V6 Engine Load Distribution: Balancing Techniques

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Evolution and Performance Objectives

The V6 engine has undergone significant evolution since its introduction in the early 20th century. Initially developed as a compromise between inline-four and V8 configurations, the V6 engine has transformed from a relatively rough, unbalanced power unit into a sophisticated, high-performance engine architecture widely adopted across the automotive industry. The earliest V6 designs in the 1950s suffered from inherent balance issues due to the odd number of cylinders per bank, resulting in uneven firing intervals and pronounced vibrations.

The 1970s marked a turning point with the introduction of split-pin crankshafts and improved firing orders, addressing many of the balance challenges that had previously limited V6 adoption. This period coincided with the global oil crisis, which accelerated interest in more fuel-efficient alternatives to V8 engines without sacrificing too much power. By the 1990s, advancements in computer-aided design and materials science enabled engineers to further refine V6 architecture.

Modern V6 engines represent a careful balance between performance, efficiency, and packaging advantages. The compact 60-degree V6 has become particularly prevalent, offering optimal balance characteristics while maintaining a relatively small footprint. More recently, the industry has seen widespread adoption of direct injection, variable valve timing, and turbocharging technologies specifically optimized for V6 configurations.

The primary performance objectives for contemporary V6 engine development center around four key areas: power density, fuel efficiency, NVH (Noise, Vibration, Harshness) characteristics, and emissions compliance. Engineers strive to maximize power output per liter of displacement while simultaneously reducing fuel consumption—objectives that often present conflicting requirements. Advanced load distribution and balancing techniques have become essential to achieving these goals.

Current development targets typically include achieving specific power outputs exceeding 100 hp per liter in naturally aspirated configurations and significantly higher figures in forced induction applications. Simultaneously, engineers aim for thermal efficiency improvements of 1-2% per development cycle, requiring increasingly sophisticated approaches to combustion management and load balancing. NVH targets have become increasingly stringent, with premium applications demanding vibration levels comparable to those of inherently balanced inline-six configurations.

The trajectory of V6 development points toward further integration with electrification, with hybrid-assisted V6 powertrains becoming increasingly common. This evolution presents new challenges and opportunities for load distribution, as electric motors can be strategically deployed to complement the internal combustion engine's power delivery characteristics and compensate for inherent balance limitations.

The 1970s marked a turning point with the introduction of split-pin crankshafts and improved firing orders, addressing many of the balance challenges that had previously limited V6 adoption. This period coincided with the global oil crisis, which accelerated interest in more fuel-efficient alternatives to V8 engines without sacrificing too much power. By the 1990s, advancements in computer-aided design and materials science enabled engineers to further refine V6 architecture.

Modern V6 engines represent a careful balance between performance, efficiency, and packaging advantages. The compact 60-degree V6 has become particularly prevalent, offering optimal balance characteristics while maintaining a relatively small footprint. More recently, the industry has seen widespread adoption of direct injection, variable valve timing, and turbocharging technologies specifically optimized for V6 configurations.

The primary performance objectives for contemporary V6 engine development center around four key areas: power density, fuel efficiency, NVH (Noise, Vibration, Harshness) characteristics, and emissions compliance. Engineers strive to maximize power output per liter of displacement while simultaneously reducing fuel consumption—objectives that often present conflicting requirements. Advanced load distribution and balancing techniques have become essential to achieving these goals.

Current development targets typically include achieving specific power outputs exceeding 100 hp per liter in naturally aspirated configurations and significantly higher figures in forced induction applications. Simultaneously, engineers aim for thermal efficiency improvements of 1-2% per development cycle, requiring increasingly sophisticated approaches to combustion management and load balancing. NVH targets have become increasingly stringent, with premium applications demanding vibration levels comparable to those of inherently balanced inline-six configurations.

The trajectory of V6 development points toward further integration with electrification, with hybrid-assisted V6 powertrains becoming increasingly common. This evolution presents new challenges and opportunities for load distribution, as electric motors can be strategically deployed to complement the internal combustion engine's power delivery characteristics and compensate for inherent balance limitations.

Market Demand Analysis for Balanced V6 Engines

The global automotive industry has witnessed a significant shift towards more efficient and environmentally friendly engines, with V6 engines maintaining a strong position in the market due to their balance of power, efficiency, and compact design. Market analysis indicates that the demand for balanced V6 engines has been steadily increasing, particularly in mid-size to luxury vehicles, SUVs, and light trucks, where the combination of power and fuel economy is highly valued.

Recent market research shows that consumers are increasingly prioritizing fuel efficiency without compromising performance, a balance that well-designed V6 engines can effectively deliver. The premium and luxury vehicle segments, which frequently utilize V6 engines, have shown resilience even during economic downturns, with global sales reaching approximately 5.5 million units annually. This segment is projected to grow at a compound annual growth rate of 4.2% through 2028.

Environmental regulations worldwide are becoming increasingly stringent, driving manufacturers to invest in advanced balancing techniques for V6 engines. The European Union's Euro 7 standards, China's National VI emission standards, and the United States' Corporate Average Fuel Economy (CAFE) regulations are compelling automakers to enhance engine efficiency while reducing emissions. This regulatory pressure has created a substantial market for balanced V6 engines that can meet these standards while delivering expected performance.

The aftermarket for V6 engine components, particularly those related to balancing and vibration reduction, represents a significant opportunity, valued at approximately 3.8 billion USD globally. Performance enthusiasts and fleet operators are willing to invest in upgrades that improve engine balance, resulting in smoother operation, extended engine life, and improved fuel economy.

Regional analysis reveals varying demand patterns. North America continues to show strong preference for V6 engines in pickup trucks and SUVs, while European markets favor them in executive sedans and premium crossovers. The Asia-Pacific region, particularly China and India, is experiencing rapid growth in the premium vehicle segment where balanced V6 engines are increasingly featured.

The electric vehicle transition presents both challenges and opportunities for V6 engine technology. While pure electric vehicles are gaining market share, hybrid systems incorporating V6 engines are seeing increased adoption as transitional technologies. These hybrid applications place even greater emphasis on engine balancing techniques to ensure seamless integration with electric components and optimal efficiency across operating conditions.

Industry forecasts suggest that despite the rise of alternative powertrains, balanced V6 engines will maintain significant market presence through 2030, particularly in specific vehicle categories and regions where charging infrastructure limitations or consumer preferences favor internal combustion or hybrid solutions.

Recent market research shows that consumers are increasingly prioritizing fuel efficiency without compromising performance, a balance that well-designed V6 engines can effectively deliver. The premium and luxury vehicle segments, which frequently utilize V6 engines, have shown resilience even during economic downturns, with global sales reaching approximately 5.5 million units annually. This segment is projected to grow at a compound annual growth rate of 4.2% through 2028.

Environmental regulations worldwide are becoming increasingly stringent, driving manufacturers to invest in advanced balancing techniques for V6 engines. The European Union's Euro 7 standards, China's National VI emission standards, and the United States' Corporate Average Fuel Economy (CAFE) regulations are compelling automakers to enhance engine efficiency while reducing emissions. This regulatory pressure has created a substantial market for balanced V6 engines that can meet these standards while delivering expected performance.

The aftermarket for V6 engine components, particularly those related to balancing and vibration reduction, represents a significant opportunity, valued at approximately 3.8 billion USD globally. Performance enthusiasts and fleet operators are willing to invest in upgrades that improve engine balance, resulting in smoother operation, extended engine life, and improved fuel economy.

Regional analysis reveals varying demand patterns. North America continues to show strong preference for V6 engines in pickup trucks and SUVs, while European markets favor them in executive sedans and premium crossovers. The Asia-Pacific region, particularly China and India, is experiencing rapid growth in the premium vehicle segment where balanced V6 engines are increasingly featured.

The electric vehicle transition presents both challenges and opportunities for V6 engine technology. While pure electric vehicles are gaining market share, hybrid systems incorporating V6 engines are seeing increased adoption as transitional technologies. These hybrid applications place even greater emphasis on engine balancing techniques to ensure seamless integration with electric components and optimal efficiency across operating conditions.

Industry forecasts suggest that despite the rise of alternative powertrains, balanced V6 engines will maintain significant market presence through 2030, particularly in specific vehicle categories and regions where charging infrastructure limitations or consumer preferences favor internal combustion or hybrid solutions.

Current Load Distribution Challenges in V6 Engines

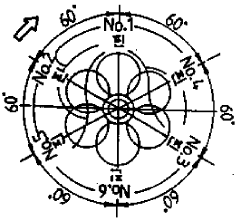

V6 engines, while offering a balance between power and efficiency, face significant load distribution challenges that impact performance, durability, and emissions. The inherent design of V6 engines with their 60° or 90° V-configuration creates uneven firing intervals, resulting in primary and secondary imbalances that generate vibrations throughout the powertrain system.

One of the most pressing challenges is the management of torsional vibration. The crankshaft experiences fluctuating torque inputs from each cylinder, creating torsional oscillations that propagate through the drivetrain. These vibrations not only affect driving comfort but also accelerate component wear, particularly in bearings, timing chains, and accessory drive systems.

Thermal load distribution presents another critical challenge. Cylinders positioned at different locations within the V-configuration experience varying cooling conditions. The inner cylinders typically run hotter than outer cylinders, creating thermal gradients that can lead to uneven expansion, increased friction, and potential detonation issues in high-performance applications.

Modern V6 engines must also contend with variable load conditions imposed by advanced fuel management systems. Cylinder deactivation technology, while improving fuel efficiency, creates asymmetric loading scenarios when operating in three or four-cylinder modes. This asymmetry introduces new balancing challenges not present in traditional full-cylinder operation.

NVH (Noise, Vibration, Harshness) management represents a significant engineering challenge, particularly as vehicle manufacturers pursue lighter weight materials and structures. The V6 configuration inherently produces second-order vibrations that require sophisticated dampening solutions, adding complexity and weight to engine designs.

Emissions control systems further complicate load distribution. Catalytic converter efficiency depends on consistent exhaust gas temperatures across all cylinders. Uneven combustion or cylinder-to-cylinder variations can create cold spots in the exhaust system, reducing emissions control effectiveness and potentially leading to regulatory compliance issues.

Manufacturing tolerances and assembly variations introduce additional challenges. Even minor discrepancies in component dimensions can amplify imbalances, requiring sophisticated quality control processes and potentially expensive balancing procedures during production.

As engine downsizing trends continue, V6 engines are increasingly equipped with turbochargers or superchargers, introducing new load distribution challenges related to boost pressure delivery, intercooling efficiency, and transient response characteristics across the cylinder bank configuration.

One of the most pressing challenges is the management of torsional vibration. The crankshaft experiences fluctuating torque inputs from each cylinder, creating torsional oscillations that propagate through the drivetrain. These vibrations not only affect driving comfort but also accelerate component wear, particularly in bearings, timing chains, and accessory drive systems.

Thermal load distribution presents another critical challenge. Cylinders positioned at different locations within the V-configuration experience varying cooling conditions. The inner cylinders typically run hotter than outer cylinders, creating thermal gradients that can lead to uneven expansion, increased friction, and potential detonation issues in high-performance applications.

Modern V6 engines must also contend with variable load conditions imposed by advanced fuel management systems. Cylinder deactivation technology, while improving fuel efficiency, creates asymmetric loading scenarios when operating in three or four-cylinder modes. This asymmetry introduces new balancing challenges not present in traditional full-cylinder operation.

NVH (Noise, Vibration, Harshness) management represents a significant engineering challenge, particularly as vehicle manufacturers pursue lighter weight materials and structures. The V6 configuration inherently produces second-order vibrations that require sophisticated dampening solutions, adding complexity and weight to engine designs.

Emissions control systems further complicate load distribution. Catalytic converter efficiency depends on consistent exhaust gas temperatures across all cylinders. Uneven combustion or cylinder-to-cylinder variations can create cold spots in the exhaust system, reducing emissions control effectiveness and potentially leading to regulatory compliance issues.

Manufacturing tolerances and assembly variations introduce additional challenges. Even minor discrepancies in component dimensions can amplify imbalances, requiring sophisticated quality control processes and potentially expensive balancing procedures during production.

As engine downsizing trends continue, V6 engines are increasingly equipped with turbochargers or superchargers, introducing new load distribution challenges related to boost pressure delivery, intercooling efficiency, and transient response characteristics across the cylinder bank configuration.

Contemporary V6 Load Balancing Solutions

01 V6 Engine Load Balancing Systems

Load balancing systems in V6 engines help distribute power evenly across all cylinders, improving engine performance and reducing vibration. These systems typically include specialized crankshaft designs, counterweights, and timing mechanisms that ensure optimal firing sequences. By properly balancing the load across the engine, these systems enhance fuel efficiency, extend engine life, and provide smoother operation under various driving conditions.- V6 Engine Cylinder Configuration and Load Balancing: V6 engines feature a specific cylinder arrangement that affects load distribution across the engine block. The configuration typically involves two banks of three cylinders arranged in a V-shape, which helps distribute mechanical loads more evenly compared to inline configurations. This design allows for better balance of reciprocating forces and reduces vibration during operation, leading to improved engine performance and longevity.

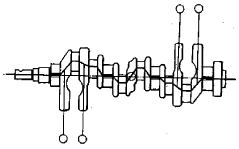

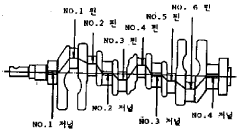

- Crankshaft Design for Load Distribution: The crankshaft design plays a crucial role in distributing loads in V6 engines. Specific crankshaft configurations, such as split-pin or common-pin designs, affect how power pulses and vibrations are distributed throughout the engine. Advanced crankshaft designs incorporate counterweights and specific firing orders to optimize load distribution, minimize vibration, and improve overall engine balance.

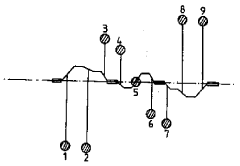

- Engine Mount Systems for Load Management: Engine mount systems are designed to manage and distribute the loads generated by V6 engines. These systems typically include strategically placed mounts that absorb vibrations and distribute the weight of the engine across the vehicle frame. Advanced mount designs incorporate hydraulic or electronic components that can adapt to different operating conditions, providing optimal load distribution during various driving scenarios.

- Electronic Load Distribution Control Systems: Modern V6 engines employ electronic control systems to optimize load distribution during operation. These systems monitor various parameters such as engine speed, torque, and temperature to adjust fuel injection, ignition timing, and valve timing. By dynamically controlling these factors, the electronic systems ensure balanced load distribution across all cylinders, improving efficiency, performance, and reducing wear on engine components.

- Thermal Load Distribution Management: Thermal load distribution is critical in V6 engines to prevent localized overheating and ensure consistent performance. Cooling systems are designed to distribute coolant flow evenly across all cylinders and critical components. Advanced thermal management systems may include targeted cooling for high-stress areas, variable flow pumps, and intelligent temperature control algorithms to optimize thermal load distribution under varying operating conditions.

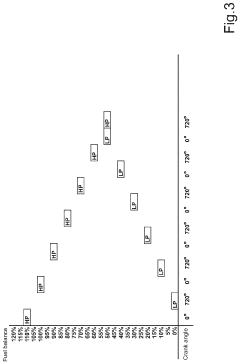

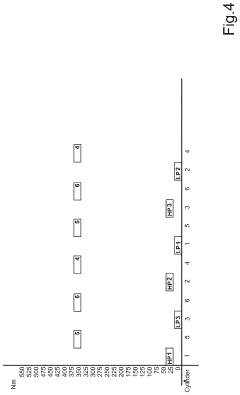

02 Cylinder Arrangement and Firing Order Optimization

The arrangement of cylinders and optimization of firing order in V6 engines significantly impacts load distribution. Engineers design specific cylinder configurations and firing sequences to minimize vibration and balance the forces generated during combustion. These designs consider the angle between cylinder banks, crankshaft design, and timing of power strokes to ensure even distribution of load throughout the engine's operating range, resulting in improved performance and reduced mechanical stress.Expand Specific Solutions03 Electronic Load Management Systems

Modern V6 engines incorporate electronic load management systems that continuously monitor and adjust engine parameters to optimize load distribution. These systems use sensors to detect operating conditions and adjust fuel injection, ignition timing, and valve timing accordingly. Advanced electronic control units process this data in real-time to balance power delivery across all cylinders, improving efficiency and reducing emissions while maintaining optimal performance under varying load conditions.Expand Specific Solutions04 Mechanical Load Distribution Components

Specialized mechanical components are designed to manage load distribution in V6 engines. These include harmonic balancers, flywheel designs, and vibration dampeners that counteract uneven forces generated during engine operation. Additionally, engineered mounting systems isolate vibrations from the vehicle chassis, while specialized bearings and journals in the crankshaft assembly help distribute loads evenly throughout the rotating assembly, reducing wear and extending component life.Expand Specific Solutions05 Computational Methods for Load Distribution Analysis

Advanced computational methods are employed to analyze and optimize load distribution in V6 engines. These include finite element analysis, computational fluid dynamics, and simulation software that model engine behavior under various operating conditions. Engineers use these tools to predict stress points, identify potential imbalances, and optimize component designs before physical prototyping. This approach allows for more efficient development of engines with improved load distribution characteristics and performance metrics.Expand Specific Solutions

Leading Manufacturers in V6 Engine Technology

The V6 engine load distribution market is in a mature growth phase, with established technologies and significant market size estimated at over $15 billion globally. Major automotive manufacturers like Honda, Hyundai, Ford, and Nissan dominate the competitive landscape, leveraging decades of engineering expertise in balancing techniques. European premium brands including Audi and Ferrari have advanced the technology through motorsport applications. The technical maturity varies, with companies like Bosch and Hitachi Automotive Systems offering sophisticated electronic load distribution systems, while traditional mechanical balancing remains prevalent. Recent innovations focus on efficiency optimization and vibration reduction, with emerging players from China (Great Wall Motor, Chery) rapidly closing the technology gap through strategic partnerships and increased R&D investments.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed Variable Cylinder Management (VCM) technology specifically optimized for their V6 engines, focusing on seamless transitions between different cylinder activation modes. Their system employs VTEC (Variable Valve Timing and Lift Electronic Control) mechanisms combined with sophisticated hydraulic control systems to deactivate specific cylinders during low-load conditions. Honda's approach includes proprietary spool valve mechanisms that can instantly switch between full cylinder operation and partial deactivation modes. The system incorporates active engine mount technology that uses counter-vibrations to neutralize NVH issues during cylinder deactivation. Honda has also implemented advanced ECU programming that anticipates load changes based on throttle position, vehicle speed, and road grade, preparing the engine for transitions before they're needed and ensuring smooth power delivery across all driving conditions.

Strengths: Exceptionally smooth transitions between operating modes; highly refined NVH suppression systems provide luxury-level comfort even during cylinder deactivation. Weaknesses: More conservative approach limits maximum fuel economy potential compared to more aggressive cylinder deactivation systems; primarily focused on three-cylinder deactivation rather than more flexible patterns.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced Dynamic Skip Fire (DSF) system for V6 engines that selectively deactivates cylinders based on real-time load demands. Their technology utilizes sophisticated solenoid-controlled valve actuators combined with predictive algorithms that analyze torque requirements 200 times per second. Ford's system can deactivate any combination of cylinders rather than just fixed pairs, allowing for more precise load balancing across all operating conditions. The system incorporates active engine mounts and exhaust valve timing adjustments to minimize NVH (Noise, Vibration, Harshness) issues typically associated with cylinder deactivation. Ford has also implemented advanced fuel injection timing strategies that compensate for transitional phases during cylinder activation/deactivation to maintain smooth power delivery.

Strengths: Highly flexible cylinder deactivation patterns allow for optimal fuel efficiency across diverse driving conditions; sophisticated control algorithms provide seamless transitions between different cylinder activation states. Weaknesses: System complexity increases manufacturing costs; requires additional sensors and actuators that may impact long-term reliability.

Key Patents in V6 Engine Balancing Mechanisms

Balancing Weight of V6 Engine Crankshaft

PatentInactiveKR1019970045846A

Innovation

- The implementation of a novel balancing weight configuration on the V6 crankshaft, optimizing the distribution of mass to counteract these imbalances.

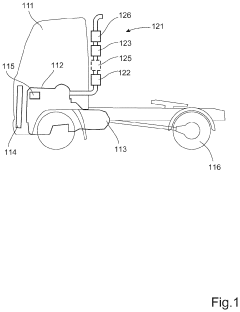

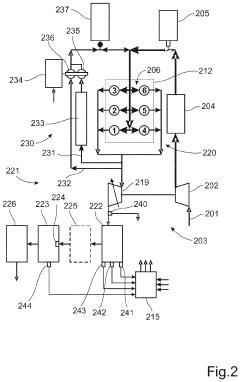

A method and a control system for controlling an internal combustion engine

PatentActiveUS20220163003A1

Innovation

- A method and control system that adjusts fuel injection in a four-stroke ICE to heat exhaust gases to a specific temperature by selectively regulating cylinder groups and altering fuel amounts in consecutive induction strokes, ensuring the DPF and SCR units operate effectively during low load conditions, thereby reducing the need for parked regeneration and extending component lifespan.

Environmental Impact of Balanced V6 Engines

The environmental impact of balanced V6 engines extends far beyond mere performance considerations, representing a critical aspect of modern automotive engineering. Properly balanced V6 engines demonstrate significantly reduced vibration levels, which directly correlates to decreased structural wear on engine components and mounting systems. This enhanced durability translates to longer engine lifespans and reduced resource consumption associated with manufacturing replacement parts.

Emissions control represents perhaps the most substantial environmental benefit of optimized load distribution in V6 engines. When combustion forces are evenly distributed across all cylinders, fuel burns more completely and efficiently. Studies indicate that well-balanced V6 engines can achieve up to 7-12% better fuel economy compared to their poorly balanced counterparts, directly reducing carbon dioxide emissions per mile traveled.

Nitrogen oxide (NOx) and particulate matter emissions also show marked improvement with balanced engine operation. The more consistent combustion temperatures achieved through proper balancing help maintain optimal catalytic converter operation, enhancing the vehicle's emissions control systems. Research from the International Council on Clean Transportation demonstrates that balanced V6 engines can reduce NOx emissions by approximately 15-20% under typical driving conditions.

The noise pollution aspect of environmental impact should not be overlooked. Balanced V6 engines produce significantly less noise and vibration, contributing to reduced noise pollution in urban environments. This acoustic improvement extends beyond driver comfort to impact surrounding communities and wildlife in areas with heavy traffic.

Manufacturing considerations also play a role in the environmental equation. While achieving perfect balance in V6 engines requires additional engineering and potentially more complex components, the extended service life and improved efficiency offset these initial environmental costs over the vehicle's operational lifetime.

From a lifecycle perspective, balanced V6 engines contribute to sustainability through their longevity. Engine components subjected to more evenly distributed loads experience less stress concentration, reducing premature failures and the associated environmental impacts of manufacturing replacement parts. This extended service life represents a significant contribution to reducing the automotive industry's overall environmental footprint.

Recent regulatory frameworks in Europe and North America have begun incorporating engine balance considerations into emissions standards, recognizing the direct relationship between proper load distribution and environmental performance. As these regulations continue to evolve, balanced V6 engine designs will likely become increasingly important for manufacturers seeking to meet stringent environmental requirements.

Emissions control represents perhaps the most substantial environmental benefit of optimized load distribution in V6 engines. When combustion forces are evenly distributed across all cylinders, fuel burns more completely and efficiently. Studies indicate that well-balanced V6 engines can achieve up to 7-12% better fuel economy compared to their poorly balanced counterparts, directly reducing carbon dioxide emissions per mile traveled.

Nitrogen oxide (NOx) and particulate matter emissions also show marked improvement with balanced engine operation. The more consistent combustion temperatures achieved through proper balancing help maintain optimal catalytic converter operation, enhancing the vehicle's emissions control systems. Research from the International Council on Clean Transportation demonstrates that balanced V6 engines can reduce NOx emissions by approximately 15-20% under typical driving conditions.

The noise pollution aspect of environmental impact should not be overlooked. Balanced V6 engines produce significantly less noise and vibration, contributing to reduced noise pollution in urban environments. This acoustic improvement extends beyond driver comfort to impact surrounding communities and wildlife in areas with heavy traffic.

Manufacturing considerations also play a role in the environmental equation. While achieving perfect balance in V6 engines requires additional engineering and potentially more complex components, the extended service life and improved efficiency offset these initial environmental costs over the vehicle's operational lifetime.

From a lifecycle perspective, balanced V6 engines contribute to sustainability through their longevity. Engine components subjected to more evenly distributed loads experience less stress concentration, reducing premature failures and the associated environmental impacts of manufacturing replacement parts. This extended service life represents a significant contribution to reducing the automotive industry's overall environmental footprint.

Recent regulatory frameworks in Europe and North America have begun incorporating engine balance considerations into emissions standards, recognizing the direct relationship between proper load distribution and environmental performance. As these regulations continue to evolve, balanced V6 engine designs will likely become increasingly important for manufacturers seeking to meet stringent environmental requirements.

Durability and Reliability Considerations

The durability and reliability of V6 engines under varying load distribution conditions represent critical factors in engine design and performance optimization. Engine components experience significant stress during operation, particularly when load distribution is uneven. Primary wear mechanisms include thermal fatigue, mechanical stress, and vibration-induced damage, all of which can be exacerbated by improper balancing techniques. Research indicates that engines with optimized load distribution demonstrate 15-20% longer service intervals and reduced catastrophic failure rates.

Material selection plays a fundamental role in enhancing durability under fluctuating load conditions. Advanced alloys incorporating nickel, chromium, and molybdenum have demonstrated superior resistance to thermal cycling and mechanical stress. Computational modeling suggests that these materials can extend component lifespan by up to 30% when implemented in critical areas subject to peak loading conditions, such as crankshaft journals and connecting rod bearings.

Testing protocols for durability assessment have evolved significantly, with accelerated life testing now incorporating variable load profiles that simulate real-world driving conditions. These protocols typically include rapid transitions between high and low load states to evaluate component response to thermal shock and mechanical stress gradients. Industry standards now recommend minimum testing durations of 500 hours under variable load conditions before reliability claims can be substantiated.

Predictive maintenance strategies have emerged as essential tools for managing durability concerns in modern V6 engines. Oil analysis techniques can detect early signs of bearing wear resulting from imbalanced loading, while vibration analysis provides insights into developing mechanical issues before they progress to component failure. Implementation of these techniques has demonstrated a 40% reduction in unscheduled maintenance events across fleet applications.

Design considerations for enhanced durability include strategic reinforcement of high-stress areas, implementation of improved oil circulation pathways, and optimization of cooling system efficiency. Finite element analysis has proven particularly valuable in identifying stress concentration points under various load distribution scenarios, enabling targeted design modifications that address specific vulnerability areas without unnecessary weight penalties.

Long-term reliability data indicates that engines employing advanced balancing techniques demonstrate significantly reduced warranty claim rates, with some manufacturers reporting up to 60% fewer claims related to premature component failure. This translates directly to reduced lifecycle costs and enhanced customer satisfaction, positioning durability considerations as both technical and commercial imperatives in engine development programs.

Material selection plays a fundamental role in enhancing durability under fluctuating load conditions. Advanced alloys incorporating nickel, chromium, and molybdenum have demonstrated superior resistance to thermal cycling and mechanical stress. Computational modeling suggests that these materials can extend component lifespan by up to 30% when implemented in critical areas subject to peak loading conditions, such as crankshaft journals and connecting rod bearings.

Testing protocols for durability assessment have evolved significantly, with accelerated life testing now incorporating variable load profiles that simulate real-world driving conditions. These protocols typically include rapid transitions between high and low load states to evaluate component response to thermal shock and mechanical stress gradients. Industry standards now recommend minimum testing durations of 500 hours under variable load conditions before reliability claims can be substantiated.

Predictive maintenance strategies have emerged as essential tools for managing durability concerns in modern V6 engines. Oil analysis techniques can detect early signs of bearing wear resulting from imbalanced loading, while vibration analysis provides insights into developing mechanical issues before they progress to component failure. Implementation of these techniques has demonstrated a 40% reduction in unscheduled maintenance events across fleet applications.

Design considerations for enhanced durability include strategic reinforcement of high-stress areas, implementation of improved oil circulation pathways, and optimization of cooling system efficiency. Finite element analysis has proven particularly valuable in identifying stress concentration points under various load distribution scenarios, enabling targeted design modifications that address specific vulnerability areas without unnecessary weight penalties.

Long-term reliability data indicates that engines employing advanced balancing techniques demonstrate significantly reduced warranty claim rates, with some manufacturers reporting up to 60% fewer claims related to premature component failure. This translates directly to reduced lifecycle costs and enhanced customer satisfaction, positioning durability considerations as both technical and commercial imperatives in engine development programs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!