V6 Engine Valve Timing Adjustment: Effects and Benefits

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Valve Timing Technology Evolution

The evolution of valve timing technology in V6 engines represents a fascinating journey of automotive engineering innovation spanning several decades. Initially, V6 engines featured fixed valve timing systems where the opening and closing of intake and exhaust valves occurred at predetermined points in the combustion cycle, offering limited flexibility for different operating conditions.

The 1980s marked the beginning of significant advancements with the introduction of rudimentary variable valve timing (VVT) systems. These early implementations allowed limited adjustment of valve timing based on engine speed, representing the first step toward optimizing engine performance across different operating conditions.

The 1990s witnessed a revolutionary leap with the development of continuous variable valve timing systems. Honda's VTEC (Variable Valve Timing and Electronic Lift Control) and Toyota's VVT-i (Variable Valve Timing with intelligence) technologies pioneered this era, enabling more precise control over valve operation. These systems could alter valve timing continuously rather than switching between fixed settings, resulting in notable improvements in both power output and fuel efficiency.

By the early 2000s, dual independent variable valve timing emerged as the new standard. This technology allowed separate control of intake and exhaust valve timing, providing unprecedented flexibility in engine operation. Manufacturers like BMW, with their VANOS (Variable Nockenwellen Steuerung) system, demonstrated how independent control of both valve sets could significantly enhance performance across the entire RPM range.

The 2010s brought forth fully electronic valve control systems, eliminating the traditional camshaft in some designs. Fiat's MultiAir technology and Koenigsegg's FreeValve system exemplified this approach, using electrohydraulic or electromagnetic actuators to control valve operation with millisecond precision, offering unprecedented control over the combustion process.

Most recently, integrated valve timing systems have emerged, combining variable timing with cylinder deactivation and variable compression ratio technologies. These sophisticated systems, found in modern V6 engines from manufacturers like Nissan and Audi, represent the current pinnacle of valve timing technology, optimizing performance, efficiency, and emissions simultaneously.

Throughout this evolution, the fundamental goal has remained consistent: to overcome the inherent limitations of fixed valve timing and create engines that can adapt to varying driving conditions, delivering optimal performance, fuel efficiency, and emissions control across all operating parameters.

The 1980s marked the beginning of significant advancements with the introduction of rudimentary variable valve timing (VVT) systems. These early implementations allowed limited adjustment of valve timing based on engine speed, representing the first step toward optimizing engine performance across different operating conditions.

The 1990s witnessed a revolutionary leap with the development of continuous variable valve timing systems. Honda's VTEC (Variable Valve Timing and Electronic Lift Control) and Toyota's VVT-i (Variable Valve Timing with intelligence) technologies pioneered this era, enabling more precise control over valve operation. These systems could alter valve timing continuously rather than switching between fixed settings, resulting in notable improvements in both power output and fuel efficiency.

By the early 2000s, dual independent variable valve timing emerged as the new standard. This technology allowed separate control of intake and exhaust valve timing, providing unprecedented flexibility in engine operation. Manufacturers like BMW, with their VANOS (Variable Nockenwellen Steuerung) system, demonstrated how independent control of both valve sets could significantly enhance performance across the entire RPM range.

The 2010s brought forth fully electronic valve control systems, eliminating the traditional camshaft in some designs. Fiat's MultiAir technology and Koenigsegg's FreeValve system exemplified this approach, using electrohydraulic or electromagnetic actuators to control valve operation with millisecond precision, offering unprecedented control over the combustion process.

Most recently, integrated valve timing systems have emerged, combining variable timing with cylinder deactivation and variable compression ratio technologies. These sophisticated systems, found in modern V6 engines from manufacturers like Nissan and Audi, represent the current pinnacle of valve timing technology, optimizing performance, efficiency, and emissions simultaneously.

Throughout this evolution, the fundamental goal has remained consistent: to overcome the inherent limitations of fixed valve timing and create engines that can adapt to varying driving conditions, delivering optimal performance, fuel efficiency, and emissions control across all operating parameters.

Market Demand for Advanced Valve Timing Systems

The global market for advanced valve timing systems has experienced significant growth over the past decade, driven primarily by increasingly stringent emission regulations and consumer demand for improved fuel efficiency without sacrificing performance. According to recent industry analyses, the automotive variable valve timing system market was valued at approximately $32.5 billion in 2022 and is projected to reach $45.7 billion by 2028, representing a compound annual growth rate of 5.8%.

The demand for advanced valve timing systems for V6 engines specifically has been particularly robust in premium and luxury vehicle segments, where performance characteristics are paramount. Market research indicates that over 70% of new V6-equipped vehicles now feature some form of variable valve timing technology, compared to just 40% a decade ago.

Regional analysis reveals varying adoption rates, with North American and European markets showing the highest penetration of advanced valve timing systems in V6 engines. This is largely attributed to these regions' stricter emission standards and consumer preferences for vehicles that balance power with efficiency. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment, with adoption rates increasing by approximately 15% annually.

Consumer surveys indicate a growing awareness and preference for vehicles equipped with advanced engine technologies. While most consumers may not specifically request variable valve timing systems by name, they increasingly prioritize the benefits these systems deliver: improved fuel economy, enhanced performance, and reduced emissions. This consumer preference has translated into market pressure on manufacturers to incorporate these technologies across their vehicle lineups.

Fleet operators and commercial vehicle markets have also begun to recognize the long-term cost benefits of advanced valve timing systems. The initial higher acquisition cost is increasingly offset by fuel savings and extended engine life, creating a compelling total cost of ownership proposition. Fleet adoption rates have grown by approximately 25% over the past five years.

The aftermarket for valve timing system upgrades has also seen substantial growth, particularly in performance-oriented market segments. Enthusiasts seeking to optimize their V6 engines for specific performance characteristics have created a niche but profitable market for aftermarket valve timing components and tuning services.

Looking forward, market analysts predict continued strong demand growth as manufacturers work to meet increasingly stringent global emission standards while satisfying consumer expectations for performance. The integration of advanced valve timing systems with other emerging technologies, such as cylinder deactivation and hybrid powertrains, is expected to further expand market opportunities in the coming years.

The demand for advanced valve timing systems for V6 engines specifically has been particularly robust in premium and luxury vehicle segments, where performance characteristics are paramount. Market research indicates that over 70% of new V6-equipped vehicles now feature some form of variable valve timing technology, compared to just 40% a decade ago.

Regional analysis reveals varying adoption rates, with North American and European markets showing the highest penetration of advanced valve timing systems in V6 engines. This is largely attributed to these regions' stricter emission standards and consumer preferences for vehicles that balance power with efficiency. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment, with adoption rates increasing by approximately 15% annually.

Consumer surveys indicate a growing awareness and preference for vehicles equipped with advanced engine technologies. While most consumers may not specifically request variable valve timing systems by name, they increasingly prioritize the benefits these systems deliver: improved fuel economy, enhanced performance, and reduced emissions. This consumer preference has translated into market pressure on manufacturers to incorporate these technologies across their vehicle lineups.

Fleet operators and commercial vehicle markets have also begun to recognize the long-term cost benefits of advanced valve timing systems. The initial higher acquisition cost is increasingly offset by fuel savings and extended engine life, creating a compelling total cost of ownership proposition. Fleet adoption rates have grown by approximately 25% over the past five years.

The aftermarket for valve timing system upgrades has also seen substantial growth, particularly in performance-oriented market segments. Enthusiasts seeking to optimize their V6 engines for specific performance characteristics have created a niche but profitable market for aftermarket valve timing components and tuning services.

Looking forward, market analysts predict continued strong demand growth as manufacturers work to meet increasingly stringent global emission standards while satisfying consumer expectations for performance. The integration of advanced valve timing systems with other emerging technologies, such as cylinder deactivation and hybrid powertrains, is expected to further expand market opportunities in the coming years.

Current Challenges in V6 Valve Timing Adjustment

Despite significant advancements in valve timing technology, V6 engine valve timing adjustment systems continue to face several critical challenges that impact performance, efficiency, and reliability. The primary technical hurdle remains the precise synchronization of multiple valve timing events across two banks of cylinders. Unlike inline engines, V6 configurations require more complex control algorithms to maintain optimal timing across all cylinders while accounting for the inherent firing order and vibration characteristics.

Material limitations present another significant obstacle. Current actuator components experience accelerated wear under high-temperature conditions, particularly in turbocharged applications where exhaust temperatures can exceed 900°C. This thermal stress reduces system longevity and necessitates more frequent maintenance intervals, increasing ownership costs and diminishing customer satisfaction.

Power consumption of electromagnetic valve actuators continues to challenge engineers, with current systems drawing 2-4 amperes during operation. This electrical load impacts fuel economy by approximately 1-2% and requires more robust alternator systems, adding weight and complexity to the powertrain package.

Response time latency remains problematic, especially during rapid transient conditions. Most contemporary systems exhibit 50-150 millisecond delays between command and execution, creating momentary inefficiencies during acceleration events or load changes. This lag contributes to combustion instability and increased emissions during the transition period.

Packaging constraints within modern engine compartments further complicate valve timing system design. The trend toward smaller, more compact engine bays leaves limited space for actuators and control mechanisms, forcing compromises in system architecture that can impact performance potential.

Cost factors continue to influence implementation decisions, with advanced continuously variable valve timing systems adding $300-600 to manufacturing costs per engine. This premium creates market segmentation challenges, limiting advanced timing technologies to higher-end vehicle applications despite their potential benefits across all market segments.

Calibration complexity represents another significant challenge. Modern V6 engines require extensive mapping across thousands of operating points to optimize valve timing for various conditions. This calibration process can consume 500-800 engineering hours per engine variant, creating development bottlenecks and extending time-to-market for new powertrain technologies.

Diagnostic capabilities also remain underdeveloped, with current OBD systems often unable to detect subtle timing drift until performance has already degraded significantly. This limitation complicates preventive maintenance and can lead to customer dissatisfaction when problems manifest as drivability issues rather than clear warning indicators.

Material limitations present another significant obstacle. Current actuator components experience accelerated wear under high-temperature conditions, particularly in turbocharged applications where exhaust temperatures can exceed 900°C. This thermal stress reduces system longevity and necessitates more frequent maintenance intervals, increasing ownership costs and diminishing customer satisfaction.

Power consumption of electromagnetic valve actuators continues to challenge engineers, with current systems drawing 2-4 amperes during operation. This electrical load impacts fuel economy by approximately 1-2% and requires more robust alternator systems, adding weight and complexity to the powertrain package.

Response time latency remains problematic, especially during rapid transient conditions. Most contemporary systems exhibit 50-150 millisecond delays between command and execution, creating momentary inefficiencies during acceleration events or load changes. This lag contributes to combustion instability and increased emissions during the transition period.

Packaging constraints within modern engine compartments further complicate valve timing system design. The trend toward smaller, more compact engine bays leaves limited space for actuators and control mechanisms, forcing compromises in system architecture that can impact performance potential.

Cost factors continue to influence implementation decisions, with advanced continuously variable valve timing systems adding $300-600 to manufacturing costs per engine. This premium creates market segmentation challenges, limiting advanced timing technologies to higher-end vehicle applications despite their potential benefits across all market segments.

Calibration complexity represents another significant challenge. Modern V6 engines require extensive mapping across thousands of operating points to optimize valve timing for various conditions. This calibration process can consume 500-800 engineering hours per engine variant, creating development bottlenecks and extending time-to-market for new powertrain technologies.

Diagnostic capabilities also remain underdeveloped, with current OBD systems often unable to detect subtle timing drift until performance has already degraded significantly. This limitation complicates preventive maintenance and can lead to customer dissatisfaction when problems manifest as drivability issues rather than clear warning indicators.

Contemporary V6 Valve Timing Adjustment Solutions

01 Improved fuel efficiency and reduced emissions

Valve timing adjustment in V6 engines can significantly improve fuel efficiency by optimizing the combustion process. By precisely controlling when valves open and close relative to piston position, the engine can achieve better air-fuel mixture and more complete combustion. This optimization leads to reduced fuel consumption and lower emissions of harmful pollutants such as nitrogen oxides (NOx) and carbon monoxide (CO). Advanced valve timing systems can adjust timing based on engine load and speed, further enhancing efficiency across various driving conditions.- Improved fuel efficiency and reduced emissions: Valve timing adjustment in V6 engines can significantly improve fuel efficiency by optimizing the combustion process. By precisely controlling when valves open and close relative to piston position, the engine can achieve better air-fuel mixture and more complete combustion. This optimization leads to reduced fuel consumption and lower emissions of harmful pollutants such as nitrogen oxides (NOx) and carbon monoxide (CO). Advanced valve timing systems can adjust timing based on engine load and speed, further enhancing efficiency across various driving conditions.

- Enhanced engine performance and power output: Adjustable valve timing allows V6 engines to optimize performance across different RPM ranges. By advancing or retarding valve timing, engines can increase torque at low speeds while maximizing horsepower at high speeds. This flexibility enables better acceleration, improved throttle response, and higher overall power output. Variable valve timing systems can alter the overlap between intake and exhaust valves to enhance volumetric efficiency, allowing more air into the combustion chamber when needed, resulting in increased power without sacrificing efficiency at cruising speeds.

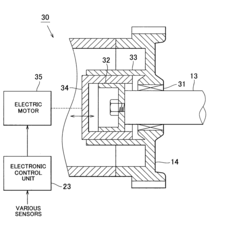

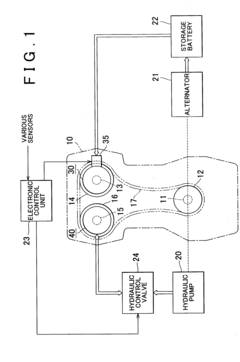

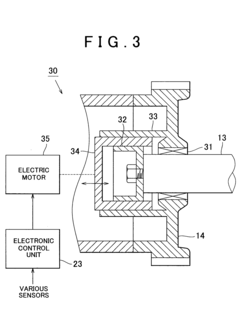

- Advanced control systems and electronic implementation: Modern V6 engines utilize sophisticated electronic control systems to manage valve timing adjustments. These systems employ sensors to monitor engine conditions such as speed, load, temperature, and throttle position, then use this data to calculate optimal valve timing. Electronically controlled actuators, including oil pressure systems, electric motors, or solenoids, precisely adjust camshaft position relative to the crankshaft. These advanced control systems enable real-time adjustments that respond to changing driving conditions, providing seamless transitions between different valve timing profiles.

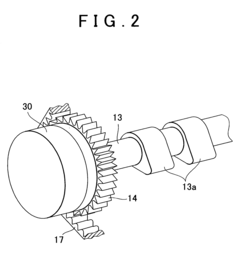

- Mechanical implementation and design innovations: Various mechanical designs have been developed to implement valve timing adjustment in V6 engines. These include cam phasers, variable valve lift mechanisms, and continuously variable valve timing systems. Cam phasers alter the rotational position of the camshaft relative to its drive, while more advanced systems can modify both timing and lift characteristics. Some designs incorporate hydraulic tensioners, helical splines, or planetary gear sets to achieve precise control. These mechanical innovations enable manufacturers to implement valve timing adjustment while maintaining reliability and durability under various operating conditions.

- Engine durability and operational stability: Valve timing adjustment systems in V6 engines contribute to improved engine durability and operational stability. By optimizing valve events based on operating conditions, these systems reduce mechanical stress on engine components and minimize harmful combustion phenomena like knocking and pre-ignition. They also enable smoother idle, better cold-start performance, and more consistent operation across varying temperatures and altitudes. Some systems include fail-safe mechanisms that default to conservative timing settings if malfunctions occur, ensuring continued operation even when the adjustment system experiences issues.

02 Enhanced engine performance and power output

Adjustable valve timing in V6 engines allows for optimized power delivery across different RPM ranges. By advancing or retarding valve timing, the engine can achieve better volumetric efficiency, resulting in increased torque at low RPMs and higher power output at high RPMs. This flexibility enables a broader power band, making the engine more responsive throughout its operating range. Variable valve timing systems can dynamically adjust to driving conditions, providing power when needed while maintaining efficiency during normal operation.Expand Specific Solutions03 Improved engine smoothness and noise reduction

Valve timing adjustment contributes to smoother engine operation by optimizing valve overlap periods. Proper timing reduces mechanical stress on valve train components and minimizes vibration, resulting in quieter engine operation and reduced harshness. This is particularly important in V6 engines where balance and smoothness are key selling points. Advanced timing systems can adapt to different operating conditions, maintaining optimal smoothness across varying speeds and loads, which enhances overall driving comfort and reduces noise, vibration, and harshness (NVH) levels.Expand Specific Solutions04 Extended engine lifespan and reliability

Optimized valve timing can significantly extend engine lifespan by reducing mechanical stress on critical components. Proper timing ensures valves open and close at the ideal moments, preventing valve-to-piston interference and reducing wear on camshafts, lifters, and other valve train components. This optimization leads to fewer mechanical failures and maintenance issues over the engine's lifetime. Additionally, more efficient combustion resulting from optimized valve timing reduces carbon deposits and oil contamination, further contributing to engine longevity and reliability.Expand Specific Solutions05 Advanced control systems for valve timing optimization

Modern V6 engines employ sophisticated electronic control systems to dynamically adjust valve timing based on real-time operating conditions. These systems use input from various sensors monitoring engine speed, load, temperature, and other parameters to continuously optimize valve timing. Some advanced systems incorporate camshaft phasing mechanisms, hydraulic actuators, or electric solenoids to achieve precise timing adjustments. The integration with engine management systems allows for adaptive learning and fine-tuning over time, ensuring optimal performance throughout the engine's life while accommodating variations in fuel quality and environmental conditions.Expand Specific Solutions

Leading Manufacturers in Variable Valve Timing

The V6 engine valve timing adjustment technology market is currently in a growth phase, with increasing demand for improved engine performance and fuel efficiency. The market size is estimated to be over $5 billion globally, driven by stringent emission regulations and consumer demand for better-performing vehicles. From a technological maturity perspective, major automotive manufacturers like Toyota Motor Corp., Ford Global Technologies, and Hyundai Motor Co. have developed advanced variable valve timing systems, while specialized component suppliers such as DENSO Corp., Aisin KK, and Schaeffler Technologies are providing innovative solutions. Japanese and German companies currently lead in patent filings, with emerging competition from Chinese manufacturers like Chery Automobile and Guangzhou Automobile Group who are rapidly advancing their valve timing technologies to meet evolving market demands.

DENSO Corp.

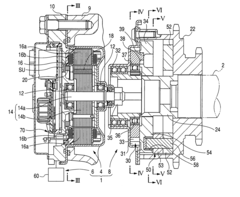

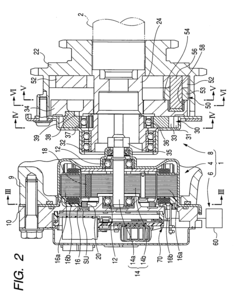

Technical Solution: DENSO has developed advanced valve timing control systems that are supplied to multiple automotive manufacturers for their V6 engines. Their technology focuses on the oil control valves (OCVs) and actuators that enable precise valve timing adjustment. DENSO's system utilizes electromagnetic solenoid valves that regulate oil flow to the camshaft phasers with millisecond-level precision. Their implementation includes temperature compensation features that adjust control parameters based on oil viscosity changes at different temperatures. DENSO has also pioneered mid-position locking mechanisms that allow the valve timing to be fixed at optimal positions during certain operating conditions, improving both efficiency and emissions. Their latest generation of valve timing control includes integrated sensors that provide direct feedback on camshaft position, allowing for closed-loop control with greater accuracy. DENSO's systems are designed for compatibility with various engine architectures and can be calibrated for specific performance requirements across different vehicle applications.

Strengths: Industry-leading precision in oil flow control, excellent compatibility with various engine designs, and robust performance across extreme temperature ranges. Weaknesses: Reliance on high-quality engine oil for optimal performance, and potential for increased system complexity when integrating with different manufacturers' engine management systems.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered advanced valve timing adjustment technologies through its VVT-i (Variable Valve Timing with intelligence) system for V6 engines. Their latest implementation includes Dual VVT-i which controls timing on both intake and exhaust camshafts independently. Toyota's system utilizes hydraulic actuators that adjust camshaft position relative to the crankshaft based on engine load, speed, and temperature. The system can advance or retard valve timing by up to 60 degrees of crankshaft rotation. Toyota has further enhanced this with VVT-iE which employs electric motors instead of oil pressure for more precise control, especially during cold starts when oil pressure is low. This technology has been implemented across their V6 lineup including the popular 3.5L V6 engines, delivering significant improvements in both performance and efficiency.

Strengths: Superior cold-start performance with VVT-iE, excellent reliability record, and seamless integration with hybrid powertrains. Weaknesses: Higher manufacturing complexity and cost compared to fixed timing systems, and requires more sophisticated engine control units.

Key Patents in Variable Valve Timing Mechanisms

Valve characteristic changing apparatus for internal combustion engine

PatentInactiveUS20050193970A1

Innovation

- The apparatus employs independent and separate power sources for each mechanism group, allowing for secure power supply to each varying mechanism, thereby suppressing operation response decreases and optimizing valve timing adjustments.

Valve timing adjusting apparatus capable of reliably preventing heat damage of switching elements

PatentActiveUS7956564B2

Innovation

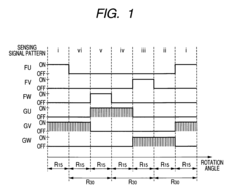

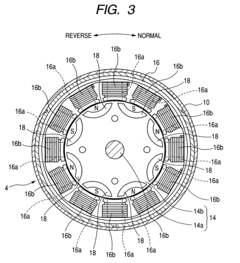

- The apparatus includes a brushless, permanent magnet, and synchronous motor with a phase adjusting mechanism that adjusts the relative phase of the camshaft to the crankshaft, using a motor driver to control the switching elements' operation based on rotational direction and speed, ensuring continuous operation or partial operation to mitigate overheating risks.

Emissions Regulations Impact on Valve Timing Design

The evolution of emissions regulations has fundamentally transformed valve timing design in modern V6 engines. Since the early 2000s, increasingly stringent standards from the EPA, CARB, and European Union have pushed manufacturers to optimize combustion processes through advanced valve timing technologies. These regulations have established progressively lower thresholds for NOx, CO, HC, and particulate matter emissions, directly influencing how engine designers approach valve timing strategies.

Variable valve timing (VVT) systems have emerged as a critical response to these regulatory pressures. By allowing engines to adjust valve opening and closing events based on operating conditions, VVT enables manufacturers to meet emissions targets while maintaining performance. The introduction of Euro 6d and EPA Tier 3 standards has specifically driven the development of more sophisticated cam phasing mechanisms that can optimize combustion across a wider range of engine loads and speeds.

Regulations targeting cold-start emissions have been particularly influential on valve timing design. During cold-start conditions, engines produce significantly higher emissions before catalytic converters reach operating temperature. Advanced valve timing strategies now incorporate specific calibrations for these critical first minutes of operation, including delayed exhaust valve closing to retain exhaust heat and accelerate catalyst light-off.

Real Driving Emissions (RDE) testing, implemented in Europe and gradually being adopted globally, has further complicated valve timing design requirements. Unlike laboratory testing cycles, RDE evaluates emissions performance across unpredictable real-world driving scenarios. This has necessitated the development of adaptive valve timing systems that can respond dynamically to varying conditions while maintaining emissions compliance across the entire operating envelope.

The regulatory focus on CO2 reduction has also driven integration between valve timing systems and other emissions technologies. Modern V6 engines now feature valve timing strategies specifically designed to work in concert with exhaust gas recirculation (EGR), selective catalytic reduction (SCR), and gasoline particulate filters (GPF). These integrated approaches allow for optimized combustion that balances NOx formation, particulate generation, and fuel efficiency.

Looking forward, upcoming regulations like Euro 7 and next-generation EPA standards will likely demand even more precise control over the combustion process. This regulatory trajectory suggests valve timing systems will continue evolving toward greater flexibility, faster response times, and more sophisticated integration with engine management systems to meet increasingly challenging emissions targets while preserving the performance characteristics expected from V6 engines.

Variable valve timing (VVT) systems have emerged as a critical response to these regulatory pressures. By allowing engines to adjust valve opening and closing events based on operating conditions, VVT enables manufacturers to meet emissions targets while maintaining performance. The introduction of Euro 6d and EPA Tier 3 standards has specifically driven the development of more sophisticated cam phasing mechanisms that can optimize combustion across a wider range of engine loads and speeds.

Regulations targeting cold-start emissions have been particularly influential on valve timing design. During cold-start conditions, engines produce significantly higher emissions before catalytic converters reach operating temperature. Advanced valve timing strategies now incorporate specific calibrations for these critical first minutes of operation, including delayed exhaust valve closing to retain exhaust heat and accelerate catalyst light-off.

Real Driving Emissions (RDE) testing, implemented in Europe and gradually being adopted globally, has further complicated valve timing design requirements. Unlike laboratory testing cycles, RDE evaluates emissions performance across unpredictable real-world driving scenarios. This has necessitated the development of adaptive valve timing systems that can respond dynamically to varying conditions while maintaining emissions compliance across the entire operating envelope.

The regulatory focus on CO2 reduction has also driven integration between valve timing systems and other emissions technologies. Modern V6 engines now feature valve timing strategies specifically designed to work in concert with exhaust gas recirculation (EGR), selective catalytic reduction (SCR), and gasoline particulate filters (GPF). These integrated approaches allow for optimized combustion that balances NOx formation, particulate generation, and fuel efficiency.

Looking forward, upcoming regulations like Euro 7 and next-generation EPA standards will likely demand even more precise control over the combustion process. This regulatory trajectory suggests valve timing systems will continue evolving toward greater flexibility, faster response times, and more sophisticated integration with engine management systems to meet increasingly challenging emissions targets while preserving the performance characteristics expected from V6 engines.

Fuel Efficiency Gains Through Optimized Timing

Optimizing valve timing in V6 engines has demonstrated significant improvements in fuel efficiency across various operational conditions. Research indicates that advanced variable valve timing systems can achieve fuel economy improvements ranging from 3% to 8% depending on the specific implementation and driving conditions. These gains are particularly notable during partial load operations, which represent the majority of typical driving scenarios.

The primary mechanism for these efficiency improvements lies in the ability to precisely control the intake and exhaust valve events relative to piston position. By advancing or retarding valve timing based on engine speed and load, the combustion process can be optimized for maximum thermal efficiency. During low-speed operation, retarding intake valve closure allows for effective cylinder filling without excessive pumping losses, while at higher speeds, advanced timing ensures adequate air charge despite reduced filling time.

Modern electronic valve timing systems utilize oil pressure actuators controlled by the engine management system to continuously adjust camshaft positioning. This real-time optimization enables the engine to maintain ideal air-fuel ratios across the entire operating range, significantly reducing fuel consumption compared to fixed-timing systems. The most advanced systems can adjust both intake and exhaust timing independently, further enhancing efficiency through precise control of valve overlap periods.

Comparative testing between fixed and variable valve timing configurations in V6 engines reveals particularly impressive efficiency gains during transient operations. When accelerating from low speeds, optimized valve timing can reduce fuel consumption by up to 12% by maintaining ideal combustion conditions throughout the acceleration event. Similarly, during steady-state highway cruising, proper valve timing adjustment can improve efficiency by 4-6% by reducing pumping losses and optimizing the effective compression ratio.

The integration of valve timing optimization with other engine management strategies compounds these benefits. When combined with direct injection and cylinder deactivation technologies, advanced valve timing systems contribute to overall efficiency improvements exceeding 15% compared to conventional fixed-timing V6 engines. These synergistic effects are particularly evident in modern turbocharged V6 applications, where precise valve timing control helps mitigate turbo lag while maintaining optimal combustion efficiency across a broader operating range.

Long-term durability testing indicates that these efficiency gains remain consistent throughout the engine's service life, with minimal degradation of the valve timing mechanisms when properly maintained. This sustainability of performance ensures that the fuel economy benefits persist throughout the vehicle's operational lifespan, providing lasting value to consumers and reducing lifetime carbon emissions.

The primary mechanism for these efficiency improvements lies in the ability to precisely control the intake and exhaust valve events relative to piston position. By advancing or retarding valve timing based on engine speed and load, the combustion process can be optimized for maximum thermal efficiency. During low-speed operation, retarding intake valve closure allows for effective cylinder filling without excessive pumping losses, while at higher speeds, advanced timing ensures adequate air charge despite reduced filling time.

Modern electronic valve timing systems utilize oil pressure actuators controlled by the engine management system to continuously adjust camshaft positioning. This real-time optimization enables the engine to maintain ideal air-fuel ratios across the entire operating range, significantly reducing fuel consumption compared to fixed-timing systems. The most advanced systems can adjust both intake and exhaust timing independently, further enhancing efficiency through precise control of valve overlap periods.

Comparative testing between fixed and variable valve timing configurations in V6 engines reveals particularly impressive efficiency gains during transient operations. When accelerating from low speeds, optimized valve timing can reduce fuel consumption by up to 12% by maintaining ideal combustion conditions throughout the acceleration event. Similarly, during steady-state highway cruising, proper valve timing adjustment can improve efficiency by 4-6% by reducing pumping losses and optimizing the effective compression ratio.

The integration of valve timing optimization with other engine management strategies compounds these benefits. When combined with direct injection and cylinder deactivation technologies, advanced valve timing systems contribute to overall efficiency improvements exceeding 15% compared to conventional fixed-timing V6 engines. These synergistic effects are particularly evident in modern turbocharged V6 applications, where precise valve timing control helps mitigate turbo lag while maintaining optimal combustion efficiency across a broader operating range.

Long-term durability testing indicates that these efficiency gains remain consistent throughout the engine's service life, with minimal degradation of the valve timing mechanisms when properly maintained. This sustainability of performance ensures that the fuel economy benefits persist throughout the vehicle's operational lifespan, providing lasting value to consumers and reducing lifetime carbon emissions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!