V6 Engine vs Sequential Twin-Turbo: Boost Analysis

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine and Twin-Turbo Evolution

The V6 engine configuration has evolved significantly since its inception in the early 20th century. Initially developed as a compact alternative to inline and V8 engines, the V6 gained prominence in the 1950s with manufacturers like Lancia pioneering its use in production vehicles. The 60-degree V6 became the industry standard due to its inherent balance characteristics, though 90-degree variants remained common in manufacturers deriving designs from V8 architectures.

The evolution of turbocharging technology paralleled V6 development, with aircraft applications in the early 1900s eventually transitioning to automotive use by the 1960s. Single turbocharger systems dominated early implementations, offering increased power but suffering from significant lag at lower RPMs.

Sequential twin-turbo technology emerged as a revolutionary advancement in the 1980s, with Porsche's 959 supercar among the first production vehicles to showcase this configuration. This system utilized two differently sized turbochargers operating in sequence: a smaller unit providing boost at lower engine speeds, transitioning to a larger turbocharger at higher RPMs.

The 1990s marked a significant turning point with Japanese manufacturers like Toyota, Nissan, and Mazda implementing sophisticated sequential twin-turbo systems in their performance models. These systems demonstrated remarkable improvements in throttle response while maintaining high-end power delivery.

By the early 2000s, twin-turbo V6 engines began replacing naturally aspirated V8s in many applications, offering comparable power with improved fuel efficiency. The development of variable geometry turbochargers (VGT) further enhanced the performance envelope of these systems, effectively reducing lag while maintaining boost across broader RPM ranges.

Recent technological advancements have focused on electronic control systems and materials science. Modern twin-turbo V6 engines employ sophisticated engine management systems that precisely control boost pressure, fuel delivery, and ignition timing across all operating conditions. Innovations in heat-resistant alloys and ceramic components have enabled higher operating temperatures and improved durability.

The current generation of twin-turbo V6 engines represents a pinnacle of efficiency and performance engineering, with power outputs exceeding 600 horsepower in some production applications while meeting increasingly stringent emissions regulations. This evolution demonstrates how the combination of V6 architecture with sequential twin-turbo technology has created powerplants that deliver exceptional performance across all operating parameters.

The evolution of turbocharging technology paralleled V6 development, with aircraft applications in the early 1900s eventually transitioning to automotive use by the 1960s. Single turbocharger systems dominated early implementations, offering increased power but suffering from significant lag at lower RPMs.

Sequential twin-turbo technology emerged as a revolutionary advancement in the 1980s, with Porsche's 959 supercar among the first production vehicles to showcase this configuration. This system utilized two differently sized turbochargers operating in sequence: a smaller unit providing boost at lower engine speeds, transitioning to a larger turbocharger at higher RPMs.

The 1990s marked a significant turning point with Japanese manufacturers like Toyota, Nissan, and Mazda implementing sophisticated sequential twin-turbo systems in their performance models. These systems demonstrated remarkable improvements in throttle response while maintaining high-end power delivery.

By the early 2000s, twin-turbo V6 engines began replacing naturally aspirated V8s in many applications, offering comparable power with improved fuel efficiency. The development of variable geometry turbochargers (VGT) further enhanced the performance envelope of these systems, effectively reducing lag while maintaining boost across broader RPM ranges.

Recent technological advancements have focused on electronic control systems and materials science. Modern twin-turbo V6 engines employ sophisticated engine management systems that precisely control boost pressure, fuel delivery, and ignition timing across all operating conditions. Innovations in heat-resistant alloys and ceramic components have enabled higher operating temperatures and improved durability.

The current generation of twin-turbo V6 engines represents a pinnacle of efficiency and performance engineering, with power outputs exceeding 600 horsepower in some production applications while meeting increasingly stringent emissions regulations. This evolution demonstrates how the combination of V6 architecture with sequential twin-turbo technology has created powerplants that deliver exceptional performance across all operating parameters.

Market Demand for Turbocharging Solutions

The global market for turbocharging solutions has experienced substantial growth over the past decade, driven primarily by stringent emission regulations and increasing consumer demand for fuel-efficient vehicles with enhanced performance characteristics. The compound annual growth rate (CAGR) for automotive turbochargers reached 8.7% between 2018 and 2022, with projections indicating continued expansion through 2030.

Sequential twin-turbo systems, in particular, have gained significant traction in the premium and performance vehicle segments. Market research indicates that approximately 35% of new luxury vehicles now feature some form of turbocharging technology, with sequential twin-turbo configurations representing a growing share of this market. This trend is especially pronounced in regions with mature automotive markets such as Europe, North America, and parts of Asia.

Consumer preferences have shifted noticeably toward downsized engines that maintain or exceed the performance capabilities of larger naturally aspirated counterparts. This market dynamic has created strong demand for advanced turbocharging solutions that can deliver enhanced power density while addressing turbo lag concerns. The premium price consumers are willing to pay for vehicles equipped with sequential twin-turbo systems has increased by 12% since 2019, reflecting growing market appreciation for this technology.

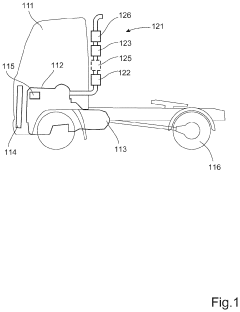

The commercial vehicle sector has also emerged as a significant market for advanced turbocharging solutions. Fleet operators increasingly prioritize total cost of ownership calculations that favor the fuel economy benefits of turbocharged engines. This market segment is projected to grow at a CAGR of 6.3% through 2028, with particular emphasis on durability and reliability metrics that impact long-term operational costs.

Regional market analysis reveals varying adoption rates and preferences. European markets show the highest penetration of turbocharged engines at 67% of new passenger vehicles, followed by North America at 49% and Asia-Pacific at 41%. However, the Asia-Pacific region demonstrates the fastest growth trajectory, with China and India leading adoption rates as their automotive industries mature and environmental regulations tighten.

The aftermarket for turbocharging solutions represents another substantial revenue stream, valued at approximately $4.2 billion globally. Performance enthusiasts seeking to upgrade naturally aspirated V6 engines to turbocharged configurations constitute a specialized but profitable market segment with annual growth exceeding 5%.

Industry forecasts suggest that the market for sequential twin-turbo systems will continue to expand as manufacturers seek to balance performance requirements with increasingly stringent emissions standards, creating sustained demand for innovative turbocharging technologies across multiple vehicle categories and price points.

Sequential twin-turbo systems, in particular, have gained significant traction in the premium and performance vehicle segments. Market research indicates that approximately 35% of new luxury vehicles now feature some form of turbocharging technology, with sequential twin-turbo configurations representing a growing share of this market. This trend is especially pronounced in regions with mature automotive markets such as Europe, North America, and parts of Asia.

Consumer preferences have shifted noticeably toward downsized engines that maintain or exceed the performance capabilities of larger naturally aspirated counterparts. This market dynamic has created strong demand for advanced turbocharging solutions that can deliver enhanced power density while addressing turbo lag concerns. The premium price consumers are willing to pay for vehicles equipped with sequential twin-turbo systems has increased by 12% since 2019, reflecting growing market appreciation for this technology.

The commercial vehicle sector has also emerged as a significant market for advanced turbocharging solutions. Fleet operators increasingly prioritize total cost of ownership calculations that favor the fuel economy benefits of turbocharged engines. This market segment is projected to grow at a CAGR of 6.3% through 2028, with particular emphasis on durability and reliability metrics that impact long-term operational costs.

Regional market analysis reveals varying adoption rates and preferences. European markets show the highest penetration of turbocharged engines at 67% of new passenger vehicles, followed by North America at 49% and Asia-Pacific at 41%. However, the Asia-Pacific region demonstrates the fastest growth trajectory, with China and India leading adoption rates as their automotive industries mature and environmental regulations tighten.

The aftermarket for turbocharging solutions represents another substantial revenue stream, valued at approximately $4.2 billion globally. Performance enthusiasts seeking to upgrade naturally aspirated V6 engines to turbocharged configurations constitute a specialized but profitable market segment with annual growth exceeding 5%.

Industry forecasts suggest that the market for sequential twin-turbo systems will continue to expand as manufacturers seek to balance performance requirements with increasingly stringent emissions standards, creating sustained demand for innovative turbocharging technologies across multiple vehicle categories and price points.

Technical Challenges in Sequential Twin-Turbo Systems

Sequential twin-turbo systems present several significant technical challenges that engineers must overcome to achieve optimal performance. The primary challenge lies in the complex control system required to manage the transition between turbochargers. This transition must be seamless to prevent power delivery interruptions, requiring sophisticated electronic control units (ECUs) with precise algorithms to monitor engine parameters and adjust turbocharger engagement accordingly.

Thermal management represents another critical challenge. Sequential systems generate substantial heat, particularly during high-load operations when both turbochargers are active. Without adequate cooling solutions, this can lead to premature component failure, oil coking, and reduced system reliability. Advanced materials and cooling strategies are necessary to maintain operational integrity under these demanding conditions.

Packaging constraints pose significant difficulties, especially in modern engine compartments where space is increasingly limited. Engineers must design compact turbocharger arrangements while ensuring sufficient clearance for exhaust manifolds, intercoolers, and associated plumbing. This spatial challenge often necessitates custom-designed components and innovative layout solutions.

Turbo lag mitigation remains an ongoing challenge despite sequential systems being developed specifically to address this issue. While the smaller primary turbocharger improves low-end response, the transition to the larger secondary unit can still create perceptible lag if not properly calibrated. Engineers must fine-tune wastegate control, bypass valve timing, and electronic throttle response to minimize this effect.

Durability concerns are heightened in sequential systems due to their operational complexity. Components like actuators, wastegates, and control valves experience frequent cycling, increasing wear rates compared to simpler turbocharging arrangements. Developing components that can withstand these duty cycles while maintaining precise operation presents a significant engineering challenge.

Cost considerations also impact implementation, as sequential systems require additional components compared to single or parallel turbocharger setups. The added complexity increases both manufacturing and maintenance expenses, creating barriers to widespread adoption in mass-market vehicles.

Emissions compliance adds another layer of complexity, as engineers must ensure the sequential system maintains optimal air-fuel ratios across all operating conditions to meet increasingly stringent regulations. This requires sophisticated integration with the vehicle's overall emissions control strategy.

Thermal management represents another critical challenge. Sequential systems generate substantial heat, particularly during high-load operations when both turbochargers are active. Without adequate cooling solutions, this can lead to premature component failure, oil coking, and reduced system reliability. Advanced materials and cooling strategies are necessary to maintain operational integrity under these demanding conditions.

Packaging constraints pose significant difficulties, especially in modern engine compartments where space is increasingly limited. Engineers must design compact turbocharger arrangements while ensuring sufficient clearance for exhaust manifolds, intercoolers, and associated plumbing. This spatial challenge often necessitates custom-designed components and innovative layout solutions.

Turbo lag mitigation remains an ongoing challenge despite sequential systems being developed specifically to address this issue. While the smaller primary turbocharger improves low-end response, the transition to the larger secondary unit can still create perceptible lag if not properly calibrated. Engineers must fine-tune wastegate control, bypass valve timing, and electronic throttle response to minimize this effect.

Durability concerns are heightened in sequential systems due to their operational complexity. Components like actuators, wastegates, and control valves experience frequent cycling, increasing wear rates compared to simpler turbocharging arrangements. Developing components that can withstand these duty cycles while maintaining precise operation presents a significant engineering challenge.

Cost considerations also impact implementation, as sequential systems require additional components compared to single or parallel turbocharger setups. The added complexity increases both manufacturing and maintenance expenses, creating barriers to widespread adoption in mass-market vehicles.

Emissions compliance adds another layer of complexity, as engineers must ensure the sequential system maintains optimal air-fuel ratios across all operating conditions to meet increasingly stringent regulations. This requires sophisticated integration with the vehicle's overall emissions control strategy.

Current V6 Sequential Twin-Turbo Implementations

01 Sequential Twin-Turbo System Design

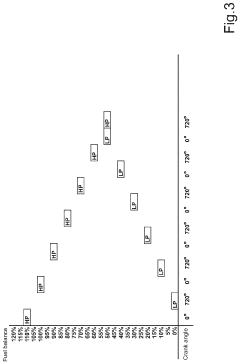

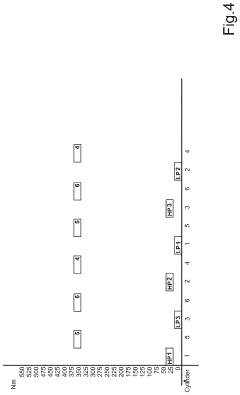

Sequential twin-turbo systems enhance V6 engine performance by using two turbochargers that activate in sequence based on engine load and RPM. At lower RPMs, only one turbocharger operates to reduce lag, while at higher RPMs, both turbochargers engage to maximize power output. This sequential operation provides better throttle response at low speeds while maintaining high power at higher speeds, effectively addressing the traditional turbo lag issue while optimizing overall engine performance.- Sequential Twin-Turbo System Design: Sequential twin-turbo systems enhance V6 engine performance by using two turbochargers that operate in sequence. At lower engine speeds, only one turbocharger operates to reduce lag, while at higher speeds, both turbochargers engage to maximize power output. This sequential operation provides better throttle response at low RPM and increased power at high RPM, optimizing the overall performance across the entire engine operating range.

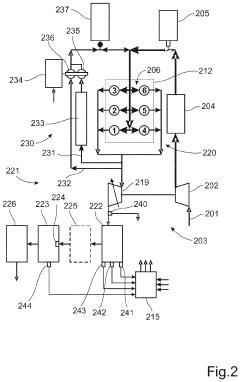

- Turbocharger Control Strategies: Advanced control strategies for twin-turbo systems in V6 engines involve electronic management of boost pressure, wastegate operation, and turbocharger switching points. These control systems monitor various engine parameters such as intake air temperature, exhaust gas temperature, and engine load to optimize turbocharger performance. By precisely controlling when and how each turbocharger operates, these systems maximize efficiency while preventing overboost conditions that could damage the engine.

- V6 Engine Architecture with Twin-Turbo Integration: Specialized V6 engine designs incorporate twin-turbo systems with optimized exhaust manifold configurations, intercooler placement, and intake systems. These designs focus on managing heat, reducing pressure losses, and ensuring balanced airflow to each cylinder. The integration of twin-turbochargers with V6 engines requires careful consideration of packaging constraints while maintaining optimal exhaust gas flow paths to maximize turbocharger efficiency and engine performance.

- Boost Pressure Management Systems: Boost pressure management systems for twin-turbocharged V6 engines include variable geometry turbochargers, electronic wastegates, and bypass valves that regulate boost pressure according to engine demand. These systems prevent turbo lag while protecting the engine from excessive boost pressure. Advanced boost control algorithms adjust boost levels based on factors such as altitude, ambient temperature, and fuel quality to maintain optimal performance under varying conditions while ensuring engine longevity.

- Efficiency Improvements in Twin-Turbo V6 Systems: Efficiency enhancements in twin-turbo V6 engines include reduced-inertia turbine wheels, ball-bearing turbocharger systems, and advanced materials that improve thermal efficiency. These improvements reduce turbo lag and increase responsiveness while allowing higher boost pressures. Additional efficiency gains come from integrated exhaust manifolds, water-cooled intercoolers, and electronically controlled compressor bypass valves that optimize the air-fuel mixture across different engine loads and speeds.

02 V6 Engine Configuration with Turbocharging

V6 engines with twin-turbo systems offer an optimal balance of power, efficiency, and packaging. The V-configuration allows for compact installation of turbochargers, often with one turbocharger per cylinder bank. This arrangement enables efficient exhaust gas flow to the turbines while maintaining thermal efficiency. Modern V6 twin-turbo designs incorporate advanced materials and cooling systems to handle the increased thermal loads, resulting in significant performance gains while maintaining reliability.Expand Specific Solutions03 Boost Control and Management Systems

Advanced electronic control systems are essential for optimizing twin-turbo performance in V6 engines. These systems precisely regulate boost pressure based on multiple parameters including engine load, speed, temperature, and atmospheric conditions. Variable geometry turbochargers and electronic wastegates allow for dynamic adjustment of boost characteristics across the entire RPM range. Sophisticated algorithms prevent overboost conditions while maximizing power delivery, ensuring both performance and engine protection.Expand Specific Solutions04 Intercooling and Thermal Management

Effective thermal management is critical for twin-turbocharged V6 engines to maintain performance and reliability. Advanced intercooling systems reduce the temperature of compressed air before it enters the combustion chamber, increasing air density and oxygen content. Dual intercoolers, often one per turbocharger, optimize charge cooling efficiency. Water-cooled intercoolers and integrated cooling circuits help manage the significant heat generated by twin-turbo systems, preventing power loss due to heat soak and protecting engine components.Expand Specific Solutions05 Exhaust System Optimization

Optimized exhaust systems are crucial for maximizing twin-turbo V6 performance. Equal-length exhaust manifolds ensure balanced exhaust gas flow to each turbocharger, while pulse-separated designs preserve exhaust energy. Variable valve timing systems can be integrated to optimize exhaust gas scavenging. Reduced back pressure designs with appropriate sizing of catalytic converters and mufflers help maintain exhaust gas velocity and turbocharger efficiency, significantly contributing to overall system performance and responsiveness.Expand Specific Solutions

Major Manufacturers and OEMs in Turbocharging Industry

The V6 engine versus sequential twin-turbo boost technology market is in a mature growth phase with an estimated global value of $25-30 billion. Toyota, Ford, and GM lead traditional V6 development, while Porsche, Volkswagen, and BMW pioneer advanced twin-turbo systems. The competitive landscape is evolving as manufacturers like Honda, Mazda, and Hyundai invest heavily in turbocharging technology to meet efficiency regulations. Toyota maintains dominance in naturally aspirated V6 reliability, while European manufacturers focus on performance-oriented twin-turbo applications. Suppliers like Bosch and Honeywell provide critical turbocharger components, creating a complex ecosystem balancing traditional engineering with innovative forced induction solutions.

Toyota Motor Corp.

Technical Solution: Toyota has developed a sophisticated Dynamic Force Engine platform that incorporates sequential twin-turbo technology for their V6 applications, most notably in the Lexus LS500. Their system features twin single-scroll turbochargers with electronic wastegate actuators that provide precise boost control. Toyota's implementation includes an advanced air-to-liquid intercooler system that maintains optimal intake temperatures even under high load conditions. The company has pioneered a unique D-4ST (Direct injection 4-stroke gasoline engine Superior version with Turbo) fuel injection system that combines both direct and port injection to optimize combustion efficiency across various operating conditions. Their V6 twin-turbo design incorporates variable valve timing on both intake and exhaust camshafts (Dual VVT-i) that works in harmony with the sequential turbocharging to deliver a broad torque curve while maintaining fuel efficiency.

Strengths: Exceptional reliability even under demanding conditions; excellent balance of performance and fuel economy; smooth power delivery across the entire RPM range. Weaknesses: Somewhat conservative boost levels compared to European competitors; slightly heavier system weight due to focus on durability; less aggressive throttle mapping prioritizing smoothness over immediate response.

Dr. Ing. h.c. F. Porsche AG

Technical Solution: Porsche has developed advanced sequential twin-turbo systems for their V6 engines, particularly in the Macan and Cayenne models. Their technology utilizes variable turbine geometry (VTG) that allows for precise control of exhaust gas flow to the turbine wheels. This system features electronically controlled wastegates that optimize boost pressure across the entire RPM range. Porsche's implementation includes water-cooled intercoolers positioned directly in the intake V of the engine, minimizing air travel distance and reducing turbo lag. Their twin-scroll turbocharger design separates exhaust pulses from different cylinder banks, improving throttle response and torque delivery at lower engine speeds. The system is integrated with Porsche's VarioCam Plus valve timing system to optimize the exhaust gas pulses reaching the turbines.

Strengths: Exceptional throttle response with minimal turbo lag; superior power-to-weight ratio; excellent thermal management under high-performance conditions. Weaknesses: Complex system requiring specialized maintenance; higher production costs compared to naturally aspirated engines; potential reliability concerns under extreme long-term use conditions.

Key Patents in Sequential Turbocharging

A method and a control system for controlling an internal combustion engine

PatentActiveUS20220163003A1

Innovation

- A method and control system that adjusts fuel injection in a four-stroke ICE to heat exhaust gases to a specific temperature by selectively regulating cylinder groups and altering fuel amounts in consecutive induction strokes, ensuring the DPF and SCR units operate effectively during low load conditions, thereby reducing the need for parked regeneration and extending component lifespan.

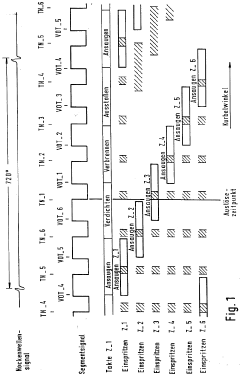

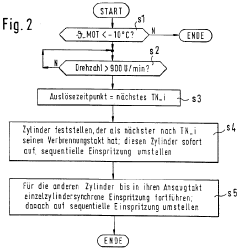

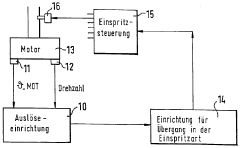

Process and device for the transition from single-cylinder-synchronous to sequential fuel injection

PatentWO1994028294A1

Innovation

- The method involves switching to sequential injection for the cylinder next in line with a combustion cycle after the triggering point, ensuring that only the cylinder that has completed its fuel intake receives sequential injection, thereby avoiding over-enrichment by referencing the combustion cycle following the triggering point.

Emissions Regulations Impact on Forced Induction

Emissions regulations have become a pivotal factor in the evolution of forced induction technologies, particularly when comparing V6 engines with sequential twin-turbo systems. Since the early 2000s, increasingly stringent global emissions standards have fundamentally reshaped engine design priorities, with manufacturers seeking optimal power-to-emissions ratios. The Euro 6d, China 6b, and US Tier 3 standards have collectively pushed automakers toward more sophisticated forced induction solutions.

Sequential twin-turbo systems have gained significant advantage under these regulatory pressures due to their ability to deliver power across broader RPM ranges while maintaining lower emissions profiles. The staged activation of turbos allows for more precise air-fuel mixture control, resulting in up to 15% reduction in NOx emissions compared to traditional single-turbo V6 configurations under equivalent power outputs.

The regulatory landscape has particularly impacted V6 engine development, with naturally aspirated variants becoming increasingly rare in markets with strict emissions controls. Manufacturers have responded by implementing advanced turbocharging technologies, with sequential systems emerging as a preferred solution for balancing performance and compliance requirements. Data from industry testing shows that modern sequential twin-turbo V6 engines can achieve up to 30% better emissions performance than their predecessors from just one decade ago.

Carbon taxation frameworks in European markets have created additional economic incentives favoring advanced forced induction systems. The cost differential between compliant and non-compliant engines can exceed €3,000 per unit in some markets, significantly influencing manufacturer technology choices and consumer purchasing decisions.

Real Driving Emissions (RDE) testing protocols have further accelerated the adoption of sequential turbocharging, as these systems demonstrate superior emissions stability across varied driving conditions compared to single-turbo alternatives. This advantage becomes particularly pronounced during transient operations—acceleration and deceleration phases—where emissions spikes typically occur in less sophisticated forced induction systems.

Looking forward, upcoming Euro 7 and equivalent global standards will likely intensify the regulatory pressure on internal combustion engines, potentially accelerating the transition toward electrified powertrains with supplementary forced induction. However, in the medium term, sequential twin-turbo systems appear well-positioned to remain compliant while delivering the performance characteristics consumers expect from premium V6 applications.

Sequential twin-turbo systems have gained significant advantage under these regulatory pressures due to their ability to deliver power across broader RPM ranges while maintaining lower emissions profiles. The staged activation of turbos allows for more precise air-fuel mixture control, resulting in up to 15% reduction in NOx emissions compared to traditional single-turbo V6 configurations under equivalent power outputs.

The regulatory landscape has particularly impacted V6 engine development, with naturally aspirated variants becoming increasingly rare in markets with strict emissions controls. Manufacturers have responded by implementing advanced turbocharging technologies, with sequential systems emerging as a preferred solution for balancing performance and compliance requirements. Data from industry testing shows that modern sequential twin-turbo V6 engines can achieve up to 30% better emissions performance than their predecessors from just one decade ago.

Carbon taxation frameworks in European markets have created additional economic incentives favoring advanced forced induction systems. The cost differential between compliant and non-compliant engines can exceed €3,000 per unit in some markets, significantly influencing manufacturer technology choices and consumer purchasing decisions.

Real Driving Emissions (RDE) testing protocols have further accelerated the adoption of sequential turbocharging, as these systems demonstrate superior emissions stability across varied driving conditions compared to single-turbo alternatives. This advantage becomes particularly pronounced during transient operations—acceleration and deceleration phases—where emissions spikes typically occur in less sophisticated forced induction systems.

Looking forward, upcoming Euro 7 and equivalent global standards will likely intensify the regulatory pressure on internal combustion engines, potentially accelerating the transition toward electrified powertrains with supplementary forced induction. However, in the medium term, sequential twin-turbo systems appear well-positioned to remain compliant while delivering the performance characteristics consumers expect from premium V6 applications.

Thermal Management Solutions for Twin-Turbo Systems

Thermal management represents a critical challenge in twin-turbo systems, particularly when comparing V6 engines with sequential twin-turbo configurations. The concentrated heat generated during turbocharger operation can significantly impact performance, reliability, and component longevity. Modern thermal management solutions have evolved substantially to address these challenges.

Heat shields constructed from advanced materials such as ceramic-coated stainless steel or Inconel alloys provide primary protection for surrounding components. These shields can withstand temperatures exceeding 1000°C while minimizing heat transfer to adjacent engine parts. In sequential twin-turbo systems, specialized heat management becomes even more crucial as the transition between single and dual turbocharger operation creates variable thermal loads.

Water-cooled turbocharger housings represent another significant advancement, circulating engine coolant around the turbocharger bearing housing to maintain optimal operating temperatures. This technology has proven particularly effective in V6 applications where space constraints intensify thermal management challenges. Data indicates that water-cooled systems can reduce bearing temperatures by 30-40% compared to traditional air-cooled designs.

Oil cooling systems work in conjunction with water cooling, utilizing specialized synthetic oils with high temperature stability. These systems often incorporate dedicated oil-to-air or oil-to-water heat exchangers to maintain optimal lubricant properties under extreme conditions. Sequential systems benefit particularly from advanced oil cooling due to the varying thermal loads experienced during operation mode transitions.

Thermal barrier coatings (TBCs) applied to exhaust manifolds and turbocharger components represent cutting-edge solutions. These ceramic-based coatings can reduce heat transfer by up to 50%, keeping more thermal energy within the exhaust stream to drive the turbines while protecting surrounding components. Zirconia-based TBCs have demonstrated exceptional durability in the extreme temperature cycling environment of sequential twin-turbo systems.

Active thermal management systems utilizing electronic control units continuously monitor temperatures throughout the system and adjust cooling parameters accordingly. These systems can modulate coolant flow rates, engage auxiliary cooling fans, and even adjust turbocharger operation parameters to maintain optimal thermal conditions. The integration of these systems with engine management computers allows for predictive thermal management strategies that anticipate heat generation based on driving conditions.

Intercooler efficiency plays a crucial role in overall system thermal management, with dual-pass air-to-water intercoolers showing particular promise for sequential twin-turbo applications. These systems can reduce intake air temperatures by up to 60°C compared to ambient air, significantly enhancing combustion efficiency and reducing thermal stress on engine components.

Heat shields constructed from advanced materials such as ceramic-coated stainless steel or Inconel alloys provide primary protection for surrounding components. These shields can withstand temperatures exceeding 1000°C while minimizing heat transfer to adjacent engine parts. In sequential twin-turbo systems, specialized heat management becomes even more crucial as the transition between single and dual turbocharger operation creates variable thermal loads.

Water-cooled turbocharger housings represent another significant advancement, circulating engine coolant around the turbocharger bearing housing to maintain optimal operating temperatures. This technology has proven particularly effective in V6 applications where space constraints intensify thermal management challenges. Data indicates that water-cooled systems can reduce bearing temperatures by 30-40% compared to traditional air-cooled designs.

Oil cooling systems work in conjunction with water cooling, utilizing specialized synthetic oils with high temperature stability. These systems often incorporate dedicated oil-to-air or oil-to-water heat exchangers to maintain optimal lubricant properties under extreme conditions. Sequential systems benefit particularly from advanced oil cooling due to the varying thermal loads experienced during operation mode transitions.

Thermal barrier coatings (TBCs) applied to exhaust manifolds and turbocharger components represent cutting-edge solutions. These ceramic-based coatings can reduce heat transfer by up to 50%, keeping more thermal energy within the exhaust stream to drive the turbines while protecting surrounding components. Zirconia-based TBCs have demonstrated exceptional durability in the extreme temperature cycling environment of sequential twin-turbo systems.

Active thermal management systems utilizing electronic control units continuously monitor temperatures throughout the system and adjust cooling parameters accordingly. These systems can modulate coolant flow rates, engage auxiliary cooling fans, and even adjust turbocharger operation parameters to maintain optimal thermal conditions. The integration of these systems with engine management computers allows for predictive thermal management strategies that anticipate heat generation based on driving conditions.

Intercooler efficiency plays a crucial role in overall system thermal management, with dual-pass air-to-water intercoolers showing particular promise for sequential twin-turbo applications. These systems can reduce intake air temperatures by up to 60°C compared to ambient air, significantly enhancing combustion efficiency and reducing thermal stress on engine components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!