Understanding Pressure Loss in High-Efficiency Plate Heat Exchangers

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Plate Heat Exchanger Pressure Loss Overview

Plate heat exchangers (PHEs) have become increasingly popular in various industries due to their high efficiency and compact design. However, understanding and managing pressure loss within these systems is crucial for optimizing their performance. Pressure loss in PHEs occurs as fluids flow through the narrow channels between plates, encountering friction and turbulence along the way.

The primary factors contributing to pressure loss in high-efficiency plate heat exchangers include fluid velocity, channel geometry, plate surface characteristics, and fluid properties. As fluid velocity increases, so does the pressure drop, following a quadratic relationship. The intricate channel geometry, typically featuring chevron or herringbone patterns, creates turbulence that enhances heat transfer but also increases pressure loss.

Plate surface roughness and corrugation angle play significant roles in pressure loss. Higher surface roughness and more acute corrugation angles generally lead to increased pressure drop but also improved heat transfer. This trade-off between heat transfer efficiency and pressure loss is a key consideration in PHE design and operation.

Fluid properties, such as viscosity and density, also impact pressure loss. More viscous fluids experience higher pressure drops due to increased friction, while denser fluids require more energy to move through the exchanger. Temperature changes within the PHE can alter these fluid properties, further complicating pressure loss calculations.

The distribution of flow across the plate pack is another critical factor. Uneven flow distribution can lead to localized areas of high pressure drop and reduced overall efficiency. Proper design of inlet and outlet ports, as well as the use of flow distribution devices, can help mitigate this issue.

Understanding pressure loss in PHEs is essential for several reasons. First, it directly impacts pumping power requirements and, consequently, operating costs. Second, excessive pressure drop can lead to flow maldistribution, reducing heat transfer effectiveness and potentially causing thermal stress on the plates. Finally, accurate pressure loss prediction is crucial for proper sizing and selection of PHEs for specific applications.

Various methods exist for calculating and predicting pressure loss in plate heat exchangers. These range from empirical correlations based on experimental data to complex computational fluid dynamics (CFD) simulations. While empirical methods are often used for quick estimates, CFD analysis provides more detailed insights into local flow patterns and pressure distributions.

The primary factors contributing to pressure loss in high-efficiency plate heat exchangers include fluid velocity, channel geometry, plate surface characteristics, and fluid properties. As fluid velocity increases, so does the pressure drop, following a quadratic relationship. The intricate channel geometry, typically featuring chevron or herringbone patterns, creates turbulence that enhances heat transfer but also increases pressure loss.

Plate surface roughness and corrugation angle play significant roles in pressure loss. Higher surface roughness and more acute corrugation angles generally lead to increased pressure drop but also improved heat transfer. This trade-off between heat transfer efficiency and pressure loss is a key consideration in PHE design and operation.

Fluid properties, such as viscosity and density, also impact pressure loss. More viscous fluids experience higher pressure drops due to increased friction, while denser fluids require more energy to move through the exchanger. Temperature changes within the PHE can alter these fluid properties, further complicating pressure loss calculations.

The distribution of flow across the plate pack is another critical factor. Uneven flow distribution can lead to localized areas of high pressure drop and reduced overall efficiency. Proper design of inlet and outlet ports, as well as the use of flow distribution devices, can help mitigate this issue.

Understanding pressure loss in PHEs is essential for several reasons. First, it directly impacts pumping power requirements and, consequently, operating costs. Second, excessive pressure drop can lead to flow maldistribution, reducing heat transfer effectiveness and potentially causing thermal stress on the plates. Finally, accurate pressure loss prediction is crucial for proper sizing and selection of PHEs for specific applications.

Various methods exist for calculating and predicting pressure loss in plate heat exchangers. These range from empirical correlations based on experimental data to complex computational fluid dynamics (CFD) simulations. While empirical methods are often used for quick estimates, CFD analysis provides more detailed insights into local flow patterns and pressure distributions.

Market Demand Analysis

The market demand for high-efficiency plate heat exchangers has been steadily increasing across various industries due to their superior performance and energy-saving capabilities. These heat exchangers are widely used in HVAC systems, chemical processing, food and beverage production, and power generation, among other sectors. The global plate heat exchanger market is projected to grow significantly in the coming years, driven by the need for more efficient heat transfer solutions and stringent energy efficiency regulations.

In the industrial sector, there is a growing demand for plate heat exchangers that can handle high-pressure and high-temperature applications. This is particularly evident in the chemical and petrochemical industries, where processes often require robust heat transfer equipment. The ability to understand and mitigate pressure loss in these systems is crucial for optimizing overall plant efficiency and reducing operational costs.

The HVAC industry is another major driver of demand for high-efficiency plate heat exchangers. As buildings become more energy-efficient and environmental regulations tighten, there is an increased focus on improving the performance of heating and cooling systems. Plate heat exchangers with minimal pressure loss are essential for maintaining high coefficient of performance (COP) in HVAC systems, leading to reduced energy consumption and lower operating costs for building owners.

In the food and beverage industry, there is a rising demand for plate heat exchangers that can maintain product quality while ensuring energy efficiency. The ability to control pressure loss is critical in processes such as pasteurization, where precise temperature control is necessary. Manufacturers are seeking heat exchangers that can handle viscous fluids and particulate-laden streams without compromising on heat transfer efficiency or increasing pressure drop.

The renewable energy sector, particularly in geothermal power plants and solar thermal systems, is also driving demand for high-efficiency plate heat exchangers. These applications often involve working with low-temperature differentials, making it essential to minimize pressure losses to maintain system efficiency. As the renewable energy market expands, the demand for specialized plate heat exchangers with optimized pressure loss characteristics is expected to grow.

In the marine industry, there is an increasing focus on reducing fuel consumption and emissions. This has led to a higher demand for plate heat exchangers in ship engine cooling systems and exhaust gas heat recovery units. Understanding and minimizing pressure loss in these applications is crucial for improving overall vessel efficiency and meeting stringent environmental regulations.

The market is also seeing a trend towards modular and compact heat exchanger designs, which require even more precise control of pressure loss to maintain performance in smaller form factors. This trend is driven by space constraints in industrial settings and the need for more flexible, scalable heat transfer solutions.

In the industrial sector, there is a growing demand for plate heat exchangers that can handle high-pressure and high-temperature applications. This is particularly evident in the chemical and petrochemical industries, where processes often require robust heat transfer equipment. The ability to understand and mitigate pressure loss in these systems is crucial for optimizing overall plant efficiency and reducing operational costs.

The HVAC industry is another major driver of demand for high-efficiency plate heat exchangers. As buildings become more energy-efficient and environmental regulations tighten, there is an increased focus on improving the performance of heating and cooling systems. Plate heat exchangers with minimal pressure loss are essential for maintaining high coefficient of performance (COP) in HVAC systems, leading to reduced energy consumption and lower operating costs for building owners.

In the food and beverage industry, there is a rising demand for plate heat exchangers that can maintain product quality while ensuring energy efficiency. The ability to control pressure loss is critical in processes such as pasteurization, where precise temperature control is necessary. Manufacturers are seeking heat exchangers that can handle viscous fluids and particulate-laden streams without compromising on heat transfer efficiency or increasing pressure drop.

The renewable energy sector, particularly in geothermal power plants and solar thermal systems, is also driving demand for high-efficiency plate heat exchangers. These applications often involve working with low-temperature differentials, making it essential to minimize pressure losses to maintain system efficiency. As the renewable energy market expands, the demand for specialized plate heat exchangers with optimized pressure loss characteristics is expected to grow.

In the marine industry, there is an increasing focus on reducing fuel consumption and emissions. This has led to a higher demand for plate heat exchangers in ship engine cooling systems and exhaust gas heat recovery units. Understanding and minimizing pressure loss in these applications is crucial for improving overall vessel efficiency and meeting stringent environmental regulations.

The market is also seeing a trend towards modular and compact heat exchanger designs, which require even more precise control of pressure loss to maintain performance in smaller form factors. This trend is driven by space constraints in industrial settings and the need for more flexible, scalable heat transfer solutions.

Current Challenges

Plate heat exchangers (PHEs) have become increasingly popular in various industries due to their high efficiency and compact design. However, as the demand for higher performance and energy efficiency grows, engineers face significant challenges in understanding and mitigating pressure loss within these systems. One of the primary obstacles is the complex flow patterns that occur within the narrow channels of PHEs, which can lead to increased pressure drop and reduced overall efficiency.

The geometry of plate heat exchangers, characterized by corrugated plates and intricate flow paths, creates turbulent flow regimes that are difficult to model accurately. This complexity makes it challenging to predict pressure loss and optimize designs for specific applications. Furthermore, the presence of fouling and scaling in industrial settings can exacerbate pressure loss issues, leading to decreased heat transfer efficiency and increased operational costs.

Another significant challenge lies in balancing the trade-off between heat transfer enhancement and pressure drop. While certain plate designs and surface features can improve heat transfer, they often come at the cost of increased pressure loss. Engineers must carefully consider this balance to achieve optimal performance without compromising system efficiency or exceeding allowable pressure limits.

The development of advanced computational fluid dynamics (CFD) models to accurately simulate flow behavior in PHEs remains an ongoing challenge. Current models often struggle to capture the full complexity of the flow patterns, particularly in areas with high turbulence or near contact points between plates. This limitation hinders the ability to predict pressure loss accurately and design more efficient heat exchangers.

Material selection also presents challenges in managing pressure loss. While thinner plates can reduce overall pressure drop, they may compromise the mechanical integrity of the heat exchanger, especially in high-pressure applications. Conversely, thicker plates that provide better structural support may lead to increased pressure loss due to the reduced flow area.

As industries push for more compact and efficient heat exchange solutions, the miniaturization of plate heat exchangers introduces new challenges in pressure loss management. Smaller channel dimensions can lead to higher pressure drops, requiring innovative design approaches to maintain acceptable performance levels.

The integration of PHEs into complex systems, such as those found in the chemical processing or power generation industries, adds another layer of complexity to pressure loss considerations. Engineers must account for system-wide effects and interactions that can influence pressure drop across the heat exchanger, making it difficult to isolate and address specific issues within the PHE itself.

The geometry of plate heat exchangers, characterized by corrugated plates and intricate flow paths, creates turbulent flow regimes that are difficult to model accurately. This complexity makes it challenging to predict pressure loss and optimize designs for specific applications. Furthermore, the presence of fouling and scaling in industrial settings can exacerbate pressure loss issues, leading to decreased heat transfer efficiency and increased operational costs.

Another significant challenge lies in balancing the trade-off between heat transfer enhancement and pressure drop. While certain plate designs and surface features can improve heat transfer, they often come at the cost of increased pressure loss. Engineers must carefully consider this balance to achieve optimal performance without compromising system efficiency or exceeding allowable pressure limits.

The development of advanced computational fluid dynamics (CFD) models to accurately simulate flow behavior in PHEs remains an ongoing challenge. Current models often struggle to capture the full complexity of the flow patterns, particularly in areas with high turbulence or near contact points between plates. This limitation hinders the ability to predict pressure loss accurately and design more efficient heat exchangers.

Material selection also presents challenges in managing pressure loss. While thinner plates can reduce overall pressure drop, they may compromise the mechanical integrity of the heat exchanger, especially in high-pressure applications. Conversely, thicker plates that provide better structural support may lead to increased pressure loss due to the reduced flow area.

As industries push for more compact and efficient heat exchange solutions, the miniaturization of plate heat exchangers introduces new challenges in pressure loss management. Smaller channel dimensions can lead to higher pressure drops, requiring innovative design approaches to maintain acceptable performance levels.

The integration of PHEs into complex systems, such as those found in the chemical processing or power generation industries, adds another layer of complexity to pressure loss considerations. Engineers must account for system-wide effects and interactions that can influence pressure drop across the heat exchanger, making it difficult to isolate and address specific issues within the PHE itself.

Existing Solutions

01 Plate design optimization

Optimizing the design of heat exchanger plates can significantly reduce pressure loss. This includes modifying plate geometry, corrugation patterns, and flow channel configurations to improve fluid distribution and minimize turbulence. Such design improvements can enhance heat transfer efficiency while reducing the overall pressure drop across the exchanger.- Plate design optimization: Optimizing the design of heat exchanger plates can significantly reduce pressure loss. This includes modifying plate geometry, corrugation patterns, and flow channel configurations to improve fluid distribution and minimize turbulence. Such design improvements can enhance heat transfer efficiency while reducing the overall pressure drop across the exchanger.

- Flow distribution techniques: Implementing effective flow distribution techniques can help minimize pressure loss in plate heat exchangers. This may involve the use of specially designed inlet and outlet manifolds, baffles, or flow guides to ensure uniform fluid distribution across the plates. Proper flow distribution reduces localized pressure drops and improves overall exchanger performance.

- Surface enhancement methods: Enhancing the surface characteristics of heat exchanger plates can contribute to reduced pressure loss. This may include the application of specialized coatings, surface texturing, or the integration of micro-structures to modify fluid behavior at the plate surface. These enhancements can help to reduce friction and turbulence, thereby minimizing pressure drop.

- Gasket and sealing improvements: Advancements in gasket design and sealing technologies can help reduce pressure loss in plate heat exchangers. This includes developing more efficient gasket profiles, using advanced materials with better sealing properties, and improving gasket installation techniques. These improvements minimize leakage and ensure optimal flow paths, reducing pressure drop.

- Multi-pass configurations: Utilizing multi-pass configurations in plate heat exchangers can help manage pressure loss more effectively. By strategically arranging the fluid flow paths through multiple passes, the overall pressure drop can be distributed more evenly. This approach allows for better control of fluid velocities and can lead to improved heat transfer efficiency with reduced pressure loss.

02 Flow distribution techniques

Implementing advanced flow distribution techniques can help minimize pressure loss in plate heat exchangers. This may involve the use of specially designed inlet and outlet manifolds, baffles, or flow guides to ensure uniform fluid distribution across the plates. Proper flow distribution reduces localized pressure drops and improves overall exchanger performance.Expand Specific Solutions03 Surface enhancement methods

Enhancing the surface characteristics of heat exchanger plates can contribute to reduced pressure loss. This may include applying special coatings, creating micro-structures, or incorporating turbulence promoters that improve heat transfer without significantly increasing pressure drop. These surface modifications can optimize the balance between heat transfer and pressure loss.Expand Specific Solutions04 Gasket and sealing improvements

Advancements in gasket design and sealing techniques can help reduce pressure loss in plate heat exchangers. This includes developing more efficient gasket profiles, using advanced sealing materials, and improving gasket compression methods. These enhancements minimize leakage and ensure optimal flow paths, thereby reducing pressure drops at the plate interfaces.Expand Specific Solutions05 Multi-pass configurations

Utilizing multi-pass configurations in plate heat exchangers can help manage pressure loss more effectively. By dividing the flow into multiple passes, the fluid velocity and associated pressure drop can be reduced while maintaining heat transfer efficiency. This approach allows for greater flexibility in balancing heat transfer requirements with acceptable pressure loss levels.Expand Specific Solutions

Key Industry Players

The market for high-efficiency plate heat exchangers is in a mature growth stage, with a global market size estimated to exceed $5 billion by 2025. The technology has reached a high level of maturity, with ongoing innovations focused on improving efficiency and reducing pressure loss. Key players like Alfa Laval, Kelvion, and SWEP dominate the market, leveraging their extensive R&D capabilities and global presence. Emerging companies such as Modine Manufacturing and Hanon Systems are also making significant strides in technological advancements. The competitive landscape is characterized by a mix of established multinational corporations and specialized heat exchanger manufacturers, driving continuous innovation in pressure loss reduction and overall system performance.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed advanced plate heat exchanger technologies to address pressure loss challenges. Their AlfaNova fusion-bonded plate heat exchangers utilize a unique Active Formulation (AF) technology, which creates complex channel geometries to optimize flow distribution and minimize pressure drop[1]. The company has also introduced the AlfaQ series, featuring asymmetric plate designs that reduce turbulence and pressure loss while maintaining high heat transfer efficiency[2]. Additionally, Alfa Laval's PressureSecure design incorporates reinforced contact points and optimized plate patterns to withstand higher pressure differentials, allowing for more compact and efficient heat exchanger configurations[3].

Strengths: Industry-leading innovation in plate design and bonding technology, resulting in high efficiency and low pressure drop. Weaknesses: Higher initial cost compared to traditional heat exchangers, which may limit adoption in cost-sensitive applications.

DAIKIN INDUSTRIES Ltd.

Technical Solution: Daikin has developed advanced plate heat exchanger technologies focusing on refrigeration and air conditioning applications. Their Super Channel Heat Exchanger (SCHE) design incorporates micro-channels and optimized refrigerant flow paths to significantly reduce pressure drop while maintaining high heat transfer efficiency[10]. Daikin has also introduced a novel plate fin design that utilizes a staggered louver pattern to create controlled turbulence, enhancing heat transfer while minimizing pressure losses[11]. Additionally, the company's VRV (Variable Refrigerant Volume) systems employ sophisticated control algorithms to optimize refrigerant flow and pressure across multiple heat exchangers, further reducing overall system pressure losses[12].

Strengths: Specialized expertise in HVAC and refrigeration applications, with integrated system solutions that address pressure loss holistically. Weaknesses: Technologies may be less adaptable to non-HVAC applications, limiting broader market potential.

Core Innovations

Plate heat exchanger

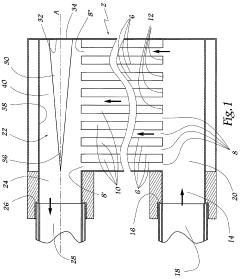

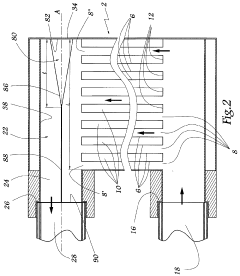

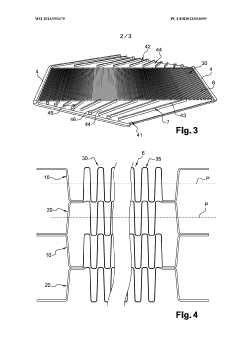

PatentWO2001073366A1

Innovation

- Incorporating an attached member within the outlet manifold that continuously reduces the fluid passage section from the bottom of the manifold, such as a conical body, to enhance fluid distribution and reduce pressure losses.

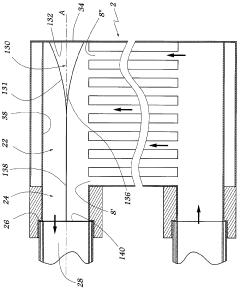

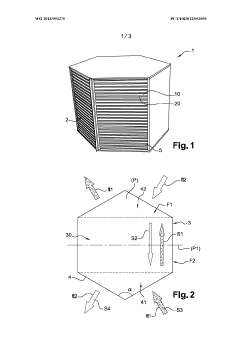

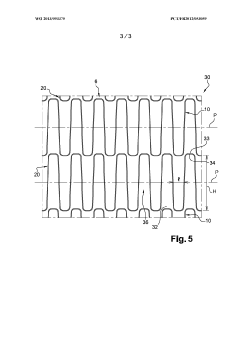

Plate for heat exchanger

PatentWO2013093375A1

Innovation

- The plate design features a core zone with undulations forming cavities and entry/exit zones with ribs and grooves, orienting the fluid flow transversely, concentrating pressure drops within the core zone and reducing them at inlets and outlets, while alternating plate types in the stack enhances fluid interpenetration and heat exchange.

Efficiency vs Pressure Loss

The relationship between efficiency and pressure loss in high-efficiency plate heat exchangers is a critical aspect of their design and operation. As heat transfer efficiency increases, there is often a corresponding increase in pressure loss, creating a trade-off that engineers must carefully balance.

Plate heat exchangers are designed to maximize heat transfer by creating turbulent flow patterns within the narrow channels between plates. This turbulence enhances heat transfer by increasing the mixing of fluid particles and reducing the thickness of the thermal boundary layer. However, these same flow patterns that improve heat transfer also contribute to increased pressure loss due to friction and flow separation.

The efficiency of a plate heat exchanger is typically measured by its overall heat transfer coefficient, which represents the rate of heat transfer per unit area per degree of temperature difference. As the heat transfer coefficient increases, so does the exchanger's efficiency. This can be achieved through various design features such as corrugated plate patterns, smaller channel gaps, and increased flow velocities.

However, these efficiency-enhancing features often lead to higher pressure losses. Corrugated plates, while promoting turbulence and heat transfer, also increase fluid friction. Smaller channel gaps result in higher fluid velocities and greater shear stress at the plate surfaces. Increased flow velocities, while improving heat transfer, directly contribute to higher pressure drops across the exchanger.

The pressure loss in a plate heat exchanger is a function of several factors, including fluid velocity, channel geometry, fluid properties, and the number of passes. As pressure loss increases, the pumping power required to maintain the desired flow rate also increases, potentially offsetting the energy savings gained from improved heat transfer efficiency.

Engineers must therefore strike a balance between heat transfer efficiency and pressure loss. This balance is often application-specific, depending on factors such as available pumping power, allowable pressure drop, and the relative costs of energy for pumping versus heating or cooling. In some cases, a slightly lower efficiency may be acceptable if it results in significantly reduced pressure loss and pumping costs.

Advanced design techniques and optimization algorithms are employed to find the best compromise between efficiency and pressure loss. These may include computational fluid dynamics (CFD) simulations to analyze flow patterns and heat transfer, as well as genetic algorithms to explore vast design spaces and identify optimal configurations.

Plate heat exchangers are designed to maximize heat transfer by creating turbulent flow patterns within the narrow channels between plates. This turbulence enhances heat transfer by increasing the mixing of fluid particles and reducing the thickness of the thermal boundary layer. However, these same flow patterns that improve heat transfer also contribute to increased pressure loss due to friction and flow separation.

The efficiency of a plate heat exchanger is typically measured by its overall heat transfer coefficient, which represents the rate of heat transfer per unit area per degree of temperature difference. As the heat transfer coefficient increases, so does the exchanger's efficiency. This can be achieved through various design features such as corrugated plate patterns, smaller channel gaps, and increased flow velocities.

However, these efficiency-enhancing features often lead to higher pressure losses. Corrugated plates, while promoting turbulence and heat transfer, also increase fluid friction. Smaller channel gaps result in higher fluid velocities and greater shear stress at the plate surfaces. Increased flow velocities, while improving heat transfer, directly contribute to higher pressure drops across the exchanger.

The pressure loss in a plate heat exchanger is a function of several factors, including fluid velocity, channel geometry, fluid properties, and the number of passes. As pressure loss increases, the pumping power required to maintain the desired flow rate also increases, potentially offsetting the energy savings gained from improved heat transfer efficiency.

Engineers must therefore strike a balance between heat transfer efficiency and pressure loss. This balance is often application-specific, depending on factors such as available pumping power, allowable pressure drop, and the relative costs of energy for pumping versus heating or cooling. In some cases, a slightly lower efficiency may be acceptable if it results in significantly reduced pressure loss and pumping costs.

Advanced design techniques and optimization algorithms are employed to find the best compromise between efficiency and pressure loss. These may include computational fluid dynamics (CFD) simulations to analyze flow patterns and heat transfer, as well as genetic algorithms to explore vast design spaces and identify optimal configurations.

Environmental Impact

The environmental impact of high-efficiency plate heat exchangers is a critical consideration in their design and implementation. These heat exchangers offer significant advantages in terms of energy efficiency and reduced carbon footprint compared to traditional heat transfer systems. By minimizing pressure loss, these devices can operate with lower pumping power requirements, leading to decreased energy consumption and associated greenhouse gas emissions.

The compact design of plate heat exchangers contributes to material conservation, as they require less raw materials for construction compared to shell-and-tube heat exchangers of equivalent capacity. This reduction in material usage translates to lower environmental impact during manufacturing and transportation processes. Additionally, the smaller footprint of plate heat exchangers allows for more efficient use of space in industrial settings, potentially reducing the overall environmental impact of facility construction and operation.

Water conservation is another key environmental benefit of high-efficiency plate heat exchangers. Their ability to operate with smaller temperature approaches allows for more effective heat recovery, reducing the demand for cooling water in industrial processes. This can be particularly significant in water-stressed regions or industries with high water consumption rates.

The improved heat transfer efficiency of plate heat exchangers also contributes to reduced thermal pollution. By extracting more heat from process streams, less waste heat is discharged into the environment, minimizing the impact on local ecosystems, particularly in aquatic environments where thermal discharge can affect biodiversity.

Maintenance and longevity aspects of plate heat exchangers also play a role in their environmental impact. The ability to easily disassemble and clean these units can extend their operational lifespan, reducing the frequency of replacement and associated material waste. Furthermore, the use of corrosion-resistant materials in their construction can minimize the need for chemical treatments, potentially reducing the release of harmful substances into the environment.

However, it is important to note that the manufacturing of high-efficiency plate heat exchangers may involve energy-intensive processes and specialized materials. The environmental impact of these factors should be weighed against the long-term operational benefits. Additionally, the disposal or recycling of plate heat exchangers at the end of their life cycle must be considered in a comprehensive environmental assessment.

In conclusion, while high-efficiency plate heat exchangers offer numerous environmental benefits through improved energy efficiency and resource conservation, a holistic approach considering their entire lifecycle is necessary to fully understand and optimize their environmental impact.

The compact design of plate heat exchangers contributes to material conservation, as they require less raw materials for construction compared to shell-and-tube heat exchangers of equivalent capacity. This reduction in material usage translates to lower environmental impact during manufacturing and transportation processes. Additionally, the smaller footprint of plate heat exchangers allows for more efficient use of space in industrial settings, potentially reducing the overall environmental impact of facility construction and operation.

Water conservation is another key environmental benefit of high-efficiency plate heat exchangers. Their ability to operate with smaller temperature approaches allows for more effective heat recovery, reducing the demand for cooling water in industrial processes. This can be particularly significant in water-stressed regions or industries with high water consumption rates.

The improved heat transfer efficiency of plate heat exchangers also contributes to reduced thermal pollution. By extracting more heat from process streams, less waste heat is discharged into the environment, minimizing the impact on local ecosystems, particularly in aquatic environments where thermal discharge can affect biodiversity.

Maintenance and longevity aspects of plate heat exchangers also play a role in their environmental impact. The ability to easily disassemble and clean these units can extend their operational lifespan, reducing the frequency of replacement and associated material waste. Furthermore, the use of corrosion-resistant materials in their construction can minimize the need for chemical treatments, potentially reducing the release of harmful substances into the environment.

However, it is important to note that the manufacturing of high-efficiency plate heat exchangers may involve energy-intensive processes and specialized materials. The environmental impact of these factors should be weighed against the long-term operational benefits. Additionally, the disposal or recycling of plate heat exchangers at the end of their life cycle must be considered in a comprehensive environmental assessment.

In conclusion, while high-efficiency plate heat exchangers offer numerous environmental benefits through improved energy efficiency and resource conservation, a holistic approach considering their entire lifecycle is necessary to fully understand and optimize their environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!