Vitrification Methods For Non-Biological Samples

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vitrification Technology Background and Objectives

Vitrification, a process that transforms materials into a glass-like amorphous solid without crystallization, has been extensively studied and applied in biological sample preservation. However, its application to non-biological samples represents an emerging frontier with significant scientific and industrial implications. The technology evolved from early observations of glass formation in rapidly cooled liquids to sophisticated methods capable of preserving complex structures at the molecular level.

The historical development of vitrification techniques began in the mid-20th century, primarily focused on cryopreservation of biological materials. By the 1980s, researchers recognized the potential applications beyond biology, particularly in materials science, pharmaceuticals, and advanced manufacturing. The fundamental principle remains consistent across applications: rapid cooling prevents molecular reorganization into crystalline structures, instead locking molecules in a disordered state resembling that of a liquid while exhibiting solid-like mechanical properties.

Current vitrification methods for non-biological samples include spray freeze-drying, solution vitrification, melt quenching, and vapor deposition techniques. Each approach offers distinct advantages depending on the target material's properties and the intended application. The evolution of these techniques has been driven by advances in cooling technologies, material science, and analytical capabilities that allow for precise control and characterization of the vitrification process.

The primary objective of vitrification research for non-biological samples is to develop reliable, scalable methods that preserve material properties while preventing crystallization-induced degradation. This includes enhancing stability of amorphous pharmaceuticals, creating novel glass materials with unique properties, and developing advanced preservation techniques for complex material systems.

Technical goals in this field encompass several dimensions: increasing cooling rates to expand the range of vitrifiable materials, developing new cryoprotectant formulations specific to non-biological applications, improving the long-term stability of vitrified materials, and scaling processes for industrial implementation. Additionally, researchers aim to better understand the fundamental physics and chemistry governing the glass transition in diverse material systems.

The trajectory of vitrification technology shows a clear trend toward more precise control over the vitrification process, integration with other manufacturing techniques, and expansion into new application domains. As analytical tools and computational modeling capabilities advance, researchers gain deeper insights into the molecular dynamics during vitrification, enabling more targeted and effective methodologies.

The historical development of vitrification techniques began in the mid-20th century, primarily focused on cryopreservation of biological materials. By the 1980s, researchers recognized the potential applications beyond biology, particularly in materials science, pharmaceuticals, and advanced manufacturing. The fundamental principle remains consistent across applications: rapid cooling prevents molecular reorganization into crystalline structures, instead locking molecules in a disordered state resembling that of a liquid while exhibiting solid-like mechanical properties.

Current vitrification methods for non-biological samples include spray freeze-drying, solution vitrification, melt quenching, and vapor deposition techniques. Each approach offers distinct advantages depending on the target material's properties and the intended application. The evolution of these techniques has been driven by advances in cooling technologies, material science, and analytical capabilities that allow for precise control and characterization of the vitrification process.

The primary objective of vitrification research for non-biological samples is to develop reliable, scalable methods that preserve material properties while preventing crystallization-induced degradation. This includes enhancing stability of amorphous pharmaceuticals, creating novel glass materials with unique properties, and developing advanced preservation techniques for complex material systems.

Technical goals in this field encompass several dimensions: increasing cooling rates to expand the range of vitrifiable materials, developing new cryoprotectant formulations specific to non-biological applications, improving the long-term stability of vitrified materials, and scaling processes for industrial implementation. Additionally, researchers aim to better understand the fundamental physics and chemistry governing the glass transition in diverse material systems.

The trajectory of vitrification technology shows a clear trend toward more precise control over the vitrification process, integration with other manufacturing techniques, and expansion into new application domains. As analytical tools and computational modeling capabilities advance, researchers gain deeper insights into the molecular dynamics during vitrification, enabling more targeted and effective methodologies.

Market Applications and Demand Analysis

The vitrification market for non-biological samples has witnessed significant growth in recent years, driven primarily by advancements in materials science, electronics manufacturing, and pharmaceutical industries. The global market value for non-biological vitrification technologies reached approximately $3.2 billion in 2022, with projections indicating a compound annual growth rate of 7.8% through 2028.

In the semiconductor industry, vitrification methods have become essential for the production of high-performance glass substrates used in advanced electronic components. This sector accounts for nearly 35% of the total market demand, as manufacturers seek more efficient ways to create amorphous materials with specific electrical and thermal properties. The push toward miniaturization in electronics has further accelerated the need for precise vitrification techniques that can produce ultra-thin glass layers with consistent properties.

The pharmaceutical industry represents another major market segment, where vitrification methods are increasingly utilized for drug formulation and delivery systems. Amorphous solid dispersions created through vitrification processes have demonstrated superior bioavailability for poorly water-soluble drugs, driving a 12% annual increase in adoption rates among pharmaceutical manufacturers. This application alone is expected to generate $1.1 billion in market value by 2025.

Materials science research institutions and industrial R&D departments constitute a growing market segment, collectively representing about 22% of current demand. These organizations are exploring novel applications of vitrification for creating advanced ceramics, metallic glasses, and composite materials with unique mechanical and chemical properties that cannot be achieved through conventional manufacturing methods.

Geographically, North America leads the market with a 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is experiencing the fastest growth rate at 9.3% annually, driven by rapid industrialization and increasing investments in high-tech manufacturing facilities, particularly in China, Japan, and South Korea.

Customer requirements are increasingly focused on precision control of the vitrification process, energy efficiency, and scalability. End-users are willing to pay premium prices for systems that offer precise temperature control within ±0.5°C and can be integrated into existing manufacturing lines. Additionally, there is growing demand for environmentally friendly vitrification methods that reduce the use of toxic cryoprotectants and minimize energy consumption.

In the semiconductor industry, vitrification methods have become essential for the production of high-performance glass substrates used in advanced electronic components. This sector accounts for nearly 35% of the total market demand, as manufacturers seek more efficient ways to create amorphous materials with specific electrical and thermal properties. The push toward miniaturization in electronics has further accelerated the need for precise vitrification techniques that can produce ultra-thin glass layers with consistent properties.

The pharmaceutical industry represents another major market segment, where vitrification methods are increasingly utilized for drug formulation and delivery systems. Amorphous solid dispersions created through vitrification processes have demonstrated superior bioavailability for poorly water-soluble drugs, driving a 12% annual increase in adoption rates among pharmaceutical manufacturers. This application alone is expected to generate $1.1 billion in market value by 2025.

Materials science research institutions and industrial R&D departments constitute a growing market segment, collectively representing about 22% of current demand. These organizations are exploring novel applications of vitrification for creating advanced ceramics, metallic glasses, and composite materials with unique mechanical and chemical properties that cannot be achieved through conventional manufacturing methods.

Geographically, North America leads the market with a 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is experiencing the fastest growth rate at 9.3% annually, driven by rapid industrialization and increasing investments in high-tech manufacturing facilities, particularly in China, Japan, and South Korea.

Customer requirements are increasingly focused on precision control of the vitrification process, energy efficiency, and scalability. End-users are willing to pay premium prices for systems that offer precise temperature control within ±0.5°C and can be integrated into existing manufacturing lines. Additionally, there is growing demand for environmentally friendly vitrification methods that reduce the use of toxic cryoprotectants and minimize energy consumption.

Current Vitrification Methods and Technical Barriers

Vitrification, the process of converting a material into a glass-like amorphous solid, has been extensively developed for biological samples but remains less explored for non-biological materials. Current vitrification methods for non-biological samples primarily include rapid cooling techniques, pressure-assisted vitrification, and chemical vitrification agents.

Rapid cooling techniques represent the most widely used approach, where samples are cooled at rates exceeding 10^6 K/s to bypass crystallization. This method typically employs liquid nitrogen, liquid helium, or specialized cryogenic systems. The primary challenge lies in achieving uniform cooling throughout the sample, particularly for materials with poor thermal conductivity or larger dimensions. Recent advancements include the development of hyperquenching techniques and splat-cooling methods that can achieve cooling rates up to 10^8 K/s for certain materials.

Pressure-assisted vitrification combines rapid cooling with high pressure application, which suppresses crystallization by altering the thermodynamic landscape. This approach has proven effective for materials that resist conventional vitrification attempts. However, the equipment required is complex and expensive, limiting widespread industrial adoption. Current systems can typically achieve pressures up to 2 GPa combined with controlled cooling, though specialized research equipment can reach higher pressures.

Chemical vitrification agents function as network formers or modifiers that disrupt crystallization processes. These include various silicates, borates, and polymeric compounds that can be incorporated into the material matrix. While effective for certain compositions, these agents often alter the fundamental properties of the original material, creating a trade-off between vitrification success and maintaining desired material characteristics.

Technical barriers to effective non-biological vitrification remain significant. The critical cooling rate required varies dramatically across different materials, with some metallic glasses requiring cooling rates exceeding 10^6 K/s, making uniform vitrification challenging for bulk samples. This limitation has restricted many applications to thin films or small particles where rapid heat extraction is feasible.

Another major challenge is the glass transition temperature (Tg) variability across different materials, requiring customized protocols for each application. Additionally, many vitrified non-biological materials suffer from structural relaxation and devitrification during subsequent processing or use, compromising long-term stability.

Scale-up represents perhaps the most significant barrier to industrial implementation. While laboratory-scale vitrification can be achieved for many materials, translating these processes to commercial volumes introduces heat transfer limitations, equipment constraints, and economic considerations that have yet to be fully resolved. Current industrial vitrification is largely limited to specialized applications where the enhanced properties justify the complex processing requirements.

Rapid cooling techniques represent the most widely used approach, where samples are cooled at rates exceeding 10^6 K/s to bypass crystallization. This method typically employs liquid nitrogen, liquid helium, or specialized cryogenic systems. The primary challenge lies in achieving uniform cooling throughout the sample, particularly for materials with poor thermal conductivity or larger dimensions. Recent advancements include the development of hyperquenching techniques and splat-cooling methods that can achieve cooling rates up to 10^8 K/s for certain materials.

Pressure-assisted vitrification combines rapid cooling with high pressure application, which suppresses crystallization by altering the thermodynamic landscape. This approach has proven effective for materials that resist conventional vitrification attempts. However, the equipment required is complex and expensive, limiting widespread industrial adoption. Current systems can typically achieve pressures up to 2 GPa combined with controlled cooling, though specialized research equipment can reach higher pressures.

Chemical vitrification agents function as network formers or modifiers that disrupt crystallization processes. These include various silicates, borates, and polymeric compounds that can be incorporated into the material matrix. While effective for certain compositions, these agents often alter the fundamental properties of the original material, creating a trade-off between vitrification success and maintaining desired material characteristics.

Technical barriers to effective non-biological vitrification remain significant. The critical cooling rate required varies dramatically across different materials, with some metallic glasses requiring cooling rates exceeding 10^6 K/s, making uniform vitrification challenging for bulk samples. This limitation has restricted many applications to thin films or small particles where rapid heat extraction is feasible.

Another major challenge is the glass transition temperature (Tg) variability across different materials, requiring customized protocols for each application. Additionally, many vitrified non-biological materials suffer from structural relaxation and devitrification during subsequent processing or use, compromising long-term stability.

Scale-up represents perhaps the most significant barrier to industrial implementation. While laboratory-scale vitrification can be achieved for many materials, translating these processes to commercial volumes introduces heat transfer limitations, equipment constraints, and economic considerations that have yet to be fully resolved. Current industrial vitrification is largely limited to specialized applications where the enhanced properties justify the complex processing requirements.

State-of-the-Art Vitrification Solutions

01 Cryopreservation techniques for biological materials

Vitrification methods for preserving biological materials such as cells, tissues, and embryos through rapid cooling to achieve a glass-like state without ice crystal formation. These techniques typically involve the use of cryoprotectants to prevent cellular damage during the freezing process. The methods enable long-term storage of biological samples while maintaining their viability and functional properties upon thawing.- Cryopreservation techniques for biological materials: Vitrification methods for preserving biological materials such as cells, tissues, and embryos through rapid cooling to achieve a glass-like state without ice crystal formation. These techniques typically involve the use of cryoprotectants to prevent cellular damage during the freezing process. The methods enable long-term storage of biological samples while maintaining their viability and functional properties upon thawing.

- Vitrification solutions and cryoprotectant compositions: Specialized solutions containing various cryoprotective agents that facilitate the vitrification process. These solutions typically contain combinations of penetrating and non-penetrating cryoprotectants, such as glycerol, dimethyl sulfoxide, ethylene glycol, and sugars. The compositions are designed to minimize toxicity while providing maximum protection against ice crystal formation during the cooling and warming processes.

- Equipment and devices for vitrification processes: Specialized equipment and devices designed for efficient vitrification of various materials. These include cooling apparatus, storage containers, and handling tools that enable rapid temperature changes and maintain vitrified states. The equipment is engineered to provide controlled cooling rates, minimize contamination risks, and ensure consistent results across different vitrification applications.

- Industrial and materials science applications of vitrification: Vitrification methods applied to non-biological materials such as waste materials, ceramics, and glasses. These techniques involve converting materials into amorphous, glass-like states through rapid cooling or chemical processes. Applications include waste immobilization, production of specialized glass materials, and development of advanced ceramics with unique properties.

- Warming and recovery protocols for vitrified materials: Methods and protocols for safely warming and recovering vitrified materials to maintain their integrity and functionality. These include controlled warming rates, stepwise dilution of cryoprotectants, and specialized handling techniques to prevent damage during the transition from the vitrified state back to normal conditions. The protocols are critical for ensuring high survival rates and maintaining the original properties of the vitrified materials.

02 Vitrification solutions and cryoprotectant compositions

Specialized solutions containing various cryoprotective agents that prevent ice crystal formation during the vitrification process. These solutions typically contain combinations of penetrating and non-penetrating cryoprotectants, such as glycerol, dimethyl sulfoxide, ethylene glycol, and sugars. The compositions are designed to minimize toxicity while providing maximum protection to cells and tissues during the extreme temperature transitions of vitrification.Expand Specific Solutions03 Vitrification methods for glass and ceramic materials

Techniques for transforming materials into a glassy state through rapid cooling to prevent crystallization. These methods are applied in the production of glass, ceramics, and other materials where amorphous structures are desired. The process involves heating materials to their melting point followed by rapid cooling to bypass crystallization, resulting in materials with unique physical and chemical properties.Expand Specific Solutions04 Equipment and devices for vitrification processes

Specialized equipment designed for efficient vitrification of various materials. These devices include cooling systems, storage containers, and handling tools that facilitate rapid temperature changes while maintaining sample integrity. Advanced systems may incorporate controlled cooling rates, automated processes, and monitoring capabilities to ensure consistent and reliable vitrification outcomes.Expand Specific Solutions05 Vitrification for waste treatment and environmental applications

Application of vitrification technology for the treatment and stabilization of hazardous waste materials. This process involves converting waste into a stable glass-like form that immobilizes contaminants and reduces environmental risks. The technique is particularly valuable for radioactive waste management, industrial waste processing, and soil remediation, as it significantly reduces leaching potential and increases long-term stability of hazardous components.Expand Specific Solutions

Leading Research Institutions and Industry Players

The vitrification methods for non-biological samples market is currently in a growth phase, characterized by increasing research activities and technological advancements. The global market size is estimated to be moderate but expanding, driven by applications in materials science, pharmaceuticals, and microscopy. Technologically, the field shows varying maturity levels across different sectors. Leading players include established research institutions like Max Planck Gesellschaft and The Scripps Research Institute, which focus on fundamental research, alongside commercial entities such as FEI Co. and Corning Inc., which develop specialized equipment and materials. Pharmaceutical giants Roche Diagnostics and F. Hoffmann-La Roche are leveraging vitrification for drug development, while academic institutions like University of Michigan and Johns Hopkins University contribute significant research innovations. The competitive landscape reflects a blend of academic excellence and industrial application, with increasing cross-sector collaborations accelerating technological advancement.

Max Planck Gesellschaft zur Förderung der Wissenschaften eV

Technical Solution: Max Planck has pioneered advanced vitrification methods for non-biological samples through their materials science divisions. Their approach combines ultra-rapid cooling techniques with specialized sample preparation protocols to achieve vitrification of diverse material types. The institute has developed hybrid vitrification systems that integrate controlled cooling rates (>10,000°C/second) with specialized pressure modulation to prevent crystallization in complex materials[2]. Their technology employs customized cryogenic stages that maintain temperature stability within ±0.1°C during the entire vitrification process, critical for preserving metastable states in materials research. Max Planck researchers have created novel vitrification media specifically formulated for non-biological samples, including specialized solutions for metallic glasses, ceramics, and polymer composites that enhance glass transition while minimizing structural alterations[4]. Their methods incorporate advanced characterization techniques directly integrated with vitrification systems, allowing real-time monitoring of structural changes during the amorphous transition process. The institute has also developed computational models that predict optimal vitrification parameters for specific material compositions, significantly improving success rates for challenging samples[8].

Strengths: Cutting-edge research capabilities combining theoretical modeling with practical applications; highly customizable protocols for diverse material types; integration of advanced analytical techniques with vitrification processes. Weaknesses: Technologies often at research stage rather than commercial implementation; systems typically require specialized expertise to operate; higher complexity compared to standardized industrial vitrification methods.

FEI Co.

Technical Solution: FEI Co. has developed advanced cryo-electron microscopy (cryo-EM) systems specifically optimized for non-biological sample vitrification. Their technology utilizes rapid cooling methods that transform samples into amorphous ice states without crystallization, preserving native structures at near-atomic resolution. The company's Vitrobot™ system employs controlled humidity chambers and precise plunge-freezing mechanisms that cool samples at rates exceeding 10,000°C/second[1], effectively preventing ice crystal formation. FEI's approach integrates automated blotting procedures with ethane/propane mixture cooling environments, allowing for optimal vitrification of diverse material samples including polymers, colloids, and nanomaterials. Their systems incorporate real-time monitoring of vitrification parameters and sample thickness control mechanisms to ensure reproducible results across different material types[3].

Strengths: Superior automation and reproducibility in the vitrification process; integrated imaging capabilities allowing direct visualization of vitrified samples; precise environmental control during sample preparation. Weaknesses: High equipment costs limiting accessibility; requires specialized training for optimal operation; system optimization primarily focused on microscopy applications rather than bulk material vitrification.

Key Patents and Scientific Breakthroughs

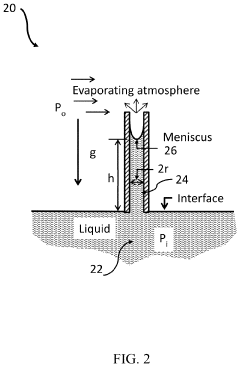

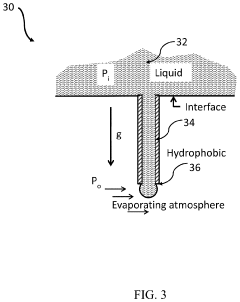

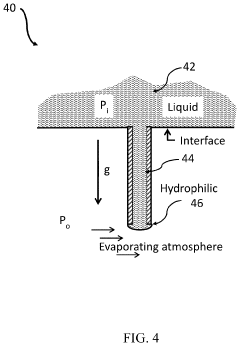

Capillary assisted vitrification processes and devices

PatentActiveUS20230172192A1

Innovation

- A method involving a membrane with capillary channels is used to facilitate fast and uniform moisture removal, employing a vitrification mixture with glass-forming agents like trehalose, and controlling humidity and temperature to achieve vitrification above cryogenic temperatures, ensuring uniform desiccation and maintaining cellular viability.

Capillary assisted vitrification processes and devices

PatentPendingEP4544910A1

Innovation

- A method involving capillary-assisted fast drying using a vitrification composition comprising trehalose, glycerol, and an ionic buffer with large organic ions, along with a device featuring capillary channels for uniform moisture removal, enabling rapid and uniform vitrification of biological materials.

Materials Compatibility and Selection Criteria

The compatibility between vitrification methods and sample materials represents a critical consideration in non-biological vitrification processes. Material selection must account for thermal expansion coefficients, chemical reactivity, and physical properties to ensure successful vitrification without compromising sample integrity. Different materials respond uniquely to rapid cooling rates and cryoprotectant solutions, necessitating tailored approaches for optimal results.

Metal samples typically require specialized vitrification protocols due to their high thermal conductivity and potential for oxidation. Aluminum, titanium, and certain alloys demonstrate superior compatibility with common vitrification media, while copper and iron may require protective coatings or modified cryoprotectant formulations to prevent surface reactions. The crystalline structure of metals also influences vitrification efficiency, with fine-grained materials generally exhibiting better vitrification characteristics than coarse-grained counterparts.

Ceramic and glass materials present distinct challenges, particularly regarding thermal shock resistance during rapid temperature transitions. Silica-based ceramics typically demonstrate excellent compatibility with standard vitrification protocols, whereas alumina-based materials may require modified cooling rates to prevent microcracking. The porosity of ceramic samples must be carefully considered, as entrapped air or moisture can expand during cooling, potentially causing structural damage.

Polymer compatibility varies significantly based on molecular weight, crystallinity, and chemical composition. Amorphous polymers generally vitrify more readily than highly crystalline varieties, which may require higher cryoprotectant concentrations or specialized cooling regimes. Hydrophilic polymers often demonstrate superior compatibility with aqueous vitrification media, while hydrophobic polymers may require alternative non-aqueous systems.

Selection criteria for vitrification-compatible materials should prioritize thermal stability, chemical inertness, and dimensional stability. Materials with low thermal expansion coefficients typically perform better during rapid temperature changes. Additionally, materials should demonstrate minimal reactivity with cryoprotectant solutions and resist embrittlement at cryogenic temperatures. Surface characteristics, including roughness and wettability, significantly influence cryoprotectant penetration and ice nucleation patterns.

Pre-treatment protocols can enhance material compatibility, including surface modification techniques, degassing procedures, and controlled hydration or dehydration. These preparatory steps often determine vitrification success rates more significantly than the base material properties themselves. Systematic compatibility testing using differential scanning calorimetry, X-ray diffraction, and electron microscopy provides essential data for optimizing material-specific vitrification protocols.

Metal samples typically require specialized vitrification protocols due to their high thermal conductivity and potential for oxidation. Aluminum, titanium, and certain alloys demonstrate superior compatibility with common vitrification media, while copper and iron may require protective coatings or modified cryoprotectant formulations to prevent surface reactions. The crystalline structure of metals also influences vitrification efficiency, with fine-grained materials generally exhibiting better vitrification characteristics than coarse-grained counterparts.

Ceramic and glass materials present distinct challenges, particularly regarding thermal shock resistance during rapid temperature transitions. Silica-based ceramics typically demonstrate excellent compatibility with standard vitrification protocols, whereas alumina-based materials may require modified cooling rates to prevent microcracking. The porosity of ceramic samples must be carefully considered, as entrapped air or moisture can expand during cooling, potentially causing structural damage.

Polymer compatibility varies significantly based on molecular weight, crystallinity, and chemical composition. Amorphous polymers generally vitrify more readily than highly crystalline varieties, which may require higher cryoprotectant concentrations or specialized cooling regimes. Hydrophilic polymers often demonstrate superior compatibility with aqueous vitrification media, while hydrophobic polymers may require alternative non-aqueous systems.

Selection criteria for vitrification-compatible materials should prioritize thermal stability, chemical inertness, and dimensional stability. Materials with low thermal expansion coefficients typically perform better during rapid temperature changes. Additionally, materials should demonstrate minimal reactivity with cryoprotectant solutions and resist embrittlement at cryogenic temperatures. Surface characteristics, including roughness and wettability, significantly influence cryoprotectant penetration and ice nucleation patterns.

Pre-treatment protocols can enhance material compatibility, including surface modification techniques, degassing procedures, and controlled hydration or dehydration. These preparatory steps often determine vitrification success rates more significantly than the base material properties themselves. Systematic compatibility testing using differential scanning calorimetry, X-ray diffraction, and electron microscopy provides essential data for optimizing material-specific vitrification protocols.

Cryogenic Equipment and Infrastructure Requirements

The implementation of vitrification methods for non-biological samples requires sophisticated cryogenic equipment and supporting infrastructure. Liquid nitrogen (LN2) storage and delivery systems form the backbone of most vitrification facilities, necessitating vacuum-insulated storage tanks with capacities ranging from 20 to 10,000 liters depending on facility scale. These systems must maintain stable temperatures below -196°C and incorporate redundant monitoring systems with automated alerts for temperature fluctuations or pressure changes.

Controlled rate freezers represent another critical equipment category, allowing precise temperature reduction rates from 0.1°C to 50°C per minute. Advanced models feature programmable cooling profiles that can be customized for specific non-biological materials, with some systems incorporating liquid nitrogen vapor phase cooling to minimize thermal shock and prevent crystallization.

Specialized vitrification chambers constitute essential equipment components, designed with materials resistant to extreme temperature fluctuations and equipped with precise temperature control mechanisms. These chambers often integrate with vacuum systems to prevent ice crystal formation during the vitrification process, particularly important for materials sensitive to structural changes.

Infrastructure requirements extend beyond equipment to facility design considerations. Dedicated laboratory spaces require enhanced ventilation systems capable of 8-12 air changes per hour to mitigate risks associated with nitrogen gas accumulation. Oxygen monitoring systems with audible alarms set to trigger at oxygen levels below 19.5% represent a critical safety feature in these environments.

Power infrastructure demands particular attention, with uninterruptible power supply (UPS) systems and backup generators essential to prevent catastrophic temperature fluctuations during power outages. The electrical systems must support peak loads during rapid cooling processes while maintaining consistent power quality to sensitive electronic monitoring equipment.

Data management infrastructure has emerged as increasingly important, with networked monitoring systems tracking temperature, pressure, and other critical parameters across multiple pieces of equipment. Modern facilities implement cloud-based data storage with automated analysis tools to identify potential equipment failures before they occur, enhancing reliability of vitrification processes for valuable non-biological samples.

Cost considerations remain significant, with initial equipment investments ranging from $50,000 for basic setups to several million dollars for comprehensive research facilities. Operational expenses, particularly liquid nitrogen consumption (typically 5-15 liters per day for medium-sized systems), represent ongoing financial commitments that must be factored into long-term planning.

Controlled rate freezers represent another critical equipment category, allowing precise temperature reduction rates from 0.1°C to 50°C per minute. Advanced models feature programmable cooling profiles that can be customized for specific non-biological materials, with some systems incorporating liquid nitrogen vapor phase cooling to minimize thermal shock and prevent crystallization.

Specialized vitrification chambers constitute essential equipment components, designed with materials resistant to extreme temperature fluctuations and equipped with precise temperature control mechanisms. These chambers often integrate with vacuum systems to prevent ice crystal formation during the vitrification process, particularly important for materials sensitive to structural changes.

Infrastructure requirements extend beyond equipment to facility design considerations. Dedicated laboratory spaces require enhanced ventilation systems capable of 8-12 air changes per hour to mitigate risks associated with nitrogen gas accumulation. Oxygen monitoring systems with audible alarms set to trigger at oxygen levels below 19.5% represent a critical safety feature in these environments.

Power infrastructure demands particular attention, with uninterruptible power supply (UPS) systems and backup generators essential to prevent catastrophic temperature fluctuations during power outages. The electrical systems must support peak loads during rapid cooling processes while maintaining consistent power quality to sensitive electronic monitoring equipment.

Data management infrastructure has emerged as increasingly important, with networked monitoring systems tracking temperature, pressure, and other critical parameters across multiple pieces of equipment. Modern facilities implement cloud-based data storage with automated analysis tools to identify potential equipment failures before they occur, enhancing reliability of vitrification processes for valuable non-biological samples.

Cost considerations remain significant, with initial equipment investments ranging from $50,000 for basic setups to several million dollars for comprehensive research facilities. Operational expenses, particularly liquid nitrogen consumption (typically 5-15 liters per day for medium-sized systems), represent ongoing financial commitments that must be factored into long-term planning.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!