V6 Engine Impact on Vehicle Dynamics: Analysis

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Evolution and Performance Objectives

The V6 engine has undergone significant evolution since its inception in the early 20th century. Initially developed as a compromise between inline-four and V8 configurations, the V6 engine has transformed from a relatively uncommon power plant to one of the most versatile and widely adopted engine layouts in modern vehicles. The compact design, offering an optimal balance between performance and efficiency, has made it particularly suitable for front-wheel-drive platforms and mid-sized vehicles where space constraints are critical considerations.

The technological progression of V6 engines has been marked by several pivotal innovations. The introduction of variable valve timing in the 1980s significantly enhanced both power output and fuel efficiency. Subsequently, direct fuel injection systems in the 1990s further optimized combustion processes, while turbocharging and supercharging technologies have enabled smaller displacement V6 engines to deliver performance comparable to naturally aspirated V8 counterparts while maintaining superior fuel economy.

Recent advancements have focused on hybridization, with V6 engines increasingly integrated into hybrid powertrains. This evolution reflects the industry's response to stringent emissions regulations and consumer demand for environmentally conscious yet powerful vehicles. Modern V6 engines frequently incorporate cylinder deactivation technology, allowing them to operate as three or four-cylinder engines under light load conditions, further improving fuel efficiency without compromising performance capabilities.

The performance objectives for contemporary V6 engines are multifaceted and increasingly demanding. Primary goals include achieving optimal power-to-weight ratios to enhance vehicle dynamics while simultaneously reducing emissions and improving fuel economy. Engineers strive to minimize vibration and noise characteristics inherent to the V6 configuration through refined balancing techniques and advanced mounting systems, ensuring a refined driving experience.

Another critical objective is thermal efficiency optimization, with manufacturers targeting conversion rates exceeding 40% through innovations in combustion chamber design, reduced friction, and improved cooling systems. The integration of V6 engines with advanced transmission technologies, particularly dual-clutch and continuously variable transmissions, further enhances overall powertrain efficiency and responsiveness.

Looking forward, the development trajectory for V6 engines is increasingly focused on compatibility with alternative fuels and electrification pathways. Research efforts are concentrated on adapting V6 architectures to accommodate hydrogen combustion and synthetic fuel technologies, potentially extending the viability of internal combustion engines in an increasingly carbon-constrained regulatory environment. These evolutionary paths demonstrate the continuing relevance of V6 engines in the automotive landscape despite the growing shift toward full electrification.

The technological progression of V6 engines has been marked by several pivotal innovations. The introduction of variable valve timing in the 1980s significantly enhanced both power output and fuel efficiency. Subsequently, direct fuel injection systems in the 1990s further optimized combustion processes, while turbocharging and supercharging technologies have enabled smaller displacement V6 engines to deliver performance comparable to naturally aspirated V8 counterparts while maintaining superior fuel economy.

Recent advancements have focused on hybridization, with V6 engines increasingly integrated into hybrid powertrains. This evolution reflects the industry's response to stringent emissions regulations and consumer demand for environmentally conscious yet powerful vehicles. Modern V6 engines frequently incorporate cylinder deactivation technology, allowing them to operate as three or four-cylinder engines under light load conditions, further improving fuel efficiency without compromising performance capabilities.

The performance objectives for contemporary V6 engines are multifaceted and increasingly demanding. Primary goals include achieving optimal power-to-weight ratios to enhance vehicle dynamics while simultaneously reducing emissions and improving fuel economy. Engineers strive to minimize vibration and noise characteristics inherent to the V6 configuration through refined balancing techniques and advanced mounting systems, ensuring a refined driving experience.

Another critical objective is thermal efficiency optimization, with manufacturers targeting conversion rates exceeding 40% through innovations in combustion chamber design, reduced friction, and improved cooling systems. The integration of V6 engines with advanced transmission technologies, particularly dual-clutch and continuously variable transmissions, further enhances overall powertrain efficiency and responsiveness.

Looking forward, the development trajectory for V6 engines is increasingly focused on compatibility with alternative fuels and electrification pathways. Research efforts are concentrated on adapting V6 architectures to accommodate hydrogen combustion and synthetic fuel technologies, potentially extending the viability of internal combustion engines in an increasingly carbon-constrained regulatory environment. These evolutionary paths demonstrate the continuing relevance of V6 engines in the automotive landscape despite the growing shift toward full electrification.

Market Demand Analysis for V6-Powered Vehicles

The global market for V6-powered vehicles has experienced significant shifts over the past decade, influenced by evolving consumer preferences, regulatory frameworks, and technological advancements. Current market analysis indicates a bifurcation in demand patterns, with premium segments maintaining strong interest in V6 engines while mass-market applications show declining adoption rates.

In North America, V6 engines continue to hold substantial market share in mid-size to large SUVs and pickup trucks, where consumers value the balance between power delivery and fuel economy compared to larger V8 alternatives. Market research indicates that approximately 38% of light trucks and 22% of mid-size to large SUVs sold in North America feature V6 powertrains, representing a significant but gradually declining segment.

The European market presents a contrasting picture, with V6 engines primarily confined to premium and luxury vehicle segments. Stringent emissions regulations and high fuel costs have accelerated the transition toward smaller displacement turbocharged engines and electrification. Nevertheless, German premium manufacturers maintain V6 offerings in their executive sedans and SUVs, targeting performance-oriented consumers willing to pay premium prices.

Asia-Pacific markets demonstrate heterogeneous demand patterns. In Japan, V6 engines maintain presence in premium domestic brands and imported luxury vehicles, while Chinese consumers increasingly favor V6 options in the rapidly growing premium SUV segment. The Australian market continues to value V6 powertrains in utility vehicles and off-road applications.

Market forecasts project a compound annual decline rate of 4.7% for V6 engine installations globally through 2028, primarily driven by the accelerating transition toward electrification and increasingly stringent emissions standards. However, this decline is not uniform across all segments, with premium applications showing greater resilience.

Consumer research reveals that vehicle dynamics remains a key purchasing consideration for buyers selecting V6-powered vehicles. Surveys indicate that 67% of V6 vehicle purchasers cite driving characteristics—including acceleration, handling, and overall performance feel—as "very important" in their decision-making process. This suggests that the distinctive dynamic characteristics of V6 engines continue to represent a marketable value proposition.

The aftermarket and performance enhancement sectors demonstrate continued robust demand for V6 platforms, particularly those with established tuning potential. This niche but profitable segment indicates ongoing enthusiast interest in the performance capabilities of well-designed V6 powertrains, especially when coupled with advanced vehicle dynamics packages.

In conclusion, while the overall market trajectory for V6 engines shows gradual contraction, significant pockets of demand persist, particularly in applications where the unique dynamic characteristics of these powertrains align with consumer expectations for performance, refinement, and driving engagement.

In North America, V6 engines continue to hold substantial market share in mid-size to large SUVs and pickup trucks, where consumers value the balance between power delivery and fuel economy compared to larger V8 alternatives. Market research indicates that approximately 38% of light trucks and 22% of mid-size to large SUVs sold in North America feature V6 powertrains, representing a significant but gradually declining segment.

The European market presents a contrasting picture, with V6 engines primarily confined to premium and luxury vehicle segments. Stringent emissions regulations and high fuel costs have accelerated the transition toward smaller displacement turbocharged engines and electrification. Nevertheless, German premium manufacturers maintain V6 offerings in their executive sedans and SUVs, targeting performance-oriented consumers willing to pay premium prices.

Asia-Pacific markets demonstrate heterogeneous demand patterns. In Japan, V6 engines maintain presence in premium domestic brands and imported luxury vehicles, while Chinese consumers increasingly favor V6 options in the rapidly growing premium SUV segment. The Australian market continues to value V6 powertrains in utility vehicles and off-road applications.

Market forecasts project a compound annual decline rate of 4.7% for V6 engine installations globally through 2028, primarily driven by the accelerating transition toward electrification and increasingly stringent emissions standards. However, this decline is not uniform across all segments, with premium applications showing greater resilience.

Consumer research reveals that vehicle dynamics remains a key purchasing consideration for buyers selecting V6-powered vehicles. Surveys indicate that 67% of V6 vehicle purchasers cite driving characteristics—including acceleration, handling, and overall performance feel—as "very important" in their decision-making process. This suggests that the distinctive dynamic characteristics of V6 engines continue to represent a marketable value proposition.

The aftermarket and performance enhancement sectors demonstrate continued robust demand for V6 platforms, particularly those with established tuning potential. This niche but profitable segment indicates ongoing enthusiast interest in the performance capabilities of well-designed V6 powertrains, especially when coupled with advanced vehicle dynamics packages.

In conclusion, while the overall market trajectory for V6 engines shows gradual contraction, significant pockets of demand persist, particularly in applications where the unique dynamic characteristics of these powertrains align with consumer expectations for performance, refinement, and driving engagement.

Current V6 Technology Landscape and Challenges

The V6 engine configuration has evolved significantly over the past decades, establishing itself as a balanced solution between the economical four-cylinder and the powerful V8 engines. Currently, the global V6 engine landscape is characterized by diverse implementations across manufacturers, with varying displacements typically ranging from 2.5 to 4.0 liters. Modern V6 engines predominantly feature aluminum construction, direct fuel injection, variable valve timing, and turbocharging or supercharging technologies to enhance performance while meeting increasingly stringent emissions regulations.

The automotive industry faces substantial challenges in V6 engine development, primarily driven by the global push toward electrification and carbon neutrality. Manufacturers must balance performance expectations with fuel efficiency requirements, creating a technical dilemma that demands innovative solutions. The compact packaging of V6 engines, particularly in transverse applications, presents significant thermal management challenges that affect both performance and reliability.

Geographically, V6 engine technology development remains concentrated in traditional automotive manufacturing centers in North America, Europe, and Japan, with emerging contributions from China and South Korea. European manufacturers typically focus on smaller displacement turbocharged V6 engines, while American producers often develop larger displacement naturally aspirated or forced induction variants for their truck and SUV applications.

A critical technical challenge for V6 engines is inherent vibration characteristics. Unlike inline-six configurations, V6 engines are not naturally balanced and require careful engineering solutions such as offset crankpins, balance shafts, or specific firing orders to mitigate NVH (Noise, Vibration, Harshness) issues that directly impact vehicle dynamics. These vibration characteristics significantly influence chassis tuning requirements and suspension design parameters.

Weight distribution represents another substantial challenge, as the V6 configuration's mass and positioning within the vehicle architecture fundamentally affects handling characteristics. Front-heavy configurations with transverse-mounted V6 engines typically exhibit understeer tendencies, while longitudinally mounted engines allow for more balanced weight distribution but present packaging challenges in modern vehicle platforms.

The integration of hybrid systems with V6 engines introduces additional complexity to vehicle dynamics. The placement of electric motors, batteries, and power electronics alters the vehicle's center of gravity and weight distribution, requiring comprehensive re-engineering of suspension systems and chassis tuning to maintain desired handling characteristics while accommodating the additional components and their weight.

Manufacturing complexity and cost considerations also present significant challenges. The V6 configuration, with its two cylinder banks and more complex intake and exhaust routing, requires sophisticated production techniques and quality control measures to ensure consistent performance characteristics across production units, directly impacting vehicle dynamics consistency in mass-produced vehicles.

The automotive industry faces substantial challenges in V6 engine development, primarily driven by the global push toward electrification and carbon neutrality. Manufacturers must balance performance expectations with fuel efficiency requirements, creating a technical dilemma that demands innovative solutions. The compact packaging of V6 engines, particularly in transverse applications, presents significant thermal management challenges that affect both performance and reliability.

Geographically, V6 engine technology development remains concentrated in traditional automotive manufacturing centers in North America, Europe, and Japan, with emerging contributions from China and South Korea. European manufacturers typically focus on smaller displacement turbocharged V6 engines, while American producers often develop larger displacement naturally aspirated or forced induction variants for their truck and SUV applications.

A critical technical challenge for V6 engines is inherent vibration characteristics. Unlike inline-six configurations, V6 engines are not naturally balanced and require careful engineering solutions such as offset crankpins, balance shafts, or specific firing orders to mitigate NVH (Noise, Vibration, Harshness) issues that directly impact vehicle dynamics. These vibration characteristics significantly influence chassis tuning requirements and suspension design parameters.

Weight distribution represents another substantial challenge, as the V6 configuration's mass and positioning within the vehicle architecture fundamentally affects handling characteristics. Front-heavy configurations with transverse-mounted V6 engines typically exhibit understeer tendencies, while longitudinally mounted engines allow for more balanced weight distribution but present packaging challenges in modern vehicle platforms.

The integration of hybrid systems with V6 engines introduces additional complexity to vehicle dynamics. The placement of electric motors, batteries, and power electronics alters the vehicle's center of gravity and weight distribution, requiring comprehensive re-engineering of suspension systems and chassis tuning to maintain desired handling characteristics while accommodating the additional components and their weight.

Manufacturing complexity and cost considerations also present significant challenges. The V6 configuration, with its two cylinder banks and more complex intake and exhaust routing, requires sophisticated production techniques and quality control measures to ensure consistent performance characteristics across production units, directly impacting vehicle dynamics consistency in mass-produced vehicles.

Contemporary V6 Engine Solutions for Vehicle Dynamics

01 Engine control systems for vehicle dynamics

Control systems that optimize V6 engine performance to enhance vehicle dynamics. These systems monitor various parameters such as throttle position, engine speed, and vehicle load to adjust engine output accordingly. Advanced algorithms and electronic control units manage fuel injection, ignition timing, and valve timing to improve responsiveness, stability, and handling characteristics of vehicles equipped with V6 engines.- Engine control systems for vehicle dynamics: Control systems that optimize V6 engine performance to enhance vehicle dynamics. These systems monitor various parameters such as throttle position, wheel speed, and vehicle stability to adjust engine output accordingly. Advanced algorithms process real-time data to improve handling, traction, and overall driving experience by modifying torque distribution and power delivery based on driving conditions.

- V6 engine configuration and performance optimization: Specific design aspects of V6 engines that affect vehicle dynamics, including cylinder arrangement, firing order, and balance shaft implementation. These configurations aim to reduce vibration, improve power delivery, and enhance overall vehicle stability. Optimization techniques focus on weight distribution, center of gravity positioning, and power-to-weight ratio to achieve better handling characteristics and driving performance.

- Suspension and chassis integration with V6 powertrains: Integration of V6 engine characteristics with suspension and chassis systems to optimize vehicle dynamics. This includes tuning suspension components to accommodate the weight, vibration patterns, and torque characteristics of V6 engines. Adaptive suspension systems that respond to engine performance parameters help maintain optimal handling across various driving conditions and engine load states.

- Torque management and distribution systems: Systems designed to manage and distribute torque from V6 engines to improve vehicle dynamics. These include electronic differential systems, torque vectoring technologies, and dynamic stability control that work in conjunction with the engine management system. By precisely controlling torque delivery to individual wheels, these systems enhance cornering ability, stability during acceleration, and overall handling characteristics.

- Simulation and modeling of V6 engine vehicle dynamics: Advanced simulation and modeling techniques used to predict and analyze the dynamic behavior of vehicles equipped with V6 engines. These computational methods help engineers optimize engine mounting positions, powertrain layout, and vehicle design parameters before physical prototyping. Simulation tools account for factors such as weight distribution, inertial effects, and powertrain-induced vibrations to improve overall vehicle dynamics.

02 Suspension and chassis integration with V6 powertrains

Integration of V6 engine characteristics with suspension and chassis systems to optimize vehicle dynamics. This includes adaptive suspension systems that respond to engine torque output, weight distribution considerations specific to V6 engine placement, and chassis tuning that accounts for the unique vibration patterns and power delivery of V6 engines. These integrations aim to improve handling, ride comfort, and overall vehicle stability.Expand Specific Solutions03 Torque management and distribution systems

Systems designed to manage and distribute torque from V6 engines to optimize vehicle dynamics. These include torque vectoring technologies, dynamic torque distribution between axles, and electronic stability control systems specifically calibrated for V6 engine characteristics. Such systems improve traction, cornering ability, and overall vehicle stability by intelligently directing engine power where it's most needed based on driving conditions.Expand Specific Solutions04 Simulation and modeling of V6 engine vehicle dynamics

Advanced simulation and modeling techniques used to predict and optimize the dynamic behavior of vehicles equipped with V6 engines. These computational methods analyze the interactions between engine performance characteristics and vehicle dynamics parameters. Engineers use these models to evaluate handling, stability, and ride quality during the design phase, allowing for optimization of vehicle systems before physical prototypes are built.Expand Specific Solutions05 Thermal management impact on vehicle dynamics

Thermal management systems for V6 engines that influence vehicle dynamics performance. These systems regulate engine operating temperatures to maintain optimal performance characteristics, affecting power delivery consistency and vehicle handling. Advanced cooling solutions, heat dissipation techniques, and thermal monitoring systems ensure that V6 engines operate within ideal temperature ranges, preventing performance degradation that could negatively impact vehicle dynamics.Expand Specific Solutions

Leading Manufacturers and Competitive V6 Engine Market

The V6 engine market is in a mature growth phase, with established players dominating the landscape. Toyota, Honda, Ford, and Hyundai lead technological innovation in this segment, focusing on optimizing V6 engines for improved vehicle dynamics. The market shows steady growth driven by demand for performance-oriented SUVs and premium sedans, with an estimated global value of $25-30 billion. Technological maturity varies across applications, with Toyota and Honda demonstrating advanced integration of V6 engines with hybrid systems, while Ford and Nissan excel in turbocharging technologies. Mercedes-Benz and Mazda are pushing boundaries in efficiency optimization, creating a competitive environment where innovation in power-to-weight ratio and dynamic response continues to evolve.

Toyota Motor Corp.

Technical Solution: Toyota's V6 engine technology focuses on optimizing vehicle dynamics through their D-4S (Direct injection 4-stroke gasoline engine Superior version) dual injection system. This system combines direct and port fuel injection to enhance power output while maintaining fuel efficiency. Toyota's V6 engines, particularly in the 3.5L configuration found in models like the Camry and Avalon, utilize Variable Valve Timing with intelligence (VVT-i) and Acoustically Controlled Induction System (ACIS) to optimize torque across the RPM range. Their Dynamic Force Engine technology incorporates high-speed combustion, reduced friction, and variable control systems that directly impact vehicle dynamics by providing more responsive acceleration and smoother power delivery. Toyota has also developed advanced engine mounts and chassis integration techniques to minimize NVH (Noise, Vibration, Harshness) transfer from their V6 engines to the vehicle body, resulting in improved handling characteristics and ride comfort.

Strengths: Superior fuel efficiency while maintaining power output; excellent NVH management; proven reliability with long service intervals. Weaknesses: Slightly heavier than some competitors' V6 designs; conservative power outputs compared to turbocharged alternatives; higher manufacturing costs due to complex dual injection systems.

Honda Motor Co., Ltd.

Technical Solution: Honda's approach to V6 engine impact on vehicle dynamics centers around their i-VTEC (intelligent Variable Valve Timing and Electronic Lift Control) technology. Their Earth Dreams V6 engines feature precision-controlled variable cylinder management (VCM) that can deactivate specific cylinders during cruising to improve fuel efficiency without compromising dynamic performance. Honda engineers have developed a unique mounting system that positions the V6 engine lower in the chassis to reduce the center of gravity, directly enhancing cornering stability and reducing body roll. Their Active Control Engine Mount (ACM) system uses electronic actuators that adjust damping characteristics based on engine RPM and vehicle speed, minimizing vibration transfer to the chassis during acceleration and deceleration phases. Honda's V6 engines also incorporate advanced materials like aluminum-silicon cylinder liners and lightweight pistons to reduce reciprocating mass, allowing for quicker engine response and more precise throttle control, which translates to improved vehicle dynamics particularly in transitional handling situations.

Strengths: Excellent power-to-weight ratio; sophisticated cylinder deactivation technology; low center of gravity engine placement enhances handling. Weaknesses: More complex maintenance requirements; higher production costs for advanced materials; VCM system can create occasional torque fluctuations during cylinder activation/deactivation transitions.

Key Technical Innovations in V6 Engine Design

Method for increasing the viscosity of automotive fuel compositions

PatentInactiveUS20090241882A1

Innovation

- Incorporating a viscosity index improving additive, such as a block copolymer containing ethylene, propylene, butylene, butadiene, isoprene, and styrene monomers, at concentrations lower than predicted to achieve the desired viscosity, which enhances the fuel's viscosity and engine performance without detrimental effects on fuel properties, particularly at lower engine speeds.

Methods and systems for NVH-based vehicle powertrain control

PatentActiveUS20210370947A1

Innovation

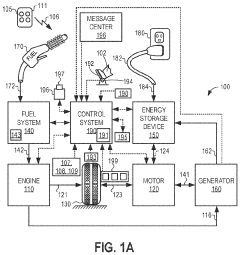

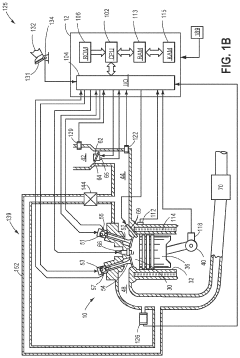

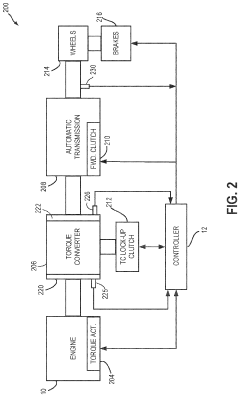

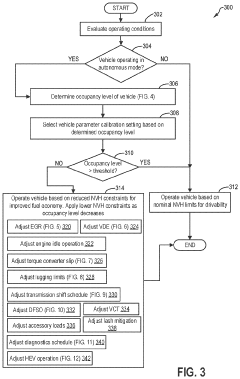

- A system that estimates the occupancy level of a vehicle based on the number of occupants, their position, and their interaction with vehicle controls, and adjusts NVH limits accordingly, allowing for relaxed NVH constraints when occupancy is low to enhance fuel economy while maintaining acceptable NVH levels.

Environmental Impact and Emissions Compliance

The V6 engine configuration presents significant environmental challenges in the contemporary automotive landscape. Emissions from these powerplants typically exceed those of smaller displacement engines, particularly in terms of carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter. Recent regulatory frameworks, including Euro 6d in Europe, China 6 in Asia, and Tier 3 in North America, have established increasingly stringent emissions thresholds that directly impact V6 engine viability. Manufacturers have responded with multi-faceted technological solutions including advanced catalytic converters, exhaust gas recirculation systems, and particulate filters specifically calibrated for V6 architecture.

Environmental compliance strategies for V6 engines have evolved substantially over the past decade. Direct injection technology, while improving fuel efficiency by approximately 15%, has introduced challenges regarding particulate emissions that require dedicated filtration systems. Cylinder deactivation technology, which allows V6 engines to operate on fewer cylinders during low-load conditions, has demonstrated fuel consumption reductions of 8-12% in highway driving scenarios, with corresponding emissions benefits.

Thermal management represents another critical aspect of V6 emissions compliance. Advanced cooling systems with precision-controlled thermostats maintain optimal operating temperatures more consistently than previous generations, reducing cold-start emissions by up to 25% according to industry testing data. Variable valve timing systems, now standard on most V6 configurations, contribute to emissions reduction by optimizing combustion efficiency across the engine's operating range.

The manufacturing environmental footprint of V6 engines presents additional considerations. The production process typically requires 15-20% more materials and energy compared to inline-four alternatives, creating upstream environmental impacts. Several manufacturers have implemented closed-loop recycling programs for aluminum engine components, reducing the lifecycle carbon footprint of V6 powerplants by approximately 30% compared to previous manufacturing methods.

Future compliance pathways for V6 engines increasingly involve hybridization. Mild hybrid systems with 48-volt architecture have demonstrated emissions reductions of 15-20% in urban driving cycles while preserving the performance characteristics that make V6 engines desirable. Full hybridization strategies, incorporating electric motors with power outputs ranging from 20-100 kW, offer pathways to meet ultra-low emission vehicle (ULEV) standards while maintaining the dynamic benefits of six-cylinder configurations.

Water injection technology has emerged as a promising emissions reduction approach specifically suited to turbocharged V6 applications. By introducing a fine mist of water into the intake manifold, combustion temperatures are reduced, decreasing NOx formation by up to 30% in laboratory testing. This technology shows particular promise for high-performance V6 variants where maintaining power output while meeting emissions standards presents the greatest engineering challenge.

Environmental compliance strategies for V6 engines have evolved substantially over the past decade. Direct injection technology, while improving fuel efficiency by approximately 15%, has introduced challenges regarding particulate emissions that require dedicated filtration systems. Cylinder deactivation technology, which allows V6 engines to operate on fewer cylinders during low-load conditions, has demonstrated fuel consumption reductions of 8-12% in highway driving scenarios, with corresponding emissions benefits.

Thermal management represents another critical aspect of V6 emissions compliance. Advanced cooling systems with precision-controlled thermostats maintain optimal operating temperatures more consistently than previous generations, reducing cold-start emissions by up to 25% according to industry testing data. Variable valve timing systems, now standard on most V6 configurations, contribute to emissions reduction by optimizing combustion efficiency across the engine's operating range.

The manufacturing environmental footprint of V6 engines presents additional considerations. The production process typically requires 15-20% more materials and energy compared to inline-four alternatives, creating upstream environmental impacts. Several manufacturers have implemented closed-loop recycling programs for aluminum engine components, reducing the lifecycle carbon footprint of V6 powerplants by approximately 30% compared to previous manufacturing methods.

Future compliance pathways for V6 engines increasingly involve hybridization. Mild hybrid systems with 48-volt architecture have demonstrated emissions reductions of 15-20% in urban driving cycles while preserving the performance characteristics that make V6 engines desirable. Full hybridization strategies, incorporating electric motors with power outputs ranging from 20-100 kW, offer pathways to meet ultra-low emission vehicle (ULEV) standards while maintaining the dynamic benefits of six-cylinder configurations.

Water injection technology has emerged as a promising emissions reduction approach specifically suited to turbocharged V6 applications. By introducing a fine mist of water into the intake manifold, combustion temperatures are reduced, decreasing NOx formation by up to 30% in laboratory testing. This technology shows particular promise for high-performance V6 variants where maintaining power output while meeting emissions standards presents the greatest engineering challenge.

NVH Characteristics of V6 Engines in Vehicle Applications

The Noise, Vibration, and Harshness (NVH) characteristics of V6 engines represent a critical aspect of vehicle dynamics that significantly impacts driver and passenger comfort, perceived quality, and overall vehicle performance. V6 engines, with their inherent balance properties and firing order, produce distinctive NVH signatures that differ substantially from inline-four or V8 configurations.

The primary NVH sources in V6 engines include combustion pressure oscillations, mechanical components interaction, and inertial forces from rotating and reciprocating masses. The 60-degree V6 configuration, commonly used by manufacturers like Honda and Nissan, offers natural primary and secondary balance advantages, resulting in smoother operation compared to 90-degree V6 designs without balance shafts. However, the latter configuration, employed by manufacturers such as Ford and GM, provides packaging benefits despite requiring additional balancing mechanisms.

Harmonic orders specific to V6 engines manifest predominantly at 1.5, 3, and 4.5 times the crankshaft rotational frequency. These harmonics transfer through various structural paths into the vehicle cabin, creating both tactile vibrations and audible noise. Modern V6 engines employ sophisticated mounting systems, including hydraulic mounts with frequency-dependent damping characteristics, to isolate these vibrations from the chassis.

The firing interval and sequence in V6 engines significantly influence their sound quality. Even-firing V6 engines produce a more balanced, smoother sound profile, while odd-firing configurations generate a distinctive, sometimes sportier acoustic character that manufacturers may deliberately enhance for performance-oriented vehicles. Advanced electronic engine mounts that adapt their stiffness based on engine speed and load conditions have become increasingly common in premium vehicle applications featuring V6 powerplants.

Cylinder deactivation technology, now prevalent in many V6 engines for fuel economy improvements, introduces additional NVH challenges during mode transitions. The sudden change in firing pattern when deactivating or reactivating cylinders can create momentary vibration spikes that require sophisticated control strategies and hardware solutions to mitigate. Active noise cancellation systems working in conjunction with the vehicle's audio system have emerged as an effective countermeasure for these transient NVH events.

Turbocharging and supercharging, increasingly common in modern V6 applications, introduce additional NVH considerations including compressor whine, turbine whistle, and altered exhaust notes. These forced induction systems modify the engine's acoustic signature substantially, requiring targeted engineering solutions such as resonators, acoustic encapsulation, and precisely tuned intake and exhaust systems to maintain desirable sound quality while suppressing unwanted noise components.

The primary NVH sources in V6 engines include combustion pressure oscillations, mechanical components interaction, and inertial forces from rotating and reciprocating masses. The 60-degree V6 configuration, commonly used by manufacturers like Honda and Nissan, offers natural primary and secondary balance advantages, resulting in smoother operation compared to 90-degree V6 designs without balance shafts. However, the latter configuration, employed by manufacturers such as Ford and GM, provides packaging benefits despite requiring additional balancing mechanisms.

Harmonic orders specific to V6 engines manifest predominantly at 1.5, 3, and 4.5 times the crankshaft rotational frequency. These harmonics transfer through various structural paths into the vehicle cabin, creating both tactile vibrations and audible noise. Modern V6 engines employ sophisticated mounting systems, including hydraulic mounts with frequency-dependent damping characteristics, to isolate these vibrations from the chassis.

The firing interval and sequence in V6 engines significantly influence their sound quality. Even-firing V6 engines produce a more balanced, smoother sound profile, while odd-firing configurations generate a distinctive, sometimes sportier acoustic character that manufacturers may deliberately enhance for performance-oriented vehicles. Advanced electronic engine mounts that adapt their stiffness based on engine speed and load conditions have become increasingly common in premium vehicle applications featuring V6 powerplants.

Cylinder deactivation technology, now prevalent in many V6 engines for fuel economy improvements, introduces additional NVH challenges during mode transitions. The sudden change in firing pattern when deactivating or reactivating cylinders can create momentary vibration spikes that require sophisticated control strategies and hardware solutions to mitigate. Active noise cancellation systems working in conjunction with the vehicle's audio system have emerged as an effective countermeasure for these transient NVH events.

Turbocharging and supercharging, increasingly common in modern V6 applications, introduce additional NVH considerations including compressor whine, turbine whistle, and altered exhaust notes. These forced induction systems modify the engine's acoustic signature substantially, requiring targeted engineering solutions such as resonators, acoustic encapsulation, and precisely tuned intake and exhaust systems to maintain desirable sound quality while suppressing unwanted noise components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!