UHMWPE for Moisture Content Management in Greenhouses

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE in Greenhouses: Background and Objectives

Ultra-High Molecular Weight Polyethylene (UHMWPE) has emerged as a promising material for moisture content management in greenhouse environments. The development of UHMWPE for this application stems from the growing need for advanced materials that can enhance crop production efficiency while maintaining optimal growing conditions. This technology aims to address the critical challenge of moisture regulation in greenhouses, which directly impacts plant health, growth rates, and overall yield.

The evolution of greenhouse technology has been driven by the increasing demand for year-round crop production and the need to optimize resource utilization in agriculture. Traditional greenhouse materials often struggle to maintain consistent humidity levels, leading to issues such as condensation, fungal growth, and inefficient water use. UHMWPE presents a novel solution to these long-standing problems, offering superior moisture management properties compared to conventional materials.

The primary objective of implementing UHMWPE in greenhouses is to create a more controlled and stable environment for plant growth. By effectively managing moisture content, this technology aims to reduce water consumption, minimize the risk of plant diseases, and improve overall crop quality. Additionally, the use of UHMWPE is expected to contribute to energy efficiency by reducing the need for artificial climate control measures within the greenhouse.

From a technical perspective, UHMWPE's unique molecular structure, characterized by extremely long chains of polyethylene, provides it with exceptional properties suitable for greenhouse applications. These include high tensile strength, excellent chemical resistance, and low moisture absorption. The goal is to leverage these inherent characteristics to develop greenhouse coverings and components that can actively regulate moisture levels while maintaining durability and transparency.

The development of UHMWPE for greenhouse use aligns with broader trends in sustainable agriculture and precision farming. As global food demand continues to rise and climate change impacts traditional farming practices, innovative greenhouse technologies play a crucial role in ensuring food security. The integration of UHMWPE into greenhouse systems represents a step towards more resilient and efficient agricultural practices.

Research and development efforts in this field are focused on optimizing UHMWPE formulations specifically for greenhouse environments. This includes enhancing its light transmission properties, improving its ability to selectively control moisture vapor transmission, and ensuring long-term performance under varying environmental conditions. The ultimate aim is to create a new generation of greenhouse materials that can adapt to changing climatic conditions while maximizing crop yields and minimizing resource inputs.

The evolution of greenhouse technology has been driven by the increasing demand for year-round crop production and the need to optimize resource utilization in agriculture. Traditional greenhouse materials often struggle to maintain consistent humidity levels, leading to issues such as condensation, fungal growth, and inefficient water use. UHMWPE presents a novel solution to these long-standing problems, offering superior moisture management properties compared to conventional materials.

The primary objective of implementing UHMWPE in greenhouses is to create a more controlled and stable environment for plant growth. By effectively managing moisture content, this technology aims to reduce water consumption, minimize the risk of plant diseases, and improve overall crop quality. Additionally, the use of UHMWPE is expected to contribute to energy efficiency by reducing the need for artificial climate control measures within the greenhouse.

From a technical perspective, UHMWPE's unique molecular structure, characterized by extremely long chains of polyethylene, provides it with exceptional properties suitable for greenhouse applications. These include high tensile strength, excellent chemical resistance, and low moisture absorption. The goal is to leverage these inherent characteristics to develop greenhouse coverings and components that can actively regulate moisture levels while maintaining durability and transparency.

The development of UHMWPE for greenhouse use aligns with broader trends in sustainable agriculture and precision farming. As global food demand continues to rise and climate change impacts traditional farming practices, innovative greenhouse technologies play a crucial role in ensuring food security. The integration of UHMWPE into greenhouse systems represents a step towards more resilient and efficient agricultural practices.

Research and development efforts in this field are focused on optimizing UHMWPE formulations specifically for greenhouse environments. This includes enhancing its light transmission properties, improving its ability to selectively control moisture vapor transmission, and ensuring long-term performance under varying environmental conditions. The ultimate aim is to create a new generation of greenhouse materials that can adapt to changing climatic conditions while maximizing crop yields and minimizing resource inputs.

Market Analysis for UHMWPE in Agriculture

The market for Ultra-High Molecular Weight Polyethylene (UHMWPE) in agriculture, particularly for moisture content management in greenhouses, is experiencing significant growth and transformation. This trend is driven by the increasing demand for advanced materials that can enhance crop yield, improve resource efficiency, and withstand harsh environmental conditions.

UHMWPE's unique properties, including high tensile strength, excellent chemical resistance, and low moisture absorption, make it an ideal candidate for various agricultural applications. In greenhouse settings, UHMWPE films and membranes are being utilized to create controlled environments that optimize moisture levels, leading to improved plant growth and reduced water consumption.

The global greenhouse film market, which includes UHMWPE products, is projected to expand substantially in the coming years. This growth is fueled by the rising adoption of protected cultivation practices, increasing food demand, and the need for sustainable agricultural solutions. Regions such as Asia-Pacific, Europe, and North America are expected to be key markets for UHMWPE in greenhouse applications.

One of the primary drivers for UHMWPE adoption in agriculture is its ability to enhance crop productivity. By effectively managing moisture content, UHMWPE films help create optimal growing conditions, resulting in higher yields and improved crop quality. This is particularly valuable in regions facing water scarcity or unpredictable weather patterns.

The durability and longevity of UHMWPE products also contribute to their market appeal. Compared to traditional greenhouse materials, UHMWPE films offer extended service life, reducing replacement costs and minimizing waste. This aligns well with the growing emphasis on sustainable and eco-friendly agricultural practices.

However, the market for UHMWPE in agriculture faces certain challenges. The relatively higher initial cost of UHMWPE products compared to conventional materials may deter some farmers, particularly in developing regions. Additionally, the need for specialized knowledge in installation and maintenance could limit widespread adoption.

Despite these challenges, the market outlook remains positive. Ongoing research and development efforts are focused on enhancing the performance of UHMWPE for agricultural applications, including improved UV resistance and better light transmission properties. These advancements are expected to further expand the market potential of UHMWPE in greenhouse moisture management.

As the agricultural sector continues to embrace technological innovations, the demand for advanced materials like UHMWPE is likely to grow. The increasing focus on precision agriculture and smart farming practices presents additional opportunities for UHMWPE applications in moisture sensors, irrigation systems, and other moisture management solutions.

UHMWPE's unique properties, including high tensile strength, excellent chemical resistance, and low moisture absorption, make it an ideal candidate for various agricultural applications. In greenhouse settings, UHMWPE films and membranes are being utilized to create controlled environments that optimize moisture levels, leading to improved plant growth and reduced water consumption.

The global greenhouse film market, which includes UHMWPE products, is projected to expand substantially in the coming years. This growth is fueled by the rising adoption of protected cultivation practices, increasing food demand, and the need for sustainable agricultural solutions. Regions such as Asia-Pacific, Europe, and North America are expected to be key markets for UHMWPE in greenhouse applications.

One of the primary drivers for UHMWPE adoption in agriculture is its ability to enhance crop productivity. By effectively managing moisture content, UHMWPE films help create optimal growing conditions, resulting in higher yields and improved crop quality. This is particularly valuable in regions facing water scarcity or unpredictable weather patterns.

The durability and longevity of UHMWPE products also contribute to their market appeal. Compared to traditional greenhouse materials, UHMWPE films offer extended service life, reducing replacement costs and minimizing waste. This aligns well with the growing emphasis on sustainable and eco-friendly agricultural practices.

However, the market for UHMWPE in agriculture faces certain challenges. The relatively higher initial cost of UHMWPE products compared to conventional materials may deter some farmers, particularly in developing regions. Additionally, the need for specialized knowledge in installation and maintenance could limit widespread adoption.

Despite these challenges, the market outlook remains positive. Ongoing research and development efforts are focused on enhancing the performance of UHMWPE for agricultural applications, including improved UV resistance and better light transmission properties. These advancements are expected to further expand the market potential of UHMWPE in greenhouse moisture management.

As the agricultural sector continues to embrace technological innovations, the demand for advanced materials like UHMWPE is likely to grow. The increasing focus on precision agriculture and smart farming practices presents additional opportunities for UHMWPE applications in moisture sensors, irrigation systems, and other moisture management solutions.

UHMWPE Moisture Management: Current State and Challenges

The current state of Ultra-High Molecular Weight Polyethylene (UHMWPE) for moisture content management in greenhouses presents both promising advancements and significant challenges. UHMWPE, known for its exceptional mechanical properties and chemical resistance, has emerged as a potential solution for controlling humidity levels in greenhouse environments.

One of the primary advantages of UHMWPE in this application is its hydrophobic nature, which allows it to repel water effectively. This property makes it an ideal candidate for creating moisture barriers and controlling condensation within greenhouses. However, the implementation of UHMWPE for moisture management is not without its difficulties.

A major challenge lies in the integration of UHMWPE into existing greenhouse structures. While the material itself is lightweight and flexible, developing cost-effective and efficient methods for large-scale application remains a hurdle. Researchers are exploring various techniques, including the use of UHMWPE films and coatings, to overcome this obstacle.

Another significant challenge is balancing moisture control with other essential greenhouse functions, such as light transmission and temperature regulation. UHMWPE's opacity can potentially reduce the amount of light reaching plants, necessitating careful design considerations to maintain optimal growing conditions.

The durability of UHMWPE in greenhouse environments is also a subject of ongoing research. While the material is known for its resistance to chemicals and UV radiation, long-term exposure to intense sunlight and varying humidity levels may affect its performance over time. Studies are underway to assess the material's longevity and develop strategies to enhance its lifespan in greenhouse applications.

Furthermore, the recyclability and environmental impact of UHMWPE in large-scale greenhouse use are areas of concern. As sustainability becomes increasingly important in agriculture, finding eco-friendly ways to produce, apply, and dispose of UHMWPE materials is crucial for widespread adoption.

Despite these challenges, recent advancements in UHMWPE technology show promise. Researchers are developing novel composites and surface treatments to enhance the material's moisture management capabilities while addressing issues related to light transmission and environmental impact.

In conclusion, while UHMWPE offers significant potential for moisture content management in greenhouses, several technical and practical challenges must be overcome. Ongoing research and development efforts are focused on optimizing the material's properties, improving application methods, and addressing environmental concerns to fully realize its benefits in greenhouse agriculture.

One of the primary advantages of UHMWPE in this application is its hydrophobic nature, which allows it to repel water effectively. This property makes it an ideal candidate for creating moisture barriers and controlling condensation within greenhouses. However, the implementation of UHMWPE for moisture management is not without its difficulties.

A major challenge lies in the integration of UHMWPE into existing greenhouse structures. While the material itself is lightweight and flexible, developing cost-effective and efficient methods for large-scale application remains a hurdle. Researchers are exploring various techniques, including the use of UHMWPE films and coatings, to overcome this obstacle.

Another significant challenge is balancing moisture control with other essential greenhouse functions, such as light transmission and temperature regulation. UHMWPE's opacity can potentially reduce the amount of light reaching plants, necessitating careful design considerations to maintain optimal growing conditions.

The durability of UHMWPE in greenhouse environments is also a subject of ongoing research. While the material is known for its resistance to chemicals and UV radiation, long-term exposure to intense sunlight and varying humidity levels may affect its performance over time. Studies are underway to assess the material's longevity and develop strategies to enhance its lifespan in greenhouse applications.

Furthermore, the recyclability and environmental impact of UHMWPE in large-scale greenhouse use are areas of concern. As sustainability becomes increasingly important in agriculture, finding eco-friendly ways to produce, apply, and dispose of UHMWPE materials is crucial for widespread adoption.

Despite these challenges, recent advancements in UHMWPE technology show promise. Researchers are developing novel composites and surface treatments to enhance the material's moisture management capabilities while addressing issues related to light transmission and environmental impact.

In conclusion, while UHMWPE offers significant potential for moisture content management in greenhouses, several technical and practical challenges must be overcome. Ongoing research and development efforts are focused on optimizing the material's properties, improving application methods, and addressing environmental concerns to fully realize its benefits in greenhouse agriculture.

Existing UHMWPE Solutions for Greenhouse Moisture Management

01 Moisture content control in UHMWPE processing

Controlling moisture content is crucial in UHMWPE processing. Proper moisture management affects the material's properties and performance. Techniques for moisture control include drying processes, storage conditions, and monitoring methods to ensure optimal moisture levels during manufacturing.- Moisture content control in UHMWPE processing: Controlling moisture content is crucial in UHMWPE processing. Proper moisture management can affect the material's properties and performance. Techniques for moisture control include drying processes, storage conditions, and monitoring methods to ensure optimal moisture levels during manufacturing.

- Impact of moisture on UHMWPE properties: Moisture content significantly influences UHMWPE's mechanical and physical properties. Excessive moisture can lead to degradation, reduced strength, and compromised performance. Understanding the relationship between moisture levels and material characteristics is essential for producing high-quality UHMWPE products.

- Moisture measurement techniques for UHMWPE: Various methods are employed to measure moisture content in UHMWPE accurately. These may include gravimetric analysis, spectroscopic techniques, and specialized moisture analyzers. Precise measurement is critical for quality control and ensuring consistent material properties.

- Moisture-resistant UHMWPE formulations: Development of moisture-resistant UHMWPE formulations aims to enhance the material's performance in high-humidity environments. These formulations may incorporate additives or modified processing techniques to reduce moisture absorption and improve long-term stability.

- Drying processes for UHMWPE: Effective drying processes are essential for controlling moisture content in UHMWPE. Various drying methods, including vacuum drying, hot air drying, and desiccant-based systems, are used to remove excess moisture from UHMWPE powders or products. Optimizing drying parameters is crucial for maintaining material quality.

02 Impact of moisture on UHMWPE properties

Moisture content significantly influences UHMWPE's mechanical and physical properties. Excessive moisture can lead to degradation, reduced strength, and compromised performance. Understanding the relationship between moisture levels and material characteristics is essential for quality control and product optimization.Expand Specific Solutions03 Moisture measurement techniques for UHMWPE

Various methods are employed to measure moisture content in UHMWPE accurately. These include gravimetric analysis, spectroscopic techniques, and specialized moisture analyzers. Precise measurement is critical for maintaining product quality and consistency in UHMWPE manufacturing processes.Expand Specific Solutions04 Moisture-resistant UHMWPE formulations

Development of moisture-resistant UHMWPE formulations aims to enhance the material's performance in high-humidity environments. These formulations may incorporate additives or modified processing techniques to reduce moisture absorption and improve long-term stability of UHMWPE products.Expand Specific Solutions05 Drying processes for UHMWPE

Effective drying processes are essential in UHMWPE production to achieve desired moisture content. Various drying methods, including vacuum drying, hot air drying, and desiccant drying, are employed. Optimizing drying parameters such as temperature, time, and airflow is crucial for maintaining UHMWPE quality.Expand Specific Solutions

Key Players in UHMWPE and Greenhouse Technology

The market for UHMWPE in greenhouse moisture management is in its early growth stage, with increasing demand driven by the need for efficient agricultural solutions. The global market size is expanding, though exact figures are limited due to the niche application. Technologically, UHMWPE for this purpose is moderately mature, with ongoing research to enhance its performance. Key players like W. L. Gore & Associates, EMD Millipore Corp., and 3M Innovative Properties Co. are actively developing advanced UHMWPE-based solutions, leveraging their expertise in materials science and filtration technologies. Academic institutions such as Université Claude Bernard Lyon 1 and research organizations like CNRS are contributing to fundamental research, potentially leading to breakthrough innovations in this field.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates has developed advanced UHMWPE-based membranes for moisture management in greenhouses. Their technology utilizes a microporous structure that allows for selective permeability, effectively controlling humidity levels while maintaining optimal growing conditions. The company's GORE-TEX fabric technology has been adapted for agricultural applications, creating a breathable barrier that regulates moisture content[1]. This innovation incorporates hydrophobic and hydrophilic elements within the UHMWPE structure, enabling efficient water vapor transmission while preventing liquid water penetration[2]. The material's high tensile strength and chemical resistance make it ideal for long-term use in greenhouse environments, withstanding exposure to various agricultural chemicals and UV radiation[3].

Strengths: Excellent moisture control, durability, and chemical resistance. Weaknesses: Potentially higher cost compared to traditional materials, may require specialized installation.

3M Innovative Properties Co.

Technical Solution: 3M has developed a novel UHMWPE-based film technology for greenhouse moisture management. Their approach involves creating a multi-layered film structure that combines UHMWPE with other polymers to achieve optimal moisture regulation. The film incorporates microporous channels that allow for controlled water vapor transmission, effectively managing humidity levels within the greenhouse[4]. 3M's technology also features a proprietary surface treatment that enhances the film's anti-fog properties, preventing condensation buildup on the greenhouse covering[5]. This innovation not only manages moisture content but also improves light transmission, crucial for plant growth. The company has integrated smart sensors into their system, enabling real-time monitoring and adjustment of moisture levels based on crop requirements and external environmental conditions[6].

Strengths: Advanced moisture control with integrated smart technology, improved light transmission. Weaknesses: May require more complex installation and maintenance compared to traditional systems.

Innovative UHMWPE Applications in Moisture Control

Method for continuously producing ultra-high molecular weight polyethylene by using slurry polymerization

PatentPendingUS20240092948A1

Innovation

- A continuous process using 2-6 ethylene slurry polymerization reaction tanks connected in series, where polymerization temperatures, pressures, and gas phase compositions are controlled within specific ranges to ensure consistent conditions across tanks, allowing for full catalyst activity and precise control of molecular weight, resulting in ultra-high viscosity-average molecular weight polyethylene with low metal and ash content.

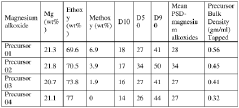

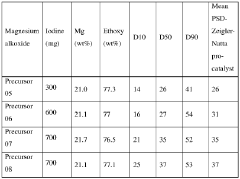

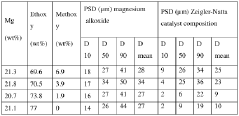

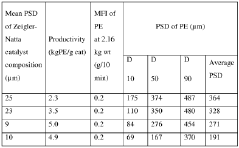

A process for controlling particle size distribution of a ziegler-natta catalyst composition

PatentWO2016162815A1

Innovation

- A process involving the reaction of magnesium metal with a mixture of alcohols and iodine to form magnesium alkoxides, followed by chlorination and mixing with a co-catalyst to achieve a Ziegler-Natta catalyst composition with controlled particle size distribution between 5 μm to 15 μm, allowing for the production of UHMWPE with a narrow particle size distribution.

Environmental Impact of UHMWPE in Agriculture

The use of Ultra-High Molecular Weight Polyethylene (UHMWPE) in agricultural applications, particularly for moisture content management in greenhouses, has significant environmental implications. UHMWPE's durability and resistance to degradation contribute to its long-term effectiveness in greenhouse environments, but also raise concerns about its environmental impact.

One of the primary environmental benefits of UHMWPE in greenhouse applications is its potential to reduce water consumption. By effectively managing moisture content, UHMWPE materials can help optimize irrigation systems, leading to more efficient water use. This is particularly important in regions facing water scarcity, where sustainable agricultural practices are crucial.

However, the production of UHMWPE involves energy-intensive processes and the use of petrochemical resources. The manufacturing process generates greenhouse gas emissions and contributes to carbon footprint. As the agricultural sector seeks to reduce its environmental impact, the lifecycle assessment of UHMWPE materials becomes increasingly important.

The longevity of UHMWPE products in agricultural settings is a double-edged sword from an environmental perspective. While it reduces the need for frequent replacements, thus minimizing waste generation, it also means that when UHMWPE materials do reach the end of their life, they persist in the environment for extended periods. The challenge of disposing of or recycling these materials adds to the environmental concerns.

UHMWPE's resistance to chemical degradation, while beneficial for its intended use, poses challenges for biodegradation. This resistance to breakdown means that any UHMWPE particles that enter the soil or water systems may persist for many years, potentially affecting soil health and aquatic ecosystems.

On the positive side, the use of UHMWPE in greenhouses can contribute to more sustainable farming practices. By creating controlled environments that optimize plant growth conditions, greenhouses using UHMWPE can increase crop yields while reducing the need for pesticides and herbicides. This can lead to a decrease in the environmental impact associated with conventional farming methods.

The potential for UHMWPE to be recycled at the end of its life in agricultural applications is an area of ongoing research. Developing effective recycling processes for UHMWPE could significantly mitigate its environmental impact, creating a more circular economy within the agricultural sector.

As the agricultural industry continues to evolve, balancing the benefits of UHMWPE in moisture content management with its environmental impact remains a key consideration. Future developments in bio-based alternatives or improvements in UHMWPE production and recycling technologies may further enhance its environmental profile in agricultural applications.

One of the primary environmental benefits of UHMWPE in greenhouse applications is its potential to reduce water consumption. By effectively managing moisture content, UHMWPE materials can help optimize irrigation systems, leading to more efficient water use. This is particularly important in regions facing water scarcity, where sustainable agricultural practices are crucial.

However, the production of UHMWPE involves energy-intensive processes and the use of petrochemical resources. The manufacturing process generates greenhouse gas emissions and contributes to carbon footprint. As the agricultural sector seeks to reduce its environmental impact, the lifecycle assessment of UHMWPE materials becomes increasingly important.

The longevity of UHMWPE products in agricultural settings is a double-edged sword from an environmental perspective. While it reduces the need for frequent replacements, thus minimizing waste generation, it also means that when UHMWPE materials do reach the end of their life, they persist in the environment for extended periods. The challenge of disposing of or recycling these materials adds to the environmental concerns.

UHMWPE's resistance to chemical degradation, while beneficial for its intended use, poses challenges for biodegradation. This resistance to breakdown means that any UHMWPE particles that enter the soil or water systems may persist for many years, potentially affecting soil health and aquatic ecosystems.

On the positive side, the use of UHMWPE in greenhouses can contribute to more sustainable farming practices. By creating controlled environments that optimize plant growth conditions, greenhouses using UHMWPE can increase crop yields while reducing the need for pesticides and herbicides. This can lead to a decrease in the environmental impact associated with conventional farming methods.

The potential for UHMWPE to be recycled at the end of its life in agricultural applications is an area of ongoing research. Developing effective recycling processes for UHMWPE could significantly mitigate its environmental impact, creating a more circular economy within the agricultural sector.

As the agricultural industry continues to evolve, balancing the benefits of UHMWPE in moisture content management with its environmental impact remains a key consideration. Future developments in bio-based alternatives or improvements in UHMWPE production and recycling technologies may further enhance its environmental profile in agricultural applications.

Cost-Benefit Analysis of UHMWPE Greenhouse Solutions

The implementation of UHMWPE (Ultra-High Molecular Weight Polyethylene) solutions for moisture content management in greenhouses presents a complex cost-benefit scenario that requires careful analysis. Initial investment costs for UHMWPE-based systems are typically higher than traditional greenhouse materials due to the advanced polymer technology and specialized manufacturing processes involved. However, these upfront expenses are often offset by long-term savings and improved crop yields.

UHMWPE's superior moisture management properties contribute to a more stable and controlled greenhouse environment. This results in reduced energy costs for humidity control and ventilation systems, as well as decreased water consumption through improved moisture retention. The material's durability and resistance to degradation also lead to lower maintenance and replacement costs over time, extending the lifespan of the greenhouse structure.

From a productivity standpoint, the enhanced moisture control provided by UHMWPE solutions can lead to significant improvements in crop quality and yield. Plants grown in optimally managed moisture conditions experience less stress, have better nutrient uptake, and are less susceptible to diseases associated with excess humidity. These factors can result in higher-value produce and increased crop cycles per year, directly impacting the grower's revenue potential.

The environmental benefits of UHMWPE greenhouse solutions also factor into the cost-benefit analysis. Reduced water and energy consumption align with sustainability goals and may qualify growers for environmental incentives or certifications, potentially opening up premium markets or reducing regulatory compliance costs.

However, the cost-benefit ratio can vary depending on factors such as local climate conditions, crop types, and energy prices. In regions with extreme weather patterns or high energy costs, the benefits of UHMWPE solutions may be more pronounced. Conversely, in areas with mild climates or for crops with lower moisture sensitivity, the return on investment may take longer to realize.

It's also important to consider the scalability of UHMWPE solutions. While the initial costs may be prohibitive for small-scale operations, larger commercial greenhouses can often achieve economies of scale that make the investment more attractive. Additionally, as the technology becomes more widespread and manufacturing processes improve, the cost of UHMWPE solutions is likely to decrease, further improving the cost-benefit ratio.

UHMWPE's superior moisture management properties contribute to a more stable and controlled greenhouse environment. This results in reduced energy costs for humidity control and ventilation systems, as well as decreased water consumption through improved moisture retention. The material's durability and resistance to degradation also lead to lower maintenance and replacement costs over time, extending the lifespan of the greenhouse structure.

From a productivity standpoint, the enhanced moisture control provided by UHMWPE solutions can lead to significant improvements in crop quality and yield. Plants grown in optimally managed moisture conditions experience less stress, have better nutrient uptake, and are less susceptible to diseases associated with excess humidity. These factors can result in higher-value produce and increased crop cycles per year, directly impacting the grower's revenue potential.

The environmental benefits of UHMWPE greenhouse solutions also factor into the cost-benefit analysis. Reduced water and energy consumption align with sustainability goals and may qualify growers for environmental incentives or certifications, potentially opening up premium markets or reducing regulatory compliance costs.

However, the cost-benefit ratio can vary depending on factors such as local climate conditions, crop types, and energy prices. In regions with extreme weather patterns or high energy costs, the benefits of UHMWPE solutions may be more pronounced. Conversely, in areas with mild climates or for crops with lower moisture sensitivity, the return on investment may take longer to realize.

It's also important to consider the scalability of UHMWPE solutions. While the initial costs may be prohibitive for small-scale operations, larger commercial greenhouses can often achieve economies of scale that make the investment more attractive. Additionally, as the technology becomes more widespread and manufacturing processes improve, the cost of UHMWPE solutions is likely to decrease, further improving the cost-benefit ratio.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!