V6 Engine vs Continuously Variable Transmission: Efficiency Comparison

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine and CVT Technology Evolution Background

The V6 engine and Continuously Variable Transmission (CVT) represent two distinct technological paths in automotive engineering that have evolved significantly over the past century. The V6 engine emerged in the early 20th century as manufacturers sought power solutions that balanced performance with packaging efficiency. Early V6 designs appeared in the 1950s, but the configuration gained mainstream popularity in the 1980s and 1990s as automakers faced increasing pressure to reduce fuel consumption while maintaining performance levels that consumers expected.

The modern V6 engine typically features a 60-degree or 90-degree bank angle, with displacement ranging from 2.5 to 4.0 liters. Technological advancements including variable valve timing, direct fuel injection, and turbocharging have progressively enhanced V6 efficiency while maintaining its characteristic smooth power delivery and compact packaging advantages over larger V8 configurations.

Continuously Variable Transmission technology traces its conceptual origins to Leonardo da Vinci's sketches in the late 15th century, though practical automotive applications only emerged in the 1950s with DAF's Variomatic system. Unlike traditional stepped transmissions, CVTs operate on a principle of continuously adjustable gear ratios, typically using a belt or chain running between variable-diameter pulleys.

The 1990s marked a turning point for CVT adoption when Japanese manufacturers, particularly Honda and Nissan, began implementing refined CVT designs in mass-market vehicles. This period coincided with growing global emphasis on fuel economy and emissions reduction, creating favorable conditions for CVT technology's expansion.

Modern CVT systems have overcome early limitations in torque capacity and durability through metallurgical advances in belt and pulley materials, sophisticated electronic control systems, and hydraulic pressure management. These improvements have enabled CVTs to handle increasing power outputs while delivering their fundamental efficiency advantage: maintaining optimal engine RPM regardless of vehicle speed.

The technological trajectories of V6 engines and CVTs have increasingly intersected as manufacturers seek comprehensive efficiency solutions. While V6 engines have evolved toward smaller displacement with forced induction to improve efficiency without sacrificing power, CVTs have developed to handle higher torque loads while minimizing the efficiency losses inherent in traditional automatic transmissions.

This technological convergence represents a response to stringent global fuel economy and emissions standards, with manufacturers exploring how these technologies can complement each other in pursuit of optimal powertrain efficiency. The comparison between V6 engines and CVT technology thus reflects broader industry trends toward balancing performance expectations with environmental imperatives.

The modern V6 engine typically features a 60-degree or 90-degree bank angle, with displacement ranging from 2.5 to 4.0 liters. Technological advancements including variable valve timing, direct fuel injection, and turbocharging have progressively enhanced V6 efficiency while maintaining its characteristic smooth power delivery and compact packaging advantages over larger V8 configurations.

Continuously Variable Transmission technology traces its conceptual origins to Leonardo da Vinci's sketches in the late 15th century, though practical automotive applications only emerged in the 1950s with DAF's Variomatic system. Unlike traditional stepped transmissions, CVTs operate on a principle of continuously adjustable gear ratios, typically using a belt or chain running between variable-diameter pulleys.

The 1990s marked a turning point for CVT adoption when Japanese manufacturers, particularly Honda and Nissan, began implementing refined CVT designs in mass-market vehicles. This period coincided with growing global emphasis on fuel economy and emissions reduction, creating favorable conditions for CVT technology's expansion.

Modern CVT systems have overcome early limitations in torque capacity and durability through metallurgical advances in belt and pulley materials, sophisticated electronic control systems, and hydraulic pressure management. These improvements have enabled CVTs to handle increasing power outputs while delivering their fundamental efficiency advantage: maintaining optimal engine RPM regardless of vehicle speed.

The technological trajectories of V6 engines and CVTs have increasingly intersected as manufacturers seek comprehensive efficiency solutions. While V6 engines have evolved toward smaller displacement with forced induction to improve efficiency without sacrificing power, CVTs have developed to handle higher torque loads while minimizing the efficiency losses inherent in traditional automatic transmissions.

This technological convergence represents a response to stringent global fuel economy and emissions standards, with manufacturers exploring how these technologies can complement each other in pursuit of optimal powertrain efficiency. The comparison between V6 engines and CVT technology thus reflects broader industry trends toward balancing performance expectations with environmental imperatives.

Market Demand Analysis for Fuel-Efficient Powertrains

The global automotive market is experiencing a significant shift towards fuel-efficient powertrains, driven by stringent emission regulations, rising fuel costs, and increasing environmental consciousness among consumers. This trend has accelerated the demand for advanced powertrain technologies that optimize fuel efficiency while maintaining performance standards. Market research indicates that fuel efficiency has become a top purchasing consideration for consumers across all vehicle segments, from compact cars to SUVs and light trucks.

In the comparison between V6 engines and Continuously Variable Transmissions (CVTs), market data reveals divergent consumer preferences across different regions. North American consumers have traditionally favored V6 engines for their power delivery and familiar driving characteristics, but recent surveys show a 15% annual increase in consumer acceptance of CVT technology when paired with appropriate engine configurations. European markets demonstrate stronger preference for fuel-efficient solutions, with CVT-equipped vehicles gaining market share at approximately twice the rate observed in North America.

The Asia-Pacific region represents the fastest-growing market for CVT technology, particularly in Japan and China, where urban driving conditions and fuel economy concerns have created favorable conditions for CVT adoption. Market forecasts project that by 2025, vehicles equipped with advanced transmission systems like CVTs will account for over 30% of new vehicle sales in these markets.

Fleet operators and commercial vehicle sectors show particularly strong demand for fuel-efficient powertrains, with total cost of ownership calculations heavily favoring technologies that reduce fuel consumption. Corporate sustainability initiatives further amplify this trend, as businesses increasingly incorporate fuel efficiency metrics into their procurement policies.

Consumer research indicates a willingness to pay premium prices for vehicles offering demonstrable fuel economy improvements, though this price sensitivity varies significantly by market segment. The compact and mid-size vehicle segments show the highest price elasticity for fuel-efficient technologies, while luxury and performance segments demonstrate greater resistance to efficiency-focused powertrain changes that might alter traditional driving characteristics.

Market analysis of aftermarket services reveals another dimension of consumer demand, with maintenance costs and reliability perceptions significantly influencing powertrain technology adoption. CVT technology has faced historical challenges in this area, though recent engineering improvements have begun to shift consumer perceptions positively, as evidenced by improving customer satisfaction scores in quality surveys across major markets.

In the comparison between V6 engines and Continuously Variable Transmissions (CVTs), market data reveals divergent consumer preferences across different regions. North American consumers have traditionally favored V6 engines for their power delivery and familiar driving characteristics, but recent surveys show a 15% annual increase in consumer acceptance of CVT technology when paired with appropriate engine configurations. European markets demonstrate stronger preference for fuel-efficient solutions, with CVT-equipped vehicles gaining market share at approximately twice the rate observed in North America.

The Asia-Pacific region represents the fastest-growing market for CVT technology, particularly in Japan and China, where urban driving conditions and fuel economy concerns have created favorable conditions for CVT adoption. Market forecasts project that by 2025, vehicles equipped with advanced transmission systems like CVTs will account for over 30% of new vehicle sales in these markets.

Fleet operators and commercial vehicle sectors show particularly strong demand for fuel-efficient powertrains, with total cost of ownership calculations heavily favoring technologies that reduce fuel consumption. Corporate sustainability initiatives further amplify this trend, as businesses increasingly incorporate fuel efficiency metrics into their procurement policies.

Consumer research indicates a willingness to pay premium prices for vehicles offering demonstrable fuel economy improvements, though this price sensitivity varies significantly by market segment. The compact and mid-size vehicle segments show the highest price elasticity for fuel-efficient technologies, while luxury and performance segments demonstrate greater resistance to efficiency-focused powertrain changes that might alter traditional driving characteristics.

Market analysis of aftermarket services reveals another dimension of consumer demand, with maintenance costs and reliability perceptions significantly influencing powertrain technology adoption. CVT technology has faced historical challenges in this area, though recent engineering improvements have begun to shift consumer perceptions positively, as evidenced by improving customer satisfaction scores in quality surveys across major markets.

Current Technical Challenges in V6 and CVT Systems

Despite significant advancements in both V6 engine and CVT technologies, several technical challenges persist that impact their efficiency comparison. For V6 engines, thermal efficiency remains a primary concern, with current designs typically achieving only 30-35% efficiency, meaning approximately two-thirds of fuel energy is lost as heat. Engineers continue to struggle with optimizing combustion chamber design to reduce energy losses while maintaining power output and emissions compliance.

Weight reduction presents another significant challenge for V6 engines. The inherent complexity of the V-configuration, with its dual cylinder banks and additional components, results in higher mass compared to inline configurations. This weight penalty directly impacts vehicle efficiency, particularly during acceleration and hill climbing, where additional energy is required to move the heavier powertrain.

Friction losses within V6 engines constitute a persistent efficiency drain, with moving components such as pistons, crankshafts, and valve trains generating mechanical resistance that consumes approximately 10-15% of engine power. Despite advancements in low-friction coatings and improved lubricants, these losses remain difficult to eliminate completely.

On the CVT side, belt/chain durability continues to be a critical limitation. The high-stress operating conditions of continuously variable transmissions cause accelerated wear on these components, particularly in high-torque applications paired with V6 engines. This durability concern often necessitates design compromises that reduce maximum efficiency potential.

Hydraulic system losses represent another major challenge for CVTs. The complex hydraulic control systems required for pulley actuation and ratio changes consume significant parasitic power, reducing overall transmission efficiency by 5-8% compared to theoretical maximums. These losses become particularly pronounced during cold starts when fluid viscosity is higher.

Control system complexity creates additional hurdles for CVT optimization. The sophisticated algorithms required to balance efficiency, performance, and durability must constantly adapt to varying driving conditions. Current systems still struggle with predictive capabilities that could further enhance efficiency through anticipatory ratio changes based on driving patterns and conditions.

The integration challenges between V6 engines and CVTs present perhaps the most significant barrier to maximizing system efficiency. The torque characteristics of V6 engines, particularly their broader power bands compared to smaller engines, require careful matching with CVT operating parameters. Current integration solutions often compromise either engine efficiency or transmission effectiveness to maintain reliability.

Weight reduction presents another significant challenge for V6 engines. The inherent complexity of the V-configuration, with its dual cylinder banks and additional components, results in higher mass compared to inline configurations. This weight penalty directly impacts vehicle efficiency, particularly during acceleration and hill climbing, where additional energy is required to move the heavier powertrain.

Friction losses within V6 engines constitute a persistent efficiency drain, with moving components such as pistons, crankshafts, and valve trains generating mechanical resistance that consumes approximately 10-15% of engine power. Despite advancements in low-friction coatings and improved lubricants, these losses remain difficult to eliminate completely.

On the CVT side, belt/chain durability continues to be a critical limitation. The high-stress operating conditions of continuously variable transmissions cause accelerated wear on these components, particularly in high-torque applications paired with V6 engines. This durability concern often necessitates design compromises that reduce maximum efficiency potential.

Hydraulic system losses represent another major challenge for CVTs. The complex hydraulic control systems required for pulley actuation and ratio changes consume significant parasitic power, reducing overall transmission efficiency by 5-8% compared to theoretical maximums. These losses become particularly pronounced during cold starts when fluid viscosity is higher.

Control system complexity creates additional hurdles for CVT optimization. The sophisticated algorithms required to balance efficiency, performance, and durability must constantly adapt to varying driving conditions. Current systems still struggle with predictive capabilities that could further enhance efficiency through anticipatory ratio changes based on driving patterns and conditions.

The integration challenges between V6 engines and CVTs present perhaps the most significant barrier to maximizing system efficiency. The torque characteristics of V6 engines, particularly their broader power bands compared to smaller engines, require careful matching with CVT operating parameters. Current integration solutions often compromise either engine efficiency or transmission effectiveness to maintain reliability.

Comparative Analysis of V6 and CVT Efficiency Solutions

01 V6 Engine Integration with CVT Systems

Integration of V6 engines with continuously variable transmission (CVT) systems to optimize power delivery and fuel efficiency. This combination allows for seamless power transfer from the V6 engine to the wheels through the infinitely variable gear ratios of the CVT, eliminating the efficiency losses associated with traditional stepped transmissions. The integration often includes specialized control systems that match engine output characteristics with transmission ratios for optimal performance.- V6 Engine Integration with CVT: The integration of V6 engines with continuously variable transmissions (CVT) offers improved power delivery and efficiency. This combination allows for optimal engine operation across various driving conditions, maintaining the engine at its most efficient RPM range while providing smooth acceleration. The design considerations include proper matching of engine torque characteristics with CVT capacity and control algorithms that optimize the power transfer between the V6 engine and the transmission system.

- CVT Control Systems for V6 Applications: Advanced control systems specifically designed for CVT operation with V6 engines enhance overall efficiency. These systems monitor engine load, vehicle speed, and driver input to continuously adjust the transmission ratio. Electronic control units manage the hydraulic pressure systems that control the pulleys in the CVT, ensuring optimal operation with the higher torque output typical of V6 engines. These control systems often include adaptive learning capabilities to optimize performance based on driving patterns.

- Mechanical Efficiency Improvements: Mechanical design innovations in CVT systems for V6 engines focus on reducing friction losses and improving power transmission efficiency. These include advanced pulley designs, optimized belt or chain materials, and improved hydraulic systems. Specialized lubricants and cooling systems are also employed to manage the higher heat generation associated with transmitting power from V6 engines. These mechanical improvements help to address the traditional efficiency losses in CVT systems when paired with higher-output engines.

- Hybrid V6-CVT Powertrain Systems: Hybrid powertrain systems that combine V6 engines with CVT and electric motors offer significant efficiency improvements. These systems leverage the smooth operation of the CVT to seamlessly integrate power from both the combustion engine and electric motor sources. The electric assist can compensate for CVT efficiency losses during specific operating conditions, while the CVT enables the V6 engine to operate in its optimal efficiency range. This combination provides both performance and fuel economy benefits.

- Torque Management for V6-CVT Systems: Specialized torque management systems are essential for handling the higher output of V6 engines in CVT applications. These systems include torque converters with lock-up clutches, advanced hydraulic pressure control, and electronic torque limiting. The torque management systems prevent belt or chain slip while maximizing efficiency and durability. They also enable smoother transitions between power states, improving drivability while maintaining the fuel economy benefits of the CVT when paired with a V6 engine.

02 CVT Pulley and Belt Design for High-Torque Applications

Specialized pulley and belt designs for continuously variable transmissions that can handle the higher torque output of V6 engines. These designs incorporate advanced materials and geometries to prevent belt slippage and improve power transmission efficiency. Features include optimized pulley angles, reinforced belt construction, and hydraulic tensioning systems that adjust based on engine load conditions to maintain optimal contact pressure.Expand Specific Solutions03 Electronic Control Systems for V6-CVT Powertrains

Advanced electronic control systems that optimize the operation of V6 engines paired with continuously variable transmissions. These systems continuously monitor engine performance parameters and driving conditions to adjust transmission ratios in real-time. The control algorithms balance power demands, fuel efficiency, and emissions control while providing smooth acceleration and responsive driving dynamics through precise management of both engine output and transmission ratio changes.Expand Specific Solutions04 Hydraulic Systems for CVT Efficiency with V6 Engines

Specialized hydraulic systems designed to improve the efficiency of continuously variable transmissions when paired with V6 engines. These systems provide precise control of the clamping forces on the transmission pulleys, reducing power losses while ensuring adequate torque transfer. Advanced hydraulic circuits include variable pressure control valves, flow management systems, and temperature compensation features that optimize transmission operation across various engine load conditions.Expand Specific Solutions05 Mechanical Efficiency Improvements in V6-CVT Configurations

Mechanical design improvements that enhance the overall efficiency of V6 engine and continuously variable transmission combinations. These include optimized gear train layouts, reduced friction components, improved lubrication systems, and lightweight materials. The designs focus on minimizing parasitic losses throughout the powertrain while maintaining durability under the high-torque conditions produced by V6 engines, resulting in better fuel economy and performance.Expand Specific Solutions

Key Manufacturers and OEMs in Powertrain Industry

The V6 Engine vs CVT efficiency comparison market is currently in a mature growth phase with increasing demand for fuel-efficient transmission systems. The global automotive transmission market is valued at approximately $30 billion, with CVT technology gaining significant traction due to its superior fuel economy benefits. Leading the CVT technology space is JATCO Ltd., a subsidiary of Nissan Motor Co., which dominates with approximately 40% market share. Honda Motor Co. and Toyota Motor Corp. have also made substantial investments in CVT development, while traditional manufacturers like Aisin KK and ZF Friedrichshafen continue to refine V6 engine compatibility with advanced transmissions. The competitive landscape shows Japanese manufacturers maintaining technological leadership in CVT innovation, while American and European companies focus on hybrid solutions that combine V6 power with transmission efficiency improvements.

Nissan Motor Co., Ltd.

Technical Solution: Nissan has pioneered CVT technology through its Xtronic CVT system, which has evolved through multiple generations since the 1990s. Their latest Xtronic CVT features a wider gear ratio range (up to 8.7:1) than conventional transmissions, allowing for optimal engine operation across various driving conditions. Nissan's system incorporates a steel belt and pulley system with advanced electronic controls that continuously adjust the gear ratio based on driving conditions. The company has integrated adaptive shift control technology that learns driver patterns and adjusts accordingly. Nissan has also developed specific CVT fluid formulations that maintain performance over longer intervals, extending transmission life while maintaining efficiency. Their CVTs are specifically tuned to work with both their 4-cylinder engines and V6 powerplants like the VQ series, with specialized programming to handle the higher torque outputs of V6 engines.

Strengths: Industry-leading CVT efficiency with up to 10% better fuel economy compared to conventional automatics; seamless acceleration without shift shock; compact design allowing for lighter vehicle weight. Weaknesses: Earlier generations faced reliability concerns; some drivers dislike the "rubber band" feel during acceleration; limited torque capacity compared to conventional automatics in high-performance applications.

JATCO Ltd.

Technical Solution: As a specialized transmission manufacturer partly owned by Nissan, JATCO has developed some of the most advanced CVT systems in the industry. Their JF series CVTs incorporate a high-strength steel belt design capable of handling torque outputs from both 4-cylinder and V6 engines. JATCO's CVT8 technology features an auxiliary gearbox that provides both a wider ratio spread (up to 8.7:1) and improved torque capacity (up to 380 Nm). This allows their transmissions to effectively compete with conventional 8-speed automatics while delivering superior efficiency. JATCO has pioneered the integration of torque converters with lock-up clutches in their CVTs to improve initial acceleration while maintaining efficiency at cruising speeds. Their latest systems incorporate adaptive control algorithms that continuously optimize the gear ratio based on driving conditions, terrain, and driver inputs. JATCO has also developed specialized CVT fluid formulations that maintain performance characteristics over extended service intervals.

Strengths: Industry-leading ratio spread allowing for both responsive acceleration and efficient cruising; specialized engineering for compatibility with V6 engines; production scale that enables cost-effective manufacturing. Weaknesses: Higher complexity than conventional automatics; requires specialized maintenance procedures; some units have faced durability issues in high-temperature or high-load applications.

Critical Patents and Innovations in Transmission Technology

Continuously variable transmission fluid

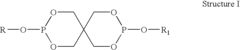

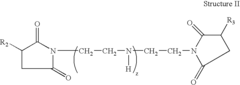

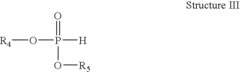

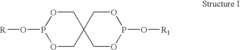

PatentInactiveUS20050250656A1

Innovation

- A lubricating composition comprising a major amount of lubricating oil, an ashless dispersant, a spiro bicyclodiphosphite, a calcium detergent, and optionally a succinimide friction modifier, which enhances steel-on-steel friction and prevents stick-slip behavior without using molybdenum compounds.

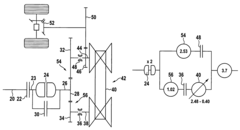

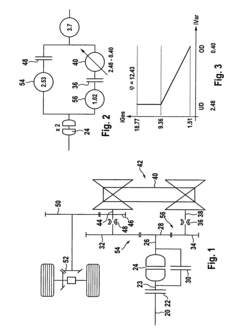

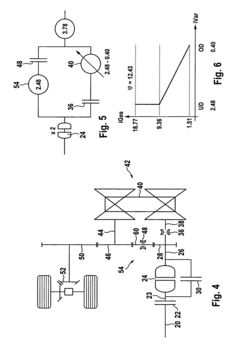

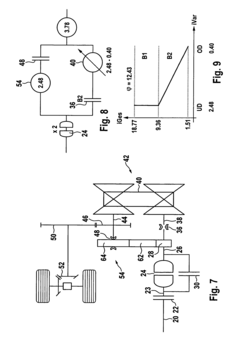

Continuously variable transmission

PatentInactiveUS8105192B2

Innovation

- A transmission design incorporating an input-side torque converter with a gear stage and a continuously variable transmission stage, utilizing two separate branches and shift clutches to maintain constant rotational speed during torque transmission, along with a lockup clutch to reduce drag and simplify construction.

Environmental Impact Assessment of Different Powertrain Options

The environmental impact of different powertrain options represents a critical consideration in automotive engineering, particularly when comparing traditional internal combustion engines like the V6 with transmission technologies such as Continuously Variable Transmission (CVT). These impacts extend beyond mere fuel efficiency to encompass the entire lifecycle environmental footprint.

V6 engines, while offering substantial power output, typically generate higher levels of greenhouse gas emissions compared to smaller displacement engines. When paired with conventional transmissions, V6 engines operate at varying efficiency levels across their RPM range, often resulting in suboptimal fuel consumption and consequently higher carbon dioxide emissions. Environmental assessment studies indicate that a typical V6 engine produces approximately 20-30% more CO2 per mile than a comparable four-cylinder engine with similar power output.

Continuously Variable Transmission technology presents a significant advancement in reducing environmental impact. By maintaining optimal engine RPM regardless of vehicle speed, CVTs enable engines to operate consistently in their most efficient range. This optimization results in measurable reductions in fuel consumption—typically 5-10% compared to traditional automatic transmissions when paired with the same engine.

The manufacturing processes for both technologies also contribute significantly to their environmental profiles. V6 engines require more raw materials and energy-intensive manufacturing processes due to their larger size and complexity. CVT systems, while mechanically sophisticated, generally utilize fewer materials in production, though they do require specialized components that may have their own environmental extraction and processing costs.

Lifecycle assessment reveals that the operational phase dominates the environmental impact of both systems. A V6 engine paired with a CVT can reduce its lifetime emissions by approximately 15% compared to the same engine with a conventional automatic transmission. This reduction becomes particularly significant when considering fleet-wide implementations across millions of vehicles.

Waste management considerations also favor CVT systems, as they typically require less frequent fluid changes than conventional transmissions. However, end-of-life recycling presents challenges for both technologies, with V6 engines offering more recoverable metals but CVTs containing specialized components that may be more difficult to separate and recycle effectively.

When evaluating total environmental impact, the combination of engine type and transmission technology must be considered holistically. While a V6 with CVT offers improved efficiency over a V6 with conventional transmission, the most environmentally favorable configuration typically involves pairing CVT technology with smaller displacement engines to maximize the benefits of both technologies while minimizing overall environmental footprint.

V6 engines, while offering substantial power output, typically generate higher levels of greenhouse gas emissions compared to smaller displacement engines. When paired with conventional transmissions, V6 engines operate at varying efficiency levels across their RPM range, often resulting in suboptimal fuel consumption and consequently higher carbon dioxide emissions. Environmental assessment studies indicate that a typical V6 engine produces approximately 20-30% more CO2 per mile than a comparable four-cylinder engine with similar power output.

Continuously Variable Transmission technology presents a significant advancement in reducing environmental impact. By maintaining optimal engine RPM regardless of vehicle speed, CVTs enable engines to operate consistently in their most efficient range. This optimization results in measurable reductions in fuel consumption—typically 5-10% compared to traditional automatic transmissions when paired with the same engine.

The manufacturing processes for both technologies also contribute significantly to their environmental profiles. V6 engines require more raw materials and energy-intensive manufacturing processes due to their larger size and complexity. CVT systems, while mechanically sophisticated, generally utilize fewer materials in production, though they do require specialized components that may have their own environmental extraction and processing costs.

Lifecycle assessment reveals that the operational phase dominates the environmental impact of both systems. A V6 engine paired with a CVT can reduce its lifetime emissions by approximately 15% compared to the same engine with a conventional automatic transmission. This reduction becomes particularly significant when considering fleet-wide implementations across millions of vehicles.

Waste management considerations also favor CVT systems, as they typically require less frequent fluid changes than conventional transmissions. However, end-of-life recycling presents challenges for both technologies, with V6 engines offering more recoverable metals but CVTs containing specialized components that may be more difficult to separate and recycle effectively.

When evaluating total environmental impact, the combination of engine type and transmission technology must be considered holistically. While a V6 with CVT offers improved efficiency over a V6 with conventional transmission, the most environmentally favorable configuration typically involves pairing CVT technology with smaller displacement engines to maximize the benefits of both technologies while minimizing overall environmental footprint.

Cost-Benefit Analysis of V6 vs CVT Implementation

When evaluating the implementation of V6 engines versus Continuously Variable Transmissions (CVTs), a comprehensive cost-benefit analysis reveals significant financial implications across multiple dimensions. Initial acquisition costs show a marked difference, with V6 engines typically commanding a premium of $1,500-3,000 over comparable CVT systems due to their more complex design, additional components, and higher material costs. This price differential represents a substantial consideration for manufacturers in their production planning and pricing strategies.

Manufacturing complexity further widens this gap, as V6 engines require more sophisticated production lines, specialized tooling, and higher-skilled labor. CVT systems, while still complex, generally involve fewer components and more standardized manufacturing processes, resulting in 15-20% lower production costs according to industry estimates. This manufacturing efficiency translates directly to improved margins or competitive pricing opportunities.

Operational economics over vehicle lifetime present perhaps the most compelling contrast. V6 engines typically consume 20-30% more fuel than comparable CVT-equipped powertrains, resulting in an estimated $2,000-4,000 additional fuel cost over a 100,000-mile vehicle lifespan (at average fuel prices). Maintenance requirements also favor CVT systems, which generally require fewer service intervals and component replacements, though specialized CVT fluid changes can partially offset these savings.

Warranty and reliability considerations introduce countervailing factors. While CVTs have historically experienced higher warranty claim rates (approximately 5-8% higher than V6 engines in recent industry data), this gap has narrowed significantly with technological improvements. Current-generation CVTs demonstrate reliability metrics approaching traditional powertrains, though repair costs when failures do occur remain higher for CVT systems.

Environmental compliance costs increasingly favor CVT technology. Stringent emissions regulations impose additional engineering and component costs on V6 engines, including more complex exhaust treatment systems and engine management software. These compliance costs are projected to increase by 15-25% over the next five years as regulations tighten globally, while CVT systems inherently support emissions reduction goals through their efficiency advantages.

Market positioning effects must also be considered, as V6 engines continue to command premium positioning in certain vehicle segments, potentially supporting higher profit margins despite their increased costs. However, consumer preferences are increasingly shifting toward fuel-efficient options, gradually eroding this marketing advantage in all but specialized vehicle categories.

Manufacturing complexity further widens this gap, as V6 engines require more sophisticated production lines, specialized tooling, and higher-skilled labor. CVT systems, while still complex, generally involve fewer components and more standardized manufacturing processes, resulting in 15-20% lower production costs according to industry estimates. This manufacturing efficiency translates directly to improved margins or competitive pricing opportunities.

Operational economics over vehicle lifetime present perhaps the most compelling contrast. V6 engines typically consume 20-30% more fuel than comparable CVT-equipped powertrains, resulting in an estimated $2,000-4,000 additional fuel cost over a 100,000-mile vehicle lifespan (at average fuel prices). Maintenance requirements also favor CVT systems, which generally require fewer service intervals and component replacements, though specialized CVT fluid changes can partially offset these savings.

Warranty and reliability considerations introduce countervailing factors. While CVTs have historically experienced higher warranty claim rates (approximately 5-8% higher than V6 engines in recent industry data), this gap has narrowed significantly with technological improvements. Current-generation CVTs demonstrate reliability metrics approaching traditional powertrains, though repair costs when failures do occur remain higher for CVT systems.

Environmental compliance costs increasingly favor CVT technology. Stringent emissions regulations impose additional engineering and component costs on V6 engines, including more complex exhaust treatment systems and engine management software. These compliance costs are projected to increase by 15-25% over the next five years as regulations tighten globally, while CVT systems inherently support emissions reduction goals through their efficiency advantages.

Market positioning effects must also be considered, as V6 engines continue to command premium positioning in certain vehicle segments, potentially supporting higher profit margins despite their increased costs. However, consumer preferences are increasingly shifting toward fuel-efficient options, gradually eroding this marketing advantage in all but specialized vehicle categories.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!