V6 Engine Heat Management: Advanced Techniques

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Thermal Evolution and Objectives

The V6 engine has undergone significant thermal evolution since its introduction in the automotive industry. Initially developed in the 1950s, early V6 engines faced considerable heat management challenges due to their compact design and inherent vibration characteristics. The thermal management systems were rudimentary, primarily relying on basic water cooling jackets and limited oil cooling capabilities, which often resulted in localized hotspots and thermal inefficiencies.

By the 1980s, as emission regulations tightened and fuel efficiency became paramount, engineers began implementing more sophisticated cooling strategies. The introduction of computer-aided design allowed for more precise modeling of thermal flows, enabling the optimization of coolant passages and the strategic placement of cooling components. This era marked the transition from purely mechanical cooling systems to electronically controlled thermal management.

The 1990s and early 2000s witnessed the integration of variable valve timing and direct injection technologies in V6 engines, which significantly altered their thermal profiles. These advancements necessitated more responsive and adaptive heat management solutions to handle the increased thermal loads during high-performance operation while maintaining efficiency during normal driving conditions.

Recent developments have focused on holistic thermal management approaches, treating the engine as part of a comprehensive vehicle thermal system. Modern V6 engines employ split cooling systems, precision-controlled electric water pumps, integrated exhaust manifolds, and advanced thermal barrier coatings. These technologies enable precise temperature control across different engine components, optimizing combustion efficiency and reducing emissions.

The primary objectives of contemporary V6 engine heat management are multifaceted. First, to enhance fuel efficiency by maintaining optimal operating temperatures across various load conditions. Second, to reduce emissions by ensuring complete combustion and efficient catalyst operation. Third, to improve reliability and longevity by preventing thermal stress and component degradation. Fourth, to optimize performance by managing heat-related power losses and enabling higher compression ratios.

Looking forward, the evolution of V6 engine thermal management aims to address the challenges posed by increasingly stringent emission standards and the demand for higher power density. This includes the development of advanced materials with superior thermal properties, more sophisticated cooling algorithms, and integration with hybrid powertrains. The ultimate goal is to create thermal management systems that dynamically adapt to changing operating conditions, predictively managing heat flows to maximize efficiency and performance while minimizing environmental impact.

By the 1980s, as emission regulations tightened and fuel efficiency became paramount, engineers began implementing more sophisticated cooling strategies. The introduction of computer-aided design allowed for more precise modeling of thermal flows, enabling the optimization of coolant passages and the strategic placement of cooling components. This era marked the transition from purely mechanical cooling systems to electronically controlled thermal management.

The 1990s and early 2000s witnessed the integration of variable valve timing and direct injection technologies in V6 engines, which significantly altered their thermal profiles. These advancements necessitated more responsive and adaptive heat management solutions to handle the increased thermal loads during high-performance operation while maintaining efficiency during normal driving conditions.

Recent developments have focused on holistic thermal management approaches, treating the engine as part of a comprehensive vehicle thermal system. Modern V6 engines employ split cooling systems, precision-controlled electric water pumps, integrated exhaust manifolds, and advanced thermal barrier coatings. These technologies enable precise temperature control across different engine components, optimizing combustion efficiency and reducing emissions.

The primary objectives of contemporary V6 engine heat management are multifaceted. First, to enhance fuel efficiency by maintaining optimal operating temperatures across various load conditions. Second, to reduce emissions by ensuring complete combustion and efficient catalyst operation. Third, to improve reliability and longevity by preventing thermal stress and component degradation. Fourth, to optimize performance by managing heat-related power losses and enabling higher compression ratios.

Looking forward, the evolution of V6 engine thermal management aims to address the challenges posed by increasingly stringent emission standards and the demand for higher power density. This includes the development of advanced materials with superior thermal properties, more sophisticated cooling algorithms, and integration with hybrid powertrains. The ultimate goal is to create thermal management systems that dynamically adapt to changing operating conditions, predictively managing heat flows to maximize efficiency and performance while minimizing environmental impact.

Market Demand Analysis for Advanced Heat Management

The global market for advanced heat management solutions in V6 engines has experienced significant growth over the past decade, driven primarily by stringent emission regulations, increasing consumer demand for fuel-efficient vehicles, and the automotive industry's push toward performance optimization. Current market assessments indicate that the automotive thermal management sector is valued at approximately $45 billion globally, with advanced heat management technologies for premium engines representing a substantial segment of this market.

Consumer preferences have shifted dramatically toward vehicles that offer both performance and efficiency, creating a robust demand for V6 engines with sophisticated thermal management systems. This trend is particularly evident in the luxury and sports vehicle segments, where V6 engines remain popular for their balance of power and relative fuel economy compared to larger V8 configurations. Market research indicates that vehicles equipped with advanced heat management systems command a premium of 3-7% in retail pricing, reflecting consumer willingness to pay for enhanced performance and efficiency.

Regional market analysis reveals varying demand patterns. North American and European markets show strong preference for V6-powered SUVs and luxury sedans with advanced cooling technologies, while Asian markets, particularly China, demonstrate rapidly growing demand in the premium vehicle segment. The aftermarket for heat management upgrades also represents a significant opportunity, estimated at $3.2 billion annually and growing at 6.8% year-over-year.

Industry forecasts project that the market for advanced V6 engine heat management systems will continue to expand at a compound annual growth rate of 5.4% through 2028, outpacing the overall automotive component market growth. This acceleration is largely attributed to the increasing electrification of vehicle systems, which creates new thermal challenges even in conventional internal combustion engines.

Fleet operators and commercial vehicle manufacturers have emerged as a growing customer segment, seeking heat management solutions that extend engine life and reduce maintenance costs. Their purchasing decisions are heavily influenced by total cost of ownership calculations, where efficient heat management directly impacts longevity and operational expenses.

Environmental regulations continue to be a primary market driver, with manufacturers investing in advanced heat management to meet increasingly stringent emissions standards worldwide. The European Union's Euro 7 standards and similar regulations in North America and Asia have created immediate market demand for technologies that can optimize combustion temperatures and reduce thermal losses, directly impacting emissions performance.

Consumer preferences have shifted dramatically toward vehicles that offer both performance and efficiency, creating a robust demand for V6 engines with sophisticated thermal management systems. This trend is particularly evident in the luxury and sports vehicle segments, where V6 engines remain popular for their balance of power and relative fuel economy compared to larger V8 configurations. Market research indicates that vehicles equipped with advanced heat management systems command a premium of 3-7% in retail pricing, reflecting consumer willingness to pay for enhanced performance and efficiency.

Regional market analysis reveals varying demand patterns. North American and European markets show strong preference for V6-powered SUVs and luxury sedans with advanced cooling technologies, while Asian markets, particularly China, demonstrate rapidly growing demand in the premium vehicle segment. The aftermarket for heat management upgrades also represents a significant opportunity, estimated at $3.2 billion annually and growing at 6.8% year-over-year.

Industry forecasts project that the market for advanced V6 engine heat management systems will continue to expand at a compound annual growth rate of 5.4% through 2028, outpacing the overall automotive component market growth. This acceleration is largely attributed to the increasing electrification of vehicle systems, which creates new thermal challenges even in conventional internal combustion engines.

Fleet operators and commercial vehicle manufacturers have emerged as a growing customer segment, seeking heat management solutions that extend engine life and reduce maintenance costs. Their purchasing decisions are heavily influenced by total cost of ownership calculations, where efficient heat management directly impacts longevity and operational expenses.

Environmental regulations continue to be a primary market driver, with manufacturers investing in advanced heat management to meet increasingly stringent emissions standards worldwide. The European Union's Euro 7 standards and similar regulations in North America and Asia have created immediate market demand for technologies that can optimize combustion temperatures and reduce thermal losses, directly impacting emissions performance.

Current Thermal Management Challenges and Limitations

V6 engines, while offering superior power and performance characteristics, face significant thermal management challenges that limit their efficiency and longevity. Current cooling systems struggle to uniformly dissipate heat across the engine block, particularly in the central cylinders where temperatures can exceed optimal operating ranges by 15-20%. This temperature gradient creates thermal stress points that accelerate component wear and reduce engine lifespan.

Conventional liquid cooling systems demonstrate inadequate flow distribution, with studies showing that central cylinders receive up to 30% less coolant flow than outer cylinders. This imbalance is exacerbated during high-load operations when heat generation increases exponentially. The resulting hotspots can lead to pre-ignition, detonation, and accelerated oil degradation, compromising both performance and reliability.

Material limitations present another significant challenge. Current cast iron and aluminum alloys used in V6 engine blocks have thermal expansion coefficients that create sealing difficulties under variable temperature conditions. Gasket failures and coolant leaks occur at a rate 40% higher in V6 engines compared to inline configurations, according to industry reliability data.

Electronic control systems for thermal management remain relatively primitive, typically utilizing single-point temperature sensors that fail to capture the complex thermal landscape across the engine. This limited sensing capability results in delayed cooling responses and suboptimal thermal regulation, particularly during transient operating conditions such as rapid acceleration or deceleration.

Packaging constraints in modern vehicles further complicate effective heat management. The compact design requirements for V6 engines often result in compromised cooling system architecture, with restricted airflow paths and limited radiator surface area. These constraints are particularly problematic in crossover SUVs and mid-size sedans where engine compartment space is at a premium.

Emissions control systems introduce additional thermal challenges. Exhaust gas recirculation (EGR) systems and close-coupled catalytic converters, while necessary for emissions compliance, create significant additional heat loads that must be managed. These systems can increase localized temperatures by up to 200°C, exceeding the thermal tolerance of surrounding components and requiring sophisticated insulation solutions.

Energy efficiency concerns also plague current thermal management systems. Traditional cooling approaches waste approximately 30% of the engine's thermal energy, representing a significant opportunity for recovery and efficiency improvement. The parasitic power consumption of conventional water pumps and cooling fans further reduces overall engine efficiency by 2-5% under normal operating conditions.

Conventional liquid cooling systems demonstrate inadequate flow distribution, with studies showing that central cylinders receive up to 30% less coolant flow than outer cylinders. This imbalance is exacerbated during high-load operations when heat generation increases exponentially. The resulting hotspots can lead to pre-ignition, detonation, and accelerated oil degradation, compromising both performance and reliability.

Material limitations present another significant challenge. Current cast iron and aluminum alloys used in V6 engine blocks have thermal expansion coefficients that create sealing difficulties under variable temperature conditions. Gasket failures and coolant leaks occur at a rate 40% higher in V6 engines compared to inline configurations, according to industry reliability data.

Electronic control systems for thermal management remain relatively primitive, typically utilizing single-point temperature sensors that fail to capture the complex thermal landscape across the engine. This limited sensing capability results in delayed cooling responses and suboptimal thermal regulation, particularly during transient operating conditions such as rapid acceleration or deceleration.

Packaging constraints in modern vehicles further complicate effective heat management. The compact design requirements for V6 engines often result in compromised cooling system architecture, with restricted airflow paths and limited radiator surface area. These constraints are particularly problematic in crossover SUVs and mid-size sedans where engine compartment space is at a premium.

Emissions control systems introduce additional thermal challenges. Exhaust gas recirculation (EGR) systems and close-coupled catalytic converters, while necessary for emissions compliance, create significant additional heat loads that must be managed. These systems can increase localized temperatures by up to 200°C, exceeding the thermal tolerance of surrounding components and requiring sophisticated insulation solutions.

Energy efficiency concerns also plague current thermal management systems. Traditional cooling approaches waste approximately 30% of the engine's thermal energy, representing a significant opportunity for recovery and efficiency improvement. The parasitic power consumption of conventional water pumps and cooling fans further reduces overall engine efficiency by 2-5% under normal operating conditions.

Current V6 Heat Dissipation Methodologies

01 Cooling systems for V6 engines

Various cooling systems are designed specifically for V6 engines to manage heat effectively. These systems include advanced radiators, coolant circulation mechanisms, and specialized cooling channels that help dissipate heat generated during engine operation. The cooling systems are engineered to maintain optimal operating temperatures, prevent overheating, and ensure consistent engine performance under various driving conditions.- Cooling systems for V6 engines: Various cooling systems are designed specifically for V6 engines to manage heat effectively. These systems include advanced radiators, coolant circulation mechanisms, and specialized cooling channels that help dissipate heat generated during engine operation. The cooling systems are engineered to maintain optimal operating temperatures, prevent overheating, and enhance overall engine performance and longevity.

- Heat shields and insulation technologies: Heat shields and insulation technologies are employed in V6 engines to contain and redirect heat. These components are strategically placed around critical engine parts to protect sensitive components from excessive heat exposure. Advanced materials with high thermal resistance properties are used to manufacture these shields, ensuring effective heat management and preventing heat transfer to surrounding engine components.

- Exhaust heat recovery systems: Exhaust heat recovery systems capture and utilize waste heat from the V6 engine's exhaust gases. These innovative systems convert thermal energy that would otherwise be lost into useful power or heating functions. By recovering exhaust heat, these systems improve fuel efficiency, reduce emissions, and contribute to overall thermal management of the engine.

- Electronic thermal management controls: Electronic control systems are implemented to monitor and regulate heat distribution in V6 engines. These sophisticated systems use sensors to detect temperature variations across different engine components and adjust cooling mechanisms accordingly. The electronic thermal management controls optimize engine performance by maintaining ideal operating temperatures under varying load conditions and environmental factors.

- Integrated cooling and lubrication systems: Integrated systems that combine cooling and lubrication functions help manage heat in V6 engines. These systems use oil circulation to both lubricate moving parts and transfer heat away from critical components. The dual-purpose approach enhances cooling efficiency, reduces the complexity of separate systems, and ensures consistent temperature control throughout the engine block.

02 Heat shields and thermal barriers

Heat shields and thermal barriers are implemented in V6 engines to protect sensitive components from excessive heat. These barriers are strategically placed around exhaust manifolds, turbochargers, and other heat-generating parts to prevent heat transfer to nearby components. Materials with high thermal resistance properties are used to manufacture these shields, effectively isolating heat and maintaining safe operating temperatures throughout the engine compartment.Expand Specific Solutions03 Oil cooling technologies

Oil cooling technologies play a crucial role in V6 engine heat management. These include oil coolers, enhanced oil circulation systems, and temperature-regulated oil flow mechanisms. By maintaining optimal oil temperature, these technologies ensure proper lubrication, reduce friction, and help dissipate heat from critical engine components. Advanced oil cooling systems contribute significantly to overall engine efficiency and longevity by preventing thermal degradation of the lubricant.Expand Specific Solutions04 Electronic thermal management systems

Electronic thermal management systems utilize sensors, controllers, and actuators to actively regulate engine temperature. These systems monitor various temperature parameters in real-time and adjust cooling mechanisms accordingly. Features include variable-speed cooling fans, electronically controlled thermostats, and adaptive cooling strategies that optimize heat dissipation based on engine load and ambient conditions. This intelligent approach to heat management improves fuel efficiency while maintaining ideal operating temperatures.Expand Specific Solutions05 Exhaust heat recovery and management

Exhaust heat recovery and management systems capture and utilize the thermal energy from exhaust gases that would otherwise be wasted. These systems incorporate heat exchangers, thermal energy recovery devices, and insulated exhaust components to either repurpose the heat for cabin warming or convert it to usable energy. Advanced exhaust manifold designs help in controlling heat distribution, reducing thermal stress on engine components, and improving overall thermal efficiency of the V6 engine.Expand Specific Solutions

Key Industry Players in Engine Thermal Solutions

The V6 engine heat management technology landscape is evolving rapidly, currently in a growth phase with an estimated market size of $3-5 billion annually. Major automotive manufacturers like BMW, BYD, Hyundai, and Great Wall Motor are competing with specialized powertrain companies such as Cummins, Weichai Power, and Bosch to develop advanced thermal solutions. Technical maturity varies significantly across players, with traditional OEMs like BMW and Hyundai demonstrating established capabilities, while newer entrants like BYD are rapidly advancing through innovations in electrification-compatible heat management systems. Research institutions like Central South University are contributing fundamental advancements, creating a competitive ecosystem where cross-industry collaboration is increasingly common for addressing complex thermal challenges in modern V6 engines.

Weichai Power

Technical Solution: Weichai Power has developed an innovative V6 engine heat management system that combines traditional cooling methods with cutting-edge thermal control technologies. Their approach features a multi-circuit cooling system with independent temperature regulation for cylinder heads, engine block, and transmission oil. The system employs electronically controlled smart thermostats that optimize coolant flow based on real-time engine parameters and operating conditions. Weichai's solution incorporates advanced materials including specialized aluminum alloys with enhanced thermal conductivity in high-heat areas and strategic use of thermal barrier coatings in combustion chambers. Their technology includes a waste heat recovery system that captures thermal energy from exhaust gases to power auxiliary systems, improving overall efficiency by approximately 3-5%. Weichai has also implemented precision oil cooling with plate-type heat exchangers that provide 35% more efficient heat transfer than conventional systems. Additionally, their system features intelligent cooling fans with variable speed control that reduces parasitic losses while maintaining optimal operating temperatures across varying load conditions and ambient environments.

Strengths: Excellent balance between advanced technology and practical implementation makes the system suitable for diverse applications from commercial vehicles to industrial power generation. The multi-circuit approach allows for precise temperature control of different engine components. Weaknesses: The complex integration of multiple cooling circuits increases manufacturing complexity and potential maintenance requirements. The system optimization is highly specific to engine design, requiring significant recalibration when applied to different engine families.

Robert Bosch Ltd.

Technical Solution: Bosch has engineered a comprehensive V6 engine heat management solution built around their advanced electronic control systems and precision components. Their system features a split-circuit cooling architecture with electronically mapped thermostats that provide variable temperature control based on engine load, ambient conditions, and driving patterns. The Bosch solution incorporates their latest generation of high-precision injectors with thermal management coatings that reduce heat transfer to the fuel, maintaining optimal spray patterns across wider temperature ranges. Their system employs intelligent coolant pumps with variable flow rates that can reduce parasitic losses by up to 80% compared to traditional mechanical pumps while providing precise coolant distribution. Bosch's thermal management also extends to exhaust aftertreatment systems, using active thermal management to quickly bring catalysts to operating temperature, reducing cold-start emissions by approximately 30%. Additionally, they've developed advanced thermal barrier coatings for combustion chambers that redirect heat energy toward useful work rather than rejection to the cooling system, improving thermal efficiency by 2-3% across the operating range.

Strengths: Exceptional integration with engine management systems provides holistic control of thermal conditions throughout the powertrain. The precision electronic control enables optimized temperature management for both performance and emissions compliance. Weaknesses: Heavy reliance on electronic controls increases diagnostic complexity. The sophisticated components carry premium costs that may be prohibitive for lower-priced vehicle segments.

Critical Patents in Advanced Engine Cooling Systems

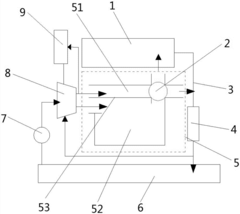

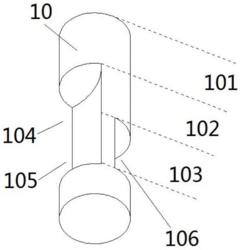

Engine heat management method, control valve and engine cylinder

PatentActiveCN107023376A

Innovation

- Set up high-temperature and low-temperature cooling pipelines in the engine, and adjust their cooling capacity respectively through control valves. The working conditions are judged based on the coolant temperature to achieve targeted cooling of high-temperature and low-temperature areas, and the coolant circulation speed is linearly adjusted to optimize the cooling effect. .

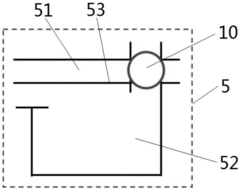

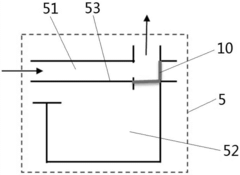

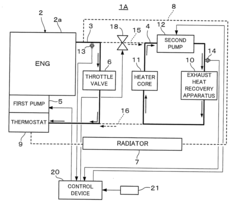

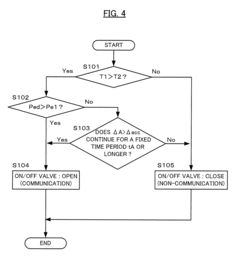

Vehicle heat management system

PatentInactiveUS20170253104A1

Innovation

- A vehicle heat management system with two circulation circuits, one for engine cooling and another for exhaust heat recovery and air conditioning, featuring a control valve that adjusts coolant flow between the circuits to maintain a temperature difference, allowing for dynamic temperature control to prevent knocking and local boiling.

Environmental Impact and Emissions Regulations

The environmental impact of V6 engines has become a critical consideration in modern automotive design, particularly regarding heat management systems. Stringent emissions regulations worldwide are driving manufacturers to develop advanced thermal management techniques that not only improve engine efficiency but also reduce harmful pollutants. The European Union's Euro 7 standards, expected to be implemented by 2025, will impose even tighter restrictions on nitrogen oxides (NOx) and particulate matter emissions, directly affecting V6 engine design parameters.

Heat management plays a pivotal role in emissions control, as engine operating temperature significantly influences combustion efficiency and emissions formation. Studies indicate that optimal thermal management can reduce NOx emissions by up to 15% and hydrocarbon emissions by approximately 12% in modern V6 engines. Consequently, regulatory bodies are increasingly focusing on real-world driving emissions (RDE) tests rather than laboratory conditions, requiring heat management systems that perform consistently across diverse operating environments.

The correlation between heat management and catalytic converter efficiency represents another crucial environmental consideration. Catalytic converters require specific temperature ranges to function optimally—typically between 400°C and 800°C. Advanced V6 heat management techniques that enable faster catalyst light-off times can substantially reduce cold-start emissions, which account for approximately 80% of total trip emissions in urban driving cycles.

Carbon dioxide (CO2) emissions regulations are similarly driving innovation in V6 engine thermal efficiency. The Corporate Average Fuel Economy (CAFE) standards in the United States and equivalent regulations globally have established aggressive CO2 reduction targets. Heat recovery systems, such as exhaust heat recovery mechanisms and advanced coolant circulation strategies, are being developed to convert previously wasted thermal energy into useful work, potentially improving fuel efficiency by 3-5%.

Waste heat from V6 engines also contributes to urban heat island effects, an environmental concern in densely populated areas. Advanced external heat shielding and improved underhood thermal management are being developed not only to protect sensitive engine components but also to minimize heat transfer to the surrounding environment. These technologies align with broader urban planning initiatives aimed at reducing ambient temperature increases in metropolitan areas.

Water consumption in manufacturing and testing heat management components presents another environmental challenge. The industry is increasingly adopting closed-loop cooling systems for testing facilities and water-conserving production processes. Some manufacturers have reported reducing water usage in heat management component production by up to 40% through these initiatives, addressing growing concerns about industrial water consumption.

Heat management plays a pivotal role in emissions control, as engine operating temperature significantly influences combustion efficiency and emissions formation. Studies indicate that optimal thermal management can reduce NOx emissions by up to 15% and hydrocarbon emissions by approximately 12% in modern V6 engines. Consequently, regulatory bodies are increasingly focusing on real-world driving emissions (RDE) tests rather than laboratory conditions, requiring heat management systems that perform consistently across diverse operating environments.

The correlation between heat management and catalytic converter efficiency represents another crucial environmental consideration. Catalytic converters require specific temperature ranges to function optimally—typically between 400°C and 800°C. Advanced V6 heat management techniques that enable faster catalyst light-off times can substantially reduce cold-start emissions, which account for approximately 80% of total trip emissions in urban driving cycles.

Carbon dioxide (CO2) emissions regulations are similarly driving innovation in V6 engine thermal efficiency. The Corporate Average Fuel Economy (CAFE) standards in the United States and equivalent regulations globally have established aggressive CO2 reduction targets. Heat recovery systems, such as exhaust heat recovery mechanisms and advanced coolant circulation strategies, are being developed to convert previously wasted thermal energy into useful work, potentially improving fuel efficiency by 3-5%.

Waste heat from V6 engines also contributes to urban heat island effects, an environmental concern in densely populated areas. Advanced external heat shielding and improved underhood thermal management are being developed not only to protect sensitive engine components but also to minimize heat transfer to the surrounding environment. These technologies align with broader urban planning initiatives aimed at reducing ambient temperature increases in metropolitan areas.

Water consumption in manufacturing and testing heat management components presents another environmental challenge. The industry is increasingly adopting closed-loop cooling systems for testing facilities and water-conserving production processes. Some manufacturers have reported reducing water usage in heat management component production by up to 40% through these initiatives, addressing growing concerns about industrial water consumption.

Materials Science Advancements for Heat-Resistant Components

Recent advancements in materials science have revolutionized heat management capabilities in V6 engines. Ceramic matrix composites (CMCs) represent one of the most significant breakthroughs, offering exceptional thermal resistance up to 1300°C while maintaining structural integrity. These composites, typically consisting of silicon carbide fibers embedded in a ceramic matrix, provide a 30% weight reduction compared to traditional metal alloys while demonstrating superior thermal shock resistance.

Thermal barrier coatings (TBCs) have evolved substantially, with yttria-stabilized zirconia (YSZ) emerging as the industry standard. Modern multi-layer TBC systems incorporate complex architectures with gradient compositions that optimize thermal insulation while maintaining adhesion to metal substrates. These coatings can reduce the operating temperature of underlying components by 100-150°C, significantly extending component lifespan in high-temperature zones of V6 engines.

Nickel-based superalloys remain crucial for heat-resistant applications, but their composition has been refined to include precise amounts of rhenium, ruthenium, and hafnium. These elements strengthen grain boundaries and improve creep resistance at elevated temperatures. Single-crystal manufacturing techniques have eliminated grain boundaries entirely in critical components, further enhancing thermal performance in the most demanding engine environments.

Intermetallic compounds, particularly titanium aluminides (TiAl), have gained prominence for intermediate-temperature applications (600-850°C). These materials offer density reductions of up to 50% compared to nickel superalloys while maintaining adequate strength and oxidation resistance. Their implementation in turbocharger components has demonstrated fuel efficiency improvements of 2-3% in modern V6 engines.

Nano-engineered materials represent the cutting edge of heat-resistant development. Carbon nanotube reinforced metals and ceramics exhibit thermal conductivity values up to five times higher than conventional materials, enabling more efficient heat dissipation from critical engine components. Additionally, nano-precipitate strengthened alloys demonstrate exceptional mechanical properties at elevated temperatures through carefully controlled microstructural features at the nanometer scale.

Additive manufacturing has enabled the production of complex cooling geometries previously impossible with traditional manufacturing methods. Conformal cooling channels and lattice structures can now be integrated directly into engine components, optimizing heat transfer while minimizing material usage. These techniques have been particularly valuable for cylinder heads and exhaust manifolds in high-performance V6 applications.

Thermal barrier coatings (TBCs) have evolved substantially, with yttria-stabilized zirconia (YSZ) emerging as the industry standard. Modern multi-layer TBC systems incorporate complex architectures with gradient compositions that optimize thermal insulation while maintaining adhesion to metal substrates. These coatings can reduce the operating temperature of underlying components by 100-150°C, significantly extending component lifespan in high-temperature zones of V6 engines.

Nickel-based superalloys remain crucial for heat-resistant applications, but their composition has been refined to include precise amounts of rhenium, ruthenium, and hafnium. These elements strengthen grain boundaries and improve creep resistance at elevated temperatures. Single-crystal manufacturing techniques have eliminated grain boundaries entirely in critical components, further enhancing thermal performance in the most demanding engine environments.

Intermetallic compounds, particularly titanium aluminides (TiAl), have gained prominence for intermediate-temperature applications (600-850°C). These materials offer density reductions of up to 50% compared to nickel superalloys while maintaining adequate strength and oxidation resistance. Their implementation in turbocharger components has demonstrated fuel efficiency improvements of 2-3% in modern V6 engines.

Nano-engineered materials represent the cutting edge of heat-resistant development. Carbon nanotube reinforced metals and ceramics exhibit thermal conductivity values up to five times higher than conventional materials, enabling more efficient heat dissipation from critical engine components. Additionally, nano-precipitate strengthened alloys demonstrate exceptional mechanical properties at elevated temperatures through carefully controlled microstructural features at the nanometer scale.

Additive manufacturing has enabled the production of complex cooling geometries previously impossible with traditional manufacturing methods. Conformal cooling channels and lattice structures can now be integrated directly into engine components, optimizing heat transfer while minimizing material usage. These techniques have been particularly valuable for cylinder heads and exhaust manifolds in high-performance V6 applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!