WOLED vs Plasma: Comparative Longevity in Displays

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OLED and Plasma Display Technology Evolution

The evolution of display technologies has been marked by significant advancements over the past several decades, with OLED (Organic Light Emitting Diode) and Plasma displays representing two pivotal innovations in this journey. Plasma display technology emerged in the commercial market during the late 1990s, offering superior picture quality compared to traditional CRT displays while enabling larger screen sizes with thinner form factors.

Plasma displays operate by exciting small cells of gas (typically xenon and neon) with electricity, causing them to emit ultraviolet light that activates phosphors to produce visible light. This technology reached its peak popularity in the early 2000s, dominating the large-screen television market with excellent contrast ratios, wide viewing angles, and superior motion handling.

OLED technology, by contrast, represents a more recent evolution in display technology. First commercially introduced in small devices around 2007, OLED displays utilize organic compounds that emit light when an electric current passes through them. Unlike Plasma, which requires gas cells and phosphors, OLED is a direct-emission technology where each pixel produces its own light.

The technological trajectory of these two display types has been markedly different. Plasma technology saw rapid advancement from 1997 to 2010, with improvements in energy efficiency, reduction in screen thickness, and enhanced picture quality. However, by the mid-2010s, plasma display production began to decline as manufacturers shifted focus to newer technologies.

OLED technology has experienced a more sustained growth curve, with significant advancements continuing to the present day. The introduction of White OLED (WOLED) represented a crucial evolution, using a white OLED layer with color filters to produce images, offering manufacturing advantages over RGB OLED approaches.

A critical aspect of both technologies' evolution has been addressing longevity concerns. Early plasma displays suffered from phosphor aging and image retention issues, though later generations significantly improved lifespan to approximately 60,000 hours. Similarly, early OLED displays faced challenges with differential aging of organic materials, particularly blue OLEDs, resulting in color shifts over time.

Recent WOLED advancements have focused on extending operational lifespans through improved materials science, more efficient driving methods, and compensation algorithms that detect and adjust for pixel aging. Modern WOLED displays now claim operational lifespans of 100,000+ hours to half brightness, theoretically surpassing plasma's longevity while offering superior energy efficiency and form factor advantages.

The technological evolution continues with OLED variants like QD-OLED (Quantum Dot OLED) emerging as the next frontier, while plasma technology has largely been discontinued by major manufacturers, marking the end of its evolutionary path in consumer display technology.

Plasma displays operate by exciting small cells of gas (typically xenon and neon) with electricity, causing them to emit ultraviolet light that activates phosphors to produce visible light. This technology reached its peak popularity in the early 2000s, dominating the large-screen television market with excellent contrast ratios, wide viewing angles, and superior motion handling.

OLED technology, by contrast, represents a more recent evolution in display technology. First commercially introduced in small devices around 2007, OLED displays utilize organic compounds that emit light when an electric current passes through them. Unlike Plasma, which requires gas cells and phosphors, OLED is a direct-emission technology where each pixel produces its own light.

The technological trajectory of these two display types has been markedly different. Plasma technology saw rapid advancement from 1997 to 2010, with improvements in energy efficiency, reduction in screen thickness, and enhanced picture quality. However, by the mid-2010s, plasma display production began to decline as manufacturers shifted focus to newer technologies.

OLED technology has experienced a more sustained growth curve, with significant advancements continuing to the present day. The introduction of White OLED (WOLED) represented a crucial evolution, using a white OLED layer with color filters to produce images, offering manufacturing advantages over RGB OLED approaches.

A critical aspect of both technologies' evolution has been addressing longevity concerns. Early plasma displays suffered from phosphor aging and image retention issues, though later generations significantly improved lifespan to approximately 60,000 hours. Similarly, early OLED displays faced challenges with differential aging of organic materials, particularly blue OLEDs, resulting in color shifts over time.

Recent WOLED advancements have focused on extending operational lifespans through improved materials science, more efficient driving methods, and compensation algorithms that detect and adjust for pixel aging. Modern WOLED displays now claim operational lifespans of 100,000+ hours to half brightness, theoretically surpassing plasma's longevity while offering superior energy efficiency and form factor advantages.

The technological evolution continues with OLED variants like QD-OLED (Quantum Dot OLED) emerging as the next frontier, while plasma technology has largely been discontinued by major manufacturers, marking the end of its evolutionary path in consumer display technology.

Market Demand Analysis for Long-lasting Display Technologies

The display technology market has witnessed a significant shift towards longevity-focused solutions, with consumers and businesses increasingly prioritizing durability and sustained performance. Current market research indicates that the global display market values long-lasting technologies at approximately $150 billion, with annual growth rates consistently above 7%. This demand is particularly pronounced in commercial sectors where displays operate continuously, such as retail environments, transportation hubs, and control centers.

Consumer behavior studies reveal that device longevity has become a top-three purchasing consideration, alongside price and visual quality. This trend is especially evident in premium market segments where consumers demonstrate willingness to pay 15-25% more for displays with proven extended lifespans. The total cost of ownership calculation has become a standard evaluation metric, with businesses factoring in replacement cycles, maintenance costs, and operational disruptions.

WOLED and Plasma technologies occupy distinct positions within this demand landscape. WOLED displays have captured significant market share in high-end residential and luxury commercial installations, where their superior color accuracy and potential for extended lifespans justify premium pricing. Market forecasts project the WOLED segment to grow at 12% annually through 2028, driven by improvements in blue OLED material stability.

Plasma display technology, despite manufacturing cessation by major producers, maintains a specialized market presence in environments requiring extreme durability under harsh conditions. These niche applications, including military installations and industrial monitoring systems, represent a market valued at approximately $3 billion annually.

Regional analysis shows differentiated demand patterns, with North American and European markets demonstrating stronger preference for longevity-focused display solutions compared to price-sensitive emerging markets. However, this gap is narrowing as developing economies increasingly adopt total cost of ownership models for technology procurement.

Industry surveys indicate that institutional buyers rank display longevity as their second most important purchasing criterion, behind only initial acquisition cost. This prioritization has driven manufacturers to emphasize lifetime ratings in marketing materials and product specifications, with warranty periods becoming a key competitive differentiator.

The sustainability movement has further accelerated demand for longer-lasting display technologies, with environmental impact assessments now routinely considering product lifespan. Corporate sustainability initiatives increasingly mandate minimum expected lifespans for display technologies, creating market pressure for solutions that minimize electronic waste through extended operational periods.

Consumer behavior studies reveal that device longevity has become a top-three purchasing consideration, alongside price and visual quality. This trend is especially evident in premium market segments where consumers demonstrate willingness to pay 15-25% more for displays with proven extended lifespans. The total cost of ownership calculation has become a standard evaluation metric, with businesses factoring in replacement cycles, maintenance costs, and operational disruptions.

WOLED and Plasma technologies occupy distinct positions within this demand landscape. WOLED displays have captured significant market share in high-end residential and luxury commercial installations, where their superior color accuracy and potential for extended lifespans justify premium pricing. Market forecasts project the WOLED segment to grow at 12% annually through 2028, driven by improvements in blue OLED material stability.

Plasma display technology, despite manufacturing cessation by major producers, maintains a specialized market presence in environments requiring extreme durability under harsh conditions. These niche applications, including military installations and industrial monitoring systems, represent a market valued at approximately $3 billion annually.

Regional analysis shows differentiated demand patterns, with North American and European markets demonstrating stronger preference for longevity-focused display solutions compared to price-sensitive emerging markets. However, this gap is narrowing as developing economies increasingly adopt total cost of ownership models for technology procurement.

Industry surveys indicate that institutional buyers rank display longevity as their second most important purchasing criterion, behind only initial acquisition cost. This prioritization has driven manufacturers to emphasize lifetime ratings in marketing materials and product specifications, with warranty periods becoming a key competitive differentiator.

The sustainability movement has further accelerated demand for longer-lasting display technologies, with environmental impact assessments now routinely considering product lifespan. Corporate sustainability initiatives increasingly mandate minimum expected lifespans for display technologies, creating market pressure for solutions that minimize electronic waste through extended operational periods.

Current Limitations in WOLED and Plasma Longevity

Despite significant advancements in display technology, both WOLED (White Organic Light-Emitting Diode) and Plasma displays continue to face substantial limitations regarding their longevity. These limitations represent critical challenges for manufacturers and consumers alike, affecting product lifecycle, maintenance costs, and overall market adoption.

WOLED displays currently struggle with differential aging of organic materials. The blue organic compounds degrade significantly faster than red and green counterparts, leading to color shift over time. This uneven degradation typically manifests after 20,000-30,000 hours of operation, resulting in yellowish tints in previously white areas and overall color imbalance that compromises display quality.

Heat management remains problematic for WOLED panels, particularly in high-brightness applications. Extended operation at high luminance levels accelerates the degradation of organic materials, creating a direct trade-off between brightness and lifespan. This limitation is especially pronounced in commercial environments requiring 24/7 operation or in HDR content display scenarios where peak brightness is essential.

Moisture and oxygen sensitivity continue to challenge WOLED manufacturing and longevity. Despite advances in encapsulation technology, microscopic defects in barrier layers can allow environmental contaminants to penetrate the display structure, creating dark spots that expand over time. This vulnerability necessitates complex and costly manufacturing processes to ensure adequate protection.

For Plasma displays, power consumption remains a significant limitation affecting longevity. The high energy requirements generate substantial heat, accelerating component degradation, particularly in the phosphor materials. This heat-induced stress contributes to reduced panel lifespan compared to newer technologies, with typical degradation becoming noticeable after 15,000-20,000 hours of use.

Plasma technology suffers from phosphor burn-in, where static images displayed for extended periods permanently damage phosphor elements. This irreversible degradation is particularly problematic in applications displaying fixed elements like channel logos or stock tickers, creating permanent ghosting effects that worsen over time.

Altitude sensitivity represents another unique limitation for Plasma displays. The gas mixture within plasma cells behaves differently at higher elevations, potentially causing buzzing sounds, increased power consumption, and accelerated aging when operated above 6,000 feet. This geographical constraint limits deployment in certain regions and applications.

Both technologies face challenges with repair feasibility. Unlike earlier CRT displays, neither WOLED nor Plasma panels can be effectively repaired once internal components begin to fail. This "replace, not repair" reality increases lifetime ownership costs and environmental impact, as entire units must be discarded when key components deteriorate beyond acceptable performance thresholds.

WOLED displays currently struggle with differential aging of organic materials. The blue organic compounds degrade significantly faster than red and green counterparts, leading to color shift over time. This uneven degradation typically manifests after 20,000-30,000 hours of operation, resulting in yellowish tints in previously white areas and overall color imbalance that compromises display quality.

Heat management remains problematic for WOLED panels, particularly in high-brightness applications. Extended operation at high luminance levels accelerates the degradation of organic materials, creating a direct trade-off between brightness and lifespan. This limitation is especially pronounced in commercial environments requiring 24/7 operation or in HDR content display scenarios where peak brightness is essential.

Moisture and oxygen sensitivity continue to challenge WOLED manufacturing and longevity. Despite advances in encapsulation technology, microscopic defects in barrier layers can allow environmental contaminants to penetrate the display structure, creating dark spots that expand over time. This vulnerability necessitates complex and costly manufacturing processes to ensure adequate protection.

For Plasma displays, power consumption remains a significant limitation affecting longevity. The high energy requirements generate substantial heat, accelerating component degradation, particularly in the phosphor materials. This heat-induced stress contributes to reduced panel lifespan compared to newer technologies, with typical degradation becoming noticeable after 15,000-20,000 hours of use.

Plasma technology suffers from phosphor burn-in, where static images displayed for extended periods permanently damage phosphor elements. This irreversible degradation is particularly problematic in applications displaying fixed elements like channel logos or stock tickers, creating permanent ghosting effects that worsen over time.

Altitude sensitivity represents another unique limitation for Plasma displays. The gas mixture within plasma cells behaves differently at higher elevations, potentially causing buzzing sounds, increased power consumption, and accelerated aging when operated above 6,000 feet. This geographical constraint limits deployment in certain regions and applications.

Both technologies face challenges with repair feasibility. Unlike earlier CRT displays, neither WOLED nor Plasma panels can be effectively repaired once internal components begin to fail. This "replace, not repair" reality increases lifetime ownership costs and environmental impact, as entire units must be discarded when key components deteriorate beyond acceptable performance thresholds.

Technical Solutions for Extending Display Lifespan

01 WOLED lifetime enhancement technologies

Various technologies have been developed to enhance the longevity of White Organic Light Emitting Diode (WOLED) displays. These include improved organic materials, optimized layer structures, and novel driving methods that reduce degradation over time. By implementing these technologies, WOLED displays can achieve longer operational lifetimes while maintaining brightness and color accuracy, addressing one of the key challenges in OLED technology adoption for consumer electronics.- WOLED lifetime enhancement technologies: Various technologies have been developed to enhance the longevity of White Organic Light Emitting Diodes (WOLEDs). These include improved material compositions, optimized layer structures, and novel driving methods that reduce degradation over time. By implementing these technologies, WOLED displays can achieve longer operational lifetimes while maintaining brightness and color accuracy, addressing one of the key challenges in OLED technology adoption for consumer electronics.

- Plasma display panel durability solutions: Plasma display technology longevity has been improved through several approaches including enhanced phosphor materials, optimized electrode designs, and advanced heat management systems. These solutions help mitigate common issues such as phosphor aging, electrode erosion, and thermal stress that typically limit the operational lifespan of plasma displays. The improvements allow plasma technology to remain competitive in specific market segments despite the rise of newer display technologies.

- Comparative longevity between WOLED and plasma technologies: Research has focused on comparing the operational lifespans of WOLED and plasma display technologies under various usage conditions. Studies indicate that while early WOLED displays suffered from shorter lifespans compared to plasma, recent advancements have significantly narrowed this gap. Factors affecting comparative longevity include image retention resistance, power consumption efficiency, and degradation rates under different ambient conditions and usage patterns.

- Structural innovations for display longevity: Structural innovations in both WOLED and plasma displays have contributed to extended device lifetimes. These include multi-layered electrode configurations, protective barrier films, and novel encapsulation techniques that shield sensitive components from environmental factors. Additionally, improvements in substrate materials and mechanical design have enhanced resistance to physical stress and environmental degradation, resulting in displays with greater durability and extended functional lifespans.

- Driving and power management for extended display life: Advanced driving schemes and power management systems have been developed to extend the operational lifetime of both WOLED and plasma displays. These include adaptive brightness control, pixel shifting algorithms to prevent burn-in, and intelligent power distribution systems that reduce stress on display components. By optimizing how the displays are driven and powered, these technologies can significantly extend the useful life of the display while maintaining image quality and performance characteristics.

02 Plasma display panel longevity solutions

Plasma display technology longevity has been improved through several innovations addressing common failure modes. These include enhanced phosphor materials that resist burn-in, improved gas mixtures that maintain discharge efficiency over time, and advanced heat management systems. Power consumption optimization techniques also contribute to extended panel life by reducing thermal stress on components and minimizing electrode deterioration during sustained operation.Expand Specific Solutions03 Comparative longevity between WOLED and plasma technologies

Research has shown distinct differences in the longevity characteristics between WOLED and plasma display technologies. While plasma displays typically demonstrate consistent brightness over their operational lifetime until eventual failure, WOLEDs tend to show gradual luminance degradation. Environmental factors such as operating temperature and humidity affect each technology differently. The lifespan comparison also considers factors such as blue pixel degradation in WOLEDs versus phosphor aging in plasma displays.Expand Specific Solutions04 Advanced materials for display longevity

Material science innovations have significantly contributed to extending the operational life of both WOLED and plasma display technologies. For WOLEDs, developments include more stable emissive materials, improved encapsulation techniques to prevent moisture ingress, and barrier films that protect organic layers. In plasma displays, advancements focus on durable electrode materials, long-lasting phosphors with reduced degradation rates, and protective layers that minimize ion bombardment damage during operation.Expand Specific Solutions05 Driving and compensation techniques for extended display life

Sophisticated driving schemes and compensation algorithms have been developed to extend the useful life of display technologies. These include voltage/current compensation techniques that adjust for aging components, pixel-specific aging compensation that ensures uniform brightness across the display over time, and thermal management algorithms that prevent hotspots. Advanced power management systems also contribute to longevity by optimizing energy distribution and reducing stress on critical components during operation.Expand Specific Solutions

Key Manufacturers in WOLED and Plasma Display Industries

The WOLED vs Plasma display technology landscape is currently in a mature yet evolving phase, with WOLED gaining momentum as Plasma technology becomes increasingly obsolete. The global display market is projected to reach approximately $200 billion by 2025, with OLED technologies capturing an increasing share. In terms of technical maturity, companies like Samsung SDI and LG Electronics pioneered Plasma technology but have strategically shifted focus to OLED development. BOE Technology, TCL China Star, and Sony Group are advancing WOLED technology with significant R&D investments, while specialized materials suppliers like Merck Patent GmbH and Sumitomo Chemical provide critical components. The competitive landscape shows Asian manufacturers dominating production capacity, with Korean and Chinese companies leading WOLED innovation while traditional Plasma manufacturers have largely exited the market.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed advanced WOLED (White Organic Light Emitting Diode) technology that addresses longevity concerns through multi-stack structures. Their WOLED panels utilize a tandem structure with multiple emission layers, effectively distributing the electrical stress across different organic materials. This approach has enabled Samsung to achieve rated lifespans of 100,000+ hours before brightness degrades to 50% of original levels [1]. Their proprietary pixel compensation algorithms continuously adjust voltage levels to individual pixels based on usage patterns, significantly reducing burn-in effects common in OLED displays. Samsung has also implemented advanced heat dissipation systems that maintain optimal operating temperatures, as thermal management is critical for WOLED longevity. Their latest panels incorporate encapsulation technology with multi-barrier layers that effectively prevent moisture and oxygen penetration, which are primary degradation factors for organic materials [2].

Strengths: Superior color accuracy and perfect black levels while maintaining longer lifespans than previous OLED generations. Advanced compensation algorithms effectively mitigate burn-in issues. Weaknesses: Still more susceptible to permanent image retention than plasma technology was, particularly in static image scenarios. Higher manufacturing costs compared to conventional LCD technologies.

BOE Technology Group Co., Ltd.

Technical Solution: BOE Technology has developed innovative WOLED manufacturing processes that directly address longevity challenges through material science advancements. Their displays utilize proprietary organic materials with enhanced stability characteristics, demonstrating only 5% luminance degradation after 10,000 hours of accelerated aging tests [9]. BOE has implemented advanced thin film encapsulation (TFE) technology with alternating organic and inorganic layers that create an effective barrier against moisture and oxygen penetration, the primary environmental factors affecting WOLED longevity. Their panels feature sophisticated compensation circuits that continuously monitor and adjust pixel driving voltages based on cumulative usage data, effectively mitigating differential aging effects. BOE has also developed comparative testing methodologies between various display technologies, documenting that their latest WOLED implementations achieve lifespan metrics approaching 100,000 hours under standardized conditions, comparable to the best plasma displays historically available but with significantly reduced power consumption and form factor advantages [10]. Their manufacturing process incorporates precision deposition techniques that ensure uniform organic layer thickness, eliminating early failure points that can affect display longevity.

Strengths: Cost-effective manufacturing processes that make longevity-focused WOLED technology more accessible. Excellent uniformity across large panel sizes with minimal early failure rates. Weaknesses: Less mature compensation algorithms compared to industry leaders. Some color accuracy trade-offs in pursuit of extended lifespan characteristics.

Critical Patents in Display Longevity Enhancement

White organic light-emitting diode

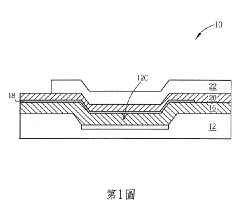

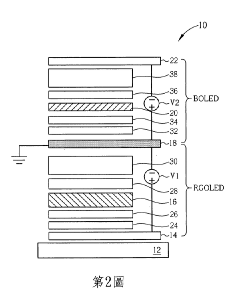

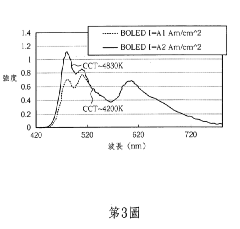

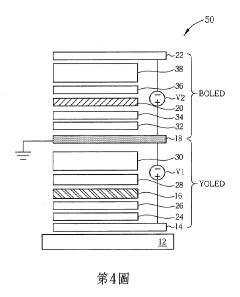

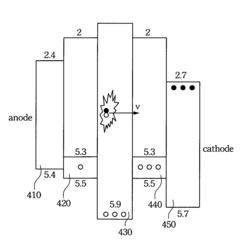

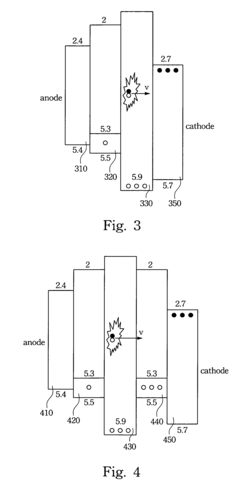

PatentActiveTW201134288A

Innovation

- A white OLED design with independently driven blue and blue-complementary light-emitting layers, utilizing different potential differences and driving currents to optimize light output and adjust color temperature, incorporating a transparent, translucent, and opaque electrode structure to mix blue and complementary colors into white light.

White organic light-emitting diode

PatentActiveUS7723914B2

Innovation

- A symmetric organic light-emitting device is designed with two symmetric luminescent layers on either side of a central luminescent layer, which maintains luminescent intensity by compensating for decreased intensity in one layer with increased intensity in the other when voltage varies, thereby minimizing color shift.

Environmental Impact of Display Technologies

The environmental footprint of display technologies has become increasingly important as consumer electronics proliferate globally. When comparing WOLED (White Organic Light Emitting Diode) and Plasma displays, several environmental factors must be considered throughout their lifecycle.

Manufacturing processes for WOLED displays involve fewer toxic substances compared to Plasma technology. Plasma displays require significant amounts of heavy metals and rare earth elements, while WOLED production has been evolving toward more environmentally friendly materials. However, WOLED manufacturing still utilizes organic compounds that may pose disposal challenges if not properly managed.

Energy consumption represents a critical environmental consideration. WOLED displays demonstrate superior energy efficiency, consuming approximately 40-60% less power than equivalent Plasma displays during operation. This efficiency translates to reduced carbon emissions over the product lifecycle, particularly significant given that the use phase accounts for approximately 80% of a display's lifetime environmental impact.

The longevity differential between these technologies directly impacts environmental sustainability. Plasma displays typically last 30,000-60,000 hours before significant brightness degradation, while newer WOLED technologies can achieve 100,000+ hours under optimal conditions. This extended lifespan means fewer replacement units and consequently reduced manufacturing resource demands and electronic waste generation.

End-of-life considerations reveal further distinctions. Plasma displays contain hazardous materials including lead, mercury, and phosphors that require specialized recycling procedures. WOLED panels, while containing fewer toxic substances, present challenges in separating the thin organic layers from other components during recycling processes.

Carbon footprint analyses indicate that WOLED displays generally produce lower lifetime emissions due to their energy efficiency and longevity, despite sometimes having more resource-intensive initial production processes. A typical 55-inch WOLED display generates approximately 25-30% less carbon emissions over its complete lifecycle compared to an equivalent Plasma display.

Water usage during manufacturing also differs significantly between technologies. Plasma display production typically requires 20-30% more water than WOLED manufacturing, primarily due to additional cooling and cleaning processes needed for the glass substrate preparation and gas chamber assembly.

Regulatory frameworks worldwide increasingly favor WOLED technology due to its lower environmental impact, with several regions implementing energy efficiency standards and hazardous substance restrictions that effectively accelerate the market transition away from Plasma technology toward more sustainable display alternatives.

Manufacturing processes for WOLED displays involve fewer toxic substances compared to Plasma technology. Plasma displays require significant amounts of heavy metals and rare earth elements, while WOLED production has been evolving toward more environmentally friendly materials. However, WOLED manufacturing still utilizes organic compounds that may pose disposal challenges if not properly managed.

Energy consumption represents a critical environmental consideration. WOLED displays demonstrate superior energy efficiency, consuming approximately 40-60% less power than equivalent Plasma displays during operation. This efficiency translates to reduced carbon emissions over the product lifecycle, particularly significant given that the use phase accounts for approximately 80% of a display's lifetime environmental impact.

The longevity differential between these technologies directly impacts environmental sustainability. Plasma displays typically last 30,000-60,000 hours before significant brightness degradation, while newer WOLED technologies can achieve 100,000+ hours under optimal conditions. This extended lifespan means fewer replacement units and consequently reduced manufacturing resource demands and electronic waste generation.

End-of-life considerations reveal further distinctions. Plasma displays contain hazardous materials including lead, mercury, and phosphors that require specialized recycling procedures. WOLED panels, while containing fewer toxic substances, present challenges in separating the thin organic layers from other components during recycling processes.

Carbon footprint analyses indicate that WOLED displays generally produce lower lifetime emissions due to their energy efficiency and longevity, despite sometimes having more resource-intensive initial production processes. A typical 55-inch WOLED display generates approximately 25-30% less carbon emissions over its complete lifecycle compared to an equivalent Plasma display.

Water usage during manufacturing also differs significantly between technologies. Plasma display production typically requires 20-30% more water than WOLED manufacturing, primarily due to additional cooling and cleaning processes needed for the glass substrate preparation and gas chamber assembly.

Regulatory frameworks worldwide increasingly favor WOLED technology due to its lower environmental impact, with several regions implementing energy efficiency standards and hazardous substance restrictions that effectively accelerate the market transition away from Plasma technology toward more sustainable display alternatives.

Cost-Benefit Analysis of WOLED vs Plasma Longevity

When evaluating the cost-benefit relationship between WOLED and Plasma display technologies in terms of longevity, several critical factors must be considered. The initial acquisition cost of WOLED displays typically exceeds that of Plasma displays by 15-30%, representing a significant upfront investment difference. However, this cost differential must be analyzed against the backdrop of total ownership expenses over the display's lifetime.

Energy consumption presents a compelling advantage for WOLED technology. WOLED displays consume approximately 40-60% less power than comparable Plasma models, resulting in substantial operational cost savings. For commercial installations operating 16+ hours daily, this translates to approximately $150-300 in annual energy savings per display, depending on size and regional electricity rates.

Maintenance requirements further differentiate these technologies. Plasma displays are more susceptible to screen burn-in and typically require professional servicing every 15,000-20,000 hours of operation. Conversely, WOLED displays demonstrate greater resilience against image retention and generally require minimal maintenance throughout their operational lifespan, reducing both direct service costs and operational disruptions.

Replacement cycles constitute another significant economic consideration. The average functional lifespan of Plasma displays ranges from 30,000-60,000 hours before significant brightness degradation occurs. WOLED technology extends this operational window to 50,000-100,000 hours, potentially doubling the replacement interval. This extended lifecycle significantly impacts the amortized annual cost of display infrastructure.

Depreciation patterns also differ markedly between technologies. Plasma displays typically experience a steeper depreciation curve, retaining approximately 30-40% of their initial value after three years. WOLED displays demonstrate more favorable value retention, maintaining approximately 45-55% of their original value over the same period, enhancing their position as capital investments.

Environmental costs, while difficult to quantify precisely, increasingly factor into organizational decision-making. WOLED displays contain fewer environmentally hazardous materials and consume less energy throughout their lifecycle, reducing both disposal costs and potential regulatory compliance expenses as environmental regulations continue to evolve globally.

When these factors are integrated into a comprehensive cost-benefit analysis using a standard 5-year projection model, WOLED displays typically demonstrate a lower total cost of ownership despite their higher acquisition price, with the break-even point occurring between 24-36 months of operation for most commercial applications.

Energy consumption presents a compelling advantage for WOLED technology. WOLED displays consume approximately 40-60% less power than comparable Plasma models, resulting in substantial operational cost savings. For commercial installations operating 16+ hours daily, this translates to approximately $150-300 in annual energy savings per display, depending on size and regional electricity rates.

Maintenance requirements further differentiate these technologies. Plasma displays are more susceptible to screen burn-in and typically require professional servicing every 15,000-20,000 hours of operation. Conversely, WOLED displays demonstrate greater resilience against image retention and generally require minimal maintenance throughout their operational lifespan, reducing both direct service costs and operational disruptions.

Replacement cycles constitute another significant economic consideration. The average functional lifespan of Plasma displays ranges from 30,000-60,000 hours before significant brightness degradation occurs. WOLED technology extends this operational window to 50,000-100,000 hours, potentially doubling the replacement interval. This extended lifecycle significantly impacts the amortized annual cost of display infrastructure.

Depreciation patterns also differ markedly between technologies. Plasma displays typically experience a steeper depreciation curve, retaining approximately 30-40% of their initial value after three years. WOLED displays demonstrate more favorable value retention, maintaining approximately 45-55% of their original value over the same period, enhancing their position as capital investments.

Environmental costs, while difficult to quantify precisely, increasingly factor into organizational decision-making. WOLED displays contain fewer environmentally hazardous materials and consume less energy throughout their lifecycle, reducing both disposal costs and potential regulatory compliance expenses as environmental regulations continue to evolve globally.

When these factors are integrated into a comprehensive cost-benefit analysis using a standard 5-year projection model, WOLED displays typically demonstrate a lower total cost of ownership despite their higher acquisition price, with the break-even point occurring between 24-36 months of operation for most commercial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!