TIM For Liquid Cooling Cold Plates: Interface Requirements And Surface Finish Tolerances

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TIM Liquid Cooling Evolution and Objectives

Thermal Interface Materials (TIMs) for liquid cooling systems have undergone significant evolution over the past decades, transitioning from simple thermal greases to advanced composite materials engineered specifically for high-performance cooling applications. The development trajectory has been primarily driven by the increasing power densities in electronic components, particularly in data centers, high-performance computing, and electric vehicle battery systems, where thermal management has become a critical factor in system reliability and performance.

The earliest implementations of liquid cooling systems in the 1980s utilized basic silicone-based thermal compounds with relatively low thermal conductivity values of 0.5-1.0 W/mK. These materials were adequate for the thermal loads of that era but proved insufficient as power densities increased exponentially in subsequent decades. The 1990s saw the introduction of metal-loaded compounds, incorporating particles of silver, aluminum, or zinc oxide to enhance thermal conductivity to 3-5 W/mK.

A significant technological leap occurred in the early 2000s with the development of phase-change materials (PCMs) specifically designed for liquid cooling interfaces. These materials offered the advantage of transitioning from solid to liquid at operating temperatures, ensuring optimal thermal contact while minimizing pump-out effects common in high-pressure liquid cooling systems. This period also marked the beginning of research into carbon-based TIMs, incorporating graphite, carbon nanotubes, and later graphene.

The current generation of TIMs for liquid cooling cold plates achieves thermal conductivity values of 10-15 W/mK through advanced composite formulations. These materials are engineered to maintain performance under the unique conditions of liquid cooling systems, including resistance to pump-induced vibration, compatibility with various coolants, and long-term stability under thermal cycling conditions.

The primary objective in TIM development for liquid cooling applications is to minimize thermal resistance at the interface between heat-generating components and cold plates while addressing the specific challenges of liquid cooling environments. This includes achieving consistent performance under variable pressure conditions, maintaining interface integrity despite mechanical stresses from coolant flow, and ensuring long-term reliability without degradation from thermal cycling or coolant exposure.

Secondary objectives include developing TIMs with improved application characteristics for manufacturing environments, reducing the environmental impact of materials used, and decreasing the total cost of ownership for cooling systems through extended maintenance intervals and simplified assembly processes. The industry is also focused on standardizing testing methodologies specifically for liquid cooling interfaces to enable more accurate comparison between different TIM solutions.

The earliest implementations of liquid cooling systems in the 1980s utilized basic silicone-based thermal compounds with relatively low thermal conductivity values of 0.5-1.0 W/mK. These materials were adequate for the thermal loads of that era but proved insufficient as power densities increased exponentially in subsequent decades. The 1990s saw the introduction of metal-loaded compounds, incorporating particles of silver, aluminum, or zinc oxide to enhance thermal conductivity to 3-5 W/mK.

A significant technological leap occurred in the early 2000s with the development of phase-change materials (PCMs) specifically designed for liquid cooling interfaces. These materials offered the advantage of transitioning from solid to liquid at operating temperatures, ensuring optimal thermal contact while minimizing pump-out effects common in high-pressure liquid cooling systems. This period also marked the beginning of research into carbon-based TIMs, incorporating graphite, carbon nanotubes, and later graphene.

The current generation of TIMs for liquid cooling cold plates achieves thermal conductivity values of 10-15 W/mK through advanced composite formulations. These materials are engineered to maintain performance under the unique conditions of liquid cooling systems, including resistance to pump-induced vibration, compatibility with various coolants, and long-term stability under thermal cycling conditions.

The primary objective in TIM development for liquid cooling applications is to minimize thermal resistance at the interface between heat-generating components and cold plates while addressing the specific challenges of liquid cooling environments. This includes achieving consistent performance under variable pressure conditions, maintaining interface integrity despite mechanical stresses from coolant flow, and ensuring long-term reliability without degradation from thermal cycling or coolant exposure.

Secondary objectives include developing TIMs with improved application characteristics for manufacturing environments, reducing the environmental impact of materials used, and decreasing the total cost of ownership for cooling systems through extended maintenance intervals and simplified assembly processes. The industry is also focused on standardizing testing methodologies specifically for liquid cooling interfaces to enable more accurate comparison between different TIM solutions.

Market Analysis for Liquid Cooling TIM Solutions

The global market for Thermal Interface Materials (TIMs) in liquid cooling applications is experiencing robust growth, driven primarily by increasing power densities in electronic components and the subsequent need for more efficient thermal management solutions. The liquid cooling TIM market was valued at approximately $350 million in 2022 and is projected to grow at a compound annual growth rate of 8.7% through 2028, potentially reaching $580 million by the end of the forecast period.

Data centers represent the largest market segment, accounting for nearly 40% of the total liquid cooling TIM market. This dominance is attributed to the escalating deployment of high-performance computing systems and the industry's shift toward more energy-efficient cooling solutions. The automotive sector, particularly with the rise of electric vehicles requiring sophisticated battery thermal management systems, constitutes the second-largest market segment at 25%.

Consumer electronics manufacturers are increasingly adopting liquid cooling solutions for premium products, creating a rapidly expanding market segment with 15% annual growth. Industrial applications, including power electronics and industrial computing systems, represent approximately 18% of the market share.

Geographically, North America leads the market with a 38% share, followed by Asia-Pacific at 35%, which is experiencing the fastest growth rate due to expanding manufacturing capabilities and increasing adoption of advanced cooling technologies in countries like China, Taiwan, and South Korea. Europe accounts for 22% of the market, with particular strength in automotive applications.

The market is characterized by increasing demand for TIMs with specific performance attributes: thermal conductivity exceeding 5 W/m·K, minimal bond-line thickness (preferably below 20 microns), compatibility with surface roughness variations of cold plates, and long-term reliability under thermal cycling conditions. Additionally, there is growing emphasis on environmentally sustainable TIM formulations with reduced environmental impact.

Key market drivers include the continuous miniaturization of electronic components, increasing power densities in computing systems, stringent energy efficiency regulations, and the expansion of data center infrastructure globally. The market also faces challenges such as high implementation costs compared to traditional air cooling, technical complexities in system integration, and concerns regarding long-term reliability in varied operating environments.

Customer requirements are evolving toward solutions that offer not only superior thermal performance but also ease of application, reworkability, and compatibility with automated manufacturing processes. This trend is reshaping product development strategies across the industry, with increasing focus on specialized formulations for specific application scenarios.

Data centers represent the largest market segment, accounting for nearly 40% of the total liquid cooling TIM market. This dominance is attributed to the escalating deployment of high-performance computing systems and the industry's shift toward more energy-efficient cooling solutions. The automotive sector, particularly with the rise of electric vehicles requiring sophisticated battery thermal management systems, constitutes the second-largest market segment at 25%.

Consumer electronics manufacturers are increasingly adopting liquid cooling solutions for premium products, creating a rapidly expanding market segment with 15% annual growth. Industrial applications, including power electronics and industrial computing systems, represent approximately 18% of the market share.

Geographically, North America leads the market with a 38% share, followed by Asia-Pacific at 35%, which is experiencing the fastest growth rate due to expanding manufacturing capabilities and increasing adoption of advanced cooling technologies in countries like China, Taiwan, and South Korea. Europe accounts for 22% of the market, with particular strength in automotive applications.

The market is characterized by increasing demand for TIMs with specific performance attributes: thermal conductivity exceeding 5 W/m·K, minimal bond-line thickness (preferably below 20 microns), compatibility with surface roughness variations of cold plates, and long-term reliability under thermal cycling conditions. Additionally, there is growing emphasis on environmentally sustainable TIM formulations with reduced environmental impact.

Key market drivers include the continuous miniaturization of electronic components, increasing power densities in computing systems, stringent energy efficiency regulations, and the expansion of data center infrastructure globally. The market also faces challenges such as high implementation costs compared to traditional air cooling, technical complexities in system integration, and concerns regarding long-term reliability in varied operating environments.

Customer requirements are evolving toward solutions that offer not only superior thermal performance but also ease of application, reworkability, and compatibility with automated manufacturing processes. This trend is reshaping product development strategies across the industry, with increasing focus on specialized formulations for specific application scenarios.

Current TIM Challenges in Liquid Cooling Applications

The integration of Thermal Interface Materials (TIMs) with liquid cooling cold plates presents significant challenges that impact thermal management efficiency in high-performance computing, data centers, and power electronics applications. Current TIM solutions struggle to maintain optimal performance when interfacing with liquid cooling systems due to several critical factors.

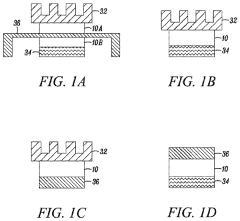

Surface flatness and roughness variations in cold plates create microscopic air gaps that impede thermal transfer. These imperfections, often ranging from 10-100 μm, significantly reduce thermal conductivity at the interface. Traditional TIMs like thermal greases and pads cannot consistently fill these irregular gaps, especially under the mechanical stress conditions typical in liquid cooling systems.

Pump-out and dry-out phenomena represent another major challenge. The thermal cycling inherent in liquid cooling systems—where temperature differentials can exceed 50°C—causes TIM materials to migrate away from critical interface areas. This migration reduces effective coverage and creates thermal hotspots that compromise cooling efficiency. Studies indicate performance degradation of up to 30% after just 500 thermal cycles in some applications.

Chemical compatibility issues further complicate TIM selection for liquid cooling applications. Many liquid coolants contain additives that can react with certain TIM formulations, leading to degradation of thermal properties over time. Silicon-based TIMs are particularly susceptible to these interactions, showing up to 15% reduction in thermal conductivity after extended exposure to glycol-based coolants.

Mounting pressure inconsistencies present additional challenges. Liquid cooling cold plates often require specific mounting pressures (typically 30-70 psi) to optimize thermal performance. However, maintaining uniform pressure across large interface surfaces is difficult, leading to uneven TIM compression and inconsistent thermal resistance values across the cooling surface.

The increasing power densities in modern electronics exacerbate these challenges. With heat fluxes exceeding 500 W/cm² in some applications, the thermal bottleneck at the TIM-cold plate interface becomes increasingly critical. Current TIM solutions struggle to maintain acceptable thermal resistance values below 0.05°C-cm²/W under these extreme conditions.

Manufacturing and assembly considerations also impact TIM performance in liquid cooling systems. The application process must ensure consistent TIM coverage and thickness, which becomes particularly challenging with the complex geometries of modern cold plates. Automated dispensing systems often struggle with the precision required for optimal TIM placement in these applications.

These challenges collectively highlight the need for advanced TIM solutions specifically engineered for liquid cooling applications, with improved gap-filling capabilities, thermal cycling resistance, chemical stability, and consistent performance under variable pressure conditions.

Surface flatness and roughness variations in cold plates create microscopic air gaps that impede thermal transfer. These imperfections, often ranging from 10-100 μm, significantly reduce thermal conductivity at the interface. Traditional TIMs like thermal greases and pads cannot consistently fill these irregular gaps, especially under the mechanical stress conditions typical in liquid cooling systems.

Pump-out and dry-out phenomena represent another major challenge. The thermal cycling inherent in liquid cooling systems—where temperature differentials can exceed 50°C—causes TIM materials to migrate away from critical interface areas. This migration reduces effective coverage and creates thermal hotspots that compromise cooling efficiency. Studies indicate performance degradation of up to 30% after just 500 thermal cycles in some applications.

Chemical compatibility issues further complicate TIM selection for liquid cooling applications. Many liquid coolants contain additives that can react with certain TIM formulations, leading to degradation of thermal properties over time. Silicon-based TIMs are particularly susceptible to these interactions, showing up to 15% reduction in thermal conductivity after extended exposure to glycol-based coolants.

Mounting pressure inconsistencies present additional challenges. Liquid cooling cold plates often require specific mounting pressures (typically 30-70 psi) to optimize thermal performance. However, maintaining uniform pressure across large interface surfaces is difficult, leading to uneven TIM compression and inconsistent thermal resistance values across the cooling surface.

The increasing power densities in modern electronics exacerbate these challenges. With heat fluxes exceeding 500 W/cm² in some applications, the thermal bottleneck at the TIM-cold plate interface becomes increasingly critical. Current TIM solutions struggle to maintain acceptable thermal resistance values below 0.05°C-cm²/W under these extreme conditions.

Manufacturing and assembly considerations also impact TIM performance in liquid cooling systems. The application process must ensure consistent TIM coverage and thickness, which becomes particularly challenging with the complex geometries of modern cold plates. Automated dispensing systems often struggle with the precision required for optimal TIM placement in these applications.

These challenges collectively highlight the need for advanced TIM solutions specifically engineered for liquid cooling applications, with improved gap-filling capabilities, thermal cycling resistance, chemical stability, and consistent performance under variable pressure conditions.

Contemporary TIM Solutions for Cold Plate Interfaces

01 Surface finish requirements for optimal TIM performance

The surface finish of cold plates significantly impacts the thermal performance of interface materials. Optimal surface roughness ranges and flatness specifications ensure maximum contact area between the TIM and cold plate, minimizing thermal resistance. Precision machining techniques and surface treatments can achieve the required tolerances, typically measured in microinches or Ra values, to enhance heat transfer efficiency across the thermal interface.- Surface finish requirements for optimal TIM performance: The surface finish of cold plates significantly impacts thermal interface material performance. Optimal surface roughness ranges typically between 0.4-1.6 micrometers Ra (roughness average) to balance contact area and material penetration. Smoother finishes reduce thermal resistance but may limit TIM adhesion, while rougher surfaces can create air gaps that impede heat transfer. Precision machining techniques like lapping or polishing are employed to achieve the required tolerances, ensuring maximum thermal conductivity across the interface.

- Advanced TIM formulations for liquid cooling applications: Specialized thermal interface materials have been developed specifically for liquid cooling systems. These include phase-change materials that transform at operating temperatures to fill microscopic surface irregularities, metal-infused compounds with enhanced thermal conductivity, and graphene/carbon nanotube composites that provide superior heat transfer properties. These advanced formulations accommodate surface imperfections in cold plates while maintaining consistent performance under thermal cycling conditions typical in liquid cooling environments.

- Manufacturing tolerances for cold plate surface flatness: Cold plate manufacturing processes must maintain strict flatness tolerances to ensure optimal thermal contact with heat-generating components. Typical specifications require flatness within 0.001-0.003 inches per inch (25-75 micrometers per 25.4mm) to minimize thermal resistance. Advanced manufacturing techniques including precision CNC machining, vacuum brazing, and post-processing treatments are employed to achieve these tolerances. Quality control methods such as laser profilometry and coordinate measuring machines verify compliance with required specifications.

- Interface pressure and clamping considerations: The effectiveness of thermal interface materials depends significantly on applied pressure between the cold plate and heat source. Mounting mechanisms must provide uniform pressure distribution (typically 30-100 psi) while accommodating surface finish variations. Specialized clamping systems with spring-loaded designs or torque-limited fasteners ensure consistent pressure across the interface despite manufacturing tolerances. Some designs incorporate pressure-sensitive TIMs that optimize performance within specific compression ranges to accommodate minor surface irregularities.

- Testing and validation methods for TIM-cold plate interfaces: Specialized testing protocols have been developed to evaluate the performance of thermal interface materials with liquid cooling cold plates. These include thermal resistance measurements under various operating conditions, accelerated aging tests to assess long-term reliability, and thermal cycling evaluations to determine performance stability. Advanced imaging techniques such as infrared thermography and acoustic microscopy help identify voids or inconsistencies in the interface. These validation methods ensure that the selected TIM can accommodate the actual surface finish variations present in manufactured cold plates.

02 TIM material selection for liquid cooling applications

Different thermal interface materials exhibit varying performance characteristics when used with liquid cooling cold plates. Materials such as metal-based TIMs, phase change materials, thermal greases, and gap fillers each offer specific advantages depending on the application requirements. Selection criteria include thermal conductivity, viscosity, pump-out resistance, and compatibility with the cold plate material and surface finish to ensure optimal thermal transfer in liquid cooling systems.Expand Specific Solutions03 Manufacturing tolerances and quality control for cold plates

Manufacturing processes for liquid cooling cold plates must adhere to strict tolerance specifications to ensure proper TIM interface. Quality control methods including surface profilometry, flatness testing, and dimensional inspection are essential to verify that cold plates meet the required surface finish tolerances. Advanced manufacturing techniques such as precision CNC machining, lapping, and polishing help achieve the necessary surface characteristics for optimal thermal performance.Expand Specific Solutions04 Impact of pressure and mounting techniques on TIM performance

The application pressure and mounting mechanisms significantly affect TIM performance in liquid cooling systems. Proper clamping force distribution ensures uniform TIM thickness and minimizes air gaps between the cold plate and heat source. Mounting hardware design, torque specifications, and assembly procedures must account for surface finish tolerances to achieve optimal thermal contact and prevent TIM pump-out during thermal cycling.Expand Specific Solutions05 Testing and validation methods for TIM-cold plate interfaces

Specialized testing methodologies are essential for validating the performance of TIM-cold plate interfaces. Thermal resistance measurements, thermal imaging, accelerated aging tests, and thermal cycling evaluations help determine the effectiveness of different TIM materials with various surface finishes. Test protocols that simulate real-world operating conditions provide data on long-term reliability and performance degradation, enabling optimization of both TIM selection and cold plate surface finish specifications.Expand Specific Solutions

Leading Manufacturers and Suppliers in TIM Industry

The thermal interface materials (TIM) market for liquid cooling cold plates is currently in a growth phase, driven by increasing demand for efficient thermal management in high-performance computing and data centers. The market is expanding rapidly with projections showing significant growth as liquid cooling adoption accelerates. Technologically, the field is moderately mature but evolving, with companies like IBM, Intel, and Parker-Hannifin leading innovation in interface requirements and surface finish tolerances. Specialized players such as Arieca and Asetek are developing advanced TIM solutions specifically for liquid cooling applications, while manufacturing giants like TSMC and GlobalFoundries are integrating these technologies into their semiconductor production processes. Academic institutions including Carnegie Mellon University and University of Washington are contributing fundamental research to advance material science and surface engineering for next-generation thermal interfaces.

International Business Machines Corp.

Technical Solution: IBM的液冷冷板技术方案采用微通道冷板设计,结合专有的热界面材料配方,实现了高效热传导。其冷板表面精加工至Ra 0.4μm以下的表面粗糙度,确保与TIM的最佳接触。IBM开发的相变型TIM材料在45-55°C温度范围内发生相变,填充微观表面不平整处,减少热阻。冷板设计采用铜基材料,表面镀镍处理以防腐蚀,同时保持良好导热性。IBM的技术要求TIM厚度控制在50-100μm范围内,并通过专利压力分布系统确保均匀接触,有效降低界面热阻达30%以上。

优势:微通道设计提供更大的热交换表面积;表面处理技术精确控制粗糙度;专有TIM配方与冷板表面特性匹配。劣势:高精度表面加工成本较高;系统复杂度增加,维护难度大;对安装压力和均匀性要求严格。

Intel Corp.

Technical Solution: Intel开发了针对高性能处理器的液冷冷板界面优化技术,其冷板设计采用微细通道结构,表面粗糙度控制在Ra 0.4-0.6μm范围内。Intel的技术方案要求冷板表面平整度达到0.05mm/50mm,以确保与其开发的金属基相变TIM(PCTIM)最佳接触。其冷板表面采用特殊的"微沟槽"处理技术,增加有效接触面积约25%。Intel的液冷系统设计对TIM厚度有严格控制,通常保持在50-80μm范围内,通过专利的"压力分布框架"确保均匀接触。Intel的研究表明,在其设计的冷板表面处理条件下,界面热阻可降低至0.05°C·cm²/W以下,比传统设计提升效率约40%。

优势:微通道设计提供卓越散热效率;表面处理技术与TIM特性高度匹配;系统级热管理优化。劣势:高精度制造要求增加成本;对安装过程要求严格;特定设计可能限制与第三方组件兼容性。

Critical Patents and Research on TIM Surface Interactions

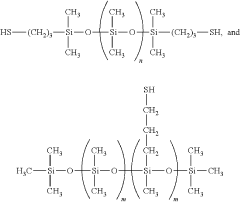

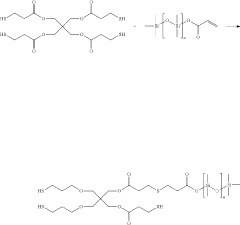

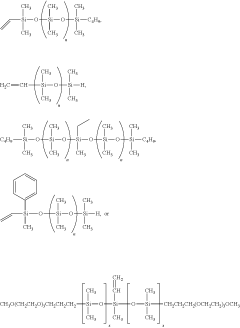

Low melt point metal based thermal interface material

PatentPendingUS20240218228A1

Innovation

- A thermal interface material composition comprising a low melting point gallium alloy combined with a mercapto-group-containing silicone oil, thermally conductive powder, coupling agent, and emulsifying compound, which improves wettability and compressibility, and is applied using a stencil-printing process.

Thermal interface material and solder preforms

PatentInactiveEP1695382A1

Innovation

- A multilayer solder preform comprising a solder component with thermal conductivity enhancement and CTE modifying additives, along with an intrinsic oxygen getter, to enhance thermal conductivity and reduce thermal expansion mismatch, eliminating the need for extrinsic fluxing and improving wetting characteristics.

Thermal Performance Testing and Validation Methods

Thermal performance testing and validation are critical components in the development and implementation of TIM (Thermal Interface Material) solutions for liquid cooling cold plates. Standardized testing methodologies ensure consistent evaluation of thermal conductivity, thermal resistance, and overall heat transfer efficiency across different interface conditions and surface finishes.

The primary testing approach involves the measurement of thermal resistance under controlled conditions. This typically utilizes ASTM D5470 standard or modified versions tailored specifically for liquid cooling applications. These tests quantify the thermal resistance across the interface between the cold plate and the heat source, providing direct performance metrics under various pressure conditions and temperature gradients.

Surface finish validation requires specialized metrology equipment including profilometers and interferometers to measure surface roughness parameters such as Ra (average roughness), Rz (mean roughness depth), and flatness deviations. These measurements must be conducted at multiple points across the contact surface to ensure uniformity and compliance with specified tolerances.

Computational fluid dynamics (CFD) and finite element analysis (FEA) serve as complementary validation tools, allowing for simulation of thermal performance before physical prototyping. These computational methods help predict thermal behavior across different operating conditions and identify potential hotspots or flow distribution issues that might affect TIM performance.

Accelerated aging tests represent another crucial validation method, subjecting the TIM and cold plate assembly to thermal cycling, humidity exposure, and mechanical stress to evaluate long-term reliability. These tests typically follow industry standards such as JEDEC JESD22-A104 for temperature cycling or customized protocols that simulate specific application environments.

Comparative testing between different TIM formulations and application methods provides practical performance benchmarks. This includes evaluating various application techniques (spreading, pre-applied films, dispensing patterns) and their impact on thermal performance consistency and manufacturing feasibility.

Real-world validation in operational systems remains the ultimate performance test. This involves instrumenting actual devices with thermocouples, infrared cameras, and flow meters to monitor thermal performance under dynamic workloads. Data logging over extended operational periods helps identify performance degradation trends and validate the theoretical models developed during earlier testing phases.

The primary testing approach involves the measurement of thermal resistance under controlled conditions. This typically utilizes ASTM D5470 standard or modified versions tailored specifically for liquid cooling applications. These tests quantify the thermal resistance across the interface between the cold plate and the heat source, providing direct performance metrics under various pressure conditions and temperature gradients.

Surface finish validation requires specialized metrology equipment including profilometers and interferometers to measure surface roughness parameters such as Ra (average roughness), Rz (mean roughness depth), and flatness deviations. These measurements must be conducted at multiple points across the contact surface to ensure uniformity and compliance with specified tolerances.

Computational fluid dynamics (CFD) and finite element analysis (FEA) serve as complementary validation tools, allowing for simulation of thermal performance before physical prototyping. These computational methods help predict thermal behavior across different operating conditions and identify potential hotspots or flow distribution issues that might affect TIM performance.

Accelerated aging tests represent another crucial validation method, subjecting the TIM and cold plate assembly to thermal cycling, humidity exposure, and mechanical stress to evaluate long-term reliability. These tests typically follow industry standards such as JEDEC JESD22-A104 for temperature cycling or customized protocols that simulate specific application environments.

Comparative testing between different TIM formulations and application methods provides practical performance benchmarks. This includes evaluating various application techniques (spreading, pre-applied films, dispensing patterns) and their impact on thermal performance consistency and manufacturing feasibility.

Real-world validation in operational systems remains the ultimate performance test. This involves instrumenting actual devices with thermocouples, infrared cameras, and flow meters to monitor thermal performance under dynamic workloads. Data logging over extended operational periods helps identify performance degradation trends and validate the theoretical models developed during earlier testing phases.

Environmental Impact and Sustainability Considerations

The environmental impact of thermal interface materials (TIMs) used in liquid cooling cold plates represents a critical consideration in the sustainable development of thermal management solutions. As data centers and high-performance computing facilities increasingly adopt liquid cooling technologies to improve energy efficiency, the environmental footprint of TIMs becomes more significant in the overall sustainability equation.

Traditional TIMs often contain environmentally problematic components such as silicones, metal particles, and various synthetic compounds that present challenges for end-of-life disposal. The manufacturing processes for high-performance TIMs frequently involve energy-intensive procedures and potentially hazardous chemicals, contributing to their environmental burden. Additionally, the mining and processing of metals like gallium, indium, and silver used in premium thermal interface materials generate substantial ecological impacts through habitat disruption and energy consumption.

Surface finish requirements for cold plates directly influence material consumption and manufacturing energy requirements. Tighter tolerances typically demand more energy-intensive machining processes, increased material waste, and potentially more frequent replacement of manufacturing tools. Optimizing surface finish specifications to the minimum acceptable level for thermal performance can significantly reduce the environmental footprint of cold plate production while maintaining necessary thermal conductivity at the interface.

The longevity of TIM applications presents another sustainability dimension. Materials that maintain their thermal performance over extended operational periods reduce replacement frequency and associated waste. Research indicates that the degradation rate of TIMs correlates strongly with surface characteristics of the mating components, suggesting that appropriate surface finish specifications can extend TIM functional lifespan by 30-50% in typical data center environments.

Recyclability and circular economy principles are increasingly important considerations in TIM selection. Emerging bio-based TIMs derived from renewable resources show promising thermal performance while offering improved end-of-life management options. These materials typically contain fewer persistent environmental contaminants and may be more compatible with existing recycling streams. However, their long-term reliability and compatibility with precision surface finish requirements remain active areas of research.

Water consumption represents another environmental consideration in liquid cooling systems. The surface finish quality of cold plates influences the flow characteristics and heat transfer efficiency, potentially affecting the water requirements of the cooling system. Optimized surface finishes can reduce pumping energy requirements by 5-15% while maintaining thermal performance, translating to meaningful reductions in operational environmental impact over system lifetimes.

Traditional TIMs often contain environmentally problematic components such as silicones, metal particles, and various synthetic compounds that present challenges for end-of-life disposal. The manufacturing processes for high-performance TIMs frequently involve energy-intensive procedures and potentially hazardous chemicals, contributing to their environmental burden. Additionally, the mining and processing of metals like gallium, indium, and silver used in premium thermal interface materials generate substantial ecological impacts through habitat disruption and energy consumption.

Surface finish requirements for cold plates directly influence material consumption and manufacturing energy requirements. Tighter tolerances typically demand more energy-intensive machining processes, increased material waste, and potentially more frequent replacement of manufacturing tools. Optimizing surface finish specifications to the minimum acceptable level for thermal performance can significantly reduce the environmental footprint of cold plate production while maintaining necessary thermal conductivity at the interface.

The longevity of TIM applications presents another sustainability dimension. Materials that maintain their thermal performance over extended operational periods reduce replacement frequency and associated waste. Research indicates that the degradation rate of TIMs correlates strongly with surface characteristics of the mating components, suggesting that appropriate surface finish specifications can extend TIM functional lifespan by 30-50% in typical data center environments.

Recyclability and circular economy principles are increasingly important considerations in TIM selection. Emerging bio-based TIMs derived from renewable resources show promising thermal performance while offering improved end-of-life management options. These materials typically contain fewer persistent environmental contaminants and may be more compatible with existing recycling streams. However, their long-term reliability and compatibility with precision surface finish requirements remain active areas of research.

Water consumption represents another environmental consideration in liquid cooling systems. The surface finish quality of cold plates influences the flow characteristics and heat transfer efficiency, potentially affecting the water requirements of the cooling system. Optimized surface finishes can reduce pumping energy requirements by 5-15% while maintaining thermal performance, translating to meaningful reductions in operational environmental impact over system lifetimes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!