Tungsten Filaments: History And Modern Applications

Tungsten Filament Evolution

The evolution of tungsten filaments is a fascinating journey that spans over a century, marked by significant technological advancements and diverse applications. The story begins in the late 19th century when inventors were seeking a suitable material for incandescent light bulbs. Tungsten, with its high melting point and durability, emerged as the ideal candidate.

In 1904, Alexander Just and Franz Hanaman patented the first tungsten filament lamp, revolutionizing the lighting industry. This breakthrough led to the rapid adoption of tungsten filaments in electric lighting, replacing carbon filaments and dramatically improving the efficiency and lifespan of light bulbs.

The 1910s saw further refinements in tungsten filament production. General Electric developed a process to create ductile tungsten, allowing for the production of coiled filaments. This innovation increased the luminous efficacy of lamps and paved the way for more compact bulb designs.

During the interwar period, research focused on improving the structural integrity and performance of tungsten filaments. The introduction of doped tungsten in the 1930s enhanced the filament's resistance to sagging and improved its longevity, particularly in high-temperature applications.

The mid-20th century witnessed the expansion of tungsten filament applications beyond lighting. The aerospace industry began utilizing tungsten filaments in rocket nozzles and heat shields due to their exceptional heat resistance. Simultaneously, the electronics sector incorporated tungsten filaments into vacuum tubes and cathode ray tubes.

In the 1960s and 1970s, as semiconductor technology advanced, tungsten filaments found new roles in the manufacturing of integrated circuits. They became crucial in chemical vapor deposition processes, serving as heating elements in epitaxial reactors.

The late 20th century saw a shift towards energy-efficient lighting solutions, leading to a decline in traditional incandescent bulb usage. However, this period also marked the diversification of tungsten filament applications in specialized fields such as electron microscopy and X-ray technology.

Today, while LED technology has largely supplanted tungsten filaments in general lighting, these versatile components continue to evolve and find new applications. Modern tungsten filaments are engineered at the nanoscale, opening up possibilities in areas like field emission displays and advanced sensors. The ongoing research into tungsten nanostructures promises to extend the legacy of this remarkable material well into the future.

Market Demand Analysis

The market demand for tungsten filaments has experienced significant shifts over the past century, driven by technological advancements and changing consumer preferences. Initially, the primary application of tungsten filaments was in incandescent light bulbs, which dominated the lighting industry for decades. However, the advent of more energy-efficient lighting technologies, such as LED and CFL, has led to a decline in the traditional incandescent bulb market.

Despite this decline in the lighting sector, tungsten filaments have found new applications in various industries, creating a diversified market demand. In the electronics industry, tungsten filaments are used in cathode ray tubes, electron microscopes, and X-ray tubes. The aerospace and automotive sectors utilize tungsten filaments in specialized lighting applications, such as aircraft landing lights and high-performance automotive headlights.

The medical field has also embraced tungsten filaments, particularly in diagnostic imaging equipment like X-ray machines and CT scanners. The unique properties of tungsten, including its high melting point and excellent thermal conductivity, make it ideal for these applications. Additionally, the semiconductor industry employs tungsten filaments in the production of integrated circuits and microchips.

In the realm of additive manufacturing, tungsten filaments are gaining traction as a material for 3D printing applications, especially in industries requiring high-temperature resistance and durability. This emerging market segment shows promising growth potential as additive manufacturing technologies continue to evolve.

The global tungsten market, which includes filaments and other tungsten products, has shown steady growth. The increasing demand for tungsten in various industrial applications has offset the decline in traditional lighting uses. Developing economies, particularly in Asia-Pacific, are driving much of this growth due to rapid industrialization and infrastructure development.

Environmental concerns and energy efficiency regulations have influenced market dynamics, pushing manufacturers to develop more sustainable and eco-friendly tungsten filament products. This trend has led to innovations in filament design and production processes, aiming to reduce energy consumption and extend product lifespan.

Looking ahead, the market for tungsten filaments is expected to remain stable, with growth opportunities in specialized applications offsetting declines in traditional markets. The ongoing research and development in materials science may uncover new applications for tungsten filaments, potentially opening up new market segments and driving future demand.

Current Tech Challenges

Despite its long history, tungsten filament technology continues to face several challenges in modern applications. One of the primary issues is the inherent fragility of tungsten filaments, particularly in high-temperature environments. The brittleness of tungsten at room temperature makes it susceptible to breakage during handling and installation, limiting its durability in certain applications.

Energy efficiency remains a significant concern for tungsten filaments. While they have been widely used in incandescent lighting, their low luminous efficacy compared to newer lighting technologies like LEDs has led to a decline in their use for general illumination. This efficiency gap presents a challenge for researchers and engineers seeking to improve the performance of tungsten filaments in lighting applications.

The high operating temperature of tungsten filaments, typically around 2500-3000°C, poses challenges in terms of heat management and energy consumption. This characteristic limits their use in compact or heat-sensitive devices and contributes to increased energy costs in applications where they are still employed.

Tungsten's tendency to evaporate at high temperatures leads to gradual thinning of the filament over time, reducing its lifespan and performance. This phenomenon, known as "tungsten loss," is particularly problematic in applications requiring long-term stability and consistent performance, such as in certain types of sensors or specialized lighting systems.

The manufacturing process for high-quality tungsten filaments remains complex and resource-intensive. Achieving the necessary purity and structural integrity for optimal performance requires sophisticated production techniques, which can impact the cost-effectiveness of tungsten filament-based solutions in competitive markets.

Environmental concerns have also emerged as a challenge for tungsten filament technology. The mining and processing of tungsten ore can have significant environmental impacts, and the disposal of tungsten-containing products at the end of their life cycle presents recycling and waste management challenges.

In specialized applications such as electron microscopy and X-ray tubes, where tungsten filaments are still widely used, there is an ongoing challenge to develop filaments with improved electron emission characteristics and longer operational lifetimes. Researchers are exploring ways to enhance the surface properties of tungsten filaments to achieve these goals.

The development of alternative materials and technologies that can match or exceed the performance of tungsten filaments in specific applications presents a competitive challenge. For instance, in some high-temperature applications, materials like rhenium or molybdenum are being investigated as potential replacements for tungsten filaments.

Modern Filament Solutions

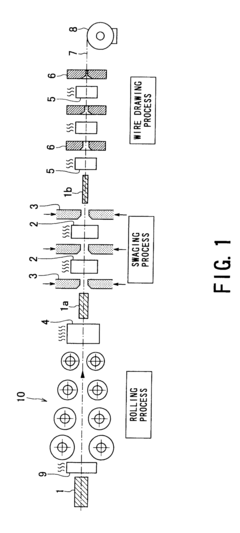

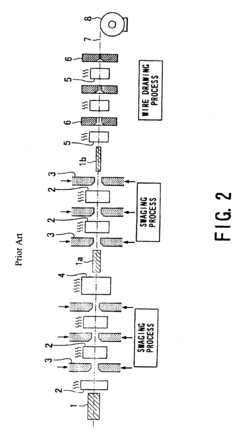

01 Manufacturing processes for tungsten filaments

Various methods and techniques for manufacturing tungsten filaments are described, including drawing, sintering, and shaping processes. These methods aim to produce filaments with desired properties such as strength, durability, and electrical conductivity for use in lighting and other applications.- Manufacturing processes for tungsten filaments: Various manufacturing processes are employed to produce tungsten filaments, including drawing, sintering, and specialized techniques to achieve desired properties such as strength and durability. These processes often involve careful control of temperature, pressure, and material composition to create filaments suitable for use in lighting and other applications.

- Composition and alloying of tungsten filaments: The composition of tungsten filaments can be modified through alloying or the addition of other elements to enhance specific properties. This may include improving ductility, increasing resistance to sagging, or optimizing electrical characteristics. Different compositions are developed to suit various applications and operating conditions.

- Structural design and geometry of tungsten filaments: The structural design and geometry of tungsten filaments play a crucial role in their performance and longevity. This includes considerations such as coil shape, diameter, and spacing, which can affect factors like light output, energy efficiency, and resistance to mechanical stress. Various designs are developed to optimize filament performance for specific applications.

- Surface treatment and coating of tungsten filaments: Surface treatments and coatings are applied to tungsten filaments to enhance their properties or protect them from degradation. These treatments may include chemical processes, physical vapor deposition, or the application of protective layers. Such modifications can improve emission characteristics, extend filament life, or provide additional functionality.

- Applications and innovations in tungsten filament technology: Tungsten filaments find applications in various fields beyond traditional lighting, including specialized industrial processes, scientific instruments, and emerging technologies. Ongoing innovations focus on improving efficiency, developing novel applications, and addressing environmental concerns associated with tungsten filament production and use.

02 Composition and treatment of tungsten filaments

Innovations in the composition and treatment of tungsten filaments are presented, including alloying with other materials, heat treatments, and surface modifications. These improvements aim to enhance the performance, longevity, and efficiency of the filaments in various applications.Expand Specific Solutions03 Tungsten filament applications in lighting

The use of tungsten filaments in various lighting applications is explored, including incandescent lamps, halogen lamps, and specialized lighting solutions. Innovations focus on improving light output, energy efficiency, and lifespan of the filaments in these applications.Expand Specific Solutions04 Tungsten filament support structures and mounting

Designs and methods for supporting and mounting tungsten filaments within devices are presented. These innovations aim to improve stability, reduce vibration, and enhance overall performance of the filaments in various applications, particularly in lighting and electronic devices.Expand Specific Solutions05 Specialized tungsten filament designs

Unique and specialized designs for tungsten filaments are described, including coiled filaments, multi-strand filaments, and filaments with specific geometries. These designs aim to optimize performance, increase efficiency, and address specific application requirements in various industries.Expand Specific Solutions

Key Industry Players

The tungsten filament industry is in a mature stage, with a stable global market size estimated at around $1.5 billion. The technology has evolved from its historical use in incandescent lighting to modern applications in semiconductor manufacturing, aerospace, and advanced materials. Companies like Applied Materials, Lam Research, and Toshiba are leading the way in developing cutting-edge tungsten filament technologies for semiconductor processes. Emerging players such as Chongyi Zhangyuan Tungsten and Xiamen Tungsten are focusing on material innovations. The competitive landscape is characterized by a mix of established tech giants and specialized materials companies, with ongoing research at institutions like Central South University and University of Science & Technology Beijing driving further advancements in tungsten filament applications.

Applied Materials, Inc.

Toshiba Corp.

Innovative Filament Tech

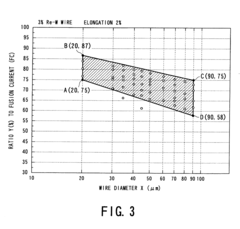

- The process of rolling tungsten sintered compact at a high rate of 40 to 75% after initial heating, followed by controlled electrical heating treatment, enhances elongation properties, allowing for efficient production of tungsten wires with improved strength and durability for high-temperature applications.

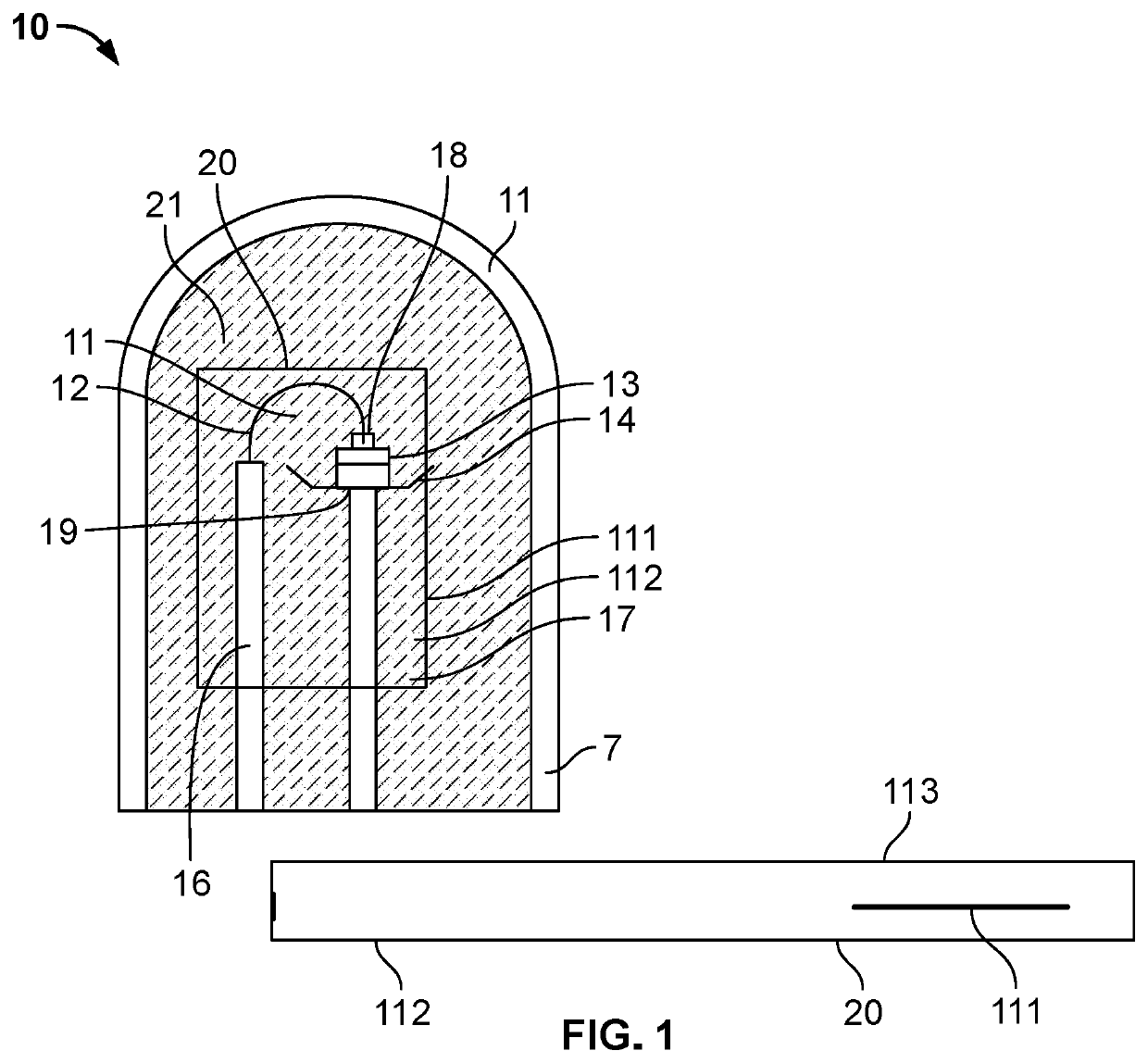

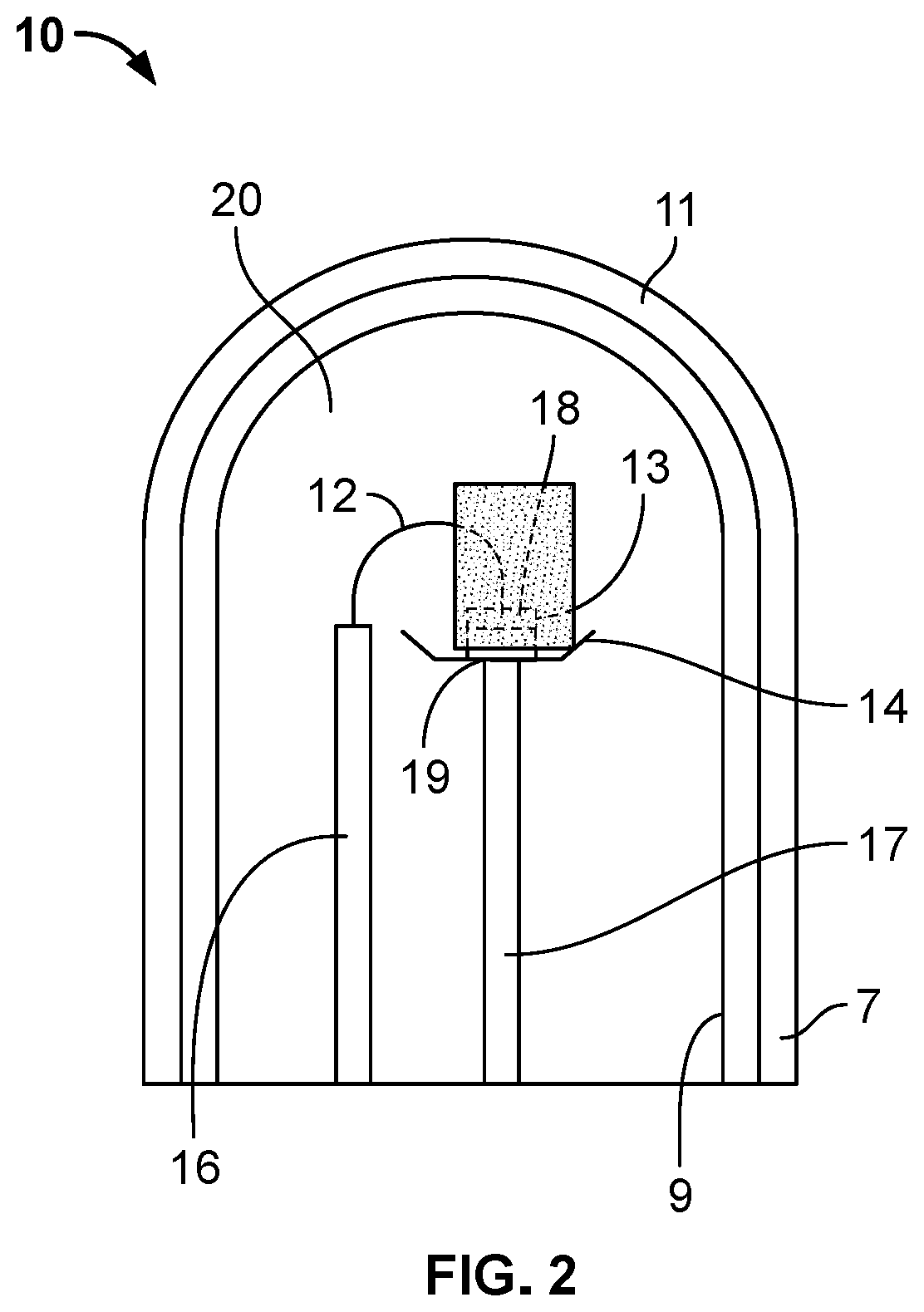

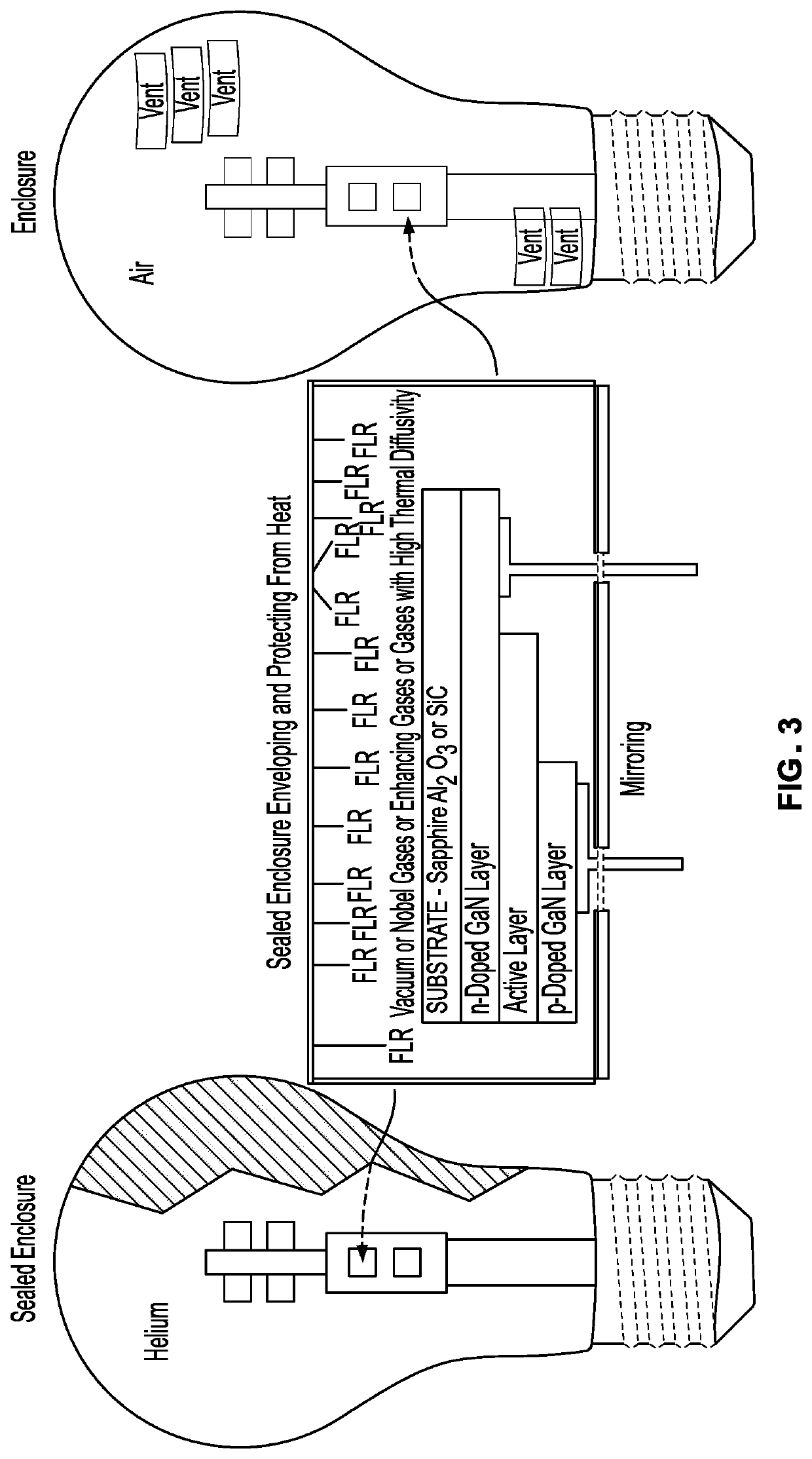

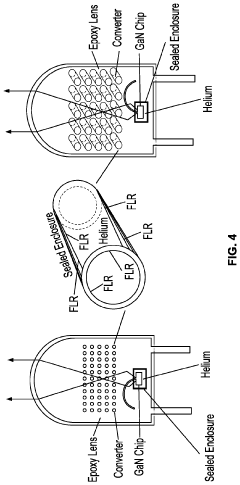

- A solid-state light emitting device design that utilizes a single diode die capable of producing primary radiation, which is enhanced and protected by an enclosure, allowing for efficient energy transfer to secondary luminescent elements to generate achromatic or chromatic light, thereby improving light output, efficiency, durability, and physiological appeal.

Environmental Impact

The environmental impact of tungsten filaments is a critical consideration in their production, use, and disposal. The manufacturing process of tungsten filaments involves energy-intensive mining and refining operations, which contribute to greenhouse gas emissions and potential habitat disruption. Tungsten ore extraction can lead to soil erosion and water pollution if not managed properly, affecting local ecosystems and biodiversity.

During the use phase, tungsten filaments in incandescent light bulbs are notoriously inefficient, converting only about 5% of energy into visible light while the rest is lost as heat. This inefficiency results in higher energy consumption and, consequently, increased carbon emissions from power generation. However, in other applications such as X-ray tubes and electron microscopes, tungsten filaments contribute to scientific advancements that may indirectly benefit environmental research and monitoring.

The disposal of tungsten filaments presents both challenges and opportunities. While tungsten is not considered toxic, improper disposal can lead to unnecessary landfill accumulation. Recycling tungsten filaments is technically feasible and environmentally beneficial, as it reduces the need for new raw material extraction. Advanced recycling processes can recover up to 95% of tungsten from used filaments, significantly reducing the environmental footprint of tungsten production.

In recent years, there has been a shift towards more environmentally friendly alternatives in lighting applications, such as LED technology, which has reduced the demand for tungsten filaments in this sector. This transition has led to a decrease in the overall environmental impact associated with tungsten filament production for lighting purposes. However, the unique properties of tungsten ensure its continued use in specialized applications where suitable alternatives are not yet available.

The longevity of tungsten filaments in certain applications contributes to resource conservation. In high-temperature industrial processes, tungsten's durability reduces the frequency of replacements, thereby minimizing waste generation and the environmental impacts associated with manufacturing and transportation of replacement parts.

As environmental concerns gain prominence, research into more sustainable production methods for tungsten filaments is ongoing. This includes exploring less energy-intensive refining processes, developing more efficient recycling technologies, and investigating potential bio-based alternatives for certain applications. These efforts aim to mitigate the environmental impact of tungsten filaments while maintaining their crucial role in various technological and industrial applications.

Material Science Advances

The field of material science has witnessed significant advancements in the development and application of tungsten filaments. These innovations have revolutionized various industries, from lighting to electronics and beyond. The evolution of tungsten filament technology has been driven by the unique properties of tungsten, including its high melting point, excellent electrical conductivity, and exceptional durability.

In the realm of lighting, tungsten filaments have undergone substantial improvements since their initial introduction. Modern manufacturing techniques have enabled the production of thinner, more uniform filaments that offer enhanced luminous efficacy and longer lifespans. These advancements have led to the development of halogen lamps, which utilize a halogen gas cycle to redeposit evaporated tungsten back onto the filament, significantly extending bulb life and maintaining consistent light output.

The electronics industry has also benefited from progress in tungsten filament technology. In cathode ray tubes (CRTs) and vacuum tubes, refined tungsten filaments serve as efficient electron emitters, crucial for display and signal amplification applications. The ability to precisely control the size and shape of tungsten filaments has allowed for the miniaturization of electronic components, contributing to the development of more compact and powerful devices.

Advancements in material science have led to the creation of tungsten alloys and composites, further expanding the application range of tungsten filaments. These new materials combine the inherent strengths of tungsten with additional properties such as improved ductility or enhanced heat resistance. For instance, tungsten-rhenium alloys exhibit superior mechanical properties at high temperatures, making them ideal for use in extreme environments like aerospace applications or nuclear reactors.

Nanotechnology has opened up new frontiers for tungsten filament applications. Tungsten nanowires and nanostructures have shown promise in fields such as field emission displays, where their unique properties can be leveraged to create highly efficient electron sources. Additionally, the development of tungsten-based nanomaterials has potential applications in energy storage, catalysis, and advanced sensing technologies.

The ongoing research in material science continues to push the boundaries of tungsten filament technology. Scientists are exploring novel fabrication methods, such as additive manufacturing techniques, to create complex tungsten structures with tailored properties. These advancements may lead to breakthroughs in areas like thermionic energy conversion, where tungsten's high work function and thermal stability make it an attractive candidate for efficient electron emission.