dispensing process. These include temperature control mechanisms, degassing equipment, and mixing systems that ensure optimal material properties at the point of application. Advanced material handling solutions maintain consistent viscosity and flow characteristics, which are critical for precise dispensing operations and final thermal performance.

02 Quality control and verification in TIM dispensing

Quality control mechanisms in TIM dispensing processes involve inspection systems that verify the proper application of thermal interface materials. These systems use machine vision, weight measurement, and pattern recognition to detect defects or inconsistencies in TIM application. Real-time verification ensures that the dispensed material meets specifications for coverage, thickness, and position, reducing manufacturing defects and improving thermal performance of assembled components.Expand Specific Solutions03 Integration of TIM dispensing with manufacturing systems

TIM dispensing automation is integrated with broader manufacturing execution systems and production lines. These integrated solutions coordinate TIM application with other assembly processes, enabling seamless workflow and production scheduling. The systems incorporate data exchange between dispensing equipment and central control systems, allowing for production tracking, material usage optimization, and process parameter adjustments based on manufacturing requirements.Expand Specific Solutions04 Adaptive process control for TIM dispensing

Adaptive control systems for TIM dispensing utilize machine learning and feedback mechanisms to optimize dispensing parameters in real-time. These systems can adjust to variations in material properties, environmental conditions, and substrate characteristics. By continuously analyzing process data and outcomes, the adaptive controls can modify dispensing patterns, pressure, and timing to maintain consistent results despite changing conditions, reducing waste and improving thermal interface quality.Expand Specific Solutions05 Material handling and preparation in TIM dispensing systems

Automated TIM dispensing systems incorporate specialized material handling and preparation controls to ensure optimal material properties during application. These systems manage material temperature, viscosity, and mixing ratios for multi-component TIMs. Controlled material preparation includes degassing, pre-heating, and conditioning processes that ensure consistent material flow and adhesion properties, which are critical for achieving reliable thermal interfaces in electronic assemblies.Expand Specific Solutions

Key Industry Players in TIM Dispensing Equipment

The TIM (Thermal Interface Material) dispensing automation market is currently in a growth phase, with increasing demand driven by electronics manufacturing and automotive industries. The market size is expanding rapidly due to the need for precise thermal management in high-performance devices. Technologically, the field shows varying maturity levels, with established players like Nordson Corp. and YASKAWA Electric offering advanced solutions, while newer entrants like BICO Group and Changzhou Mingseal Robot Technology are introducing innovative approaches. Companies such as Tecan Trading, Hamilton Bonaduz, and Protec are developing specialized dispensing systems with improved precision and throughput capabilities. Academic institutions including Tsinghua University and RWTH Aachen are contributing research to advance process controls, indicating a collaborative ecosystem between industry and academia for future technological developments.

COROB SpA

Technical Solution: COROB has developed a specialized TIM dispensing automation platform that leverages their extensive experience in precision fluid handling technologies. Their system employs a modular architecture that can be configured for various production volumes and material types. At the core of their solution is a proprietary piston-based volumetric dispensing technology that achieves dosing accuracy of ±1% even with highly viscous thermal interface materials[1]. COROB's platform incorporates advanced material conditioning systems including temperature-controlled material reservoirs and feed lines to maintain consistent viscosity throughout production shifts. Their process control software features machine learning algorithms that continuously analyze dispensing results and automatically adjust parameters to compensate for material aging, environmental changes, and other variables that could affect dispensing quality[2]. The system also includes automated cleaning and purging cycles that minimize material waste while ensuring consistent dispensing performance over extended production runs without operator intervention[3].

Strengths: Exceptional volumetric accuracy with highly viscous materials; intelligent self-adjusting algorithms that maintain process stability; modular design allows for cost-effective scaling based on production needs. Weaknesses: More limited throughput compared to some dedicated high-speed systems; specialized maintenance requirements for precision components; potentially higher material waste during changeovers between different TIM formulations.

Justech Precision Industry Co. Ltd.

Technical Solution: Justech has engineered a comprehensive TIM dispensing automation solution specifically designed for high-volume electronics manufacturing environments. Their system features a precision XYZ gantry platform with linear motors capable of accelerations up to 1.5G while maintaining positioning accuracy of ±20 microns[1]. The dispensing head incorporates advanced pressure-time dispensing technology with closed-loop feedback that continuously monitors and adjusts dispensing parameters in real-time. Justech's solution includes proprietary "Dynamic Viscosity Compensation" technology that automatically adjusts dispensing parameters based on material temperature, pressure, and aging characteristics to maintain consistent output regardless of environmental variations[2]. Their process control software provides comprehensive data collection and analysis capabilities, including automated SPC charting and trend analysis to identify process drift before it affects product quality. The system also features automated needle calibration and cleaning stations that maintain dispensing consistency without operator intervention, enabling continuous operation across multiple production shifts[3].

Strengths: High-speed operation optimized for electronics manufacturing; sophisticated real-time viscosity compensation technology; comprehensive data collection for process optimization and traceability. Weaknesses: Less flexibility for handling extremely diverse product types compared to robotic solutions; higher sensitivity to vibration requiring specialized installation considerations; more complex maintenance requirements for high-precision components.

Critical Process Control Technologies and Patents

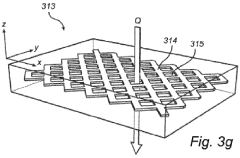

Thermal interface material on package

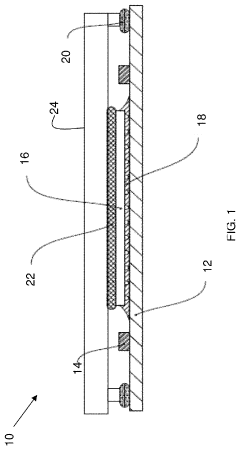

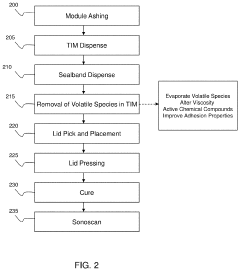

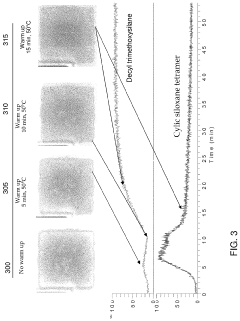

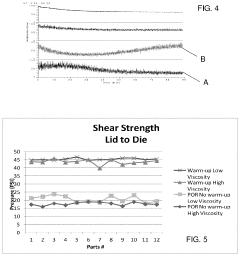

PatentInactiveUS10896862B2

Innovation

- A method involving the removal of volatile species from TIM through processes like extended delay, low-temperature heating, or vacuum outgassing, followed by lid placement and pressing, to enhance adhesion and minimize voiding, optimizing process parameters for improved thermal performance.

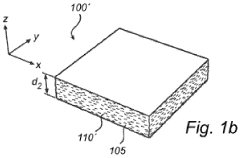

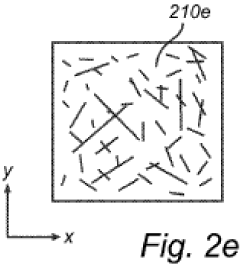

Thermal interface material

PatentActiveIN7138CHENP2014A

Innovation

- A TIM with an activable shrinkage material that increases in thickness upon activation, providing enhanced contact pressure and robustness by expanding in the z-direction, thus eliminating the need for external pressure and addressing surface curvature and roughness, using heat-sensitive fibers or monomers that polymerize or expand to enhance thermal interface performance.

Quality Assurance Systems for TIM Dispensing

Quality assurance systems for TIM (Thermal Interface Material) dispensing represent a critical component in ensuring consistent product quality in volume production environments. These systems encompass a comprehensive framework of monitoring tools, inspection protocols, and statistical process control methods specifically designed for thermal interface material applications.

Real-time monitoring systems form the foundation of quality assurance in TIM dispensing operations. Advanced vision systems equipped with high-resolution cameras capture dispensing patterns and detect anomalies such as air bubbles, inconsistent bead width, or material splatter. These systems typically operate at speeds compatible with production line requirements, analyzing hundreds of units per hour without creating bottlenecks.

Statistical Process Control (SPC) methodologies have been adapted specifically for TIM dispensing processes. Key parameters including dispensing pressure, material temperature, flow rate, and pattern accuracy are continuously monitored and plotted against control limits. Modern systems implement automated SPC with capabilities for trend analysis and early warning indicators when processes begin to drift toward control limits.

Material verification systems ensure that the correct TIM is being used and that its properties remain within specifications throughout the production run. Integrated viscosity testing, thermal conductivity sampling, and cure rate verification help prevent quality issues stemming from material degradation or improper storage conditions.

Traceability features have become standard in quality assurance systems for TIM dispensing. Each dispensing operation is logged with timestamp, operator ID, material batch number, and process parameters. This data chain enables root cause analysis when defects are discovered downstream and facilitates continuous improvement initiatives.

Closed-loop feedback mechanisms represent the most advanced quality assurance approach. These systems not only detect deviations but automatically adjust dispensing parameters to compensate for environmental changes or material variations. For example, if ambient temperature rises, affecting TIM viscosity, the system can modify dispensing pressure to maintain consistent output volume.

Calibration protocols ensure measurement accuracy across all quality assurance components. Regular verification using known standards helps maintain system integrity, with many modern systems incorporating self-diagnostic capabilities that alert maintenance personnel when calibration drift is detected.

Integration with Manufacturing Execution Systems (MES) allows quality data from TIM dispensing to be correlated with downstream process results and final product performance. This holistic approach enables manufacturers to identify subtle interactions between dispensing parameters and product reliability, driving continuous refinement of both process controls and quality thresholds.

Real-time monitoring systems form the foundation of quality assurance in TIM dispensing operations. Advanced vision systems equipped with high-resolution cameras capture dispensing patterns and detect anomalies such as air bubbles, inconsistent bead width, or material splatter. These systems typically operate at speeds compatible with production line requirements, analyzing hundreds of units per hour without creating bottlenecks.

Statistical Process Control (SPC) methodologies have been adapted specifically for TIM dispensing processes. Key parameters including dispensing pressure, material temperature, flow rate, and pattern accuracy are continuously monitored and plotted against control limits. Modern systems implement automated SPC with capabilities for trend analysis and early warning indicators when processes begin to drift toward control limits.

Material verification systems ensure that the correct TIM is being used and that its properties remain within specifications throughout the production run. Integrated viscosity testing, thermal conductivity sampling, and cure rate verification help prevent quality issues stemming from material degradation or improper storage conditions.

Traceability features have become standard in quality assurance systems for TIM dispensing. Each dispensing operation is logged with timestamp, operator ID, material batch number, and process parameters. This data chain enables root cause analysis when defects are discovered downstream and facilitates continuous improvement initiatives.

Closed-loop feedback mechanisms represent the most advanced quality assurance approach. These systems not only detect deviations but automatically adjust dispensing parameters to compensate for environmental changes or material variations. For example, if ambient temperature rises, affecting TIM viscosity, the system can modify dispensing pressure to maintain consistent output volume.

Calibration protocols ensure measurement accuracy across all quality assurance components. Regular verification using known standards helps maintain system integrity, with many modern systems incorporating self-diagnostic capabilities that alert maintenance personnel when calibration drift is detected.

Integration with Manufacturing Execution Systems (MES) allows quality data from TIM dispensing to be correlated with downstream process results and final product performance. This holistic approach enables manufacturers to identify subtle interactions between dispensing parameters and product reliability, driving continuous refinement of both process controls and quality thresholds.

ROI Analysis for TIM Automation Implementation

Implementing TIM (Thermal Interface Material) dispensing automation for volume production requires significant capital investment. This ROI analysis examines the financial justification for such implementation, considering both direct and indirect returns on investment.

The initial capital expenditure for TIM automation equipment typically ranges from $150,000 to $500,000 depending on the level of sophistication, throughput requirements, and integration complexity. This includes dispensing robots, vision systems, material handling equipment, and control software. Additionally, implementation costs such as facility modifications, training, and production downtime during installation must be factored in, typically adding 15-25% to the base equipment cost.

Labor cost reduction represents the most immediate and quantifiable return. Manual TIM application processes typically require 1-3 operators per shift, while automated systems can operate with minimal supervision. Based on industry averages, this translates to annual labor savings of $80,000-$240,000 depending on production volume and regional labor costs. The payback period for labor savings alone typically ranges from 1.5 to 3 years.

Material efficiency improvements provide substantial additional returns. Automated dispensing systems achieve precision control of TIM volume with typical material waste reduction of 30-50% compared to manual processes. For high-volume operations using premium TIM materials, this can represent savings of $50,000-$200,000 annually depending on production volume and material costs.

Quality improvements deliver significant but less directly quantifiable returns. Automated TIM dispensing reduces defect rates by 60-85% compared to manual application, minimizing rework costs and warranty claims. For electronics manufacturers, this quality improvement can reduce scrap and rework costs by $30,000-$100,000 annually while enhancing brand reputation.

Throughput increases represent another valuable return factor. Automated systems typically improve cycle times by 40-60% compared to manual processes, increasing production capacity without facility expansion. This throughput enhancement can generate additional revenue of $100,000-$500,000 annually depending on market demand and product margins.

Long-term strategic benefits include manufacturing flexibility, data collection capabilities for process optimization, and reduced dependency on skilled labor in tight labor markets. While more difficult to quantify, these advantages typically add 15-25% to the calculated ROI.

The initial capital expenditure for TIM automation equipment typically ranges from $150,000 to $500,000 depending on the level of sophistication, throughput requirements, and integration complexity. This includes dispensing robots, vision systems, material handling equipment, and control software. Additionally, implementation costs such as facility modifications, training, and production downtime during installation must be factored in, typically adding 15-25% to the base equipment cost.

Labor cost reduction represents the most immediate and quantifiable return. Manual TIM application processes typically require 1-3 operators per shift, while automated systems can operate with minimal supervision. Based on industry averages, this translates to annual labor savings of $80,000-$240,000 depending on production volume and regional labor costs. The payback period for labor savings alone typically ranges from 1.5 to 3 years.

Material efficiency improvements provide substantial additional returns. Automated dispensing systems achieve precision control of TIM volume with typical material waste reduction of 30-50% compared to manual processes. For high-volume operations using premium TIM materials, this can represent savings of $50,000-$200,000 annually depending on production volume and material costs.

Quality improvements deliver significant but less directly quantifiable returns. Automated TIM dispensing reduces defect rates by 60-85% compared to manual application, minimizing rework costs and warranty claims. For electronics manufacturers, this quality improvement can reduce scrap and rework costs by $30,000-$100,000 annually while enhancing brand reputation.

Throughput increases represent another valuable return factor. Automated systems typically improve cycle times by 40-60% compared to manual processes, increasing production capacity without facility expansion. This throughput enhancement can generate additional revenue of $100,000-$500,000 annually depending on market demand and product margins.

Long-term strategic benefits include manufacturing flexibility, data collection capabilities for process optimization, and reduced dependency on skilled labor in tight labor markets. While more difficult to quantify, these advantages typically add 15-25% to the calculated ROI.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!