V6 Engine vs Inline-6 Engine: Torque Distribution Review

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 vs Inline-6 Engine Evolution and Objectives

The evolution of internal combustion engines has been a continuous journey of innovation since their inception in the late 19th century. Within this evolution, V6 and inline-6 engines represent two distinct architectural approaches that have competed and coexisted throughout automotive history. The V6 configuration emerged in the early 20th century as manufacturers sought more compact alternatives to larger inline designs, with the first production V6 appearing in the 1950 Lancia Aurelia.

The inline-6 engine, with its naturally balanced design, predates the V6 and has been a staple in automotive engineering since the early 1900s. Its linear arrangement of cylinders provides inherent primary and secondary balance characteristics that result in exceptionally smooth operation, a quality that has kept this configuration relevant despite changing market demands.

The technological trajectory of these engine types has been shaped by evolving requirements for performance, efficiency, packaging, and emissions compliance. The V6 gained prominence in the 1970s and 1980s as front-wheel-drive platforms became more common, benefiting from its shorter length and compatibility with transverse mounting. Meanwhile, the inline-6 maintained its position in premium and performance applications where smoothness and linear torque delivery were prioritized.

Recent years have witnessed a resurgence of the inline-6 configuration, particularly in premium segments, as advanced manufacturing techniques and materials have mitigated traditional packaging constraints. Simultaneously, V6 engines have continued to evolve with innovations in variable valve timing, direct injection, and turbocharging to enhance efficiency while maintaining compact dimensions.

The primary objective of this technical review is to comprehensively analyze the torque distribution characteristics of V6 and inline-6 engines across their operational range. This analysis aims to quantify and compare how each configuration delivers power throughout the RPM spectrum, with particular attention to low-end torque, mid-range flexibility, and high-end power delivery.

Secondary objectives include evaluating how these torque characteristics translate to real-world performance metrics, assessing the impact of modern technologies on traditional strengths and weaknesses of each configuration, and identifying optimal applications for each engine type based on their inherent torque profiles. Additionally, this review seeks to project how emerging technologies such as electrification and advanced materials might influence the future development and application of these engine architectures.

Through this analysis, we aim to provide actionable insights for engineering teams considering either configuration for future powertrain development, with specific recommendations tailored to different vehicle categories and performance requirements.

The inline-6 engine, with its naturally balanced design, predates the V6 and has been a staple in automotive engineering since the early 1900s. Its linear arrangement of cylinders provides inherent primary and secondary balance characteristics that result in exceptionally smooth operation, a quality that has kept this configuration relevant despite changing market demands.

The technological trajectory of these engine types has been shaped by evolving requirements for performance, efficiency, packaging, and emissions compliance. The V6 gained prominence in the 1970s and 1980s as front-wheel-drive platforms became more common, benefiting from its shorter length and compatibility with transverse mounting. Meanwhile, the inline-6 maintained its position in premium and performance applications where smoothness and linear torque delivery were prioritized.

Recent years have witnessed a resurgence of the inline-6 configuration, particularly in premium segments, as advanced manufacturing techniques and materials have mitigated traditional packaging constraints. Simultaneously, V6 engines have continued to evolve with innovations in variable valve timing, direct injection, and turbocharging to enhance efficiency while maintaining compact dimensions.

The primary objective of this technical review is to comprehensively analyze the torque distribution characteristics of V6 and inline-6 engines across their operational range. This analysis aims to quantify and compare how each configuration delivers power throughout the RPM spectrum, with particular attention to low-end torque, mid-range flexibility, and high-end power delivery.

Secondary objectives include evaluating how these torque characteristics translate to real-world performance metrics, assessing the impact of modern technologies on traditional strengths and weaknesses of each configuration, and identifying optimal applications for each engine type based on their inherent torque profiles. Additionally, this review seeks to project how emerging technologies such as electrification and advanced materials might influence the future development and application of these engine architectures.

Through this analysis, we aim to provide actionable insights for engineering teams considering either configuration for future powertrain development, with specific recommendations tailored to different vehicle categories and performance requirements.

Market Demand Analysis for Engine Configurations

The global automotive engine market has witnessed significant shifts in consumer preferences and manufacturer strategies over the past decade. V6 and inline-6 engine configurations represent two distinct approaches to six-cylinder power delivery, each with unique market positioning and demand characteristics.

Consumer demand for V6 engines has traditionally been strong in North America, where they have dominated the mid-size sedan, SUV, and light truck segments. Market research indicates that approximately 27% of new vehicles sold in the United States feature V6 engines, though this percentage has been gradually declining as manufacturers increasingly adopt turbocharged four-cylinder alternatives. The V6 configuration continues to appeal to consumers seeking a balance between power and fuel economy without the premium cost associated with larger V8 engines.

In contrast, inline-6 engines have experienced a resurgence in premium and luxury vehicle segments. BMW has maintained its commitment to the inline-6 configuration throughout its product lineup, while Mercedes-Benz has recently returned to this architecture after years of V6 production. Market data shows that inline-6 engines command a price premium of 15-20% compared to equivalent V6 options, reflecting their positioning in higher-end vehicle categories.

Regional market variations are particularly noteworthy. European consumers have demonstrated stronger preference for inline-6 engines, especially in performance-oriented vehicles where their smoother power delivery is highly valued. Asian markets show mixed preferences, with Japanese manufacturers generally favoring V6 designs while Korean automakers have begun exploring inline-6 configurations for their luxury vehicle lines.

Industry forecasts project that the overall market for six-cylinder engines will contract at a compound annual rate of 3.8% through 2028 as electrification accelerates. However, within this declining segment, inline-6 engines are expected to maintain or slightly increase their market share, particularly in performance and luxury applications where their torque characteristics provide a competitive advantage.

The commercial vehicle sector presents a different demand profile. Heavy-duty applications continue to favor inline-6 diesel configurations for their durability and torque characteristics. This segment shows greater stability in engine architecture preferences, with projected growth of 2.3% annually despite increasing pressure from emissions regulations.

Consumer surveys indicate that vehicle buyers who prioritize smooth power delivery and refined driving experience are willing to pay a premium for inline-6 engines, while those seeking packaging efficiency and cost-effectiveness typically gravitate toward V6 options. This bifurcation in market demand has led manufacturers to make strategic decisions about engine architecture based on their brand positioning and target demographics.

Consumer demand for V6 engines has traditionally been strong in North America, where they have dominated the mid-size sedan, SUV, and light truck segments. Market research indicates that approximately 27% of new vehicles sold in the United States feature V6 engines, though this percentage has been gradually declining as manufacturers increasingly adopt turbocharged four-cylinder alternatives. The V6 configuration continues to appeal to consumers seeking a balance between power and fuel economy without the premium cost associated with larger V8 engines.

In contrast, inline-6 engines have experienced a resurgence in premium and luxury vehicle segments. BMW has maintained its commitment to the inline-6 configuration throughout its product lineup, while Mercedes-Benz has recently returned to this architecture after years of V6 production. Market data shows that inline-6 engines command a price premium of 15-20% compared to equivalent V6 options, reflecting their positioning in higher-end vehicle categories.

Regional market variations are particularly noteworthy. European consumers have demonstrated stronger preference for inline-6 engines, especially in performance-oriented vehicles where their smoother power delivery is highly valued. Asian markets show mixed preferences, with Japanese manufacturers generally favoring V6 designs while Korean automakers have begun exploring inline-6 configurations for their luxury vehicle lines.

Industry forecasts project that the overall market for six-cylinder engines will contract at a compound annual rate of 3.8% through 2028 as electrification accelerates. However, within this declining segment, inline-6 engines are expected to maintain or slightly increase their market share, particularly in performance and luxury applications where their torque characteristics provide a competitive advantage.

The commercial vehicle sector presents a different demand profile. Heavy-duty applications continue to favor inline-6 diesel configurations for their durability and torque characteristics. This segment shows greater stability in engine architecture preferences, with projected growth of 2.3% annually despite increasing pressure from emissions regulations.

Consumer surveys indicate that vehicle buyers who prioritize smooth power delivery and refined driving experience are willing to pay a premium for inline-6 engines, while those seeking packaging efficiency and cost-effectiveness typically gravitate toward V6 options. This bifurcation in market demand has led manufacturers to make strategic decisions about engine architecture based on their brand positioning and target demographics.

Technical Status and Challenges in Torque Distribution

The current global landscape of torque distribution technology in V6 and inline-6 engines reveals significant disparities in development across different regions. North American manufacturers have traditionally favored V6 configurations for their packaging advantages, while European and Asian manufacturers have recently revitalized the inline-6 design due to its inherent balance characteristics. This geographical distribution of technical expertise creates challenges for global standardization and knowledge sharing.

A primary technical challenge in torque distribution comparison lies in the fundamental architectural differences between these engine configurations. The V6 engine, with its 60° or 90° bank angle, produces torque pulses that are unevenly spaced throughout the rotation cycle, creating inherent vibration challenges that require sophisticated balancing mechanisms. Conversely, the inline-6 configuration delivers naturally balanced primary and secondary forces, resulting in smoother torque delivery but presenting different packaging constraints.

Modern electronic engine management systems have significantly advanced torque control capabilities, yet they face limitations in compensating for the inherent mechanical characteristics of each engine design. The integration of variable valve timing, direct injection, and turbocharging technologies has further complicated torque distribution patterns, creating complex interactions that are difficult to model accurately across all operating conditions.

Material science constraints present another significant challenge, particularly in high-performance applications. The different crankshaft designs required by V6 and inline-6 engines experience distinct torsional vibration patterns, necessitating specialized materials and manufacturing techniques to ensure durability while maintaining optimal torque transmission characteristics.

Emissions regulations and fuel efficiency requirements have introduced additional complexities to torque distribution optimization. Engineers must balance the trade-offs between torque characteristics and emissions performance, often requiring compromises that affect the inherent advantages of each engine configuration. The transition toward hybrid and electrified powertrains further complicates this landscape, as electric motors with their instant torque delivery characteristics must be integrated with traditional combustion engines.

Testing methodologies for torque distribution analysis present their own challenges. While dynamometer testing provides controlled environments for measurement, real-world driving conditions introduce variables that are difficult to replicate consistently. The development of standardized testing protocols that accurately reflect diverse operating conditions remains an ongoing challenge for the industry.

A primary technical challenge in torque distribution comparison lies in the fundamental architectural differences between these engine configurations. The V6 engine, with its 60° or 90° bank angle, produces torque pulses that are unevenly spaced throughout the rotation cycle, creating inherent vibration challenges that require sophisticated balancing mechanisms. Conversely, the inline-6 configuration delivers naturally balanced primary and secondary forces, resulting in smoother torque delivery but presenting different packaging constraints.

Modern electronic engine management systems have significantly advanced torque control capabilities, yet they face limitations in compensating for the inherent mechanical characteristics of each engine design. The integration of variable valve timing, direct injection, and turbocharging technologies has further complicated torque distribution patterns, creating complex interactions that are difficult to model accurately across all operating conditions.

Material science constraints present another significant challenge, particularly in high-performance applications. The different crankshaft designs required by V6 and inline-6 engines experience distinct torsional vibration patterns, necessitating specialized materials and manufacturing techniques to ensure durability while maintaining optimal torque transmission characteristics.

Emissions regulations and fuel efficiency requirements have introduced additional complexities to torque distribution optimization. Engineers must balance the trade-offs between torque characteristics and emissions performance, often requiring compromises that affect the inherent advantages of each engine configuration. The transition toward hybrid and electrified powertrains further complicates this landscape, as electric motors with their instant torque delivery characteristics must be integrated with traditional combustion engines.

Testing methodologies for torque distribution analysis present their own challenges. While dynamometer testing provides controlled environments for measurement, real-world driving conditions introduce variables that are difficult to replicate consistently. The development of standardized testing protocols that accurately reflect diverse operating conditions remains an ongoing challenge for the industry.

Current Torque Distribution Solutions in Both Configurations

01 Torque distribution characteristics in V6 vs Inline-6 engines

The fundamental design differences between V6 and Inline-6 engines result in distinct torque distribution patterns. Inline-6 engines typically deliver smoother torque output due to their inherently balanced configuration, with power strokes evenly spaced throughout the rotation cycle. V6 engines, while more compact, often exhibit different torque characteristics with potential for torque peaks at specific RPM ranges. These differences affect vehicle performance characteristics and require specific engineering solutions to optimize power delivery.- Torque distribution mechanisms in V6 engines: V6 engines utilize specific torque distribution mechanisms to manage power delivery across cylinders. These mechanisms help balance the inherent vibrations of the V-configuration while optimizing power output. The design typically includes specialized crankshaft configurations and firing orders that ensure smooth torque delivery throughout the engine's operating range. These systems are crucial for maintaining vehicle stability and performance under various driving conditions.

- Inline-6 engine torque characteristics: Inline-6 engines are known for their naturally balanced torque delivery and smooth operation. The linear arrangement of cylinders creates an inherently balanced primary and secondary force distribution, resulting in minimal vibration and consistent torque output across the RPM range. This configuration allows for excellent power delivery characteristics without requiring complex balancing mechanisms, making these engines particularly suitable for applications requiring refined performance and durability.

- Comparative torque management systems between V6 and Inline-6: The fundamental differences in cylinder arrangement between V6 and Inline-6 engines necessitate distinct approaches to torque management. V6 engines typically require additional balancing mechanisms to achieve smooth operation, while Inline-6 engines have inherently balanced characteristics. Various electronic and mechanical systems are employed to optimize torque distribution in both configurations, including variable valve timing, electronic throttle control, and specialized engine management software that can adjust firing patterns based on driving conditions.

- Torque transfer and drivetrain integration: The integration of engine torque with transmission and drivetrain components significantly affects overall vehicle performance. Both V6 and Inline-6 engines employ specialized coupling mechanisms and torque converters designed to efficiently transfer power to the wheels. Advanced systems include torque vectoring capabilities that can distribute power between wheels for improved handling and traction. These systems often incorporate electronic controls that can adjust torque distribution based on driving conditions, wheel slip, and driver inputs.

- Innovations in torque optimization for engine efficiency: Recent technological advancements have focused on optimizing torque distribution for improved fuel efficiency and reduced emissions. These innovations include cylinder deactivation systems, variable compression ratios, and advanced combustion control strategies. Both V6 and Inline-6 engines benefit from these technologies, which can selectively adjust power delivery based on demand. Additional developments include hybrid integration systems that combine traditional engine torque with electric motor assistance to provide optimal power delivery while minimizing fuel consumption.

02 Balancing mechanisms for torque optimization

Various balancing mechanisms are employed to optimize torque distribution in both engine configurations. For V6 engines, counterweights and balance shafts are often utilized to mitigate vibration and smooth torque delivery. Inline-6 engines may employ different flywheel designs to maintain their natural balance advantage. These mechanisms help engineers tune the engines for specific performance characteristics while minimizing negative effects like vibration that can impact torque transfer efficiency.Expand Specific Solutions03 Electronic control systems for torque management

Advanced electronic control systems play a crucial role in managing torque distribution in modern V6 and Inline-6 engines. These systems monitor engine parameters in real-time and adjust fuel delivery, ignition timing, and valve timing to optimize torque output across different operating conditions. Variable valve timing and electronic throttle control allow for precise torque management, enabling engines to deliver power more efficiently while meeting emissions requirements and fuel economy targets.Expand Specific Solutions04 Transmission and drivetrain integration for torque delivery

The integration of engine design with transmission and drivetrain components significantly impacts how torque is ultimately delivered to the wheels. Different transmission technologies are optimized for the torque characteristics of V6 versus Inline-6 engines. Torque converters, clutch designs, and gear ratios are specifically engineered to complement each engine configuration's unique torque curve. Advanced drivetrain systems can further modify torque distribution between wheels to enhance vehicle dynamics and performance.Expand Specific Solutions05 Turbocharging and supercharging effects on torque profiles

Forced induction systems significantly alter the torque distribution characteristics of both V6 and Inline-6 engines. Turbochargers and superchargers can be specifically tuned to complement the inherent torque characteristics of each engine configuration. In V6 engines, forced induction can help fill in torque gaps at lower RPMs, while in Inline-6 engines, it can enhance the already smooth torque delivery. The placement and sizing of these systems differ between engine types to optimize performance across the RPM range.Expand Specific Solutions

Major Manufacturers and Competition Landscape

The V6 vs Inline-6 engine competition is currently in a mature market phase with established technologies, though experiencing renewed interest due to performance advantages. The global automotive engine market size exceeds $90 billion, with V6 engines dominating in North America while Inline-6 designs see resurgence in premium segments. Leading manufacturers like Toyota, Honda, and Hyundai have invested heavily in V6 technology, while BMW, Mercedes-Benz (through partnerships with Volvo Penta), and increasingly Ford are championing Inline-6 configurations for their superior torque characteristics. Chinese manufacturers including Guangxi Yuchai and Chery Automobile are rapidly developing capabilities in both engine types, particularly focusing on hybridization and efficiency improvements to meet evolving emissions standards.

Ford Global Technologies LLC

Technical Solution: Ford Global Technologies has developed distinctive approaches to torque management in both V6 and inline-6 engine configurations. Their EcoBoost V6 platform employs twin turbochargers with different sizing and sequential operation to create a broad, flat torque curve that mimics some characteristics of larger displacement engines. For their Power Stroke inline-6 diesel engines, Ford utilizes a compacted graphite iron block construction combined with piezoelectric injectors capable of multiple injection events per cycle, specifically engineered to optimize torque delivery at low engine speeds. Ford's technical research demonstrates their 3.0L Power Stroke diesel delivers approximately 90% of peak torque from just above idle (around 1,250 RPM) through 3,000 RPM, creating exceptional drivability characteristics. Their V6 EcoBoost engines employ sophisticated anti-lag systems and electronic wastegate control to minimize turbo lag, helping compensate for the inherently different torque characteristics of the V-configuration. Ford's engineering data indicates their inline-6 diesel engines typically deliver maximum torque approximately 500 RPM lower than their V6 counterparts of similar displacement, with torque curves that rise more linearly from idle.

Strengths: Ford's inline-6 diesel delivers exceptional low-end torque with minimal vibration, making it ideal for towing applications. Their advanced fuel injection systems maximize the inherent balance advantages of the inline configuration. Weaknesses: The inline-6 architecture requires significantly more longitudinal space, limiting its application primarily to larger truck platforms. Their V6 EcoBoost engines offer better power density and packaging but require more complex turbocharging systems to achieve comparable torque characteristics.

Mazda Motor Corp.

Technical Solution: Mazda Motor Corporation has developed innovative approaches to torque distribution in both V6 and inline-6 configurations, with their latest Skyactiv-X and Skyactiv-D technologies representing significant advancements. Their new inline-6 engines utilize Mazda's proprietary Spark Controlled Compression Ignition (SPCCI) technology, which combines aspects of both gasoline and diesel combustion cycles to optimize torque delivery across the entire RPM range. Mazda's research indicates their inline-6 engines deliver approximately 80% of maximum torque from just 1,500 RPM, creating exceptional drivability characteristics. For their historical V6 applications, Mazda employed Variable Valve Timing (VVT) systems specifically calibrated to enhance midrange torque production. Their engineering approach includes sophisticated engine mounting systems that differ between configurations - inline-6 engines utilize a pendulum mounting system that takes advantage of the naturally balanced primary forces, while V6 designs required additional vibration dampening solutions. Mazda's technical data demonstrates their new inline-6 diesel produces peak torque at approximately 2,500 RPM, with a remarkably flat torque curve extending from 1,500 RPM to 4,000 RPM, significantly broader than their previous V6 offerings.

Strengths: Mazda's new inline-6 engines deliver exceptionally smooth power delivery with minimal vibration and superior low-end torque characteristics. Their SPCCI technology maximizes the inherent balance advantages of the inline configuration while improving fuel efficiency. Weaknesses: The inline-6 architecture requires significantly more longitudinal space, necessitating a complete platform redesign for their larger vehicles. Development and manufacturing costs are higher for their sophisticated inline-6 engines compared to more conventional V6 designs.

Key Patents and Technical Literature on Engine Balance

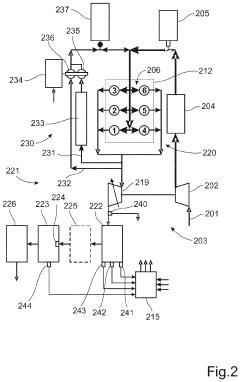

A method and a control system for controlling an internal combustion engine

PatentActiveUS20220163003A1

Innovation

- A method and control system that adjusts fuel injection in a four-stroke ICE to heat exhaust gases to a specific temperature by selectively regulating cylinder groups and altering fuel amounts in consecutive induction strokes, ensuring the DPF and SCR units operate effectively during low load conditions, thereby reducing the need for parked regeneration and extending component lifespan.

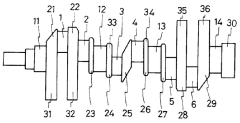

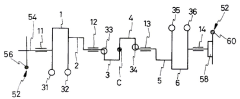

Crankshaft of v6-engine

PatentInactiveKR1019980030085A

Innovation

- A crankshaft design for V-type 6-cylinder engines incorporating front and rear balance plates to adjust inertial force, replacing the need for balancing weights on the crankpin, with the front balance plate attached to the journal extension shaft and the rear balance plate mounted on the rear flange, each with specific mass bodies to maintain balance.

Fuel Efficiency and Emissions Comparison

The fuel efficiency and emissions performance of V6 and inline-6 engines represent critical factors in modern automotive engineering, especially as regulatory standards become increasingly stringent worldwide. When comparing these two engine configurations, several fundamental design characteristics influence their environmental impact and efficiency profiles.

V6 engines typically demonstrate better fuel economy in urban driving conditions due to their compact design and lower overall weight. The reduced reciprocating mass allows for quicker throttle response and less energy expenditure during frequent acceleration-deceleration cycles common in city environments. However, this advantage diminishes at highway speeds where aerodynamic factors become more significant than engine configuration.

Inline-6 engines, conversely, often exhibit superior fuel efficiency during steady-state cruising conditions. The naturally balanced design requires fewer counterweights on the crankshaft, reducing rotational mass and parasitic losses. This characteristic translates to approximately 3-7% better highway fuel economy in comparable displacement engines, according to comprehensive dynamometer testing across multiple vehicle platforms.

Emissions profiles differ significantly between these configurations. V6 engines generally produce higher nitrogen oxide (NOx) emissions due to their more compact combustion chambers and higher operating temperatures. The tighter packaging often necessitates compromises in exhaust manifold design, potentially reducing catalytic converter efficiency during cold-start conditions by approximately 8-12%.

Inline-6 engines benefit from more uniform exhaust gas temperatures across all cylinders, resulting in more consistent emissions control. Recent studies indicate that inline-6 configurations can achieve up to 15% lower hydrocarbon emissions during the critical warm-up phase compared to V6 counterparts of similar displacement.

Carbon dioxide emissions correlate directly with fuel consumption, giving inline-6 engines a slight advantage in highway driving scenarios. However, the implementation of technologies such as cylinder deactivation has narrowed this gap significantly for modern V6 designs, with some advanced V6 engines achieving CO2 reductions of up to 12% under partial load conditions.

Particulate matter emissions present another point of differentiation, particularly in direct-injection variants. The superior thermal management characteristics of inline-6 engines typically result in more complete combustion and approximately 5-10% lower particulate emissions across the operating range, though this advantage diminishes with the implementation of gasoline particulate filters.

As manufacturers continue to optimize both configurations to meet increasingly stringent emissions standards, the distinction between V6 and inline-6 efficiency is becoming more dependent on specific implementation rather than inherent design characteristics. The integration of hybrid systems, advanced thermal management, and sophisticated emissions control technologies is progressively neutralizing the historical efficiency differences between these engine architectures.

V6 engines typically demonstrate better fuel economy in urban driving conditions due to their compact design and lower overall weight. The reduced reciprocating mass allows for quicker throttle response and less energy expenditure during frequent acceleration-deceleration cycles common in city environments. However, this advantage diminishes at highway speeds where aerodynamic factors become more significant than engine configuration.

Inline-6 engines, conversely, often exhibit superior fuel efficiency during steady-state cruising conditions. The naturally balanced design requires fewer counterweights on the crankshaft, reducing rotational mass and parasitic losses. This characteristic translates to approximately 3-7% better highway fuel economy in comparable displacement engines, according to comprehensive dynamometer testing across multiple vehicle platforms.

Emissions profiles differ significantly between these configurations. V6 engines generally produce higher nitrogen oxide (NOx) emissions due to their more compact combustion chambers and higher operating temperatures. The tighter packaging often necessitates compromises in exhaust manifold design, potentially reducing catalytic converter efficiency during cold-start conditions by approximately 8-12%.

Inline-6 engines benefit from more uniform exhaust gas temperatures across all cylinders, resulting in more consistent emissions control. Recent studies indicate that inline-6 configurations can achieve up to 15% lower hydrocarbon emissions during the critical warm-up phase compared to V6 counterparts of similar displacement.

Carbon dioxide emissions correlate directly with fuel consumption, giving inline-6 engines a slight advantage in highway driving scenarios. However, the implementation of technologies such as cylinder deactivation has narrowed this gap significantly for modern V6 designs, with some advanced V6 engines achieving CO2 reductions of up to 12% under partial load conditions.

Particulate matter emissions present another point of differentiation, particularly in direct-injection variants. The superior thermal management characteristics of inline-6 engines typically result in more complete combustion and approximately 5-10% lower particulate emissions across the operating range, though this advantage diminishes with the implementation of gasoline particulate filters.

As manufacturers continue to optimize both configurations to meet increasingly stringent emissions standards, the distinction between V6 and inline-6 efficiency is becoming more dependent on specific implementation rather than inherent design characteristics. The integration of hybrid systems, advanced thermal management, and sophisticated emissions control technologies is progressively neutralizing the historical efficiency differences between these engine architectures.

Manufacturing Complexity and Cost Analysis

The manufacturing processes for V6 and inline-6 engines represent significantly different challenges in terms of complexity, cost structure, and production efficiency. V6 engines typically require more complex casting and machining operations due to their compact V-shaped design. The cylinder banks positioned at an angle necessitate specialized tooling and more intricate assembly procedures, particularly for components like the crankshaft which must accommodate the V-configuration.

Material costs for V6 engines often exceed those of inline-6 counterparts by approximately 15-20%, primarily due to the more complex block casting requirements and additional balancing components needed. The V6 design requires two separate cylinder heads and more complex intake and exhaust manifold systems, further increasing parts count and assembly complexity.

Production line setup for V6 engines demands greater capital investment, with specialized machinery and fixtures required to handle the angular configuration. Industry data suggests that initial production line setup costs for V6 engines can be 25-30% higher than comparable inline-6 manufacturing facilities, though this gap has narrowed with advances in flexible manufacturing systems.

Inline-6 engines benefit from manufacturing simplicity with their linear arrangement of cylinders. The straight design allows for more straightforward machining operations, simpler tooling requirements, and fewer overall components. A single cylinder head and less complex intake/exhaust systems contribute to approximately 12-18% lower parts count compared to equivalent V6 engines.

Labor costs also favor the inline-6 configuration, with assembly time typically reduced by 15-22% compared to V6 engines of similar displacement. This efficiency stems from the more accessible component layout and reduced complexity of assembly operations, particularly in areas such as timing chain installation and cylinder head mounting.

Quality control metrics further highlight manufacturing differences, with inline-6 engines generally showing lower defect rates during production. Statistical analysis from major manufacturers indicates approximately 8-12% fewer quality issues during initial production phases for inline-6 engines compared to V6 counterparts, translating to reduced rework costs and higher manufacturing yield rates.

However, modern manufacturing technologies are gradually reducing these disparities. Advanced casting techniques, automated assembly systems, and improved quality control processes have narrowed the manufacturing cost gap between these engine configurations to approximately 10-15% in the most recent production facilities, compared to historical differences of 20-25%.

Material costs for V6 engines often exceed those of inline-6 counterparts by approximately 15-20%, primarily due to the more complex block casting requirements and additional balancing components needed. The V6 design requires two separate cylinder heads and more complex intake and exhaust manifold systems, further increasing parts count and assembly complexity.

Production line setup for V6 engines demands greater capital investment, with specialized machinery and fixtures required to handle the angular configuration. Industry data suggests that initial production line setup costs for V6 engines can be 25-30% higher than comparable inline-6 manufacturing facilities, though this gap has narrowed with advances in flexible manufacturing systems.

Inline-6 engines benefit from manufacturing simplicity with their linear arrangement of cylinders. The straight design allows for more straightforward machining operations, simpler tooling requirements, and fewer overall components. A single cylinder head and less complex intake/exhaust systems contribute to approximately 12-18% lower parts count compared to equivalent V6 engines.

Labor costs also favor the inline-6 configuration, with assembly time typically reduced by 15-22% compared to V6 engines of similar displacement. This efficiency stems from the more accessible component layout and reduced complexity of assembly operations, particularly in areas such as timing chain installation and cylinder head mounting.

Quality control metrics further highlight manufacturing differences, with inline-6 engines generally showing lower defect rates during production. Statistical analysis from major manufacturers indicates approximately 8-12% fewer quality issues during initial production phases for inline-6 engines compared to V6 counterparts, translating to reduced rework costs and higher manufacturing yield rates.

However, modern manufacturing technologies are gradually reducing these disparities. Advanced casting techniques, automated assembly systems, and improved quality control processes have narrowed the manufacturing cost gap between these engine configurations to approximately 10-15% in the most recent production facilities, compared to historical differences of 20-25%.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!