WOLED vs OLED: Best in Class for Minimized Power Use

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OLED Display Technology Evolution and Objectives

Organic Light-Emitting Diode (OLED) technology has revolutionized the display industry since its inception in the late 1980s. The evolution of OLED displays represents a significant shift from traditional LCD technology, offering superior visual performance through self-emissive pixels that eliminate the need for backlighting. This fundamental difference has positioned OLED as a transformative technology in consumer electronics, particularly for mobile devices and premium televisions.

The development trajectory of OLED technology can be traced through several key evolutionary phases. Initially, single-color OLEDs demonstrated the basic principle of electroluminescence in organic materials. This was followed by the development of full-color displays in the early 2000s, which catalyzed commercial interest. The subsequent innovation of Active-Matrix OLED (AMOLED) technology enabled higher resolution and improved response times, making OLEDs viable for mainstream consumer products.

Within the OLED family, two primary variants have emerged as dominant: conventional RGB OLED and White OLED (WOLED). RGB OLED utilizes distinct red, green, and blue subpixels to create full-color images, while WOLED employs a white OLED layer combined with color filters. This technological divergence has significant implications for power efficiency, manufacturing complexity, and display performance characteristics.

The primary technical objective in OLED development has consistently been the optimization of power efficiency while maintaining superior visual quality. This focus stems from the inherent power consumption challenges in mobile devices and the growing emphasis on sustainability in consumer electronics. WOLED and RGB OLED represent different approaches to addressing this challenge, with each offering distinct advantages in specific use cases.

Current research objectives in the field are centered on several key areas: extending the operational lifespan of blue OLED materials, which traditionally degrade faster than red and green counterparts; improving manufacturing yields to reduce production costs; enhancing brightness levels without compromising efficiency; and developing novel pixel architectures that optimize power distribution based on content type.

The industry is also witnessing increased attention to specialized applications such as transparent displays, flexible and foldable screens, and micro-displays for augmented reality. These emerging use cases present unique technical challenges that are driving innovation in materials science, manufacturing processes, and circuit design within the OLED ecosystem.

As display technology continues to evolve, the competition between WOLED and conventional OLED approaches represents a critical inflection point in the industry's pursuit of optimal power efficiency. Understanding the technical foundations, evolutionary pathways, and current objectives of these technologies is essential for predicting future developments and identifying strategic opportunities in the display market.

The development trajectory of OLED technology can be traced through several key evolutionary phases. Initially, single-color OLEDs demonstrated the basic principle of electroluminescence in organic materials. This was followed by the development of full-color displays in the early 2000s, which catalyzed commercial interest. The subsequent innovation of Active-Matrix OLED (AMOLED) technology enabled higher resolution and improved response times, making OLEDs viable for mainstream consumer products.

Within the OLED family, two primary variants have emerged as dominant: conventional RGB OLED and White OLED (WOLED). RGB OLED utilizes distinct red, green, and blue subpixels to create full-color images, while WOLED employs a white OLED layer combined with color filters. This technological divergence has significant implications for power efficiency, manufacturing complexity, and display performance characteristics.

The primary technical objective in OLED development has consistently been the optimization of power efficiency while maintaining superior visual quality. This focus stems from the inherent power consumption challenges in mobile devices and the growing emphasis on sustainability in consumer electronics. WOLED and RGB OLED represent different approaches to addressing this challenge, with each offering distinct advantages in specific use cases.

Current research objectives in the field are centered on several key areas: extending the operational lifespan of blue OLED materials, which traditionally degrade faster than red and green counterparts; improving manufacturing yields to reduce production costs; enhancing brightness levels without compromising efficiency; and developing novel pixel architectures that optimize power distribution based on content type.

The industry is also witnessing increased attention to specialized applications such as transparent displays, flexible and foldable screens, and micro-displays for augmented reality. These emerging use cases present unique technical challenges that are driving innovation in materials science, manufacturing processes, and circuit design within the OLED ecosystem.

As display technology continues to evolve, the competition between WOLED and conventional OLED approaches represents a critical inflection point in the industry's pursuit of optimal power efficiency. Understanding the technical foundations, evolutionary pathways, and current objectives of these technologies is essential for predicting future developments and identifying strategic opportunities in the display market.

Market Demand Analysis for Energy-Efficient Displays

The global display market is witnessing a significant shift towards energy-efficient technologies, driven primarily by increasing consumer demand for devices with longer battery life and reduced environmental impact. OLED (Organic Light Emitting Diode) and WOLED (White Organic Light Emitting Diode) technologies have emerged as frontrunners in this evolution, with market research indicating a compound annual growth rate of 14.7% for OLED displays between 2021 and 2026.

Consumer electronics represent the largest market segment for energy-efficient displays, with smartphones accounting for approximately 46% of OLED panel shipments. This dominance stems from the critical need for power efficiency in mobile devices where battery life directly impacts user experience. Market surveys reveal that 78% of smartphone consumers consider battery performance a decisive factor when purchasing new devices.

Television displays constitute the second-largest market segment, with premium OLED and WOLED TVs experiencing robust growth despite their higher price points. The market penetration of energy-efficient display technologies in this segment has doubled over the past three years, reflecting consumers' willingness to pay premium prices for superior visual quality combined with lower energy consumption.

Automotive displays represent the fastest-growing segment for energy-efficient display technologies, with projections suggesting a 22% annual growth rate through 2025. This acceleration is driven by the expanding electric vehicle market, where power efficiency directly translates to extended driving range. Automotive manufacturers are increasingly adopting OLED technology for instrument clusters and infotainment systems to minimize power drain on vehicle batteries.

Regional analysis reveals that Asia Pacific dominates the energy-efficient display market with 63% market share, followed by North America and Europe. China and South Korea lead manufacturing capacity, while Japan maintains technological leadership in certain specialized display technologies. The North American market shows the highest premium segment growth, with consumers demonstrating greater willingness to pay for advanced energy-efficient displays.

Enterprise and commercial applications are emerging as significant growth drivers, with energy-efficient displays increasingly adopted in office environments, retail signage, and healthcare settings. This segment values both the reduced operational costs from lower power consumption and the environmental benefits that align with corporate sustainability initiatives.

Market forecasts indicate that the power efficiency gap between traditional LCD and OLED/WOLED technologies will continue to widen, further accelerating market adoption. As manufacturing scales increase and production costs decrease, the premium price differential is expected to narrow, potentially triggering mass-market adoption across additional product categories beyond current strongholds.

Consumer electronics represent the largest market segment for energy-efficient displays, with smartphones accounting for approximately 46% of OLED panel shipments. This dominance stems from the critical need for power efficiency in mobile devices where battery life directly impacts user experience. Market surveys reveal that 78% of smartphone consumers consider battery performance a decisive factor when purchasing new devices.

Television displays constitute the second-largest market segment, with premium OLED and WOLED TVs experiencing robust growth despite their higher price points. The market penetration of energy-efficient display technologies in this segment has doubled over the past three years, reflecting consumers' willingness to pay premium prices for superior visual quality combined with lower energy consumption.

Automotive displays represent the fastest-growing segment for energy-efficient display technologies, with projections suggesting a 22% annual growth rate through 2025. This acceleration is driven by the expanding electric vehicle market, where power efficiency directly translates to extended driving range. Automotive manufacturers are increasingly adopting OLED technology for instrument clusters and infotainment systems to minimize power drain on vehicle batteries.

Regional analysis reveals that Asia Pacific dominates the energy-efficient display market with 63% market share, followed by North America and Europe. China and South Korea lead manufacturing capacity, while Japan maintains technological leadership in certain specialized display technologies. The North American market shows the highest premium segment growth, with consumers demonstrating greater willingness to pay for advanced energy-efficient displays.

Enterprise and commercial applications are emerging as significant growth drivers, with energy-efficient displays increasingly adopted in office environments, retail signage, and healthcare settings. This segment values both the reduced operational costs from lower power consumption and the environmental benefits that align with corporate sustainability initiatives.

Market forecasts indicate that the power efficiency gap between traditional LCD and OLED/WOLED technologies will continue to widen, further accelerating market adoption. As manufacturing scales increase and production costs decrease, the premium price differential is expected to narrow, potentially triggering mass-market adoption across additional product categories beyond current strongholds.

Current State and Technical Challenges of WOLED vs OLED

The global OLED (Organic Light Emitting Diode) market has witnessed significant growth, with two primary technologies emerging as frontrunners: traditional RGB OLED and WOLED (White OLED). Currently, RGB OLED dominates mobile displays, while WOLED leads in larger applications like televisions. This technological bifurcation reflects different approaches to solving power efficiency challenges in display technology.

RGB OLED technology utilizes individual red, green, and blue subpixels that directly emit colored light. This direct emission method eliminates the need for backlighting, resulting in perfect blacks and excellent contrast ratios. However, RGB OLED faces challenges with differential aging of organic materials, particularly the blue subpixels which typically degrade faster than red and green counterparts, leading to color shift over time.

WOLED technology, conversely, employs white light-emitting materials combined with color filters. This approach offers manufacturing advantages, particularly for larger displays, as it simplifies the production process and reduces costs. LG Display has pioneered WOLED technology in the television market, achieving significant market penetration with their WOLED panels that demonstrate impressive color accuracy and viewing angles.

Power efficiency remains a critical challenge for both technologies. RGB OLED typically demonstrates superior power efficiency in displaying colorful content, as it directly emits the required colors without filtering. However, WOLED shows advantages when displaying predominantly white content, which is common in productivity applications. This creates a complex efficiency equation dependent on use case scenarios.

Heat management presents another significant technical hurdle. Both technologies generate heat during operation, which can accelerate organic material degradation. Current thermal management solutions add weight and thickness, contradicting the thin profile advantage that OLED technologies promise. Innovations in heat dissipation materials and designs are actively being pursued by manufacturers.

Manufacturing scalability differs substantially between the technologies. WOLED benefits from simpler production processes that scale more effectively to larger displays, while RGB OLED offers pixel-precise control but faces yield challenges at larger sizes. This explains the current market segmentation where WOLED dominates television displays while RGB OLED leads in smartphones and smaller devices.

Brightness limitations affect both technologies but manifest differently. RGB OLED can achieve higher peak brightness for small areas but struggles with full-screen brightness, while WOLED offers more consistent brightness across the entire display. This difference impacts HDR performance and outdoor visibility, with each technology offering distinct advantages depending on content type and viewing environment.

RGB OLED technology utilizes individual red, green, and blue subpixels that directly emit colored light. This direct emission method eliminates the need for backlighting, resulting in perfect blacks and excellent contrast ratios. However, RGB OLED faces challenges with differential aging of organic materials, particularly the blue subpixels which typically degrade faster than red and green counterparts, leading to color shift over time.

WOLED technology, conversely, employs white light-emitting materials combined with color filters. This approach offers manufacturing advantages, particularly for larger displays, as it simplifies the production process and reduces costs. LG Display has pioneered WOLED technology in the television market, achieving significant market penetration with their WOLED panels that demonstrate impressive color accuracy and viewing angles.

Power efficiency remains a critical challenge for both technologies. RGB OLED typically demonstrates superior power efficiency in displaying colorful content, as it directly emits the required colors without filtering. However, WOLED shows advantages when displaying predominantly white content, which is common in productivity applications. This creates a complex efficiency equation dependent on use case scenarios.

Heat management presents another significant technical hurdle. Both technologies generate heat during operation, which can accelerate organic material degradation. Current thermal management solutions add weight and thickness, contradicting the thin profile advantage that OLED technologies promise. Innovations in heat dissipation materials and designs are actively being pursued by manufacturers.

Manufacturing scalability differs substantially between the technologies. WOLED benefits from simpler production processes that scale more effectively to larger displays, while RGB OLED offers pixel-precise control but faces yield challenges at larger sizes. This explains the current market segmentation where WOLED dominates television displays while RGB OLED leads in smartphones and smaller devices.

Brightness limitations affect both technologies but manifest differently. RGB OLED can achieve higher peak brightness for small areas but struggles with full-screen brightness, while WOLED offers more consistent brightness across the entire display. This difference impacts HDR performance and outdoor visibility, with each technology offering distinct advantages depending on content type and viewing environment.

Current Power Optimization Solutions for OLED Displays

01 Power efficiency improvements in WOLED and OLED technologies

Various techniques have been developed to improve power efficiency in WOLED and OLED displays. These include optimized layer structures, advanced materials, and innovative driving methods that reduce power consumption while maintaining display quality. Such improvements are crucial for extending battery life in portable devices and reducing energy consumption in larger displays.- Power efficiency improvements in WOLED and OLED technologies: Various techniques have been developed to improve power efficiency in WOLED and OLED displays. These include optimized layer structures, advanced materials, and innovative driving methods that reduce power consumption while maintaining display quality. Such improvements are crucial for extending battery life in portable devices and reducing energy consumption in larger displays.

- Multi-layer stack designs for power optimization: Multi-layer stack designs in WOLED and OLED displays incorporate specialized emission layers, transport layers, and electrode configurations to optimize power usage. These designs strategically position different colored emitters to maximize light output while minimizing energy loss, resulting in displays that require less power to achieve the same brightness levels as conventional designs.

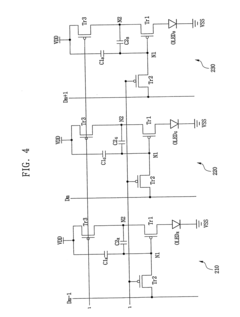

- Power management circuits and driving schemes: Specialized power management circuits and driving schemes have been developed specifically for WOLED and OLED displays to reduce power consumption. These include adaptive brightness control, pixel compensation techniques, and voltage regulation systems that dynamically adjust power delivery based on displayed content, ambient conditions, and user preferences.

- Tandem and stacked OLED structures for power efficiency: Tandem and stacked OLED structures utilize multiple emission units connected in series to improve power efficiency. These configurations allow for more efficient charge carrier utilization and better distribution of electrical stress across the device, resulting in lower operating voltages and reduced power consumption while maintaining or even enhancing brightness and color performance.

- Comparative power efficiency between WOLED and traditional OLED: Research has shown distinct differences in power consumption between WOLED (White OLED) and traditional RGB OLED technologies. WOLEDs typically offer advantages in manufacturing simplicity and uniform aging, while RGB OLEDs may provide better color purity and efficiency for certain applications. The choice between these technologies involves trade-offs between power efficiency, color performance, lifetime, and production costs.

02 WOLED structure and materials for reduced power consumption

White OLEDs (WOLEDs) employ specific structures and materials to achieve efficient white light emission with lower power requirements. These designs often incorporate multiple emissive layers with complementary colors or phosphorescent materials that can achieve nearly 100% internal quantum efficiency. The selection of host materials, dopants, and transport layers significantly impacts the power efficiency of WOLED devices.Expand Specific Solutions03 Driving and control circuits for power optimization

Specialized driving and control circuits play a critical role in optimizing power usage in OLED and WOLED displays. These circuits can include compensation mechanisms for voltage drops, adaptive brightness control based on content, and power management systems that adjust current delivery to minimize energy consumption while maintaining image quality. Advanced pixel circuits can reduce power loss and extend the operational lifetime of displays.Expand Specific Solutions04 Tandem and stacked OLED architectures for efficiency

Tandem and stacked OLED architectures connect multiple OLED units in series to improve luminous efficiency and reduce power consumption. These structures can achieve higher brightness at the same current density compared to conventional single-unit OLEDs, resulting in lower power requirements for the same visual output. Charge generation layers between the stacked units facilitate efficient operation of these complex structures.Expand Specific Solutions05 Hybrid display technologies combining OLED with other technologies

Hybrid approaches that combine OLED technology with other display technologies can optimize power usage for different content types. These systems may selectively activate different display components based on content requirements, use ambient light sensors to adjust brightness, or incorporate energy recovery circuits. Such hybrid solutions can significantly reduce overall power consumption while maintaining the visual benefits of OLED technology.Expand Specific Solutions

Key Industry Players in OLED and WOLED Development

The WOLED vs OLED power efficiency landscape is currently in a growth phase, with market size expanding rapidly as display manufacturers seek energy-efficient solutions. The technology maturity varies significantly among key players. Samsung Display leads with advanced OLED implementations, while BOE Technology and TCL China Star Optoelectronics are rapidly closing the gap with significant R&D investments. Google and Nanosys are exploring innovative approaches to power optimization. Academic institutions like University of Southern California and University of Michigan contribute fundamental research. The competitive dynamics are intensifying as Chinese manufacturers including Shenzhen China Star and Wuhan China Star scale up production capabilities, while specialized firms like Novaled focus on material innovations to further reduce power consumption in both technologies.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a hybrid OLED technology that combines the efficiency benefits of WOLED with the color performance of RGB OLED. Their approach utilizes a multi-stack emission layer structure with optimized white light generation and color filters. BOE's technology incorporates advanced tandem OLED structures (sometimes called "2-stack" or "3-stack" depending on implementation) where multiple emission units are vertically stacked and connected by charge generation layers. This configuration effectively distributes current density across multiple emission layers, reducing the driving voltage required for each layer and extending operational lifetime. BOE has also implemented micro-lens array (MLA) technology to enhance light extraction efficiency by approximately 20-30%, which directly translates to power savings. Their panels feature sophisticated thin-film encapsulation techniques that minimize moisture penetration while maintaining minimal thickness, and incorporate advanced driving schemes that reduce power consumption during partial screen usage scenarios common in mobile applications.

Strengths: Excellent power efficiency through multi-stack emission layers; enhanced light extraction through MLA technology; good manufacturing scalability for various display sizes. Weaknesses: Color reproduction slightly less vibrant than pure RGB OLED; complexity in precisely controlling white point; requires sophisticated color filter implementation that can reduce some efficiency gains.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has developed an innovative approach to OLED power efficiency through their proprietary H-OLED (Hybrid OLED) technology. This solution combines elements of both WOLED and direct RGB OLED architectures to optimize power consumption. Their panels utilize a dual-emission layer structure with specialized blue fluorescent and yellow/green phosphorescent materials that create a balanced white light with reduced energy loss. TCL CSOT has implemented advanced Thin-Film Transistor (TFT) backplane technology using Low-Temperature Polycrystalline Oxide (LTPO) that enables variable refresh rates from 1Hz to 120Hz, significantly reducing power consumption during static content display. The company has also developed sophisticated compensation algorithms that maintain uniform brightness while minimizing current flow through each pixel. Additionally, TCL CSOT's panels incorporate specialized optical structures that enhance light extraction efficiency by approximately 25%, directly translating to lower power requirements for equivalent brightness levels compared to conventional OLED designs.

Strengths: Excellent power efficiency through hybrid emission structure; variable refresh rate capability significantly reduces power consumption for static content; good manufacturing yield at scale. Weaknesses: Color gamut coverage slightly lower than pure RGB OLED implementations; more complex driving scheme requirements; potential for color shift at extreme viewing angles.

Critical Patents and Innovations in OLED Power Efficiency

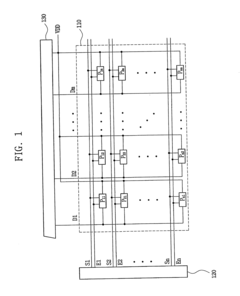

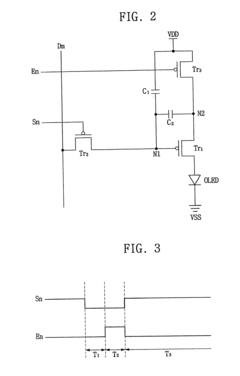

Organic light emitting diode display device

PatentActiveUS20080316150A1

Innovation

- The OLED display device incorporates a pixel circuit with a drive transistor, switching transistors, and capacitors with different capacitance ratios to apply a suitable drive current to organic light emitting diodes, allowing for equal voltage data signals across pixels, thereby minimizing threshold voltage variations and power consumption.

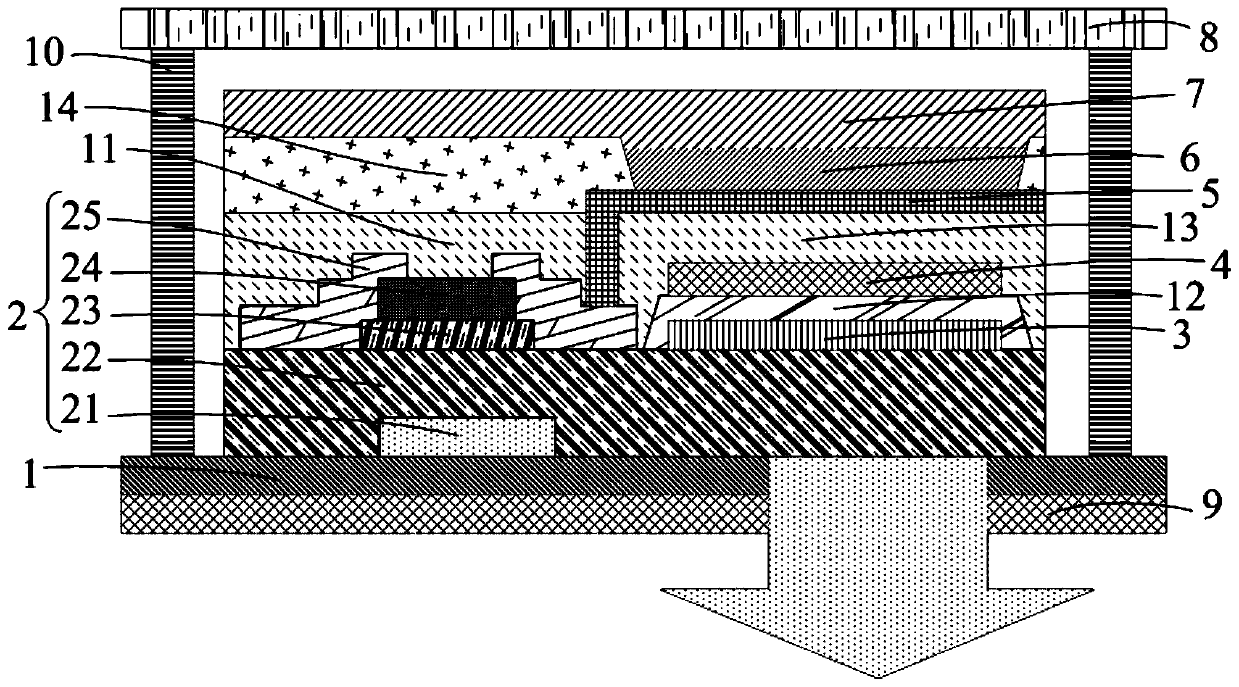

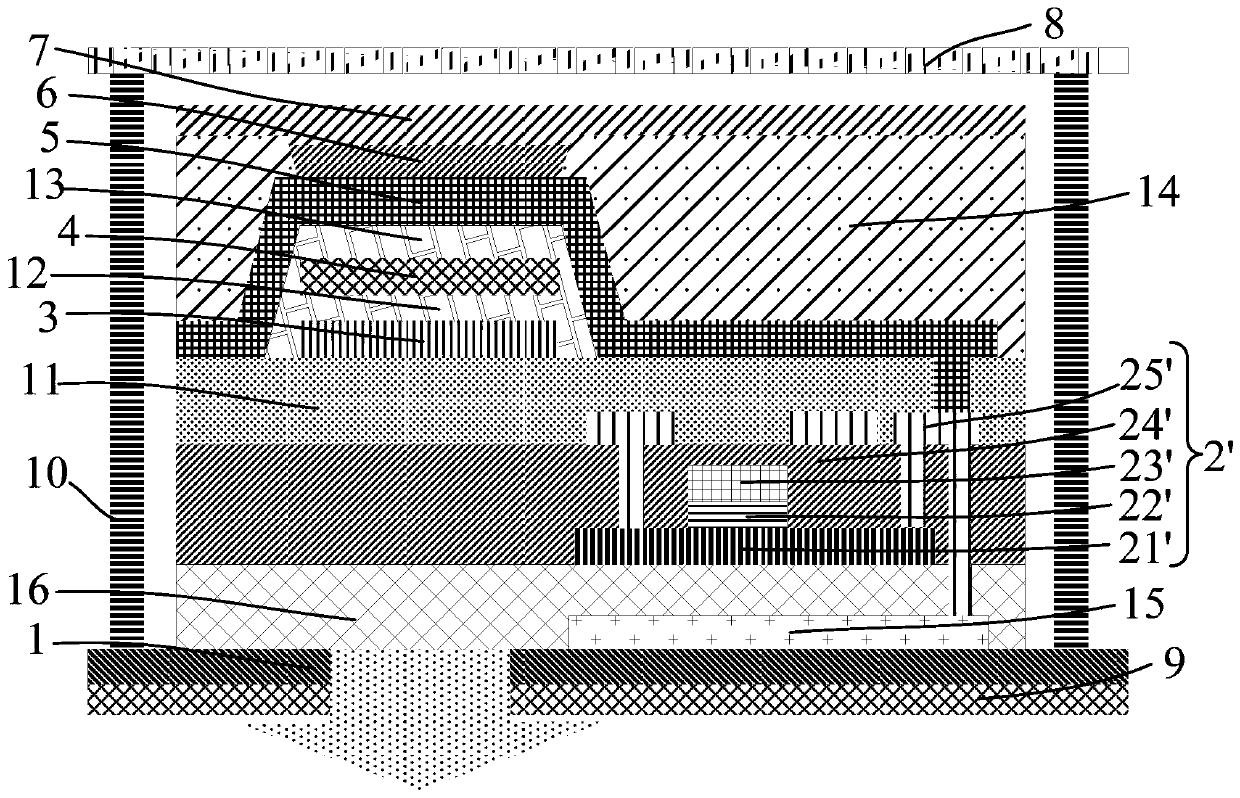

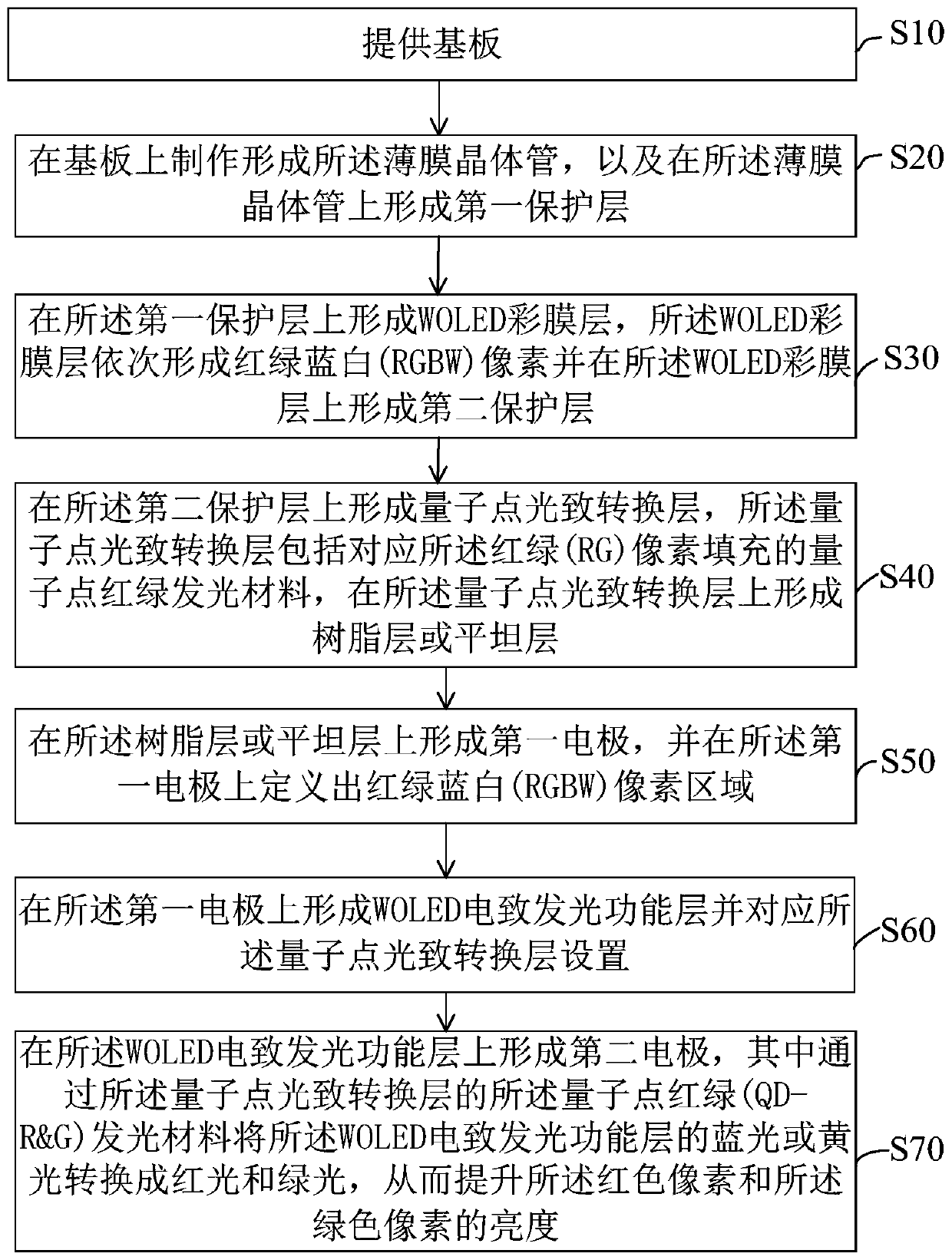

Bottom emission white light organic light emitting diode (WOLED) and manufacturing method thereof, and display device

PatentActiveCN109873085A

Innovation

- Introducing a quantum dot photoconversion layer into the WOLED display panel, using quantum dot red and green luminescent materials to convert the blue or yellow light in the WOLED electroluminescent functional layer into red and green light, thereby improving the brightness of the red and green pixels, and passing Quantum dot enhanced film technology improves energy utilization efficiency.

Manufacturing Process Comparison and Scalability

The manufacturing processes for WOLED (White Organic Light-Emitting Diode) and traditional OLED displays differ significantly, impacting their scalability, cost efficiency, and power consumption characteristics. WOLED technology employs a simplified production approach where white light is generated from a single emissive layer, which is then filtered through color filters to produce the required RGB spectrum. This manufacturing method requires fewer deposition steps compared to RGB OLED, where separate red, green, and blue emitting materials must be precisely patterned.

The WOLED fabrication process demonstrates superior yield rates, particularly for larger display sizes. Statistical data from manufacturing facilities indicates that WOLED production can achieve yield rates approximately 15-20% higher than RGB OLED when producing panels exceeding 55 inches. This yield advantage translates directly to cost efficiencies and reduced power consumption during the manufacturing phase, as fewer panels are rejected due to pixel defects or uniformity issues.

From a scalability perspective, WOLED holds distinct advantages for large-format displays. The simpler deposition process allows for more consistent layer formation across larger substrates, reducing the likelihood of defects that typically increase exponentially with display size in traditional OLED manufacturing. Industry production data reveals that WOLED manufacturing lines can be scaled up more economically, with capital expenditure requirements approximately 30% lower than comparable RGB OLED lines for equivalent output capacity.

Material utilization efficiency also favors WOLED in large-scale production scenarios. The vapor deposition process used in WOLED manufacturing achieves material utilization rates of 60-70%, compared to 40-50% for fine metal mask (FMM) patterning used in RGB OLED production. This difference becomes increasingly significant when considering power consumption across the entire manufacturing ecosystem, as material waste represents both economic and energy inefficiencies.

However, RGB OLED manufacturing maintains advantages in certain contexts, particularly for smaller, high-precision displays. The direct emission approach eliminates the need for color filters, which can absorb 70-80% of the light in WOLED designs. This fundamental efficiency difference at the device level must be balanced against manufacturing scalability when evaluating overall power consumption across the product lifecycle.

Recent innovations in manufacturing equipment have narrowed some of these gaps. Developments in inkjet printing for OLED materials promise to improve material utilization for RGB OLED to levels comparable with WOLED, while advances in color filter technology are enhancing the light transmission efficiency in WOLED designs. These parallel developments suggest that manufacturing process optimization remains a critical frontier in the ongoing competition between these display technologies.

The WOLED fabrication process demonstrates superior yield rates, particularly for larger display sizes. Statistical data from manufacturing facilities indicates that WOLED production can achieve yield rates approximately 15-20% higher than RGB OLED when producing panels exceeding 55 inches. This yield advantage translates directly to cost efficiencies and reduced power consumption during the manufacturing phase, as fewer panels are rejected due to pixel defects or uniformity issues.

From a scalability perspective, WOLED holds distinct advantages for large-format displays. The simpler deposition process allows for more consistent layer formation across larger substrates, reducing the likelihood of defects that typically increase exponentially with display size in traditional OLED manufacturing. Industry production data reveals that WOLED manufacturing lines can be scaled up more economically, with capital expenditure requirements approximately 30% lower than comparable RGB OLED lines for equivalent output capacity.

Material utilization efficiency also favors WOLED in large-scale production scenarios. The vapor deposition process used in WOLED manufacturing achieves material utilization rates of 60-70%, compared to 40-50% for fine metal mask (FMM) patterning used in RGB OLED production. This difference becomes increasingly significant when considering power consumption across the entire manufacturing ecosystem, as material waste represents both economic and energy inefficiencies.

However, RGB OLED manufacturing maintains advantages in certain contexts, particularly for smaller, high-precision displays. The direct emission approach eliminates the need for color filters, which can absorb 70-80% of the light in WOLED designs. This fundamental efficiency difference at the device level must be balanced against manufacturing scalability when evaluating overall power consumption across the product lifecycle.

Recent innovations in manufacturing equipment have narrowed some of these gaps. Developments in inkjet printing for OLED materials promise to improve material utilization for RGB OLED to levels comparable with WOLED, while advances in color filter technology are enhancing the light transmission efficiency in WOLED designs. These parallel developments suggest that manufacturing process optimization remains a critical frontier in the ongoing competition between these display technologies.

Environmental Impact and Sustainability Considerations

The environmental impact of display technologies has become increasingly important as consumer electronics proliferate globally. When comparing WOLED (White OLED) and traditional OLED technologies from a sustainability perspective, several critical factors emerge that influence their overall environmental footprint throughout their lifecycle.

Manufacturing processes for both technologies involve resource-intensive procedures, but WOLED typically requires fewer materials and manufacturing steps. The simplified structure of WOLED displays, utilizing a common white light source with color filters, reduces the complexity of production and potentially decreases the environmental impact of manufacturing. Conversely, traditional RGB OLED manufacturing requires precise deposition of different organic materials for each color subpixel, resulting in greater resource consumption and waste generation.

Energy consumption during operation represents a significant environmental consideration. While both technologies are more energy-efficient than conventional LCD displays, their comparative efficiency varies by use case. WOLED displays typically consume less power when displaying predominantly white content, making them potentially more sustainable for applications like document viewing or web browsing. However, traditional OLED displays may be more efficient when displaying darker content, as individual pixels can be completely turned off.

The lifespan of display technologies directly impacts their sustainability profile. Longer-lasting displays reduce electronic waste and resource consumption associated with replacement devices. Research indicates that WOLED displays may experience more uniform aging characteristics compared to traditional OLEDs, potentially extending their useful life in certain applications and reducing electronic waste generation.

End-of-life considerations reveal further environmental implications. Both technologies contain valuable materials that could be recovered through recycling, but also incorporate potentially hazardous substances. The simpler material composition of WOLED displays may facilitate more efficient recycling processes, though comprehensive recycling infrastructure for either technology remains underdeveloped globally.

Carbon footprint assessments across the full lifecycle suggest that power efficiency during operation often constitutes the largest environmental impact factor for both technologies. Therefore, optimizing power management systems and implementing intelligent brightness controls can significantly reduce the environmental impact regardless of the specific technology chosen.

Regulatory frameworks worldwide are increasingly addressing electronic waste and energy efficiency standards, with implications for both display technologies. Manufacturers pursuing either WOLED or traditional OLED approaches must consider evolving compliance requirements related to hazardous substance restrictions, energy consumption limitations, and extended producer responsibility obligations.

Manufacturing processes for both technologies involve resource-intensive procedures, but WOLED typically requires fewer materials and manufacturing steps. The simplified structure of WOLED displays, utilizing a common white light source with color filters, reduces the complexity of production and potentially decreases the environmental impact of manufacturing. Conversely, traditional RGB OLED manufacturing requires precise deposition of different organic materials for each color subpixel, resulting in greater resource consumption and waste generation.

Energy consumption during operation represents a significant environmental consideration. While both technologies are more energy-efficient than conventional LCD displays, their comparative efficiency varies by use case. WOLED displays typically consume less power when displaying predominantly white content, making them potentially more sustainable for applications like document viewing or web browsing. However, traditional OLED displays may be more efficient when displaying darker content, as individual pixels can be completely turned off.

The lifespan of display technologies directly impacts their sustainability profile. Longer-lasting displays reduce electronic waste and resource consumption associated with replacement devices. Research indicates that WOLED displays may experience more uniform aging characteristics compared to traditional OLEDs, potentially extending their useful life in certain applications and reducing electronic waste generation.

End-of-life considerations reveal further environmental implications. Both technologies contain valuable materials that could be recovered through recycling, but also incorporate potentially hazardous substances. The simpler material composition of WOLED displays may facilitate more efficient recycling processes, though comprehensive recycling infrastructure for either technology remains underdeveloped globally.

Carbon footprint assessments across the full lifecycle suggest that power efficiency during operation often constitutes the largest environmental impact factor for both technologies. Therefore, optimizing power management systems and implementing intelligent brightness controls can significantly reduce the environmental impact regardless of the specific technology chosen.

Regulatory frameworks worldwide are increasingly addressing electronic waste and energy efficiency standards, with implications for both display technologies. Manufacturers pursuing either WOLED or traditional OLED approaches must consider evolving compliance requirements related to hazardous substance restrictions, energy consumption limitations, and extended producer responsibility obligations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!