V6 Engine vs Full Electric Drive: Power Comparison

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine and Electric Drive Evolution Background

The internal combustion engine and electric motor technologies have evolved along distinct trajectories, each shaped by different engineering challenges and market demands. The V6 engine emerged in the early 20th century as an efficient compromise between the larger V8 and smaller inline-4 configurations. By the 1950s, V6 engines had become increasingly popular in automotive applications due to their balanced power delivery and compact design. The 1980s and 1990s witnessed significant advancements in V6 technology, including the introduction of variable valve timing, direct injection, and turbocharging, which substantially improved power output while reducing fuel consumption.

Electric drive systems, conversely, have a longer but more intermittent developmental history. While electric motors powered some of the earliest automobiles in the late 19th century, they were largely supplanted by internal combustion engines due to energy storage limitations. The modern resurgence of electric drive technology began in the late 1990s with hybrid vehicles, followed by fully electric vehicles gaining commercial viability in the 2010s with advances in battery technology and power electronics.

The fundamental operating principles of these power sources differ dramatically. V6 engines generate power through controlled combustion, converting chemical energy into mechanical energy through a complex series of thermodynamic processes. Their power delivery characteristics typically feature a bell-shaped torque curve, with peak power available within a specific RPM range. Modern V6 engines commonly produce between 250-400 horsepower in consumer applications, with specialized performance variants exceeding 500 horsepower.

Electric drive systems, by contrast, convert electrical energy directly into mechanical motion through electromagnetic interaction. This direct conversion results in instantaneous torque availability from zero RPM, a defining characteristic that fundamentally differentiates electric drives from internal combustion engines. Contemporary electric drive systems in passenger vehicles deliver between 200-500 horsepower, with high-performance models exceeding 1,000 horsepower.

The efficiency profiles of these technologies also diverge significantly. V6 engines typically operate at 25-35% thermal efficiency under optimal conditions, with substantial energy lost as heat. Electric drives achieve 85-95% efficiency in converting stored electrical energy to mechanical power at the wheels, though this advantage is partially offset by energy losses in battery charging and discharging cycles.

Recent technological convergence has seen both power sources adopt innovations from each other's domains. V6 engines increasingly incorporate electric assistance through mild hybrid systems, while electric drives have adopted multi-speed transmissions traditionally associated with combustion engines to optimize performance across different operating conditions.

Electric drive systems, conversely, have a longer but more intermittent developmental history. While electric motors powered some of the earliest automobiles in the late 19th century, they were largely supplanted by internal combustion engines due to energy storage limitations. The modern resurgence of electric drive technology began in the late 1990s with hybrid vehicles, followed by fully electric vehicles gaining commercial viability in the 2010s with advances in battery technology and power electronics.

The fundamental operating principles of these power sources differ dramatically. V6 engines generate power through controlled combustion, converting chemical energy into mechanical energy through a complex series of thermodynamic processes. Their power delivery characteristics typically feature a bell-shaped torque curve, with peak power available within a specific RPM range. Modern V6 engines commonly produce between 250-400 horsepower in consumer applications, with specialized performance variants exceeding 500 horsepower.

Electric drive systems, by contrast, convert electrical energy directly into mechanical motion through electromagnetic interaction. This direct conversion results in instantaneous torque availability from zero RPM, a defining characteristic that fundamentally differentiates electric drives from internal combustion engines. Contemporary electric drive systems in passenger vehicles deliver between 200-500 horsepower, with high-performance models exceeding 1,000 horsepower.

The efficiency profiles of these technologies also diverge significantly. V6 engines typically operate at 25-35% thermal efficiency under optimal conditions, with substantial energy lost as heat. Electric drives achieve 85-95% efficiency in converting stored electrical energy to mechanical power at the wheels, though this advantage is partially offset by energy losses in battery charging and discharging cycles.

Recent technological convergence has seen both power sources adopt innovations from each other's domains. V6 engines increasingly incorporate electric assistance through mild hybrid systems, while electric drives have adopted multi-speed transmissions traditionally associated with combustion engines to optimize performance across different operating conditions.

Market Demand Analysis for Powertrain Technologies

The global automotive powertrain market is experiencing a significant transformation driven by environmental concerns, regulatory pressures, and changing consumer preferences. Current market analysis indicates that while internal combustion engines (ICE) still dominate the global vehicle fleet, electric powertrains are gaining substantial market share at an accelerating rate. The compound annual growth rate (CAGR) for electric vehicles has consistently exceeded 40% in recent years, compared to flat or declining growth for traditional ICE vehicles.

Consumer demand patterns show distinct regional variations. In Europe and China, government incentives and emissions regulations have created strong market pull for electric vehicles, with some urban markets reaching EV adoption rates above 25%. North America presents a more complex picture, with coastal regions embracing electrification while central regions maintain stronger demand for traditional V6 and V8 engines, particularly in the truck and SUV segments.

Market research reveals evolving consumer priorities when comparing V6 engines to full electric drivetrains. Performance metrics traditionally favoring combustion engines are being challenged by advances in electric powertrain technology. Instant torque delivery, simplified maintenance requirements, and lower operational costs are increasingly valued by consumers, offsetting the higher initial purchase price of electric vehicles.

Fleet operators and commercial vehicle markets demonstrate growing interest in total cost of ownership (TCO) calculations that frequently favor electric powertrains over a 5-7 year operational period, despite higher acquisition costs. This shift is particularly evident in delivery, municipal, and short-haul transportation segments where route predictability mitigates range anxiety concerns.

Market forecasts from multiple industry analysts project electric vehicle market share to reach between 25-40% of new vehicle sales globally by 2030, with some markets potentially exceeding 70%. This transition represents both a challenge and opportunity for automotive manufacturers as they balance investment in improving traditional V6 engine efficiency while simultaneously developing electric powertrain capabilities.

Consumer surveys indicate that power delivery characteristics are becoming a key differentiator in purchase decisions. The immediate torque and smooth acceleration curve of electric vehicles is creating new expectations for performance that traditional V6 engines struggle to match without turbocharging or hybrid assistance. This perception shift is gradually redefining what consumers consider "powerful" in automotive applications.

Consumer demand patterns show distinct regional variations. In Europe and China, government incentives and emissions regulations have created strong market pull for electric vehicles, with some urban markets reaching EV adoption rates above 25%. North America presents a more complex picture, with coastal regions embracing electrification while central regions maintain stronger demand for traditional V6 and V8 engines, particularly in the truck and SUV segments.

Market research reveals evolving consumer priorities when comparing V6 engines to full electric drivetrains. Performance metrics traditionally favoring combustion engines are being challenged by advances in electric powertrain technology. Instant torque delivery, simplified maintenance requirements, and lower operational costs are increasingly valued by consumers, offsetting the higher initial purchase price of electric vehicles.

Fleet operators and commercial vehicle markets demonstrate growing interest in total cost of ownership (TCO) calculations that frequently favor electric powertrains over a 5-7 year operational period, despite higher acquisition costs. This shift is particularly evident in delivery, municipal, and short-haul transportation segments where route predictability mitigates range anxiety concerns.

Market forecasts from multiple industry analysts project electric vehicle market share to reach between 25-40% of new vehicle sales globally by 2030, with some markets potentially exceeding 70%. This transition represents both a challenge and opportunity for automotive manufacturers as they balance investment in improving traditional V6 engine efficiency while simultaneously developing electric powertrain capabilities.

Consumer surveys indicate that power delivery characteristics are becoming a key differentiator in purchase decisions. The immediate torque and smooth acceleration curve of electric vehicles is creating new expectations for performance that traditional V6 engines struggle to match without turbocharging or hybrid assistance. This perception shift is gradually redefining what consumers consider "powerful" in automotive applications.

Current Technical Challenges in Power Comparison

Comparing the power characteristics of V6 internal combustion engines and full electric drive systems presents several significant technical challenges that impact accurate assessment and benchmarking. The fundamental difference in how these systems generate and deliver power creates complications in establishing standardized comparison methodologies.

One primary challenge lies in the different power delivery mechanisms. Electric motors provide instant maximum torque from zero RPM, while V6 engines require time to reach optimal power bands. This temporal difference makes direct power curve comparisons problematic, as traditional metrics like horsepower and torque ratings at specific RPM ranges don't adequately represent the real-world performance differences experienced by drivers.

Measurement standardization presents another obstacle. The automotive industry has established protocols for measuring internal combustion engine power (such as SAE J1349 and DIN standards), but electric vehicle power measurement lacks the same level of standardized testing procedures. Different manufacturers may report electric powertrain capabilities using varying methodologies, making cross-platform comparisons inconsistent.

Thermal management significantly impacts power sustainability in both systems but manifests differently. V6 engines maintain relatively stable power output once at operating temperature, with gradual performance degradation under extreme conditions. Electric systems, however, experience more dramatic power limitations when battery thermal thresholds are approached, creating a variable performance envelope that's difficult to quantify in standardized tests.

Battery state-of-charge introduces another variable absent in combustion engine testing. An electric vehicle's power availability varies significantly between 100% and low charge states, while a V6 engine with adequate fuel supply maintains consistent performance regardless of tank level. This creates challenges in establishing representative test conditions that reflect typical usage patterns.

Weight-to-power ratios and efficiency metrics also complicate comparisons. Electric systems benefit from regenerative braking and higher energy conversion efficiency but carry substantial battery weight penalties. V6 engines have lower thermal efficiency but benefit from energy-dense fuel. These tradeoffs create multidimensional comparison challenges that simple power figures fail to capture.

Finally, real-world environmental factors affect each system differently. Temperature extremes, altitude, and humidity impact combustion efficiency in V6 engines, while electric systems see performance variations based on battery temperature and electrical system thermal management capabilities. Creating test protocols that account for these environmental variables remains an ongoing challenge in establishing fair comparison methodologies.

One primary challenge lies in the different power delivery mechanisms. Electric motors provide instant maximum torque from zero RPM, while V6 engines require time to reach optimal power bands. This temporal difference makes direct power curve comparisons problematic, as traditional metrics like horsepower and torque ratings at specific RPM ranges don't adequately represent the real-world performance differences experienced by drivers.

Measurement standardization presents another obstacle. The automotive industry has established protocols for measuring internal combustion engine power (such as SAE J1349 and DIN standards), but electric vehicle power measurement lacks the same level of standardized testing procedures. Different manufacturers may report electric powertrain capabilities using varying methodologies, making cross-platform comparisons inconsistent.

Thermal management significantly impacts power sustainability in both systems but manifests differently. V6 engines maintain relatively stable power output once at operating temperature, with gradual performance degradation under extreme conditions. Electric systems, however, experience more dramatic power limitations when battery thermal thresholds are approached, creating a variable performance envelope that's difficult to quantify in standardized tests.

Battery state-of-charge introduces another variable absent in combustion engine testing. An electric vehicle's power availability varies significantly between 100% and low charge states, while a V6 engine with adequate fuel supply maintains consistent performance regardless of tank level. This creates challenges in establishing representative test conditions that reflect typical usage patterns.

Weight-to-power ratios and efficiency metrics also complicate comparisons. Electric systems benefit from regenerative braking and higher energy conversion efficiency but carry substantial battery weight penalties. V6 engines have lower thermal efficiency but benefit from energy-dense fuel. These tradeoffs create multidimensional comparison challenges that simple power figures fail to capture.

Finally, real-world environmental factors affect each system differently. Temperature extremes, altitude, and humidity impact combustion efficiency in V6 engines, while electric systems see performance variations based on battery temperature and electrical system thermal management capabilities. Creating test protocols that account for these environmental variables remains an ongoing challenge in establishing fair comparison methodologies.

Comparative Power Delivery Solutions

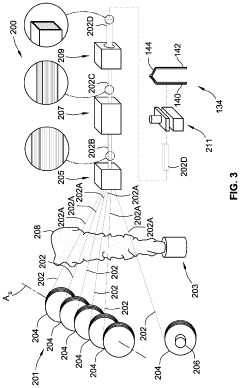

01 Hybrid propulsion systems combining V6 engines with electric drives

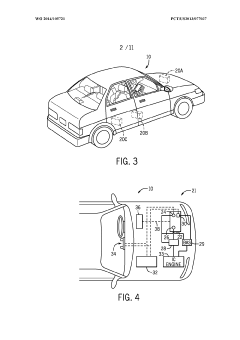

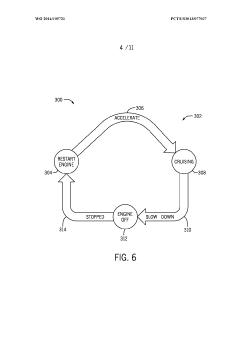

Hybrid propulsion systems that integrate V6 internal combustion engines with electric drive motors to provide improved fuel efficiency and reduced emissions. These systems typically use the V6 engine for primary propulsion while the electric drive provides supplementary power during acceleration or can operate independently for short distances. The combination allows for optimal power distribution between the two energy sources based on driving conditions.- Hybrid powertrain systems combining V6 engines with electric drives: Hybrid powertrain systems that integrate V6 internal combustion engines with electric drive motors to provide improved fuel efficiency and performance. These systems typically use the V6 engine as the primary power source while the electric drive provides supplementary power during acceleration or can operate independently for short distances. The combination allows for reduced emissions while maintaining the power characteristics expected from V6 engines.

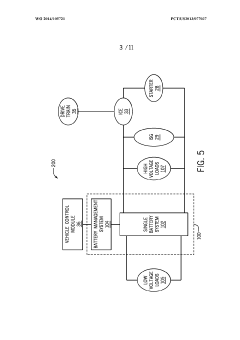

- Power management systems for V6 hybrid vehicles: Advanced control systems designed to optimize the power distribution between V6 engines and electric drive components. These management systems determine the most efficient operating mode based on driving conditions, battery state of charge, and power demands. They can seamlessly transition between combustion engine power, electric power, or combined power modes to maximize efficiency while maintaining performance requirements.

- Electric drive integration with conventional V6 powertrains: Technical solutions for integrating electric drive systems with traditional V6 engine architectures. These innovations focus on the mechanical and electrical interfaces between the combustion engine and electric components, including mounting arrangements, transmission connections, and cooling systems. The integration designs aim to minimize space requirements while maximizing power transfer efficiency between the two power sources.

- Regenerative braking systems for V6 hybrid vehicles: Systems that capture kinetic energy during vehicle deceleration and braking in V6 hybrid vehicles. These regenerative braking systems convert the captured energy into electrical power that is stored in batteries for later use by the electric drive. The technology helps extend the electric driving range and improves overall efficiency of vehicles equipped with both V6 engines and electric drive systems.

- Transitional technologies toward full electrification: Innovations that represent stepping stones from V6 engine dominance toward full electric drive systems. These technologies include plug-in hybrid configurations with extended electric range, modular powertrain designs that can be adapted for different levels of electrification, and systems that allow V6 engines to function primarily as range extenders for predominantly electric operation. These approaches help bridge the gap between conventional V6 power and fully electric vehicles.

02 Power management systems for V6 hybrid vehicles

Advanced power management systems designed specifically for vehicles equipped with both V6 engines and electric drive components. These systems control the power flow between the combustion engine and electric motors, optimize energy recovery during braking, and manage battery charging. The control algorithms determine when to use the V6 engine, when to use electric power, and when to combine both for maximum efficiency or performance.Expand Specific Solutions03 Transmission systems for V6 hybrid electric vehicles

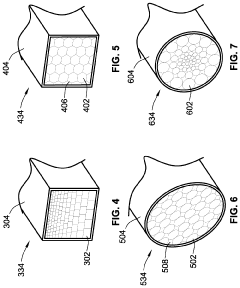

Specialized transmission systems that enable efficient power transfer from both V6 engines and electric motors to the wheels. These transmissions may include power-split devices, planetary gear sets, or dedicated clutch mechanisms that allow seamless transitions between combustion engine power, electric power, or combined power modes. The designs focus on minimizing energy losses while providing smooth operation across various driving conditions.Expand Specific Solutions04 Cooling and thermal management for hybrid V6 powertrains

Thermal management solutions specifically designed for hybrid powertrains that combine V6 engines with electric drive systems. These systems address the different cooling requirements of combustion engines and electric components, including motors, power electronics, and batteries. Advanced cooling circuits, heat exchangers, and temperature control strategies ensure optimal operating temperatures for all powertrain components under various load conditions.Expand Specific Solutions05 Integration of V6 engines with high-power electric drive systems

Engineering solutions for the physical integration of V6 engines with high-power electric drive components in vehicle architectures. These designs address packaging constraints, weight distribution, vibration isolation, and structural integrity while accommodating both propulsion systems. The integration approaches focus on optimizing space utilization, serviceability, and safety while maintaining vehicle performance characteristics.Expand Specific Solutions

Key Manufacturers and Industry Competition

The electric vehicle market is transitioning from early adoption to mainstream growth, with the power comparison between V6 engines and full electric drives representing a critical technological inflection point. The market is expanding rapidly, projected to reach $802.81 billion by 2027, with a CAGR of 22.6%. Regarding technological maturity, traditional automakers like GM, BMW, and Hyundai-Kia are balancing their portfolios between refined V6 technologies and emerging electric platforms, while Geely and its subsidiaries are aggressively investing in electric drive systems. ZF Friedrichshafen and Johnson Controls are developing supporting technologies for both powertrains, with BMW and Hyundai demonstrating the most advanced integration of power management systems across both technologies.

GM Global Technology Operations LLC

Technical Solution: GM has developed a comprehensive dual-path strategy comparing traditional V6 engines with electric powertrains. Their V6 engines, particularly the 3.6L V6 found in vehicles like the Cadillac CT5, deliver approximately 335 horsepower and 285 lb-ft of torque. In contrast, their Ultium electric drive platform delivers significantly higher instantaneous torque, with configurations reaching up to 1,000 horsepower in performance applications. GM's electric architecture operates at 800V, enabling faster charging and more efficient power delivery. Their testing shows electric powertrains achieve 0-60 mph times approximately 30% faster than comparable V6 engines while eliminating transmission-related power losses. GM has also developed proprietary thermal management systems for their electric powertrains that maintain optimal operating temperatures across various driving conditions.

Strengths: GM's electric platform offers superior torque delivery and acceleration performance while eliminating transmission power losses. Their 800V architecture provides charging advantages and better efficiency. Weaknesses: The V6 engines still offer better range without refueling/recharging and faster refueling times. Electric powertrains also face challenges with battery degradation over time that don't affect traditional engines.

Bayerische Motoren Werke AG

Technical Solution: BMW has conducted extensive comparative analysis between their TwinPower Turbo V6 engines and fifth-generation eDrive technology. Their V6 engines typically produce 335-382 horsepower with peak torque of approximately 330-370 lb-ft, requiring engine speeds of 1,800-5,000 RPM to access full power. By contrast, BMW's latest electric drive units deliver up to 536 horsepower in dual-motor configurations with instantaneous torque availability of up to 586 lb-ft from 0 RPM. BMW's testing demonstrates that electric powertrains provide 20-30% improvement in power-to-weight ratio compared to equivalent V6 engines. Their proprietary power electronics system optimizes energy flow with 95% efficiency, significantly higher than the 30-35% thermal efficiency of their best V6 engines. BMW has also developed an integrated cooling system for electric components that maintains optimal performance across diverse driving conditions and temperatures.

Strengths: BMW's electric drive technology offers significantly higher efficiency (95% vs 35%), instant torque delivery, and superior power-to-weight ratio. Weaknesses: Their V6 engines still maintain advantages in long-distance driving scenarios, established service infrastructure, and consistent performance regardless of ambient temperature conditions.

Technical Analysis of Power Generation Methods

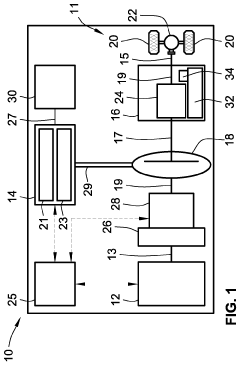

Dual function battery system and method

PatentWO2014105721A2

Innovation

- A dual function energy storage system with a single battery module that can provide both high and low voltage levels by selectively connecting subsets of energy storage modules across primary and secondary terminals, managed by a battery management system to optimize state of charge and prevent deep depletion.

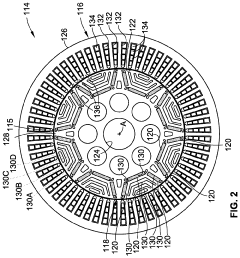

Segmented bar conductors for electric machines

PatentActiveUS20220216756A1

Innovation

- The use of segmented hairpin bar conductors fabricated from bundled wires with varying geometries and dimensions, joined via adhesives or insulation, reduces material losses and improves slot-fill functionality, allowing for increased efficiency and new design possibilities by minimizing copper losses and AC skin effect.

Environmental Impact Assessment

The environmental impact of vehicle propulsion systems represents a critical dimension in the comparative analysis of V6 engines versus full electric drives. Traditional V6 internal combustion engines generate significant greenhouse gas emissions throughout their operational lifecycle, with the average V6 engine producing approximately 200-250 grams of CO2 per kilometer driven. These direct emissions contribute substantially to urban air pollution and global climate change concerns.

Beyond carbon dioxide, V6 engines release nitrogen oxides, particulate matter, and volatile organic compounds that degrade air quality and pose public health risks. The extraction, refinement, and transportation of petroleum fuels create additional environmental burdens through potential habitat disruption, water contamination, and energy-intensive processing requirements.

Electric drive systems, while producing zero tailpipe emissions, shift their environmental impact to electricity generation sources. In regions heavily dependent on coal or natural gas for electricity production, the net environmental benefit of electric vehicles may be diminished. However, in areas with substantial renewable energy integration, electric drives demonstrate significantly lower lifecycle emissions, potentially reducing carbon footprint by 50-70% compared to V6 counterparts.

Battery production for electric vehicles presents notable environmental challenges, particularly regarding the mining of lithium, cobalt, and other critical minerals. These extraction processes can lead to habitat destruction, water depletion, and toxic waste generation in mining regions. However, emerging battery recycling technologies and sustainable sourcing initiatives are progressively mitigating these impacts.

Noise pollution represents another environmental consideration, with electric drives offering substantial advantages. V6 engines typically generate 70-80 decibels during operation, while electric drives operate at approximately 50-60 decibels, reducing urban noise pollution and potentially improving quality of life in densely populated areas.

Water consumption patterns differ significantly between the two technologies. Petroleum refining for V6 engines requires approximately 3-6 gallons of water per gallon of gasoline produced, while electricity generation for electric vehicles varies widely depending on the source—from negligible amounts for solar and wind to substantial quantities for thermoelectric plants.

The end-of-life environmental impact also favors electric drives, as battery recycling infrastructure continues to develop, potentially recovering up to 95% of critical materials. In contrast, disposal of conventional engine components often involves hazardous waste management challenges and lower material recovery rates.

Beyond carbon dioxide, V6 engines release nitrogen oxides, particulate matter, and volatile organic compounds that degrade air quality and pose public health risks. The extraction, refinement, and transportation of petroleum fuels create additional environmental burdens through potential habitat disruption, water contamination, and energy-intensive processing requirements.

Electric drive systems, while producing zero tailpipe emissions, shift their environmental impact to electricity generation sources. In regions heavily dependent on coal or natural gas for electricity production, the net environmental benefit of electric vehicles may be diminished. However, in areas with substantial renewable energy integration, electric drives demonstrate significantly lower lifecycle emissions, potentially reducing carbon footprint by 50-70% compared to V6 counterparts.

Battery production for electric vehicles presents notable environmental challenges, particularly regarding the mining of lithium, cobalt, and other critical minerals. These extraction processes can lead to habitat destruction, water depletion, and toxic waste generation in mining regions. However, emerging battery recycling technologies and sustainable sourcing initiatives are progressively mitigating these impacts.

Noise pollution represents another environmental consideration, with electric drives offering substantial advantages. V6 engines typically generate 70-80 decibels during operation, while electric drives operate at approximately 50-60 decibels, reducing urban noise pollution and potentially improving quality of life in densely populated areas.

Water consumption patterns differ significantly between the two technologies. Petroleum refining for V6 engines requires approximately 3-6 gallons of water per gallon of gasoline produced, while electricity generation for electric vehicles varies widely depending on the source—from negligible amounts for solar and wind to substantial quantities for thermoelectric plants.

The end-of-life environmental impact also favors electric drives, as battery recycling infrastructure continues to develop, potentially recovering up to 95% of critical materials. In contrast, disposal of conventional engine components often involves hazardous waste management challenges and lower material recovery rates.

Energy Efficiency Metrics and Standards

Energy efficiency metrics provide essential frameworks for comparing the performance of V6 engines and full electric drive systems. The automotive industry utilizes several standardized measurements to evaluate energy consumption and conversion efficiency. For internal combustion engines (ICEs) like V6 configurations, efficiency is typically measured in terms of thermal efficiency, which represents the percentage of fuel energy converted to mechanical work. Modern V6 engines generally achieve thermal efficiencies between 25-35%, with advanced designs incorporating direct injection and variable valve timing reaching the higher end of this range.

Electric drive systems, by contrast, are evaluated using electrical efficiency metrics, measuring the conversion of electrical energy from batteries to mechanical power at the wheels. These systems consistently demonstrate efficiency ratings of 85-95%, representing a significant advantage over combustion engines. This efficiency gap stems from fundamental differences in energy conversion processes, with electric motors avoiding the thermodynamic limitations inherent to combustion cycles.

Regulatory bodies worldwide have established standards for measuring and reporting vehicle efficiency. In the United States, the Environmental Protection Agency (EPA) employs the Miles Per Gallon (MPG) standard for conventional vehicles and Miles Per Gallon Equivalent (MPGe) for electric vehicles, allowing cross-platform comparisons. The European Union utilizes the Worldwide Harmonized Light Vehicles Test Procedure (WLTP), which measures CO2 emissions in grams per kilometer, providing a more comprehensive assessment of environmental impact alongside efficiency.

For performance-oriented comparisons, metrics such as energy consumption per unit distance (kWh/100km for EVs and liters/100km for ICE vehicles) offer more direct efficiency evaluations. When normalized for energy content, these measurements reveal that electric vehicles typically require 70-80% less energy to travel the same distance as V6-powered counterparts under comparable conditions.

Well-to-wheel efficiency standards further extend the comparison by accounting for the entire energy supply chain. This holistic approach considers energy losses during fuel extraction, processing, transportation, and final conversion in the vehicle. Even when powered by electricity from fossil fuel plants, electric drives generally maintain a significant efficiency advantage, though the margin narrows in regions heavily dependent on coal-generated electricity.

Emerging standards are beginning to incorporate lifecycle assessment methodologies, evaluating the embedded energy costs in manufacturing and eventual recycling of powertrain components. This approach is particularly relevant when comparing resource-intensive battery production against the long-term operational efficiency benefits of electric systems versus traditional V6 engines.

Electric drive systems, by contrast, are evaluated using electrical efficiency metrics, measuring the conversion of electrical energy from batteries to mechanical power at the wheels. These systems consistently demonstrate efficiency ratings of 85-95%, representing a significant advantage over combustion engines. This efficiency gap stems from fundamental differences in energy conversion processes, with electric motors avoiding the thermodynamic limitations inherent to combustion cycles.

Regulatory bodies worldwide have established standards for measuring and reporting vehicle efficiency. In the United States, the Environmental Protection Agency (EPA) employs the Miles Per Gallon (MPG) standard for conventional vehicles and Miles Per Gallon Equivalent (MPGe) for electric vehicles, allowing cross-platform comparisons. The European Union utilizes the Worldwide Harmonized Light Vehicles Test Procedure (WLTP), which measures CO2 emissions in grams per kilometer, providing a more comprehensive assessment of environmental impact alongside efficiency.

For performance-oriented comparisons, metrics such as energy consumption per unit distance (kWh/100km for EVs and liters/100km for ICE vehicles) offer more direct efficiency evaluations. When normalized for energy content, these measurements reveal that electric vehicles typically require 70-80% less energy to travel the same distance as V6-powered counterparts under comparable conditions.

Well-to-wheel efficiency standards further extend the comparison by accounting for the entire energy supply chain. This holistic approach considers energy losses during fuel extraction, processing, transportation, and final conversion in the vehicle. Even when powered by electricity from fossil fuel plants, electric drives generally maintain a significant efficiency advantage, though the margin narrows in regions heavily dependent on coal-generated electricity.

Emerging standards are beginning to incorporate lifecycle assessment methodologies, evaluating the embedded energy costs in manufacturing and eventual recycling of powertrain components. This approach is particularly relevant when comparing resource-intensive battery production against the long-term operational efficiency benefits of electric systems versus traditional V6 engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!