Why SLAM Is Key To Warehouse Automation?

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SLAM Technology Evolution and Warehouse Automation Goals

Simultaneous Localization and Mapping (SLAM) technology has evolved significantly since its inception in the 1980s, transitioning from theoretical concepts to practical applications across various industries. The evolution of SLAM has been characterized by increasing accuracy, computational efficiency, and adaptability to dynamic environments. Early SLAM systems relied heavily on expensive sensors and had limited real-time processing capabilities, making them impractical for commercial applications. However, advancements in sensor technology, computational power, and algorithm development have transformed SLAM into a cornerstone technology for autonomous navigation systems.

In the warehouse automation context, SLAM technology has undergone specific adaptations to address the unique challenges of indoor logistics environments. The integration of visual sensors, LiDAR, and inertial measurement units has enabled more robust performance in complex warehouse settings characterized by varying lighting conditions, reflective surfaces, and dynamic obstacles. Modern warehouse-focused SLAM solutions now incorporate deep learning techniques to enhance object recognition and environmental understanding, allowing for more intelligent navigation and interaction with warehouse elements.

The primary goal of implementing SLAM in warehouse automation is to achieve flexible, scalable, and cost-effective autonomous navigation without requiring extensive infrastructure modifications. Traditional warehouse automation systems often relied on fixed infrastructure such as magnetic strips, QR codes, or reflective markers, which limited adaptability and increased implementation costs. SLAM technology aims to eliminate these constraints by enabling robots to create and update maps dynamically while simultaneously determining their position within these maps.

Another critical objective is to enhance operational efficiency through improved path planning and obstacle avoidance. SLAM-enabled warehouse robots can identify optimal routes, adapt to changing environments, and navigate around unexpected obstacles, significantly reducing downtime and increasing throughput. This capability is particularly valuable in high-volume e-commerce fulfillment centers where layout changes are frequent and operational agility is paramount.

Safety enhancement represents another fundamental goal of SLAM implementation in warehouse environments. By providing robots with accurate environmental awareness and precise localization capabilities, SLAM technology enables safer human-robot collaboration in shared workspaces. This aspect is increasingly important as warehouses evolve toward hybrid operational models where human workers and autonomous systems coexist.

The long-term strategic objective of SLAM in warehouse automation extends beyond navigation to comprehensive spatial intelligence. Advanced SLAM systems aim to provide actionable insights about warehouse operations by analyzing spatial data patterns, identifying bottlenecks, and suggesting layout optimizations. This evolution from simple navigation tool to spatial intelligence platform represents the next frontier in warehouse automation, promising to deliver unprecedented levels of operational efficiency and adaptability.

In the warehouse automation context, SLAM technology has undergone specific adaptations to address the unique challenges of indoor logistics environments. The integration of visual sensors, LiDAR, and inertial measurement units has enabled more robust performance in complex warehouse settings characterized by varying lighting conditions, reflective surfaces, and dynamic obstacles. Modern warehouse-focused SLAM solutions now incorporate deep learning techniques to enhance object recognition and environmental understanding, allowing for more intelligent navigation and interaction with warehouse elements.

The primary goal of implementing SLAM in warehouse automation is to achieve flexible, scalable, and cost-effective autonomous navigation without requiring extensive infrastructure modifications. Traditional warehouse automation systems often relied on fixed infrastructure such as magnetic strips, QR codes, or reflective markers, which limited adaptability and increased implementation costs. SLAM technology aims to eliminate these constraints by enabling robots to create and update maps dynamically while simultaneously determining their position within these maps.

Another critical objective is to enhance operational efficiency through improved path planning and obstacle avoidance. SLAM-enabled warehouse robots can identify optimal routes, adapt to changing environments, and navigate around unexpected obstacles, significantly reducing downtime and increasing throughput. This capability is particularly valuable in high-volume e-commerce fulfillment centers where layout changes are frequent and operational agility is paramount.

Safety enhancement represents another fundamental goal of SLAM implementation in warehouse environments. By providing robots with accurate environmental awareness and precise localization capabilities, SLAM technology enables safer human-robot collaboration in shared workspaces. This aspect is increasingly important as warehouses evolve toward hybrid operational models where human workers and autonomous systems coexist.

The long-term strategic objective of SLAM in warehouse automation extends beyond navigation to comprehensive spatial intelligence. Advanced SLAM systems aim to provide actionable insights about warehouse operations by analyzing spatial data patterns, identifying bottlenecks, and suggesting layout optimizations. This evolution from simple navigation tool to spatial intelligence platform represents the next frontier in warehouse automation, promising to deliver unprecedented levels of operational efficiency and adaptability.

Market Demand Analysis for Automated Warehouse Solutions

The global warehouse automation market is experiencing unprecedented growth, driven by the convergence of e-commerce expansion, labor shortages, and technological advancements. Current market valuations place the automated warehouse solutions sector at approximately $15 billion, with projections indicating a compound annual growth rate of 14-16% through 2028. This acceleration reflects the urgent need for more efficient, scalable, and responsive supply chain operations across industries.

E-commerce has fundamentally transformed consumer expectations, with same-day and next-day delivery becoming standard requirements rather than premium services. This shift has created substantial demand for warehouse solutions that can process orders with greater speed and accuracy. SLAM (Simultaneous Localization and Mapping) technology has emerged as a critical enabler in this environment, allowing autonomous mobile robots to navigate complex warehouse environments without extensive infrastructure modifications.

Labor challenges represent another significant market driver. Warehousing operations globally face persistent staffing difficulties, with vacancy rates in logistics positions reaching 30% in some regions. The COVID-19 pandemic exacerbated these challenges while simultaneously accelerating e-commerce adoption. Companies are increasingly viewing automation not merely as an efficiency tool but as a business continuity necessity, with SLAM-enabled solutions offering flexibility that fixed automation cannot match.

The market demonstrates strong regional variations in adoption patterns. North America leads in implementation of advanced SLAM-based warehouse automation, accounting for approximately 38% of global market share. Asia-Pacific represents the fastest-growing region with 18% annual growth, driven primarily by China's massive e-commerce sector and manufacturing capabilities. European markets show particular interest in SLAM solutions that can be deployed in older, space-constrained facilities common throughout the region.

Industry-specific demand patterns reveal retail and third-party logistics providers as the primary adopters, collectively representing over 60% of market demand. However, pharmaceutical and food distribution sectors are showing the fastest growth rates in adoption, driven by requirements for traceability and temperature-controlled environments where SLAM-enabled robots excel.

Customer expectations are evolving beyond basic automation. End-users increasingly demand solutions offering scalability, flexibility, and intelligence. SLAM technology addresses these requirements by enabling systems that can adapt to changing warehouse layouts, integrate with existing operations, and continuously improve performance through machine learning capabilities. Market research indicates that 73% of warehouse operators now prioritize flexibility in automation investments over raw throughput metrics.

Return on investment considerations remain paramount, with most enterprises expecting payback periods under 24 months. SLAM-based solutions typically demonstrate favorable economics compared to fixed automation infrastructure, particularly for mid-sized operations where adaptability to seasonal fluctuations is essential.

E-commerce has fundamentally transformed consumer expectations, with same-day and next-day delivery becoming standard requirements rather than premium services. This shift has created substantial demand for warehouse solutions that can process orders with greater speed and accuracy. SLAM (Simultaneous Localization and Mapping) technology has emerged as a critical enabler in this environment, allowing autonomous mobile robots to navigate complex warehouse environments without extensive infrastructure modifications.

Labor challenges represent another significant market driver. Warehousing operations globally face persistent staffing difficulties, with vacancy rates in logistics positions reaching 30% in some regions. The COVID-19 pandemic exacerbated these challenges while simultaneously accelerating e-commerce adoption. Companies are increasingly viewing automation not merely as an efficiency tool but as a business continuity necessity, with SLAM-enabled solutions offering flexibility that fixed automation cannot match.

The market demonstrates strong regional variations in adoption patterns. North America leads in implementation of advanced SLAM-based warehouse automation, accounting for approximately 38% of global market share. Asia-Pacific represents the fastest-growing region with 18% annual growth, driven primarily by China's massive e-commerce sector and manufacturing capabilities. European markets show particular interest in SLAM solutions that can be deployed in older, space-constrained facilities common throughout the region.

Industry-specific demand patterns reveal retail and third-party logistics providers as the primary adopters, collectively representing over 60% of market demand. However, pharmaceutical and food distribution sectors are showing the fastest growth rates in adoption, driven by requirements for traceability and temperature-controlled environments where SLAM-enabled robots excel.

Customer expectations are evolving beyond basic automation. End-users increasingly demand solutions offering scalability, flexibility, and intelligence. SLAM technology addresses these requirements by enabling systems that can adapt to changing warehouse layouts, integrate with existing operations, and continuously improve performance through machine learning capabilities. Market research indicates that 73% of warehouse operators now prioritize flexibility in automation investments over raw throughput metrics.

Return on investment considerations remain paramount, with most enterprises expecting payback periods under 24 months. SLAM-based solutions typically demonstrate favorable economics compared to fixed automation infrastructure, particularly for mid-sized operations where adaptability to seasonal fluctuations is essential.

Current SLAM Implementation Challenges in Warehouses

Despite the promising potential of SLAM (Simultaneous Localization and Mapping) in warehouse automation, several significant challenges impede its widespread implementation. The dynamic nature of warehouse environments presents a fundamental obstacle, as constantly moving objects, changing inventory layouts, and human workers create an ever-evolving landscape that challenges SLAM algorithms designed for static environments.

Lighting conditions in warehouses vary dramatically, from brightly lit areas to shadowy corners and aisles. These inconsistent illumination patterns can severely impact visual SLAM systems that rely on cameras for environmental perception, leading to tracking failures and mapping inaccuracies during routine operations.

The scale and complexity of modern warehouses introduce computational challenges that strain current SLAM implementations. Processing vast spatial data in real-time requires substantial computational resources, creating a tension between system responsiveness and hardware costs. This becomes particularly problematic when deploying multiple autonomous robots simultaneously across large facilities.

Reflective surfaces, common in warehouse environments through metal shelving, plastic wrapping, and polished floors, create perceptual anomalies for both LiDAR and camera-based SLAM systems. These surfaces generate false readings, ghost reflections, and depth perception errors that compromise mapping accuracy and robot localization.

Integration challenges with existing warehouse management systems (WMS) further complicate SLAM implementation. Many warehouses operate with legacy infrastructure that lacks standardized protocols for communicating with modern robotic systems, creating data silos that prevent seamless operation between inventory management and autonomous navigation systems.

The multi-robot coordination problem remains largely unsolved in practical warehouse implementations. When multiple robots utilize SLAM simultaneously, map sharing, conflict resolution, and collaborative mapping become critical requirements that current systems struggle to address efficiently without centralized control architectures.

Cost considerations present another significant barrier, as high-quality sensors required for robust SLAM performance (particularly industrial-grade LiDAR) remain expensive, pushing the total deployment cost beyond the reach of many small to medium-sized warehouse operations. This creates a technological divide where only larger operations can afford cutting-edge automation solutions.

Finally, the reliability requirements in warehouse environments exceed what many current SLAM implementations can deliver. Warehouse operations demand near-perfect uptime and consistent performance across seasonal peaks, with minimal tolerance for navigation failures or system recalibrations that interrupt critical fulfillment operations.

Lighting conditions in warehouses vary dramatically, from brightly lit areas to shadowy corners and aisles. These inconsistent illumination patterns can severely impact visual SLAM systems that rely on cameras for environmental perception, leading to tracking failures and mapping inaccuracies during routine operations.

The scale and complexity of modern warehouses introduce computational challenges that strain current SLAM implementations. Processing vast spatial data in real-time requires substantial computational resources, creating a tension between system responsiveness and hardware costs. This becomes particularly problematic when deploying multiple autonomous robots simultaneously across large facilities.

Reflective surfaces, common in warehouse environments through metal shelving, plastic wrapping, and polished floors, create perceptual anomalies for both LiDAR and camera-based SLAM systems. These surfaces generate false readings, ghost reflections, and depth perception errors that compromise mapping accuracy and robot localization.

Integration challenges with existing warehouse management systems (WMS) further complicate SLAM implementation. Many warehouses operate with legacy infrastructure that lacks standardized protocols for communicating with modern robotic systems, creating data silos that prevent seamless operation between inventory management and autonomous navigation systems.

The multi-robot coordination problem remains largely unsolved in practical warehouse implementations. When multiple robots utilize SLAM simultaneously, map sharing, conflict resolution, and collaborative mapping become critical requirements that current systems struggle to address efficiently without centralized control architectures.

Cost considerations present another significant barrier, as high-quality sensors required for robust SLAM performance (particularly industrial-grade LiDAR) remain expensive, pushing the total deployment cost beyond the reach of many small to medium-sized warehouse operations. This creates a technological divide where only larger operations can afford cutting-edge automation solutions.

Finally, the reliability requirements in warehouse environments exceed what many current SLAM implementations can deliver. Warehouse operations demand near-perfect uptime and consistent performance across seasonal peaks, with minimal tolerance for navigation failures or system recalibrations that interrupt critical fulfillment operations.

Current SLAM-based Navigation Approaches for Robots

01 Visual SLAM techniques for autonomous navigation

Visual SLAM techniques use camera data to simultaneously map an environment and locate a device within it. These systems process visual features to create 3D maps while tracking the camera's position in real-time. Advanced implementations incorporate deep learning for improved feature detection and matching, enabling more robust performance in challenging environments such as low-light conditions or dynamic scenes. These technologies are particularly valuable for autonomous vehicles, drones, and robots that need to navigate without external positioning systems.- Visual SLAM techniques for autonomous navigation: Visual SLAM techniques use camera data to simultaneously map an environment and locate a device within it. These systems process visual features to create 3D maps while tracking the camera's position in real-time. Advanced algorithms handle feature detection, matching, and optimization to ensure accurate positioning even in dynamic environments. This approach is particularly valuable for autonomous vehicles, drones, and robots that need to navigate without external positioning systems.

- SLAM integration with machine learning and AI: Machine learning and artificial intelligence significantly enhance SLAM capabilities by improving feature recognition, prediction accuracy, and adaptability to changing environments. Neural networks can be trained to identify objects and landmarks more effectively than traditional algorithms, while also predicting motion patterns. These AI-enhanced SLAM systems can better handle challenging scenarios like low-light conditions, featureless environments, or occlusions, making them more robust for real-world applications.

- Sensor fusion approaches for robust SLAM: Sensor fusion combines data from multiple sensors such as cameras, LiDAR, radar, IMUs, and GPS to create more accurate and reliable SLAM systems. By integrating complementary sensor data, these systems can overcome the limitations of individual sensors, providing continuous operation across diverse environments and conditions. Advanced filtering techniques like Kalman filters or particle filters help merge the various data streams while minimizing errors and uncertainties in the mapping and localization process.

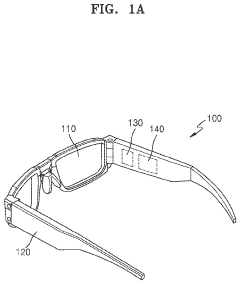

- SLAM for augmented and virtual reality applications: SLAM technology enables immersive AR/VR experiences by accurately tracking device position and mapping physical spaces in real-time. This allows virtual objects to be placed convincingly within the real world for AR applications or creates accurate virtual representations of physical spaces for VR. These systems must operate with minimal latency on resource-constrained devices while maintaining precise tracking to prevent motion sickness and ensure seamless integration between virtual and physical elements.

- Optimization techniques for real-time SLAM performance: Various optimization techniques improve SLAM performance for real-time applications on devices with limited computational resources. These include loop closure detection to correct accumulated errors, graph-based optimization to maintain global consistency, and efficient data structures for map representation. Edge computing approaches distribute processing between devices and servers, while hardware acceleration leverages specialized processors like GPUs or custom ASICs to speed up computationally intensive SLAM operations.

02 SLAM for augmented and virtual reality applications

SLAM technology enables precise spatial mapping and device positioning for AR/VR applications. By tracking the user's movement in real-time while building a map of the surrounding environment, these systems can accurately place virtual objects in the physical world or create immersive virtual experiences. The technology processes sensor data from cameras and IMUs to detect features, estimate motion, and construct 3D representations of spaces. This allows for persistent AR experiences where digital content remains fixed in physical locations even as users move around.Expand Specific Solutions03 Integration of SLAM with artificial intelligence and machine learning

Modern SLAM systems increasingly incorporate AI and machine learning techniques to enhance mapping accuracy and object recognition capabilities. Neural networks are used to improve feature extraction, scene understanding, and prediction of dynamic elements in the environment. These AI-enhanced SLAM systems can identify and classify objects within the mapped space, predict movement patterns, and adapt to changing environments. The integration enables more intelligent navigation decisions and better performance in complex, crowded, or changing environments where traditional SLAM algorithms might struggle.Expand Specific Solutions04 Multi-sensor fusion approaches for robust SLAM

Multi-sensor fusion approaches combine data from various sensors such as cameras, LiDAR, radar, IMUs, and GPS to create more robust SLAM systems. By integrating complementary sensor information, these systems can overcome limitations of single-sensor approaches, such as visual SLAM's vulnerability to lighting conditions or LiDAR's limited range. Sensor fusion algorithms synchronize and calibrate data from different sources, weighting inputs based on reliability in various conditions. This approach enables continuous operation across diverse environments and conditions, making SLAM more dependable for critical applications.Expand Specific Solutions05 Optimization techniques for real-time SLAM performance

Various optimization techniques are employed to enhance SLAM performance for real-time applications with limited computational resources. These include efficient data structures for map representation, loop closure detection to correct accumulated errors, and graph-based optimization to maintain global consistency. Hardware acceleration using GPUs or specialized processors enables faster processing of sensor data and map updates. Edge computing approaches distribute computational load between devices and nearby servers, while sparse mapping techniques reduce memory requirements by storing only essential features of the environment.Expand Specific Solutions

Key Industry Players in Warehouse SLAM Solutions

SLAM technology is emerging as a critical enabler for warehouse automation, currently in its growth phase with the market expected to reach significant expansion in the coming years. The technology has evolved from experimental to commercially viable, with varying degrees of maturity across implementations. Companies like Locus Robotics are leading commercial applications with advanced mobile robots for e-commerce fulfillment, while research institutions such as Beijing Institute of Technology and National University of Defense Technology are pushing technical boundaries. TRX Systems and ARpalus demonstrate SLAM's diversification beyond traditional navigation into inventory management and retail analytics. The ecosystem shows a balanced mix of established players and innovative startups, indicating a technology approaching mainstream adoption while still offering substantial growth opportunities.

Locus Robotics Corp.

Technical Solution: Locus Robotics has developed an advanced SLAM (Simultaneous Localization and Mapping) system specifically optimized for warehouse environments. Their LocusBot autonomous mobile robots utilize a multi-sensor fusion approach combining LiDAR, cameras, and inertial measurement units to create accurate real-time maps of dynamic warehouse environments. The system employs proprietary algorithms that can distinguish between permanent warehouse fixtures and temporary obstacles like pallets or personnel. Their SLAM technology enables robots to navigate collaboratively in high-density environments, with each robot contributing to a shared mapping database that improves over time through machine learning. This allows for efficient path planning even in constantly changing warehouse layouts without requiring expensive infrastructure modifications.

Strengths: Superior multi-robot coordination capabilities allow for scalable fleets that maintain efficiency even as robot numbers increase. Their system adapts quickly to layout changes without requiring remapping. Weaknesses: Higher initial implementation costs compared to some competitors, and the system requires more sophisticated IT infrastructure to support the collaborative mapping database.

TRX Systems, Inc.

Technical Solution: TRX Systems has developed NEON® Warehouse, a specialized SLAM solution designed for warehouse automation that functions in GPS-denied environments. Their technology combines inertial sensors, RF signal analysis, and advanced sensor fusion algorithms to provide continuous 3D positioning and mapping capabilities. What distinguishes TRX's approach is their hybrid SLAM system that can operate without relying solely on visual features, making it effective in visually challenging warehouse conditions such as varying lighting, dust, or areas with minimal distinguishing features. The system incorporates machine learning algorithms that improve mapping accuracy over time by recognizing patterns in warehouse operations and environmental characteristics. TRX's solution also includes infrastructure-free location tracking for both automated systems and human workers, enabling comprehensive warehouse activity monitoring and optimization.

Strengths: Exceptional performance in visually challenging environments where traditional vision-based SLAM systems struggle. Their solution requires minimal fixed infrastructure, reducing installation costs and complexity. Weaknesses: Processing requirements can be higher than simpler SLAM implementations, potentially requiring more powerful onboard computing for mobile robots.

Core SLAM Algorithms and Mapping Techniques Analysis

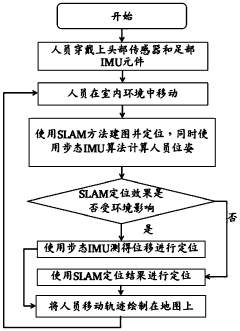

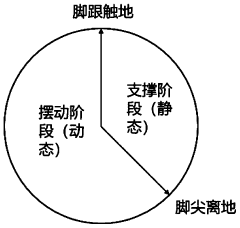

Indoor personnel autonomous positioning method based on SLAM and gait IMU fusion

PatentInactiveCN109974696A

Innovation

- Using a fusion positioning method based on SLAM and gait IMU, through wireless communication between SLAM sensors and IMU components, combined with the Magwick AHRS algorithm and gait characteristics to eliminate IMU cumulative errors, fuse SLAM and IMU positioning results, and use IMU to provide accurate positioning in smoke environments Motion trajectory data to improve positioning accuracy.

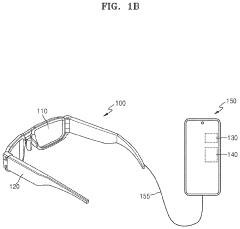

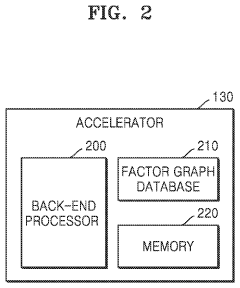

Method for performing simultaneous localization and mapping and device using same

PatentActiveUS20220254046A1

Innovation

- An accelerator is provided in an electronic device, comprising a factor graph database, memory, and a back-end processor that performs optimization calculations by converting data into matrices, dividing them into sub-tracks, and performing parallel matrix and vector calculations, allowing for efficient reuse of matrices and reduced data loading times.

ROI Assessment of SLAM-Powered Warehouse Systems

Implementing SLAM (Simultaneous Localization and Mapping) technology in warehouse automation represents a significant capital investment that requires thorough financial analysis. When evaluating the ROI of SLAM-powered warehouse systems, organizations must consider both direct cost savings and broader operational benefits that contribute to long-term value creation.

Initial implementation costs typically include hardware components (sensors, cameras, computing units), software licenses, integration services, and staff training. These upfront investments generally range from $250,000 to $2 million depending on warehouse size and complexity. However, these costs have been decreasing by approximately 15-20% annually as the technology matures and competition increases among solution providers.

Labor cost reduction represents the most immediate and quantifiable return, with SLAM-enabled autonomous systems reducing manual material handling requirements by 40-60%. A mid-sized warehouse operation can typically recoup labor savings of $300,000-$500,000 annually through reduced headcount and reallocation of human resources to higher-value tasks.

Operational efficiency gains provide additional financial benefits through increased throughput and inventory accuracy. SLAM-powered systems demonstrate 25-35% improvements in picking rates and reduce error rates by up to 70%, translating to annual savings of $150,000-$400,000 for medium-sized operations through reduced mis-picks, returns processing, and customer service issues.

Space utilization optimization represents another significant ROI factor. SLAM navigation enables narrower aisles and more dynamic storage configurations, increasing storage capacity by 15-25% without facility expansion. This space efficiency can defer capital expenditures for new facilities, potentially saving millions in construction costs.

Energy consumption typically decreases by 10-15% with optimized routing and operations, while maintenance costs for SLAM systems have proven lower than traditional automation due to fewer mechanical components and predictive maintenance capabilities.

The payback period for comprehensive SLAM warehouse implementations currently averages 18-36 months, with ROI improving as technology costs continue to decline. Organizations implementing SLAM in phases, beginning with high-impact areas, often achieve faster returns on initial investments while building institutional knowledge for broader deployment.

When calculating comprehensive ROI, organizations should also factor in less tangible benefits such as improved worker safety (reducing insurance premiums and liability), enhanced operational resilience, and increased capacity to handle seasonal peaks without temporary staffing surges.

Initial implementation costs typically include hardware components (sensors, cameras, computing units), software licenses, integration services, and staff training. These upfront investments generally range from $250,000 to $2 million depending on warehouse size and complexity. However, these costs have been decreasing by approximately 15-20% annually as the technology matures and competition increases among solution providers.

Labor cost reduction represents the most immediate and quantifiable return, with SLAM-enabled autonomous systems reducing manual material handling requirements by 40-60%. A mid-sized warehouse operation can typically recoup labor savings of $300,000-$500,000 annually through reduced headcount and reallocation of human resources to higher-value tasks.

Operational efficiency gains provide additional financial benefits through increased throughput and inventory accuracy. SLAM-powered systems demonstrate 25-35% improvements in picking rates and reduce error rates by up to 70%, translating to annual savings of $150,000-$400,000 for medium-sized operations through reduced mis-picks, returns processing, and customer service issues.

Space utilization optimization represents another significant ROI factor. SLAM navigation enables narrower aisles and more dynamic storage configurations, increasing storage capacity by 15-25% without facility expansion. This space efficiency can defer capital expenditures for new facilities, potentially saving millions in construction costs.

Energy consumption typically decreases by 10-15% with optimized routing and operations, while maintenance costs for SLAM systems have proven lower than traditional automation due to fewer mechanical components and predictive maintenance capabilities.

The payback period for comprehensive SLAM warehouse implementations currently averages 18-36 months, with ROI improving as technology costs continue to decline. Organizations implementing SLAM in phases, beginning with high-impact areas, often achieve faster returns on initial investments while building institutional knowledge for broader deployment.

When calculating comprehensive ROI, organizations should also factor in less tangible benefits such as improved worker safety (reducing insurance premiums and liability), enhanced operational resilience, and increased capacity to handle seasonal peaks without temporary staffing surges.

Safety Standards and Compliance for Autonomous Warehouse Operations

The implementation of autonomous systems in warehouse environments necessitates strict adherence to established safety standards and regulatory compliance frameworks. As SLAM technology becomes increasingly central to warehouse automation, organizations must navigate a complex landscape of safety regulations designed to protect human workers, equipment, and operational integrity.

International safety standards such as ISO 10218 and ISO/TS 15066 provide guidelines for collaborative robot systems, while ANSI/RIA R15.06 specifically addresses industrial robot safety requirements. These standards establish parameters for risk assessment, safety-rated monitored stops, and human-robot collaboration zones that directly impact SLAM-enabled autonomous mobile robots (AMRs) in warehouse settings.

Regulatory bodies including OSHA in the United States and the European Union's Machinery Directive 2006/42/EC mandate specific safety protocols for automated equipment. Compliance with these regulations requires SLAM systems to incorporate robust obstacle detection, predictive collision avoidance, and emergency stop capabilities that exceed minimum performance thresholds.

Risk assessment methodologies form the foundation of safety compliance for SLAM-based warehouse automation. These assessments must evaluate potential hazards related to robot movement patterns, interaction zones with human workers, and system failure scenarios. The integration of SLAM technology introduces unique safety considerations regarding localization accuracy, map degradation, and sensor reliability that must be systematically addressed.

Safety-rated sensors represent a critical component of compliant autonomous systems. LiDAR, stereo cameras, and proximity sensors must meet performance specifications for detection range, response time, and environmental resilience. SLAM algorithms must be designed to prioritize safety-critical information processing even under computational constraints.

Functional safety standards such as IEC 61508 and ISO 13849 establish requirements for the reliability of safety-related control systems. SLAM implementations must demonstrate appropriate Safety Integrity Levels (SIL) or Performance Levels (PL) through verification and validation processes that include fault injection testing and failure mode analysis.

Training and operational protocols constitute another essential dimension of safety compliance. Personnel working alongside SLAM-enabled autonomous systems require specialized training on interaction procedures, safety zones, and emergency protocols. Documentation of these training programs is typically mandated by regulatory frameworks and insurance requirements.

As warehouse automation technology evolves, safety standards continue to adapt. Emerging standards specifically addressing autonomous mobile robots, such as ANSI/RIA R15.08, are establishing more precise requirements for SLAM-based navigation systems, including performance metrics for localization accuracy and environmental perception reliability.

International safety standards such as ISO 10218 and ISO/TS 15066 provide guidelines for collaborative robot systems, while ANSI/RIA R15.06 specifically addresses industrial robot safety requirements. These standards establish parameters for risk assessment, safety-rated monitored stops, and human-robot collaboration zones that directly impact SLAM-enabled autonomous mobile robots (AMRs) in warehouse settings.

Regulatory bodies including OSHA in the United States and the European Union's Machinery Directive 2006/42/EC mandate specific safety protocols for automated equipment. Compliance with these regulations requires SLAM systems to incorporate robust obstacle detection, predictive collision avoidance, and emergency stop capabilities that exceed minimum performance thresholds.

Risk assessment methodologies form the foundation of safety compliance for SLAM-based warehouse automation. These assessments must evaluate potential hazards related to robot movement patterns, interaction zones with human workers, and system failure scenarios. The integration of SLAM technology introduces unique safety considerations regarding localization accuracy, map degradation, and sensor reliability that must be systematically addressed.

Safety-rated sensors represent a critical component of compliant autonomous systems. LiDAR, stereo cameras, and proximity sensors must meet performance specifications for detection range, response time, and environmental resilience. SLAM algorithms must be designed to prioritize safety-critical information processing even under computational constraints.

Functional safety standards such as IEC 61508 and ISO 13849 establish requirements for the reliability of safety-related control systems. SLAM implementations must demonstrate appropriate Safety Integrity Levels (SIL) or Performance Levels (PL) through verification and validation processes that include fault injection testing and failure mode analysis.

Training and operational protocols constitute another essential dimension of safety compliance. Personnel working alongside SLAM-enabled autonomous systems require specialized training on interaction procedures, safety zones, and emergency protocols. Documentation of these training programs is typically mandated by regulatory frameworks and insurance requirements.

As warehouse automation technology evolves, safety standards continue to adapt. Emerging standards specifically addressing autonomous mobile robots, such as ANSI/RIA R15.08, are establishing more precise requirements for SLAM-based navigation systems, including performance metrics for localization accuracy and environmental perception reliability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!