Tungsten's Emerging Role In Satellite Systems

Tungsten in Space Tech: Background and Objectives

Tungsten, a metal known for its exceptional properties, has been gaining prominence in the field of satellite systems and space technology. The evolution of tungsten's role in this domain can be traced back to the early days of space exploration, where its high melting point and density made it an attractive material for spacecraft components. As space missions became more complex and demanding, the need for materials that could withstand extreme conditions grew, propelling tungsten to the forefront of space technology research.

The trajectory of tungsten's development in space applications has been marked by significant milestones. Initially used primarily in thermal protection systems, tungsten's application has expanded to include radiation shielding, propulsion systems, and structural components. This expansion has been driven by the increasing demands of modern satellite systems, which require materials capable of withstanding the harsh environment of space while maintaining optimal performance.

The technological goals associated with tungsten in satellite systems are multifaceted. Researchers and engineers aim to harness tungsten's unique properties to enhance the longevity, efficiency, and reliability of satellites. Key objectives include improving thermal management in spacecraft, developing more efficient propulsion systems, and creating stronger, lighter structural components. Additionally, there is a focus on leveraging tungsten's radiation-shielding capabilities to protect sensitive electronic equipment from the damaging effects of cosmic radiation.

As the space industry continues to evolve, with a growing emphasis on miniaturization and cost-effectiveness, the role of tungsten is expected to become even more critical. Emerging trends in satellite technology, such as the development of CubeSats and other small satellite platforms, present new challenges and opportunities for tungsten applications. The material's high density-to-strength ratio makes it particularly valuable in these compact designs, where every gram of weight matters.

The future trajectory of tungsten in space technology is likely to be shaped by advancements in materials science and manufacturing techniques. Researchers are exploring novel alloys and composites that incorporate tungsten to create materials with enhanced properties tailored for specific space applications. Furthermore, the development of additive manufacturing techniques for tungsten components promises to open up new possibilities for complex geometries and optimized designs in satellite systems.

Market Analysis for Tungsten-Based Satellite Components

The market for tungsten-based satellite components is experiencing significant growth, driven by the increasing demand for advanced satellite systems across various sectors. Tungsten's unique properties, including its high melting point, excellent thermal conductivity, and superior strength-to-weight ratio, make it an ideal material for critical satellite components. This market is primarily segmented into communication satellites, earth observation satellites, navigation satellites, and scientific research satellites.

In the communication satellite segment, tungsten components are gaining traction due to their ability to withstand extreme temperatures and radiation in geostationary orbits. The global communication satellite market is projected to expand rapidly, with a compound annual growth rate (CAGR) exceeding 8% over the next five years. This growth is fueled by the increasing demand for high-speed internet connectivity, particularly in remote and underserved areas.

Earth observation satellites represent another significant market for tungsten-based components. These satellites require materials that can maintain structural integrity under the harsh conditions of low Earth orbit. The earth observation satellite market is expected to grow substantially, driven by applications in climate monitoring, disaster management, and urban planning. Tungsten's resistance to thermal expansion makes it particularly valuable in maintaining the precise alignment of optical systems in these satellites.

The navigation satellite market, dominated by global navigation satellite systems (GNSS) like GPS, Galileo, and BeiDou, is also a key consumer of tungsten components. These systems require highly stable and precise components to maintain accurate positioning services. The GNSS market is forecasted to grow steadily, with increasing applications in autonomous vehicles, precision agriculture, and location-based services.

In the scientific research satellite segment, tungsten is finding applications in specialized instruments and shielding components. This niche market is driven by government and institutional investments in space exploration and astronomical research. While smaller in volume compared to commercial satellite markets, it offers high-value opportunities for advanced tungsten-based solutions.

The market for tungsten-based satellite components is characterized by a high barrier to entry due to the specialized nature of space-grade materials and stringent quality requirements. Key market players include established aerospace manufacturers and specialized materials suppliers. The supply chain for these components is complex, involving raw material suppliers, precision machining companies, and system integrators.

Geographically, North America and Europe currently dominate the market, owing to their advanced space industries and significant investments in satellite technology. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by ambitious space programs in countries like China, India, and Japan. This regional diversification is expected to create new opportunities for tungsten component suppliers and foster innovation in satellite technology.

Current Challenges in Tungsten Space Applications

Despite tungsten's promising properties for space applications, several challenges currently hinder its widespread adoption in satellite systems. One of the primary obstacles is the material's high density, which significantly impacts launch costs and payload capacity. While tungsten's density provides excellent radiation shielding, it also increases the overall mass of satellite components, requiring more powerful and expensive launch vehicles.

Another challenge lies in the manufacturing and processing of tungsten for space-grade applications. The material's high melting point and hardness make it difficult to machine and form into complex shapes required for satellite components. This limitation often results in increased production costs and longer lead times, which can be detrimental in the fast-paced satellite industry.

Thermal management presents another significant hurdle in tungsten's space applications. Although the material's high thermal conductivity is beneficial for heat dissipation, its thermal expansion characteristics can cause issues in the extreme temperature fluctuations experienced in space. Engineers must carefully design components to account for these thermal stresses, which adds complexity to the development process.

Tungsten's susceptibility to oxidation at high temperatures poses a challenge for reusable space systems, such as those being developed for future missions. While this is less of an issue in the vacuum of space, it becomes problematic during re-entry or in scenarios where satellites may encounter trace amounts of oxygen in low Earth orbit.

The integration of tungsten components with other materials commonly used in satellite construction also presents challenges. Joining tungsten to lighter materials like aluminum or composites requires specialized techniques to ensure structural integrity and prevent galvanic corrosion. This necessitates additional research and development in advanced joining and coating technologies.

Lastly, the limited availability of high-purity tungsten suitable for space applications and the geopolitical concerns surrounding its supply chain add another layer of complexity. With most tungsten reserves concentrated in a few countries, ensuring a stable and reliable supply for critical space components becomes a strategic challenge for space agencies and satellite manufacturers.

Addressing these challenges requires a multidisciplinary approach, combining materials science, advanced manufacturing techniques, and innovative design solutions. As the demand for more robust and efficient satellite systems grows, overcoming these obstacles will be crucial in fully leveraging tungsten's potential in space applications.

Existing Tungsten Solutions for Satellites

01 Tungsten deposition and film formation

Various methods and processes for depositing tungsten and forming tungsten films on substrates. This includes techniques such as chemical vapor deposition (CVD), atomic layer deposition (ALD), and physical vapor deposition (PVD). These processes are crucial in semiconductor manufacturing for creating interconnects, contacts, and other conductive structures.- Tungsten deposition methods: Various methods for depositing tungsten on substrates, including chemical vapor deposition (CVD) and atomic layer deposition (ALD). These techniques are used to create thin films of tungsten for applications in semiconductor manufacturing and other industries.

- Tungsten-based alloys and composites: Development of tungsten-based alloys and composite materials with enhanced properties, such as improved strength, hardness, and thermal stability. These materials find applications in aerospace, defense, and high-temperature industrial processes.

- Tungsten in electronic devices: Utilization of tungsten in electronic devices, particularly in the fabrication of integrated circuits and microelectronic components. This includes the use of tungsten as interconnects, gate electrodes, and diffusion barriers in semiconductor devices.

- Tungsten processing and recycling: Methods for processing tungsten ores, refining tungsten, and recycling tungsten-containing materials. These processes aim to improve the efficiency of tungsten production and reduce environmental impact through recycling and waste management.

- Tungsten surface treatment and modification: Techniques for modifying and treating tungsten surfaces to enhance their properties or compatibility with other materials. This includes methods for cleaning, etching, and functionalizing tungsten surfaces for various applications.

02 Tungsten etching and patterning

Techniques for etching and patterning tungsten layers in semiconductor devices. This includes selective etching processes, plasma etching, and methods for creating precise patterns in tungsten films. These processes are essential for creating intricate circuit designs and structures in microelectronics.Expand Specific Solutions03 Tungsten alloys and composites

Development and production of tungsten alloys and composite materials. This includes combining tungsten with other elements or materials to enhance its properties or create new materials with specific characteristics. These alloys and composites find applications in various industries, including aerospace, defense, and high-temperature applications.Expand Specific Solutions04 Tungsten in electronic components

Use of tungsten in various electronic components and devices. This includes applications in field emission displays, electron emitters, and other electronic structures that benefit from tungsten's unique properties such as high melting point and good electrical conductivity.Expand Specific Solutions05 Tungsten powder production and processing

Methods for producing and processing tungsten powder, including techniques for controlling particle size, shape, and purity. This encompasses various processes such as reduction of tungsten oxides, mechanical alloying, and powder metallurgy techniques. These processes are crucial for creating high-quality tungsten products and components.Expand Specific Solutions

Key Players in Tungsten-Satellite Industry

The emerging role of tungsten in satellite systems is gaining momentum in a rapidly evolving market. The industry is in a growth phase, with increasing demand for advanced satellite technologies driving innovation. Market size is expanding as more countries and private companies invest in space exploration and satellite communications. Technologically, the field is progressing from experimental to early commercial applications. Companies like Thales SA, The Boeing Co., and China Academy of Space Technology are at the forefront, developing tungsten-based solutions for satellite systems. Emerging players such as Akash Systems, Inc. and Star Mesh LLC are also contributing to technological advancements. The involvement of established semiconductor manufacturers like Taiwan Semiconductor Manufacturing Co., Ltd. and Texas Instruments Incorporated indicates the growing importance of tungsten in satellite electronics, suggesting a trend towards integration of terrestrial and space-based technologies.

Thales SA

The Boeing Co.

Innovative Tungsten Applications in Satellites

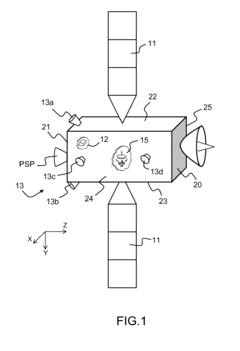

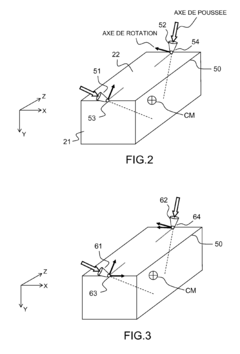

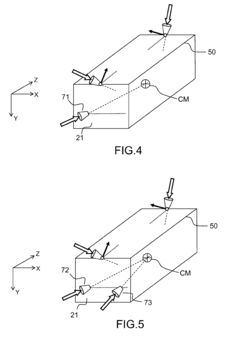

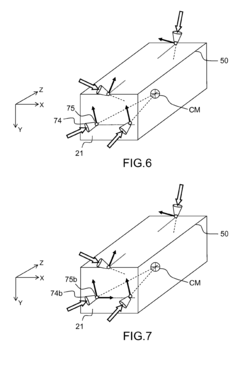

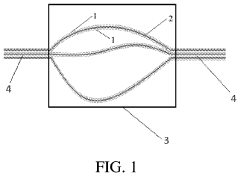

- A new propulsion device architecture featuring two thrusters arranged on the same face of the satellite, on either side of the center of mass along the Z axis, configured to produce a thrust with a majority component along the Y axis, allowing simultaneous ignition to compensate for unwanted forces and improve inclination control, while also enabling torque generation along three axes through motorized mechanisms that orient thrusters.

- A nano-carbon composite film is developed with flexible adhesive layers, including carbon nanotube films or resin slurries, laminated with graphene layers to enhance adhesion and flexibility, allowing for high thermal conductivity and durability.

Space Debris Mitigation with Tungsten

Space debris mitigation has become a critical concern in the satellite industry, and tungsten is emerging as a promising material for addressing this challenge. Tungsten's unique properties make it an excellent candidate for developing innovative solutions to reduce space debris and enhance the sustainability of satellite operations.

One of the primary applications of tungsten in space debris mitigation is in the development of advanced shielding systems for satellites. Tungsten's high density and exceptional strength-to-weight ratio allow for the creation of thin yet highly effective protective layers. These shields can significantly reduce the risk of damage from micrometeorites and small debris particles, extending the operational life of satellites and reducing the likelihood of satellite fragmentation upon impact.

Tungsten is also being explored for use in de-orbiting systems. As satellites reach the end of their operational life, they need to be safely removed from orbit to prevent them from becoming space debris. Tungsten-based thrusters and propulsion systems are being developed to provide efficient and reliable de-orbiting capabilities. The high melting point and resistance to erosion of tungsten make it ideal for use in these systems, ensuring consistent performance even in the harsh space environment.

Another innovative application of tungsten in space debris mitigation is in the development of "drag sails" or "drag augmentation devices." These devices are designed to increase the surface area of a satellite at the end of its mission, accelerating its natural orbital decay and reducing the time it remains in orbit as potential debris. Tungsten's strength and durability allow for the creation of lightweight yet robust sail structures that can withstand the rigors of deployment and operation in space.

Researchers are also investigating the use of tungsten in active debris removal technologies. Concepts such as tungsten-tipped harpoons or nets with tungsten weights are being explored as potential methods for capturing and de-orbiting large pieces of space debris. The high density of tungsten provides the necessary mass for these capture devices while minimizing their overall size.

Furthermore, tungsten is being considered for use in the construction of satellite components that are designed to break apart or vaporize upon re-entry into Earth's atmosphere. This controlled fragmentation approach aims to reduce the risk of large debris pieces surviving re-entry and potentially causing harm on the ground. Tungsten's high melting point and ability to ablate in a controlled manner make it an attractive material for this purpose.

As the space industry continues to grapple with the growing challenge of space debris, tungsten's role in mitigation strategies is likely to expand. Its unique combination of properties offers numerous opportunities for innovation in satellite design, debris prevention, and active removal technologies. Ongoing research and development in this area promise to yield new and more effective solutions for ensuring the long-term sustainability of space operations.

Environmental Impact of Tungsten in Space

The increasing use of tungsten in satellite systems raises important questions about its environmental impact in space. As satellites containing tungsten components reach the end of their operational life, they contribute to the growing problem of space debris. The long-term effects of tungsten particles in Earth's orbit are not yet fully understood, but there are concerns about potential contamination and interference with other space activities.

Tungsten's high melting point and density make it resistant to degradation in the harsh space environment. While this durability is beneficial for satellite performance, it also means that tungsten components may persist in orbit for extended periods. As these components break down over time due to collisions or exposure to radiation, they can generate smaller tungsten particles that further contribute to the space debris problem.

The accumulation of tungsten debris in orbit could potentially impact future space missions and satellite operations. Tungsten particles, even at microscopic sizes, can cause damage to spacecraft surfaces and sensitive instruments due to their high density and velocity in orbit. This raises concerns about the long-term sustainability of space activities and the need for responsible management of satellite end-of-life processes.

From an environmental perspective, the introduction of tungsten into the space environment may have unforeseen consequences. While the Earth's atmosphere provides a natural barrier against most space debris, some particles eventually re-enter and burn up. The potential for tungsten particles to survive re-entry and reach Earth's surface, albeit in small quantities, raises questions about possible environmental impacts on terrestrial ecosystems.

The space industry is increasingly aware of these environmental concerns and is exploring ways to mitigate the impact of tungsten and other materials used in satellite construction. Efforts are being made to develop more environmentally friendly alternatives and improve end-of-life management strategies for satellites. These initiatives aim to reduce the generation of space debris and minimize the potential long-term environmental effects of tungsten in the space environment.