TIM Thermal Aging: Predictive Models And Real-Time Monitoring Signals

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TIM Thermal Aging Background and Objectives

Thermal Interface Materials (TIMs) have become increasingly critical components in modern electronic systems, serving as essential thermal management solutions that facilitate heat transfer between heat-generating components and heat dissipation devices. The evolution of TIMs has been closely tied to the advancement of semiconductor technology, with each generation of electronic devices demanding more efficient thermal management solutions to handle increasing power densities and thermal loads.

The historical development of TIMs began with simple thermal greases in the 1970s, progressing through phase-change materials in the 1990s, to today's advanced composite materials incorporating nanomaterials and novel fillers. This progression reflects the industry's continuous pursuit of higher thermal conductivity, lower thermal resistance, and greater long-term reliability under operating conditions.

A significant challenge in TIM application is the phenomenon of thermal aging - the degradation of thermal performance over time due to various physical and chemical mechanisms. These include material pump-out, dry-out, interfacial delamination, filler settling, and oxidative degradation. As electronic devices are expected to function reliably for years or even decades, understanding and mitigating TIM aging has become paramount for ensuring system reliability and longevity.

Current research indicates that TIM aging can lead to significant increases in thermal resistance, potentially causing thermal throttling, reduced performance, and even catastrophic failure in electronic systems. Despite its importance, the mechanisms of TIM aging remain incompletely understood, particularly in relation to different material compositions and operating environments.

The primary objective of this technical research is to develop comprehensive predictive models for TIM thermal aging and establish effective real-time monitoring signals that can accurately forecast TIM performance degradation. These models aim to incorporate multiple variables including temperature cycling, humidity exposure, mechanical stress, and material composition to predict the thermal performance trajectory of TIMs throughout their service life.

Additionally, this research seeks to identify key measurable parameters that can serve as early indicators of TIM degradation, enabling proactive maintenance and replacement strategies before system performance is compromised. The ultimate goal is to establish a scientific foundation for the development of more resilient TIMs and more effective thermal management strategies, thereby extending the reliable operational lifespan of electronic systems across various applications from consumer electronics to mission-critical infrastructure.

The historical development of TIMs began with simple thermal greases in the 1970s, progressing through phase-change materials in the 1990s, to today's advanced composite materials incorporating nanomaterials and novel fillers. This progression reflects the industry's continuous pursuit of higher thermal conductivity, lower thermal resistance, and greater long-term reliability under operating conditions.

A significant challenge in TIM application is the phenomenon of thermal aging - the degradation of thermal performance over time due to various physical and chemical mechanisms. These include material pump-out, dry-out, interfacial delamination, filler settling, and oxidative degradation. As electronic devices are expected to function reliably for years or even decades, understanding and mitigating TIM aging has become paramount for ensuring system reliability and longevity.

Current research indicates that TIM aging can lead to significant increases in thermal resistance, potentially causing thermal throttling, reduced performance, and even catastrophic failure in electronic systems. Despite its importance, the mechanisms of TIM aging remain incompletely understood, particularly in relation to different material compositions and operating environments.

The primary objective of this technical research is to develop comprehensive predictive models for TIM thermal aging and establish effective real-time monitoring signals that can accurately forecast TIM performance degradation. These models aim to incorporate multiple variables including temperature cycling, humidity exposure, mechanical stress, and material composition to predict the thermal performance trajectory of TIMs throughout their service life.

Additionally, this research seeks to identify key measurable parameters that can serve as early indicators of TIM degradation, enabling proactive maintenance and replacement strategies before system performance is compromised. The ultimate goal is to establish a scientific foundation for the development of more resilient TIMs and more effective thermal management strategies, thereby extending the reliable operational lifespan of electronic systems across various applications from consumer electronics to mission-critical infrastructure.

Market Demand Analysis for TIM Reliability Solutions

The global market for Thermal Interface Materials (TIMs) reliability solutions is experiencing robust growth, driven primarily by the increasing thermal management challenges in high-performance electronics. Current market valuations indicate the TIM market exceeds $3.5 billion annually, with a compound annual growth rate projected between 8-10% through 2028. This growth trajectory is significantly influenced by the escalating demand for effective thermal aging prediction and monitoring solutions.

Electronics manufacturers across automotive, aerospace, telecommunications, and consumer electronics sectors are expressing heightened concern regarding TIM reliability. Industry surveys reveal that over 70% of electronics failures are temperature-related, with degraded thermal interface materials being a primary contributor. This has created substantial market pull for advanced predictive modeling and real-time monitoring technologies that can accurately forecast TIM performance degradation.

The data center industry represents a particularly critical market segment, where thermal management directly impacts operational efficiency and system reliability. With global data center power consumption approaching 3% of worldwide electricity production, even marginal improvements in thermal management efficiency translate to significant operational cost savings. Market research indicates data center operators are willing to invest 15-20% premium on thermal solutions that offer predictive capabilities and extended reliability.

Consumer electronics manufacturers face increasing pressure to extend product warranties while reducing form factors, creating contradictory thermal management requirements. This market segment shows growing interest in TIM solutions with integrated monitoring capabilities that can provide early warning of potential thermal issues before catastrophic failure occurs.

The automotive sector, particularly with the rapid expansion of electric vehicles, represents another high-growth market for advanced TIM solutions. Electric vehicle battery thermal management systems require TIMs with exceptional long-term reliability under extreme operating conditions. Market analysis shows automotive manufacturers are actively seeking TIM solutions with predictive aging models to support warranty planning and maintenance scheduling.

Geographically, North America and Asia-Pacific regions dominate market demand, with China, Japan, South Korea, and the United States accounting for approximately 65% of global consumption. The European market shows accelerating adoption rates, particularly in industries with stringent reliability requirements such as medical devices and industrial automation.

Market research consistently identifies reliability prediction as the most significant unmet need in current TIM solutions, with 83% of surveyed electronics manufacturers rating improved aging prediction capabilities as "highly valuable" or "essential" for next-generation products.

Electronics manufacturers across automotive, aerospace, telecommunications, and consumer electronics sectors are expressing heightened concern regarding TIM reliability. Industry surveys reveal that over 70% of electronics failures are temperature-related, with degraded thermal interface materials being a primary contributor. This has created substantial market pull for advanced predictive modeling and real-time monitoring technologies that can accurately forecast TIM performance degradation.

The data center industry represents a particularly critical market segment, where thermal management directly impacts operational efficiency and system reliability. With global data center power consumption approaching 3% of worldwide electricity production, even marginal improvements in thermal management efficiency translate to significant operational cost savings. Market research indicates data center operators are willing to invest 15-20% premium on thermal solutions that offer predictive capabilities and extended reliability.

Consumer electronics manufacturers face increasing pressure to extend product warranties while reducing form factors, creating contradictory thermal management requirements. This market segment shows growing interest in TIM solutions with integrated monitoring capabilities that can provide early warning of potential thermal issues before catastrophic failure occurs.

The automotive sector, particularly with the rapid expansion of electric vehicles, represents another high-growth market for advanced TIM solutions. Electric vehicle battery thermal management systems require TIMs with exceptional long-term reliability under extreme operating conditions. Market analysis shows automotive manufacturers are actively seeking TIM solutions with predictive aging models to support warranty planning and maintenance scheduling.

Geographically, North America and Asia-Pacific regions dominate market demand, with China, Japan, South Korea, and the United States accounting for approximately 65% of global consumption. The European market shows accelerating adoption rates, particularly in industries with stringent reliability requirements such as medical devices and industrial automation.

Market research consistently identifies reliability prediction as the most significant unmet need in current TIM solutions, with 83% of surveyed electronics manufacturers rating improved aging prediction capabilities as "highly valuable" or "essential" for next-generation products.

Current Challenges in TIM Thermal Aging Prediction

Despite significant advancements in Thermal Interface Materials (TIMs) technology, predicting thermal aging remains one of the most challenging aspects in electronics thermal management. Current predictive models struggle with accuracy limitations when projecting long-term performance degradation under various operating conditions. Traditional Arrhenius-based models, while widely used, often fail to account for complex degradation mechanisms that occur simultaneously during thermal cycling and steady-state operation.

A fundamental challenge lies in the multi-physics nature of TIM degradation, which involves mechanical, chemical, and thermal processes occurring simultaneously. Pump-out, dry-out, and interfacial delamination mechanisms often interact in ways that are difficult to capture in simplified mathematical models. This complexity is further compounded by the diverse material compositions of modern TIMs, ranging from greases and phase-change materials to emerging carbon-based composites, each exhibiting unique aging characteristics.

Real-time monitoring signals present their own set of challenges. Current sensor technologies lack the sensitivity to detect early-stage degradation indicators before significant performance loss occurs. Temperature sensors typically only reveal problems after thermal resistance has already increased substantially, making preventive maintenance difficult to implement effectively. Additionally, the placement of sensors often creates a trade-off between measurement accuracy and potential interference with the thermal path itself.

Data interpretation presents another significant hurdle. Distinguishing between normal performance fluctuations and actual degradation signals requires sophisticated algorithms that can filter environmental noise and account for varying operational loads. Most current systems lack this capability, leading to either false alarms or missed degradation events.

The industry also faces standardization issues, with different manufacturers employing proprietary testing methodologies that make cross-comparison of aging characteristics difficult. This fragmentation hampers the development of universal predictive models and slows industry-wide progress toward reliable lifetime estimation tools.

Resource constraints further complicate matters, as accelerated aging tests—while necessary for timely product development—may not accurately represent real-world degradation pathways. The correlation between accelerated test results and actual field performance remains tenuous, creating uncertainty in lifetime predictions based on laboratory data.

Finally, emerging high-power applications in electric vehicles, data centers, and 5G infrastructure are pushing TIMs to operate under increasingly demanding conditions, exposing limitations in current predictive capabilities. As power densities continue to rise, the margin for error in thermal management predictions shrinks, making the development of more accurate aging models not just desirable but essential for future technological advancement.

A fundamental challenge lies in the multi-physics nature of TIM degradation, which involves mechanical, chemical, and thermal processes occurring simultaneously. Pump-out, dry-out, and interfacial delamination mechanisms often interact in ways that are difficult to capture in simplified mathematical models. This complexity is further compounded by the diverse material compositions of modern TIMs, ranging from greases and phase-change materials to emerging carbon-based composites, each exhibiting unique aging characteristics.

Real-time monitoring signals present their own set of challenges. Current sensor technologies lack the sensitivity to detect early-stage degradation indicators before significant performance loss occurs. Temperature sensors typically only reveal problems after thermal resistance has already increased substantially, making preventive maintenance difficult to implement effectively. Additionally, the placement of sensors often creates a trade-off between measurement accuracy and potential interference with the thermal path itself.

Data interpretation presents another significant hurdle. Distinguishing between normal performance fluctuations and actual degradation signals requires sophisticated algorithms that can filter environmental noise and account for varying operational loads. Most current systems lack this capability, leading to either false alarms or missed degradation events.

The industry also faces standardization issues, with different manufacturers employing proprietary testing methodologies that make cross-comparison of aging characteristics difficult. This fragmentation hampers the development of universal predictive models and slows industry-wide progress toward reliable lifetime estimation tools.

Resource constraints further complicate matters, as accelerated aging tests—while necessary for timely product development—may not accurately represent real-world degradation pathways. The correlation between accelerated test results and actual field performance remains tenuous, creating uncertainty in lifetime predictions based on laboratory data.

Finally, emerging high-power applications in electric vehicles, data centers, and 5G infrastructure are pushing TIMs to operate under increasingly demanding conditions, exposing limitations in current predictive capabilities. As power densities continue to rise, the margin for error in thermal management predictions shrinks, making the development of more accurate aging models not just desirable but essential for future technological advancement.

Current Predictive Models for TIM Thermal Aging

01 Composition of thermal interface materials for improved aging resistance

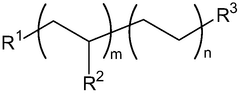

Specific compositions of thermal interface materials can be designed to enhance resistance to thermal aging. These compositions may include specialized polymers, fillers, and additives that maintain thermal conductivity and mechanical properties over extended periods of high-temperature exposure. The formulations often incorporate stabilizers that prevent degradation of the base materials during thermal cycling and prolonged heat exposure.- Composition of thermal interface materials for improved aging resistance: Specific compositions of thermal interface materials can be designed to enhance resistance to thermal aging. These compositions may include specialized polymers, fillers, and additives that maintain thermal conductivity and mechanical properties over extended periods of high-temperature exposure. The formulations are engineered to minimize degradation mechanisms such as oxidation, cross-linking, or filler separation that typically occur during thermal aging cycles.

- Testing methods for thermal aging performance of TIMs: Various testing methodologies have been developed to evaluate the thermal aging performance of interface materials. These methods include accelerated aging tests, thermal cycling, and long-term reliability assessments that measure changes in thermal conductivity, adhesion strength, and physical properties after exposure to elevated temperatures. Advanced analytical techniques are employed to characterize degradation mechanisms and predict the service life of thermal interface materials under different operating conditions.

- Novel TIM structures for enhanced thermal stability: Innovative structural designs of thermal interface materials can significantly improve their resistance to thermal aging. These designs may incorporate multi-layer configurations, gradient structures, or reinforcement elements that maintain performance during temperature fluctuations. Some approaches include the use of nanostructured materials, 3D architectures, or hybrid organic-inorganic systems that provide mechanical stability while maintaining high thermal conductivity even after prolonged exposure to elevated temperatures.

- Integration of TIMs in electronic assemblies with aging considerations: The integration of thermal interface materials into electronic assemblies requires careful consideration of thermal aging effects. This includes design strategies for semiconductor packages, heat sinks, and cooling systems that accommodate the changing properties of TIMs over time. Approaches may involve optimized clamping forces, expansion-matched materials, or redundant thermal pathways to ensure reliable heat dissipation throughout the product lifecycle despite potential degradation of the interface material.

- Self-healing and adaptive TIMs for long-term reliability: Advanced thermal interface materials with self-healing or adaptive properties have been developed to address thermal aging challenges. These materials can repair microcracks, redistribute fillers, or adjust their properties in response to temperature changes, thereby extending their functional lifetime. Some formulations incorporate phase-change components, reversible chemical bonds, or stimuli-responsive elements that actively counteract degradation mechanisms during thermal cycling and aging processes.

02 Testing methods for thermal aging evaluation of TIMs

Various testing methodologies have been developed to evaluate the thermal aging characteristics of interface materials. These include accelerated aging tests, thermal cycling protocols, and long-term reliability assessments. The testing procedures measure changes in thermal conductivity, adhesion strength, and physical properties after exposure to elevated temperatures for extended periods, providing data on the expected lifetime performance of the materials in real-world applications.Expand Specific Solutions03 Semiconductor package applications with enhanced TIM thermal aging properties

Thermal interface materials specifically designed for semiconductor packaging applications incorporate features to withstand the unique thermal aging challenges in these environments. These materials maintain effective heat dissipation from chips to heat sinks despite repeated thermal cycling and constant high-temperature operation. The formulations often balance thermal conductivity with compliance and adhesion to accommodate the different expansion rates of package components during thermal aging.Expand Specific Solutions04 Novel filler materials for improved thermal aging stability

Advanced filler materials are being incorporated into thermal interface materials to enhance their resistance to thermal aging. These fillers include specially treated metal particles, ceramic powders, and carbon-based materials that maintain their thermal conductivity properties even after prolonged exposure to high temperatures. The particle size distribution, surface treatment, and loading levels of these fillers are optimized to prevent settling, separation, or degradation during thermal aging.Expand Specific Solutions05 Electronic device cooling solutions with thermally stable TIMs

Electronic cooling solutions incorporate thermally stable interface materials that maintain performance despite aging effects. These solutions include specialized TIM formulations for high-power electronics, data center equipment, and consumer devices where consistent thermal management is critical over the product lifetime. The materials are designed to resist pump-out, dry-out, and other aging-related failure mechanisms that could compromise the thermal management of electronic components.Expand Specific Solutions

Key Industry Players in Thermal Interface Materials

The thermal aging of Thermal Interface Materials (TIM) represents a critical challenge in the evolving electronics reliability landscape, currently transitioning from early development to commercial application phase. The market is experiencing rapid growth, estimated at $3-4 billion annually with 8-10% CAGR, driven by increasing thermal management demands in electronics. Leading technology players demonstrate varying levels of maturity in predictive modeling and real-time monitoring approaches. Companies like Robert Bosch, Siemens, IBM, and Apple are advancing sophisticated predictive algorithms, while Mitsubishi Electric, Samsung Display, and GE focus on sensor-based monitoring solutions. Automotive sector players (Stellantis) and research institutions (Technion, Wuhan University) are contributing significant innovations, indicating a competitive landscape that balances established industrial players with emerging specialized solutions.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced thermal interface material (TIM) aging prediction models that combine physics-based and data-driven approaches. Their solution integrates real-time temperature sensors with machine learning algorithms to continuously monitor TIM degradation in automotive and industrial power electronics. The system employs thermal impedance spectroscopy to detect early signs of delamination and material property changes without requiring system shutdown. Bosch's predictive maintenance framework uses historical performance data and accelerated aging tests to create digital twins of TIM components, enabling accurate remaining useful life (RUL) estimation. Their technology incorporates multiple sensor types (infrared, thermocouple arrays, and embedded temperature sensors) to provide comprehensive thermal mapping and detect hotspots before critical failures occur.

Strengths: Extensive automotive validation data improves prediction accuracy; integrated sensor networks provide comprehensive coverage. Weaknesses: System complexity increases implementation costs; requires significant computational resources for real-time analysis.

Siemens AG

Technical Solution: Siemens has pioneered a comprehensive TIM thermal aging monitoring system that combines physical modeling with AI-driven predictive analytics. Their approach utilizes distributed temperature sensing networks embedded within power electronic modules to capture real-time thermal signatures. The system employs proprietary algorithms that analyze thermal impedance changes over time to detect early signs of TIM degradation. Siemens' solution incorporates a multi-physics simulation framework that accounts for thermal, mechanical, and chemical aging mechanisms, allowing for accurate prediction of remaining useful life. The technology features self-calibrating sensors that compensate for environmental variations and aging-induced drift, ensuring measurement accuracy throughout the component lifecycle. Their cloud-based analytics platform processes historical and real-time data to continuously refine prediction models, adapting to specific operating conditions and material compositions.

Strengths: Highly integrated with industrial automation systems; excellent scalability from component to system level monitoring. Weaknesses: Proprietary ecosystem may limit compatibility with third-party systems; higher initial implementation costs compared to simpler monitoring solutions.

Core Technologies for Real-Time TIM Monitoring

Method and measuring arrangement for characterizing a thermal interface material

PatentWO2012107355A1

Innovation

- A method and measuring arrangement that simulate the conditions and loads of TIM in its application, allowing for the determination of thermal properties and interfaces under mechanical loading, including power cycling and mechanical cycling, to evaluate the aging behavior and thermal resistance of TIM samples with varying layer thicknesses, and enabling the calculation of bulk and interface resistances.

Thermal interface material

PatentWO2022133850A1

Innovation

- Development of TIMs with thermal impedance values less than 0.1 ℃·cm²/W to meet the increasing heat dissipation demands of modern electronic components, particularly for bare die designs in GPU and AI chips.

- Optimization of TIM composition by balancing wax, liquid polymers, thermally conductive fillers, and softeners to achieve superior thermal conductivity while maintaining appropriate mechanical properties.

- Utilization of phase change materials with specific needle penetration values to enhance thermal interface contact and heat transfer efficiency.

Reliability Testing Standards for TIM Performance

Reliability testing standards for Thermal Interface Materials (TIMs) are critical frameworks that ensure consistent evaluation of thermal performance degradation over time. The industry has established several key standards through organizations such as JEDEC, ASTM International, and IPC that specifically address TIM reliability testing methodologies.

JEDEC JESD22-A103 provides guidelines for the thermal cycling of electronic components, which can be adapted for TIM reliability assessment. This standard outlines procedures for subjecting materials to temperature extremes ranging from -65°C to 150°C, with controlled ramp rates and dwell times to simulate accelerated aging conditions.

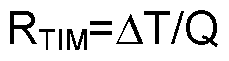

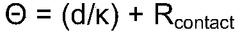

ASTM D5470 serves as the foundation for thermal conductivity measurements of TIMs, establishing a standardized method for determining thermal resistance. When incorporated into reliability testing protocols, this standard enables consistent baseline measurements before and after aging processes.

IPC-TM-650 (Method 2.4.50) addresses thermal impedance testing specifically for printed circuit board assemblies but has been widely adapted for TIM performance evaluation. This standard provides methodologies for measuring the thermal resistance of interface materials under various pressure conditions.

The ASTM E1269 standard for specific heat capacity determination using differential scanning calorimetry (DSC) is frequently employed to assess thermophysical property changes in TIMs during aging studies. This allows researchers to correlate material property shifts with performance degradation.

For accelerated aging protocols, ASTM F1980 offers guidelines that can be modified for TIM applications. This standard provides mathematical models for calculating acceleration factors based on the Arrhenius equation, enabling researchers to predict long-term reliability from short-term test data.

The automotive industry has developed specialized standards such as AEC-Q200 that include thermal cycling and high-temperature exposure tests applicable to TIMs used in vehicle electronics. These standards typically require materials to maintain performance after 1000+ temperature cycles and extended exposure to temperatures up to 125°C.

Military and aerospace applications follow MIL-STD-810G standards, which include rigorous environmental testing protocols that can be applied to TIM reliability assessment. These standards incorporate combined stressors such as temperature, humidity, and mechanical vibration to simulate real-world operational conditions.

Recent developments in reliability standards have begun to incorporate real-time monitoring methodologies, moving beyond traditional pre/post-test measurements to continuous data collection during aging processes. This evolution enables more accurate modeling of degradation mechanisms and better prediction of end-of-life performance.

JEDEC JESD22-A103 provides guidelines for the thermal cycling of electronic components, which can be adapted for TIM reliability assessment. This standard outlines procedures for subjecting materials to temperature extremes ranging from -65°C to 150°C, with controlled ramp rates and dwell times to simulate accelerated aging conditions.

ASTM D5470 serves as the foundation for thermal conductivity measurements of TIMs, establishing a standardized method for determining thermal resistance. When incorporated into reliability testing protocols, this standard enables consistent baseline measurements before and after aging processes.

IPC-TM-650 (Method 2.4.50) addresses thermal impedance testing specifically for printed circuit board assemblies but has been widely adapted for TIM performance evaluation. This standard provides methodologies for measuring the thermal resistance of interface materials under various pressure conditions.

The ASTM E1269 standard for specific heat capacity determination using differential scanning calorimetry (DSC) is frequently employed to assess thermophysical property changes in TIMs during aging studies. This allows researchers to correlate material property shifts with performance degradation.

For accelerated aging protocols, ASTM F1980 offers guidelines that can be modified for TIM applications. This standard provides mathematical models for calculating acceleration factors based on the Arrhenius equation, enabling researchers to predict long-term reliability from short-term test data.

The automotive industry has developed specialized standards such as AEC-Q200 that include thermal cycling and high-temperature exposure tests applicable to TIMs used in vehicle electronics. These standards typically require materials to maintain performance after 1000+ temperature cycles and extended exposure to temperatures up to 125°C.

Military and aerospace applications follow MIL-STD-810G standards, which include rigorous environmental testing protocols that can be applied to TIM reliability assessment. These standards incorporate combined stressors such as temperature, humidity, and mechanical vibration to simulate real-world operational conditions.

Recent developments in reliability standards have begun to incorporate real-time monitoring methodologies, moving beyond traditional pre/post-test measurements to continuous data collection during aging processes. This evolution enables more accurate modeling of degradation mechanisms and better prediction of end-of-life performance.

Environmental Impact of TIM Lifecycle Management

The environmental impact of Thermal Interface Materials (TIMs) throughout their lifecycle represents a critical consideration in sustainable electronics design. As TIMs age and degrade, their thermal conductivity diminishes, leading to increased energy consumption in cooling systems and potentially shortened device lifespans. This environmental burden is compounded by the fact that many conventional TIMs contain environmentally harmful substances such as silicones, metal particles, and other non-biodegradable components.

Lifecycle assessment studies indicate that the production phase of TIMs contributes significantly to their environmental footprint, with energy-intensive manufacturing processes and resource extraction activities. However, the end-of-life phase presents equally concerning challenges, as many TIMs are difficult to separate from electronic components during recycling processes, leading to contamination of recyclable materials or improper disposal.

Predictive modeling of TIM thermal aging can substantially mitigate these environmental impacts by enabling more precise maintenance schedules and replacement intervals. By accurately forecasting when a TIM will reach the end of its effective thermal conductivity range, unnecessary early replacements can be avoided, reducing material waste and extending the functional lifespan of electronic devices. Real-time monitoring signals further enhance this capability by providing continuous data on TIM performance, allowing for just-in-time maintenance.

Advanced TIM lifecycle management strategies incorporating predictive models have demonstrated potential reductions in electronic waste by 15-20% in data center applications. These approaches also contribute to energy savings of 5-8% through optimized thermal management, directly translating to reduced carbon emissions throughout the operational phase of electronic devices.

The development of bio-based and recyclable TIMs represents another frontier in environmental impact reduction. Research indicates that soy-based TIMs and graphene-enhanced biodegradable polymers show promising thermal performance while significantly reducing end-of-life environmental impacts. When combined with predictive aging models, these sustainable materials could revolutionize the environmental profile of thermal management systems.

Regulatory frameworks worldwide are increasingly acknowledging the environmental significance of TIM lifecycle management. The European Union's Waste Electrical and Electronic Equipment (WEEE) Directive and Restriction of Hazardous Substances (RoHS) regulations have begun to address TIM composition and disposal, while industry standards are evolving to incorporate environmental performance metrics alongside traditional thermal specifications.

Lifecycle assessment studies indicate that the production phase of TIMs contributes significantly to their environmental footprint, with energy-intensive manufacturing processes and resource extraction activities. However, the end-of-life phase presents equally concerning challenges, as many TIMs are difficult to separate from electronic components during recycling processes, leading to contamination of recyclable materials or improper disposal.

Predictive modeling of TIM thermal aging can substantially mitigate these environmental impacts by enabling more precise maintenance schedules and replacement intervals. By accurately forecasting when a TIM will reach the end of its effective thermal conductivity range, unnecessary early replacements can be avoided, reducing material waste and extending the functional lifespan of electronic devices. Real-time monitoring signals further enhance this capability by providing continuous data on TIM performance, allowing for just-in-time maintenance.

Advanced TIM lifecycle management strategies incorporating predictive models have demonstrated potential reductions in electronic waste by 15-20% in data center applications. These approaches also contribute to energy savings of 5-8% through optimized thermal management, directly translating to reduced carbon emissions throughout the operational phase of electronic devices.

The development of bio-based and recyclable TIMs represents another frontier in environmental impact reduction. Research indicates that soy-based TIMs and graphene-enhanced biodegradable polymers show promising thermal performance while significantly reducing end-of-life environmental impacts. When combined with predictive aging models, these sustainable materials could revolutionize the environmental profile of thermal management systems.

Regulatory frameworks worldwide are increasingly acknowledging the environmental significance of TIM lifecycle management. The European Union's Waste Electrical and Electronic Equipment (WEEE) Directive and Restriction of Hazardous Substances (RoHS) regulations have begun to address TIM composition and disposal, while industry standards are evolving to incorporate environmental performance metrics alongside traditional thermal specifications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!