Understanding the Limits of Plate Heat Exchanger Scale-Up Processes

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHE Scale-Up Background and Objectives

Plate heat exchangers (PHEs) have been a cornerstone of industrial heat transfer processes for decades, offering efficient and compact solutions for various applications. The concept of scaling up PHEs has gained significant attention in recent years as industries seek to optimize their processes and increase capacity. This technical research report aims to explore the limits and challenges associated with PHE scale-up processes, providing a comprehensive overview of the field's evolution and current objectives.

The development of PHE technology can be traced back to the early 20th century, with significant advancements occurring in the 1950s and 1960s. Initially designed for small-scale applications, PHEs have gradually expanded their reach to larger industrial processes. The primary driving force behind this evolution has been the need for more efficient heat transfer solutions in various sectors, including chemical processing, food and beverage production, and power generation.

As industries continue to grow and demand higher capacities, the scale-up of PHEs has become a critical area of focus. The main objective of PHE scale-up is to increase the heat transfer capacity while maintaining or improving efficiency, without compromising the compact nature of the equipment. This presents a complex challenge, as simply increasing the size of PHEs does not necessarily result in proportional performance improvements.

The technical goals associated with PHE scale-up processes are multifaceted. Firstly, there is a need to understand the fundamental heat transfer and fluid dynamics principles that govern PHE performance at larger scales. This includes investigating how factors such as plate geometry, flow distribution, and thermal resistance change as the size of the exchanger increases.

Secondly, researchers and engineers aim to develop innovative design methodologies that can accurately predict and optimize the performance of scaled-up PHEs. This involves creating advanced computational models and simulation tools that can account for the complex interactions between various design parameters and operating conditions.

Another crucial objective is to identify and overcome the practical limitations of PHE scale-up. These may include manufacturing constraints, material limitations, and operational challenges such as flow maldistribution and fouling at larger scales. By addressing these issues, the industry seeks to push the boundaries of PHE technology and expand its applicability to even larger-scale processes.

Furthermore, there is a growing emphasis on enhancing the sustainability and energy efficiency of scaled-up PHEs. This aligns with global efforts to reduce carbon footprints and optimize resource utilization in industrial processes. Researchers are exploring novel materials, surface modifications, and design innovations that can improve heat transfer performance while minimizing environmental impact.

In conclusion, the field of PHE scale-up is at a critical juncture, with significant potential for technological advancements. By understanding the historical context and current objectives, this research aims to provide valuable insights into the limits of PHE scale-up processes and pave the way for future innovations in heat exchanger technology.

The development of PHE technology can be traced back to the early 20th century, with significant advancements occurring in the 1950s and 1960s. Initially designed for small-scale applications, PHEs have gradually expanded their reach to larger industrial processes. The primary driving force behind this evolution has been the need for more efficient heat transfer solutions in various sectors, including chemical processing, food and beverage production, and power generation.

As industries continue to grow and demand higher capacities, the scale-up of PHEs has become a critical area of focus. The main objective of PHE scale-up is to increase the heat transfer capacity while maintaining or improving efficiency, without compromising the compact nature of the equipment. This presents a complex challenge, as simply increasing the size of PHEs does not necessarily result in proportional performance improvements.

The technical goals associated with PHE scale-up processes are multifaceted. Firstly, there is a need to understand the fundamental heat transfer and fluid dynamics principles that govern PHE performance at larger scales. This includes investigating how factors such as plate geometry, flow distribution, and thermal resistance change as the size of the exchanger increases.

Secondly, researchers and engineers aim to develop innovative design methodologies that can accurately predict and optimize the performance of scaled-up PHEs. This involves creating advanced computational models and simulation tools that can account for the complex interactions between various design parameters and operating conditions.

Another crucial objective is to identify and overcome the practical limitations of PHE scale-up. These may include manufacturing constraints, material limitations, and operational challenges such as flow maldistribution and fouling at larger scales. By addressing these issues, the industry seeks to push the boundaries of PHE technology and expand its applicability to even larger-scale processes.

Furthermore, there is a growing emphasis on enhancing the sustainability and energy efficiency of scaled-up PHEs. This aligns with global efforts to reduce carbon footprints and optimize resource utilization in industrial processes. Researchers are exploring novel materials, surface modifications, and design innovations that can improve heat transfer performance while minimizing environmental impact.

In conclusion, the field of PHE scale-up is at a critical juncture, with significant potential for technological advancements. By understanding the historical context and current objectives, this research aims to provide valuable insights into the limits of PHE scale-up processes and pave the way for future innovations in heat exchanger technology.

Market Demand Analysis for Large-Scale PHEs

The market demand for large-scale Plate Heat Exchangers (PHEs) has been steadily increasing across various industrial sectors. This growth is primarily driven by the need for more efficient and compact heat transfer solutions in processes that require handling large volumes of fluids. Industries such as petrochemicals, power generation, food processing, and HVAC systems are particularly interested in scaling up PHE technology to meet their expanding operational requirements.

In the petrochemical sector, the push towards larger production capacities and more complex refining processes has created a significant demand for high-performance heat exchangers capable of managing substantial heat loads. Large-scale PHEs offer advantages in terms of reduced footprint and improved heat transfer efficiency compared to traditional shell-and-tube heat exchangers, making them attractive for new plant designs and retrofits.

The power generation industry, especially in the context of renewable energy and waste heat recovery systems, is another key driver for large-scale PHEs. As power plants strive to improve overall efficiency and reduce environmental impact, there is a growing need for heat exchangers that can handle the thermal management of large-scale operations effectively.

Food and beverage processing plants are increasingly adopting large-scale PHEs to meet stringent hygiene standards while maximizing production capacity. The ability of PHEs to provide efficient, gentle heat treatment for sensitive products like dairy and juices has made them indispensable in modern food processing facilities.

In the HVAC sector, the trend towards district heating and cooling systems in urban areas has created a demand for large-scale PHEs capable of transferring heat between primary and secondary distribution networks. These systems require heat exchangers that can handle high flow rates and provide efficient heat transfer to serve multiple buildings or entire districts.

The market for large-scale PHEs is also being influenced by global sustainability initiatives. As industries focus on reducing energy consumption and carbon footprint, the superior energy efficiency of PHEs compared to other heat exchanger types is becoming a crucial factor in their adoption. This trend is expected to continue, driving further demand for scaled-up PHE solutions.

However, the market demand is tempered by certain challenges. The complexity of scaling up PHEs while maintaining optimal performance and avoiding issues like maldistribution and uneven flow patterns presents technical hurdles. Additionally, the high initial investment cost for large-scale PHEs can be a barrier for some potential adopters, especially in industries with tight capital expenditure budgets.

Despite these challenges, the overall market trajectory for large-scale PHEs remains positive. As industries continue to expand and modernize their processes, the demand for efficient, compact, and scalable heat transfer solutions is expected to grow. This presents significant opportunities for PHE manufacturers to innovate and develop solutions that can effectively meet the scaling requirements of various industries.

In the petrochemical sector, the push towards larger production capacities and more complex refining processes has created a significant demand for high-performance heat exchangers capable of managing substantial heat loads. Large-scale PHEs offer advantages in terms of reduced footprint and improved heat transfer efficiency compared to traditional shell-and-tube heat exchangers, making them attractive for new plant designs and retrofits.

The power generation industry, especially in the context of renewable energy and waste heat recovery systems, is another key driver for large-scale PHEs. As power plants strive to improve overall efficiency and reduce environmental impact, there is a growing need for heat exchangers that can handle the thermal management of large-scale operations effectively.

Food and beverage processing plants are increasingly adopting large-scale PHEs to meet stringent hygiene standards while maximizing production capacity. The ability of PHEs to provide efficient, gentle heat treatment for sensitive products like dairy and juices has made them indispensable in modern food processing facilities.

In the HVAC sector, the trend towards district heating and cooling systems in urban areas has created a demand for large-scale PHEs capable of transferring heat between primary and secondary distribution networks. These systems require heat exchangers that can handle high flow rates and provide efficient heat transfer to serve multiple buildings or entire districts.

The market for large-scale PHEs is also being influenced by global sustainability initiatives. As industries focus on reducing energy consumption and carbon footprint, the superior energy efficiency of PHEs compared to other heat exchanger types is becoming a crucial factor in their adoption. This trend is expected to continue, driving further demand for scaled-up PHE solutions.

However, the market demand is tempered by certain challenges. The complexity of scaling up PHEs while maintaining optimal performance and avoiding issues like maldistribution and uneven flow patterns presents technical hurdles. Additionally, the high initial investment cost for large-scale PHEs can be a barrier for some potential adopters, especially in industries with tight capital expenditure budgets.

Despite these challenges, the overall market trajectory for large-scale PHEs remains positive. As industries continue to expand and modernize their processes, the demand for efficient, compact, and scalable heat transfer solutions is expected to grow. This presents significant opportunities for PHE manufacturers to innovate and develop solutions that can effectively meet the scaling requirements of various industries.

Current Challenges in PHE Scale-Up

The scale-up process of Plate Heat Exchangers (PHEs) presents several significant challenges that hinder the seamless transition from small-scale prototypes to large industrial applications. One of the primary obstacles is maintaining thermal and hydraulic performance consistency across different scales. As the size of PHEs increases, the flow distribution becomes more complex, leading to potential maldistribution issues that can significantly impact heat transfer efficiency and pressure drop characteristics.

Another critical challenge lies in the mechanical design and structural integrity of larger PHEs. The increased size and weight of scaled-up units introduce new stress factors that must be carefully managed to prevent deformation, leakage, or failure under operational conditions. This includes addressing thermal expansion, vibration, and fatigue concerns that become more pronounced in larger systems.

Material selection and compatibility also pose significant hurdles in the scale-up process. While certain materials may perform adequately in smaller PHEs, they may not be suitable or cost-effective for larger applications. Engineers must navigate the trade-offs between performance, durability, and economic feasibility when selecting materials for scaled-up designs, often requiring innovative solutions or composite materials to meet the demanding requirements of industrial-scale operations.

The manufacturing and assembly processes for large-scale PHEs present their own set of challenges. Precision in plate corrugation patterns, gasket placement, and overall assembly becomes increasingly difficult as dimensions increase. Ensuring uniform plate spacing and proper sealing across a larger surface area demands advanced manufacturing techniques and quality control measures that may not be readily available or may significantly increase production costs.

Furthermore, the scale-up process must contend with the limitations of existing testing and validation methodologies. Traditional performance prediction models and simulation tools may lose accuracy when applied to significantly larger systems, necessitating the development of new computational approaches and experimental validation techniques. This gap in predictive capabilities can lead to uncertainties in performance guarantees and increase the risk associated with large-scale PHE implementations.

Lastly, the integration of scaled-up PHEs into existing industrial processes presents logistical and operational challenges. Larger units require more space, more robust support structures, and may necessitate modifications to surrounding equipment or facility layouts. The increased fluid volume and thermal inertia of larger systems also impact start-up, shutdown, and control procedures, requiring careful consideration of operational flexibility and safety measures.

Another critical challenge lies in the mechanical design and structural integrity of larger PHEs. The increased size and weight of scaled-up units introduce new stress factors that must be carefully managed to prevent deformation, leakage, or failure under operational conditions. This includes addressing thermal expansion, vibration, and fatigue concerns that become more pronounced in larger systems.

Material selection and compatibility also pose significant hurdles in the scale-up process. While certain materials may perform adequately in smaller PHEs, they may not be suitable or cost-effective for larger applications. Engineers must navigate the trade-offs between performance, durability, and economic feasibility when selecting materials for scaled-up designs, often requiring innovative solutions or composite materials to meet the demanding requirements of industrial-scale operations.

The manufacturing and assembly processes for large-scale PHEs present their own set of challenges. Precision in plate corrugation patterns, gasket placement, and overall assembly becomes increasingly difficult as dimensions increase. Ensuring uniform plate spacing and proper sealing across a larger surface area demands advanced manufacturing techniques and quality control measures that may not be readily available or may significantly increase production costs.

Furthermore, the scale-up process must contend with the limitations of existing testing and validation methodologies. Traditional performance prediction models and simulation tools may lose accuracy when applied to significantly larger systems, necessitating the development of new computational approaches and experimental validation techniques. This gap in predictive capabilities can lead to uncertainties in performance guarantees and increase the risk associated with large-scale PHE implementations.

Lastly, the integration of scaled-up PHEs into existing industrial processes presents logistical and operational challenges. Larger units require more space, more robust support structures, and may necessitate modifications to surrounding equipment or facility layouts. The increased fluid volume and thermal inertia of larger systems also impact start-up, shutdown, and control procedures, requiring careful consideration of operational flexibility and safety measures.

Existing PHE Scale-Up Methodologies

01 Computational fluid dynamics (CFD) modeling

CFD modeling is used to simulate and analyze fluid flow and heat transfer in plate heat exchangers. This technique helps in optimizing the design and predicting performance during scale-up processes. It allows engineers to evaluate different configurations and operating conditions without physical prototyping, saving time and resources.- Computational fluid dynamics (CFD) modeling: CFD modeling is used to simulate and analyze fluid flow and heat transfer in plate heat exchangers during scale-up processes. This method helps optimize design parameters, predict performance, and identify potential issues before physical prototyping.

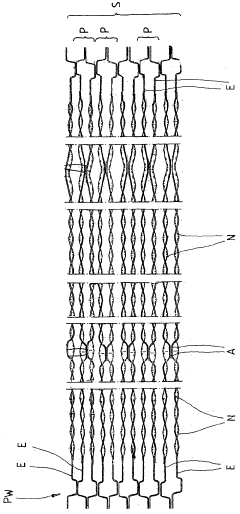

- Geometric scaling and plate design optimization: Scale-up processes involve optimizing plate geometry, including chevron angle, corrugation depth, and plate spacing. These parameters are adjusted to maintain or improve heat transfer efficiency and pressure drop characteristics as the exchanger size increases.

- Performance prediction and validation: Mathematical models and empirical correlations are developed to predict the performance of scaled-up plate heat exchangers. These predictions are then validated through experimental testing and pilot-scale studies to ensure accuracy and reliability.

- Material selection and manufacturing considerations: The scale-up process involves selecting appropriate materials that can withstand increased thermal and mechanical stresses. Manufacturing techniques are adapted to ensure consistent quality and performance of larger plate heat exchangers.

- Flow distribution and maldistribution mitigation: As plate heat exchangers are scaled up, ensuring uniform flow distribution becomes crucial. Techniques are developed to mitigate flow maldistribution, including optimizing port designs, implementing flow distributors, and adjusting plate arrangements.

02 Modular design approach

A modular design approach is employed in scaling up plate heat exchangers. This involves designing standardized modules that can be easily combined or replicated to increase capacity. This method allows for flexibility in scaling and reduces complexity in manufacturing and maintenance.Expand Specific Solutions03 Performance prediction models

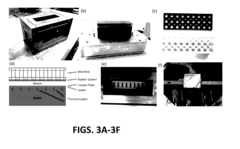

Mathematical models and algorithms are developed to predict the performance of scaled-up plate heat exchangers. These models take into account various parameters such as plate geometry, flow rates, and heat transfer coefficients to estimate the efficiency and capacity of larger units based on data from smaller prototypes.Expand Specific Solutions04 Experimental validation techniques

Experimental methods are used to validate the scale-up process and verify the performance of larger plate heat exchangers. This involves conducting tests on prototype units, measuring key parameters, and comparing the results with theoretical predictions to ensure the accuracy of the scale-up process.Expand Specific Solutions05 Advanced manufacturing techniques

Innovative manufacturing techniques are employed to produce larger and more complex plate heat exchangers. These may include advanced welding methods, precision stamping, and automated assembly processes to ensure consistent quality and performance in scaled-up units.Expand Specific Solutions

Key Players in PHE Manufacturing

The competitive landscape for understanding the limits of plate heat exchanger scale-up processes is characterized by a mature industry with established players and ongoing research efforts. The market size is substantial, driven by applications in various sectors including energy, chemical processing, and HVAC. Companies like Alfa Laval, Air Liquide, and Modine Manufacturing are at the forefront of technological advancements. The technology's maturity is evident, with continuous improvements focused on efficiency and scalability. Academic institutions such as Xi'an Jiaotong University and research organizations like CEA contribute to pushing the boundaries of current limitations, indicating a collaborative approach to innovation in this field.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed advanced computational fluid dynamics (CFD) models to understand and optimize plate heat exchanger (PHE) scale-up processes. Their approach involves detailed simulation of fluid flow and heat transfer in complex PHE geometries, allowing for accurate prediction of performance at different scales[1]. They have also implemented machine learning algorithms to analyze vast amounts of operational data, enabling more precise extrapolation of small-scale test results to industrial-scale applications[3]. Additionally, Alfa Laval has pioneered the use of 3D printing technology for rapid prototyping of novel plate designs, significantly reducing the time and cost associated with scale-up experiments[5].

Strengths: Industry-leading expertise in PHE technology, extensive R&D capabilities, and a large database of operational data. Weaknesses: High computational requirements for complex simulations, and potential limitations in extreme operating conditions.

Air Liquide SA

Technical Solution: Air Liquide has focused on developing innovative plate heat exchanger designs specifically tailored for cryogenic applications, addressing the unique challenges of scale-up in extreme temperature conditions. Their approach includes the use of advanced materials with superior thermal properties and resistance to thermal cycling[2]. They have also implemented a multi-scale modeling approach, combining molecular dynamics simulations with macroscopic heat transfer models to better understand and predict phase change phenomena during scale-up[4]. Furthermore, Air Liquide has developed in-situ monitoring techniques using fiber optic sensors to provide real-time data on temperature and pressure distributions within large-scale PHEs, enabling more accurate validation of scale-up predictions[6].

Strengths: Specialized expertise in cryogenic applications, advanced material science capabilities. Weaknesses: Limited applicability to non-cryogenic PHE applications, high cost of specialized materials and sensors.

Innovative PHE Design Approaches

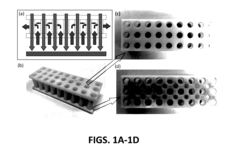

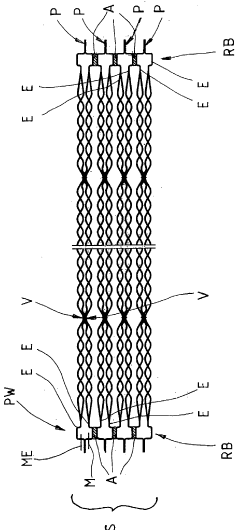

Combining complex flow manifold with three dimensional woven lattices as a thermal management unit

PatentActiveUS20160341495A1

Innovation

- A complex flow manifold designed to optimize properties such as pressure drop, pumping power, and temperature uniformity by using a layered construction with distributed inlet and outlet paths, allowing for additive manufacturing with metals or plastics, and combining with heat exchangers like 3D woven lattices to create thermal management units with scalable and identical properties.

Plate heat exchanger

PatentWO2006097116A1

Innovation

- The introduction of spacers between plate pairs allows for adjustable distances between plate pairs, enabling the formation of flow channels of any size, with spacers being either separate components or integrated into the plate design as depressions, facilitating flexible configuration and cost-effective production.

Material Advancements for PHEs

Material advancements for plate heat exchangers (PHEs) have been crucial in pushing the boundaries of their scale-up processes. Traditional materials like stainless steel and titanium have long been the standard for PHE construction, but recent developments have introduced new possibilities. Advanced alloys, such as super duplex stainless steel and nickel-based alloys, offer improved corrosion resistance and mechanical strength, allowing PHEs to operate in more aggressive environments and at higher temperatures.

Composite materials have also emerged as promising alternatives, combining the benefits of multiple materials to enhance overall performance. For instance, carbon fiber reinforced polymers (CFRP) provide excellent thermal conductivity and low weight, potentially revolutionizing PHE design for specific applications. Additionally, the development of nanomaterials and their incorporation into PHE plates has shown potential for enhancing heat transfer efficiency and fouling resistance.

Surface modifications and coatings have become an area of intense research, aiming to improve the performance of existing materials. Hydrophobic and oleophobic coatings can reduce fouling and enhance cleanability, while specialized surface textures can promote turbulence and increase heat transfer rates. These advancements not only improve efficiency but also extend the operational life of PHEs in challenging conditions.

The integration of smart materials into PHE design is another frontier in material science. Shape memory alloys and piezoelectric materials could enable adaptive geometries, allowing PHEs to optimize their performance in real-time based on operating conditions. This could lead to more flexible and efficient heat exchange systems capable of handling a wider range of process requirements.

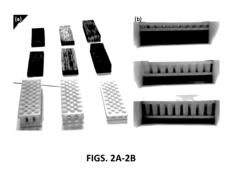

Additive manufacturing techniques have opened new possibilities for PHE material design. 3D printing of complex geometries using advanced materials allows for the creation of optimized flow channels and heat transfer surfaces that were previously impossible to manufacture. This technology enables the production of PHEs with intricate internal structures that maximize heat transfer while minimizing pressure drop.

As the demand for more efficient and robust heat exchange solutions grows, the development of novel materials and manufacturing processes continues to drive innovation in PHE technology. These advancements are essential for overcoming the current limitations in PHE scale-up processes, paving the way for larger, more efficient, and more versatile heat exchange systems across various industries.

Composite materials have also emerged as promising alternatives, combining the benefits of multiple materials to enhance overall performance. For instance, carbon fiber reinforced polymers (CFRP) provide excellent thermal conductivity and low weight, potentially revolutionizing PHE design for specific applications. Additionally, the development of nanomaterials and their incorporation into PHE plates has shown potential for enhancing heat transfer efficiency and fouling resistance.

Surface modifications and coatings have become an area of intense research, aiming to improve the performance of existing materials. Hydrophobic and oleophobic coatings can reduce fouling and enhance cleanability, while specialized surface textures can promote turbulence and increase heat transfer rates. These advancements not only improve efficiency but also extend the operational life of PHEs in challenging conditions.

The integration of smart materials into PHE design is another frontier in material science. Shape memory alloys and piezoelectric materials could enable adaptive geometries, allowing PHEs to optimize their performance in real-time based on operating conditions. This could lead to more flexible and efficient heat exchange systems capable of handling a wider range of process requirements.

Additive manufacturing techniques have opened new possibilities for PHE material design. 3D printing of complex geometries using advanced materials allows for the creation of optimized flow channels and heat transfer surfaces that were previously impossible to manufacture. This technology enables the production of PHEs with intricate internal structures that maximize heat transfer while minimizing pressure drop.

As the demand for more efficient and robust heat exchange solutions grows, the development of novel materials and manufacturing processes continues to drive innovation in PHE technology. These advancements are essential for overcoming the current limitations in PHE scale-up processes, paving the way for larger, more efficient, and more versatile heat exchange systems across various industries.

Environmental Impact of PHE Scale-Up

The scale-up of plate heat exchangers (PHEs) has significant environmental implications that must be carefully considered. As PHEs are scaled up to meet increasing industrial demands, their environmental footprint expands correspondingly. One of the primary environmental concerns is the increased energy consumption associated with larger PHE systems. While PHEs are generally more energy-efficient than traditional heat exchangers, the scale-up process can lead to higher overall energy requirements, potentially offsetting some of the efficiency gains.

Water usage is another critical environmental factor in PHE scale-up. Larger systems typically require more substantial volumes of water for heat transfer, which can strain local water resources, especially in water-scarce regions. This increased water demand may necessitate the implementation of advanced water management strategies, such as closed-loop systems or the use of alternative cooling fluids, to mitigate environmental impact.

The manufacturing process for scaled-up PHEs also contributes to environmental concerns. Larger units require more raw materials, primarily metals like stainless steel or titanium, which have their own environmental footprint in terms of mining, processing, and transportation. The production of these materials can lead to increased greenhouse gas emissions and other pollutants associated with industrial processes.

Chemical usage in PHE systems is another area of environmental consideration during scale-up. Larger systems may require greater quantities of treatment chemicals to prevent fouling and maintain efficiency. The disposal of these chemicals and the potential for leaks or spills can pose risks to local ecosystems if not properly managed.

End-of-life considerations for scaled-up PHEs also present environmental challenges. The larger size and increased complexity of these systems can make recycling and disposal more difficult and energy-intensive. Proper decommissioning and recycling protocols must be developed to minimize the environmental impact of retired PHE units.

On the positive side, the scale-up of PHEs can lead to improved overall system efficiency in industrial processes. This increased efficiency can result in reduced energy consumption and lower emissions on a per-unit-output basis, potentially offsetting some of the negative environmental impacts associated with the scale-up process itself.

To address these environmental concerns, industries implementing scaled-up PHEs are increasingly focusing on sustainable design principles. This includes the use of more environmentally friendly materials, the implementation of advanced energy recovery systems, and the development of more efficient manufacturing processes. Additionally, life cycle assessments are becoming crucial in evaluating the long-term environmental impact of scaled-up PHE systems, helping to guide more sustainable design and operational practices.

Water usage is another critical environmental factor in PHE scale-up. Larger systems typically require more substantial volumes of water for heat transfer, which can strain local water resources, especially in water-scarce regions. This increased water demand may necessitate the implementation of advanced water management strategies, such as closed-loop systems or the use of alternative cooling fluids, to mitigate environmental impact.

The manufacturing process for scaled-up PHEs also contributes to environmental concerns. Larger units require more raw materials, primarily metals like stainless steel or titanium, which have their own environmental footprint in terms of mining, processing, and transportation. The production of these materials can lead to increased greenhouse gas emissions and other pollutants associated with industrial processes.

Chemical usage in PHE systems is another area of environmental consideration during scale-up. Larger systems may require greater quantities of treatment chemicals to prevent fouling and maintain efficiency. The disposal of these chemicals and the potential for leaks or spills can pose risks to local ecosystems if not properly managed.

End-of-life considerations for scaled-up PHEs also present environmental challenges. The larger size and increased complexity of these systems can make recycling and disposal more difficult and energy-intensive. Proper decommissioning and recycling protocols must be developed to minimize the environmental impact of retired PHE units.

On the positive side, the scale-up of PHEs can lead to improved overall system efficiency in industrial processes. This increased efficiency can result in reduced energy consumption and lower emissions on a per-unit-output basis, potentially offsetting some of the negative environmental impacts associated with the scale-up process itself.

To address these environmental concerns, industries implementing scaled-up PHEs are increasingly focusing on sustainable design principles. This includes the use of more environmentally friendly materials, the implementation of advanced energy recovery systems, and the development of more efficient manufacturing processes. Additionally, life cycle assessments are becoming crucial in evaluating the long-term environmental impact of scaled-up PHE systems, helping to guide more sustainable design and operational practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!