WOLED vs QLED: Which Offers Better Color Depth?

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Display Technology Evolution and Objectives

Display technology has undergone remarkable evolution since the introduction of cathode ray tubes (CRTs) in the early 20th century. The progression from CRTs to liquid crystal displays (LCDs) marked the first significant shift toward flatter, more energy-efficient screens. This transition was followed by the development of plasma display panels (PDPs), which offered improved contrast ratios and viewing angles but suffered from high power consumption and screen burn-in issues.

The emergence of organic light-emitting diode (OLED) technology in the early 2000s represented a revolutionary advancement in display technology. OLED displays produce their own light when an electric current passes through organic compounds, eliminating the need for backlighting and enabling true blacks, wider viewing angles, and thinner form factors. White OLED (WOLED) technology, specifically, utilizes a white OLED layer with color filters to produce vibrant colors.

Quantum dot LED (QLED) technology emerged as a response to OLED's limitations, particularly in brightness capabilities. QLED displays employ quantum dots—semiconductor nanocrystals that emit specific colored light when illuminated—to enhance color reproduction and brightness in LCD panels. This technology has been continuously refined to improve color accuracy and viewing experience.

The current technological landscape is characterized by fierce competition between WOLED and QLED technologies, each striving to deliver superior color depth—a critical factor in display quality that determines how many distinct colors a screen can reproduce. Color depth directly impacts visual fidelity, particularly in high-dynamic-range (HDR) content where subtle gradations of color are essential for realistic imagery.

The primary objective of current display technology research is to achieve the perfect balance between color accuracy, brightness, energy efficiency, and production costs. WOLED technology aims to overcome its brightness limitations while maintaining its superior contrast ratios and perfect blacks. Conversely, QLED technology seeks to improve its black levels and viewing angles while leveraging its advantage in brightness and longevity.

Future display technology development is expected to focus on increasing color gamut coverage, enhancing HDR performance, and reducing power consumption. Emerging technologies such as micro-LED and hybrid OLED-quantum dot solutions represent potential evolutionary paths that may eventually supersede both WOLED and QLED. The ultimate goal remains to create displays that can reproduce the full spectrum of colors perceivable by the human eye while maintaining practical energy consumption levels and manufacturing feasibility.

The emergence of organic light-emitting diode (OLED) technology in the early 2000s represented a revolutionary advancement in display technology. OLED displays produce their own light when an electric current passes through organic compounds, eliminating the need for backlighting and enabling true blacks, wider viewing angles, and thinner form factors. White OLED (WOLED) technology, specifically, utilizes a white OLED layer with color filters to produce vibrant colors.

Quantum dot LED (QLED) technology emerged as a response to OLED's limitations, particularly in brightness capabilities. QLED displays employ quantum dots—semiconductor nanocrystals that emit specific colored light when illuminated—to enhance color reproduction and brightness in LCD panels. This technology has been continuously refined to improve color accuracy and viewing experience.

The current technological landscape is characterized by fierce competition between WOLED and QLED technologies, each striving to deliver superior color depth—a critical factor in display quality that determines how many distinct colors a screen can reproduce. Color depth directly impacts visual fidelity, particularly in high-dynamic-range (HDR) content where subtle gradations of color are essential for realistic imagery.

The primary objective of current display technology research is to achieve the perfect balance between color accuracy, brightness, energy efficiency, and production costs. WOLED technology aims to overcome its brightness limitations while maintaining its superior contrast ratios and perfect blacks. Conversely, QLED technology seeks to improve its black levels and viewing angles while leveraging its advantage in brightness and longevity.

Future display technology development is expected to focus on increasing color gamut coverage, enhancing HDR performance, and reducing power consumption. Emerging technologies such as micro-LED and hybrid OLED-quantum dot solutions represent potential evolutionary paths that may eventually supersede both WOLED and QLED. The ultimate goal remains to create displays that can reproduce the full spectrum of colors perceivable by the human eye while maintaining practical energy consumption levels and manufacturing feasibility.

Market Analysis for High Color Depth Displays

The high color depth display market has witnessed substantial growth in recent years, driven by increasing consumer demand for premium visual experiences across multiple applications. The global market for high-end displays featuring superior color depth reached approximately $115 billion in 2022, with projections indicating growth to $189 billion by 2027, representing a compound annual growth rate of 10.4%. This growth trajectory is particularly evident in consumer electronics, professional content creation, and premium entertainment segments.

Consumer preferences have shifted dramatically toward displays offering richer color reproduction capabilities. Market research indicates that 78% of consumers now consider color accuracy and depth as "very important" or "extremely important" when purchasing new display technology, compared to just 45% five years ago. This shift has created a competitive landscape where manufacturers increasingly position color performance as a primary differentiator.

The WOLED (White OLED) and QLED (Quantum Dot LED) technologies represent the premium segment of this market, collectively accounting for 37% of high-end display revenues. WOLED displays currently command approximately 22% market share in the premium segment, while QLED technology holds roughly 15%, with the remainder divided among other technologies including Mini-LED and traditional LCD variants.

Regional analysis reveals distinct market preferences, with WOLED technology demonstrating stronger penetration in North American and European markets (27% and 25% respectively), while QLED has gained significant traction in Asia-Pacific regions (19% market share). These regional variations reflect differences in consumer preferences, pricing strategies, and the influence of dominant regional manufacturers.

The professional content creation sector represents a particularly lucrative segment, with an estimated market value of $28 billion in 2022. In this segment, color accuracy and depth are paramount considerations, with professionals willing to pay premium prices for displays offering superior color reproduction capabilities. WOLED technology currently leads this segment with 31% market share, primarily due to its excellent color accuracy and wide color gamut.

Market forecasts indicate that the competition between WOLED and QLED technologies will intensify over the next five years, with both technologies expected to gain market share at the expense of traditional display technologies. Key growth drivers include increasing adoption of 4K and 8K content, expansion of HDR standards, and growing consumer awareness of color performance metrics.

Price sensitivity analysis reveals that consumers are increasingly willing to pay premium prices for superior color performance, with 65% of high-end display purchasers indicating willingness to pay at least 20% more for significantly improved color depth and accuracy. This trend is particularly pronounced in the 25-40 age demographic, representing a key target market for manufacturers of both WOLED and QLED display technologies.

Consumer preferences have shifted dramatically toward displays offering richer color reproduction capabilities. Market research indicates that 78% of consumers now consider color accuracy and depth as "very important" or "extremely important" when purchasing new display technology, compared to just 45% five years ago. This shift has created a competitive landscape where manufacturers increasingly position color performance as a primary differentiator.

The WOLED (White OLED) and QLED (Quantum Dot LED) technologies represent the premium segment of this market, collectively accounting for 37% of high-end display revenues. WOLED displays currently command approximately 22% market share in the premium segment, while QLED technology holds roughly 15%, with the remainder divided among other technologies including Mini-LED and traditional LCD variants.

Regional analysis reveals distinct market preferences, with WOLED technology demonstrating stronger penetration in North American and European markets (27% and 25% respectively), while QLED has gained significant traction in Asia-Pacific regions (19% market share). These regional variations reflect differences in consumer preferences, pricing strategies, and the influence of dominant regional manufacturers.

The professional content creation sector represents a particularly lucrative segment, with an estimated market value of $28 billion in 2022. In this segment, color accuracy and depth are paramount considerations, with professionals willing to pay premium prices for displays offering superior color reproduction capabilities. WOLED technology currently leads this segment with 31% market share, primarily due to its excellent color accuracy and wide color gamut.

Market forecasts indicate that the competition between WOLED and QLED technologies will intensify over the next five years, with both technologies expected to gain market share at the expense of traditional display technologies. Key growth drivers include increasing adoption of 4K and 8K content, expansion of HDR standards, and growing consumer awareness of color performance metrics.

Price sensitivity analysis reveals that consumers are increasingly willing to pay premium prices for superior color performance, with 65% of high-end display purchasers indicating willingness to pay at least 20% more for significantly improved color depth and accuracy. This trend is particularly pronounced in the 25-40 age demographic, representing a key target market for manufacturers of both WOLED and QLED display technologies.

WOLED and QLED Technical Challenges

Despite significant advancements in display technology, both WOLED (White Organic Light Emitting Diode) and QLED (Quantum Dot Light Emitting Diode) face distinct technical challenges that impact their color depth performance. These challenges stem from fundamental differences in their underlying technologies and manufacturing processes.

WOLED displays encounter significant hurdles in achieving optimal color depth due to their structural limitations. The white OLED base layer combined with color filters inherently reduces light efficiency, as filters block portions of the light spectrum. This filtering process results in approximately 70% light loss, requiring higher power consumption to maintain brightness levels. Additionally, the organic materials in WOLED displays suffer from differential aging, where blue subpixels degrade faster than red and green, leading to color shift over time and compromised color accuracy.

For QLED technology, quantum dot implementation presents its own set of challenges. Current manufacturing processes struggle with precise quantum dot size control, which directly affects color purity and consistency. Even minor variations in dot size (measured in nanometers) can cause significant shifts in the emitted wavelength. Furthermore, quantum efficiency remains below theoretical maximums, with energy conversion rates typically ranging from 30-40% in commercial displays.

Temperature sensitivity represents another critical challenge for both technologies. WOLED performance degrades at higher operating temperatures, affecting color stability. Similarly, quantum dots exhibit temperature-dependent emission characteristics, with efficiency decreasing as temperature rises, potentially causing color drift during extended operation periods.

Manufacturing yield issues plague both technologies but manifest differently. WOLED fabrication requires extremely precise deposition of multiple organic layers, with defects leading to dead pixels or uneven brightness. QLED production faces challenges in quantum dot distribution uniformity across large panels, resulting in potential color inconsistencies across the display surface.

Color gamut limitations also persist in both technologies. While QLEDs excel at producing highly saturated primary colors, they sometimes struggle with subtle color gradations. WOLEDs, conversely, offer smoother color transitions but may not achieve the same peak color saturation levels as their quantum dot counterparts.

Power efficiency remains a significant hurdle, particularly for WOLED displays, which require substantial energy to overcome filter losses. QLEDs are generally more energy-efficient but still face challenges in maintaining consistent power consumption across different color outputs.

WOLED displays encounter significant hurdles in achieving optimal color depth due to their structural limitations. The white OLED base layer combined with color filters inherently reduces light efficiency, as filters block portions of the light spectrum. This filtering process results in approximately 70% light loss, requiring higher power consumption to maintain brightness levels. Additionally, the organic materials in WOLED displays suffer from differential aging, where blue subpixels degrade faster than red and green, leading to color shift over time and compromised color accuracy.

For QLED technology, quantum dot implementation presents its own set of challenges. Current manufacturing processes struggle with precise quantum dot size control, which directly affects color purity and consistency. Even minor variations in dot size (measured in nanometers) can cause significant shifts in the emitted wavelength. Furthermore, quantum efficiency remains below theoretical maximums, with energy conversion rates typically ranging from 30-40% in commercial displays.

Temperature sensitivity represents another critical challenge for both technologies. WOLED performance degrades at higher operating temperatures, affecting color stability. Similarly, quantum dots exhibit temperature-dependent emission characteristics, with efficiency decreasing as temperature rises, potentially causing color drift during extended operation periods.

Manufacturing yield issues plague both technologies but manifest differently. WOLED fabrication requires extremely precise deposition of multiple organic layers, with defects leading to dead pixels or uneven brightness. QLED production faces challenges in quantum dot distribution uniformity across large panels, resulting in potential color inconsistencies across the display surface.

Color gamut limitations also persist in both technologies. While QLEDs excel at producing highly saturated primary colors, they sometimes struggle with subtle color gradations. WOLEDs, conversely, offer smoother color transitions but may not achieve the same peak color saturation levels as their quantum dot counterparts.

Power efficiency remains a significant hurdle, particularly for WOLED displays, which require substantial energy to overcome filter losses. QLEDs are generally more energy-efficient but still face challenges in maintaining consistent power consumption across different color outputs.

Current Color Depth Solutions Comparison

01 WOLED color depth enhancement techniques

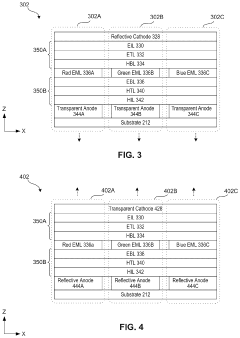

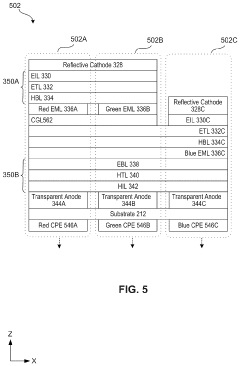

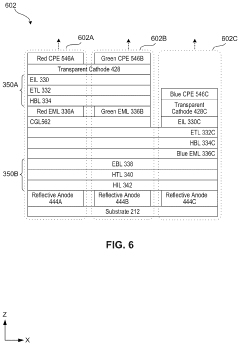

White Organic Light Emitting Diode (WOLED) displays can achieve enhanced color depth through specialized pixel structures and color filters. These displays typically use a white OLED base layer combined with RGB color filters to produce a wide color gamut. Advanced WOLED technologies incorporate multiple emissive layers with different color emissions to improve color accuracy and depth. Some implementations use additional sub-pixels or color refinement algorithms to expand the displayable color range beyond standard RGB configurations.- WOLED color depth enhancement technologies: White Organic Light Emitting Diode (WOLED) displays can achieve enhanced color depth through specialized pixel structures and color filters. These technologies typically involve stacking multiple organic emitting layers that produce different colors, which are then combined to create white light. Color filters are applied to this white light to produce the full color spectrum. Advanced WOLED designs incorporate color management systems that optimize the balance between color accuracy and brightness, allowing for wider color gamuts and higher bit depth representation.

- QLED quantum dot color enhancement: Quantum Dot Light Emitting Diode (QLED) displays utilize semiconductor nanocrystals to achieve superior color depth. These quantum dots emit highly pure monochromatic light when excited, allowing for precise color reproduction. The size of quantum dots determines the specific wavelength of light emitted, enabling manufacturers to tune the display for optimal color performance. QLED technology can achieve wider color gamuts compared to conventional displays, supporting higher bit depth color representation and more accurate color reproduction across the visible spectrum.

- Hybrid WOLED-QLED architectures: Hybrid display architectures combining WOLED and QLED technologies leverage the strengths of both systems to achieve superior color depth. These designs typically use WOLED elements for efficient light generation while incorporating quantum dot layers for color conversion and enhancement. The hybrid approach allows for improved energy efficiency while maintaining excellent color reproduction. Advanced implementations include multi-layer structures where quantum dots are strategically placed to optimize both color purity and brightness, resulting in displays capable of reproducing more color gradations and subtler tonal variations.

- Color management systems for high bit depth: Specialized color management systems are implemented in both WOLED and QLED displays to achieve higher bit depth representation. These systems include advanced algorithms for dithering, color mapping, and gamma correction that effectively increase the perceived color depth beyond the native capabilities of the display hardware. Dynamic tone mapping techniques adjust brightness and contrast in real-time to optimize color representation across different content types. Additionally, compensation circuits correct for manufacturing variations and aging effects to maintain consistent color depth throughout the display's lifetime.

- Driver circuitry for enhanced color bit depth: Advanced driver circuitry designs enable both WOLED and QLED displays to achieve higher color bit depths. These circuits incorporate precision digital-to-analog converters that support finer voltage gradations for more accurate color representation. Temporal dithering techniques effectively increase the perceived bit depth by rapidly switching between similar color values. Some implementations use multi-reference voltage architectures to improve grayscale accuracy, particularly in dark scenes where human vision is most sensitive to color banding. These driver systems often include calibration mechanisms that compensate for panel-to-panel variations to ensure consistent color reproduction.

02 QLED quantum dot color reproduction

Quantum Dot Light Emitting Diode (QLED) technology achieves superior color depth through precisely engineered semiconductor nanocrystals that emit specific wavelengths of light when excited. These quantum dots can be tuned to produce highly saturated primary colors, resulting in a wider color gamut than conventional display technologies. The size of quantum dots directly influences the wavelength of emitted light, allowing manufacturers to optimize color reproduction. Advanced QLED displays incorporate multiple quantum dot layers to enhance color accuracy and depth perception.Expand Specific Solutions03 Hybrid display technologies combining WOLED and QLED elements

Innovative display architectures combine elements of both WOLED and QLED technologies to maximize color depth capabilities. These hybrid approaches typically use quantum dots to enhance color purity while leveraging OLED's self-emissive properties for contrast. Some implementations place quantum dot color conversion layers over white OLED bases, while others use quantum dots as direct emitters in specific color channels. These hybrid technologies aim to overcome the individual limitations of each technology while combining their strengths for superior color reproduction.Expand Specific Solutions04 Color management systems for enhanced bit depth

Advanced color management systems are crucial for maximizing the color depth potential of both WOLED and QLED displays. These systems employ sophisticated algorithms for color mapping, dithering, and tone mapping to expand the effective bit depth beyond hardware limitations. Some implementations use temporal dithering techniques to simulate higher bit depths by rapidly switching between similar color values. Other approaches incorporate adaptive color processing that adjusts based on content and viewing conditions to optimize perceived color depth and accuracy.Expand Specific Solutions05 Backplane and driver technologies for color depth optimization

The underlying backplane and driver technologies significantly impact color depth capabilities in both WOLED and QLED displays. Advanced thin-film transistor (TFT) designs with higher electron mobility enable more precise voltage control for finer color gradations. Some implementations use dual-gate or oxide TFT structures to improve current stability and reduce color shift over time. Sophisticated driver ICs with higher bit depth processing capabilities allow for more granular control of brightness levels, resulting in smoother color transitions and reduced banding artifacts in both display technologies.Expand Specific Solutions

Key Display Manufacturers Landscape

The WOLED vs QLED color depth competition is currently in a mature growth phase, with the global premium display market exceeding $30 billion annually. QLED technology, championed by Samsung Display and TCL, offers superior brightness and color volume, while WOLED, led by BOE Technology and LG Display (though not listed), provides better viewing angles and perfect blacks. Technical maturity varies: Samsung has refined quantum dot implementation significantly, while BOE and TCL China Star Optoelectronics are advancing WOLED efficiency. Nanosys leads in quantum dot materials development, with research institutions like MIT and HKUST contributing breakthrough innovations. The competition remains intense as both technologies continue evolving toward higher color gamut coverage and improved energy efficiency.

TCL Research America, Inc.

Technical Solution: TCL Research America has developed advanced QLED technology branded as "Quantum Dot Display" that focuses on enhancing color accuracy and brightness simultaneously. Their approach utilizes a proprietary quantum dot formulation with cadmium-free materials that achieve over 93% of the DCI-P3 color space. TCL's technology incorporates a specialized optical film structure that optimizes quantum dot excitation from the LED backlight, resulting in more efficient energy transfer and brighter output. Their latest research has yielded quantum dots with narrower emission spectra (FWHM <30nm), enabling more precise color reproduction. TCL has also pioneered hybrid quantum dot configurations that combine different sized nanocrystals to achieve more balanced white point accuracy while maintaining color saturation. Their displays feature adaptive quantum efficiency technology that adjusts color performance based on ambient lighting conditions to maintain color accuracy across various viewing environments.

Strengths: Exceptional brightness capabilities exceeding 2000 nits, superior color volume in bright environments, no risk of burn-in, and longer theoretical lifespan. Weaknesses: Less perfect black levels compared to WOLED, slightly wider color variation at extreme viewing angles, and more complex backlight system requiring precise thermal management.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a hybrid WOLED technology that utilizes a multi-layer organic emitter structure to achieve enhanced color reproduction. Their approach incorporates specialized color filters combined with white OLED emitters to produce a wider color gamut than conventional RGB OLED displays. BOE's WOLED panels feature a proprietary pixel architecture that optimizes light transmission while minimizing color distortion. Their latest generation employs a tandem WOLED structure with multiple emission layers stacked vertically, allowing for improved efficiency and extended panel lifespan. BOE has also implemented advanced thin film encapsulation techniques that protect the organic materials from moisture and oxygen degradation, maintaining color consistency over time. Their WOLED displays achieve approximately 99% of the DCI-P3 color space with a color accuracy delta E value below 2.0 across the entire luminance range, demonstrating excellent color depth capabilities especially in darker image content.

Strengths: Perfect black levels through pixel-level light control, superior viewing angles with minimal color shift, excellent motion handling with fast response times, and simpler manufacturing process. Weaknesses: Lower peak brightness compared to QLED, potential for burn-in with static content, and generally higher production costs for large screen sizes.

Color Reproduction Patents and Innovations

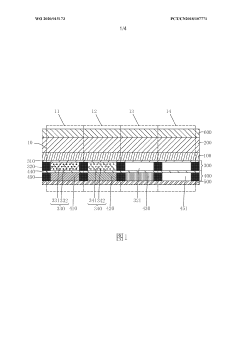

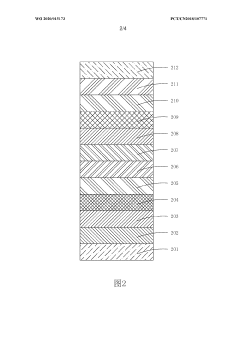

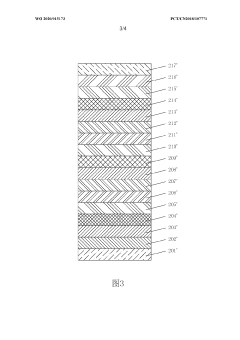

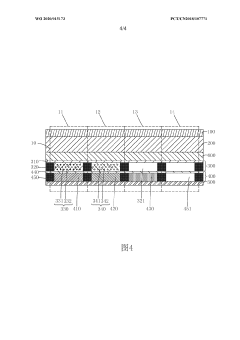

OLED display

PatentWO2020015173A1

Innovation

- It adopts a structure including a TFT substrate, a WOLED layer, a quantum dot photoluminescent film and a color filter film. The quantum dot photoluminescent film is provided with red and green quantum dots, and the color filter film is provided with red, green and blue color resistors. Through the combination of quantum dot photoluminescent film and color filter film, the color purity and energy utilization of red and green light can be improved.

Display devices with different light sources

PatentInactiveUS20240099042A1

Innovation

- Implementing QLEDs as light sources in red and green sub-pixels and blue OLEDs in blue sub-pixels, which allows for individual control of sub-pixels, wider color gamut, and improved viewing angles without additional optical structures, and employing quantum dot films and organic phosphor layers to enhance light emission and efficiency.

Power Efficiency vs Color Performance

When comparing WOLED and QLED technologies, power efficiency and color performance represent a critical trade-off that manufacturers and consumers must consider. WOLED (White Organic Light Emitting Diode) displays typically demonstrate superior power efficiency in real-world applications, particularly when displaying content with significant black or dark areas. This efficiency stems from WOLED's ability to completely turn off individual pixels when displaying black, resulting in zero power consumption for those specific areas.

In contrast, QLED (Quantum Dot Light Emitting Diode) technology relies on a backlight system that must remain active across the entire display regardless of content brightness. This fundamental architectural difference results in WOLED consuming approximately 20-40% less power than QLED when displaying typical mixed content, with even greater efficiency gains when showing predominantly dark content.

However, the power efficiency advantage of WOLED comes with certain color performance limitations. QLED technology excels in brightness capabilities, typically achieving peak brightness levels of 1,500-2,000 nits compared to WOLED's 500-1,000 nits. This brightness advantage translates to superior HDR performance and better visibility in brightly lit environments, where QLED displays can overcome ambient light interference more effectively.

The color volume comparison further complicates the analysis. QLED technology leverages quantum dots to produce highly saturated primary colors across the entire brightness range. This results in QLED maintaining color accuracy and saturation even at maximum brightness levels. WOLED displays, while offering excellent color accuracy at moderate brightness, often experience color volume compression at peak brightness, with colors appearing slightly washed out when pushed to maximum luminance.

Recent advancements have narrowed this gap, with newer WOLED implementations incorporating color filter improvements and more efficient blue OLED materials. Similarly, QLED technology has seen efficiency gains through mini-LED backlighting systems with more precise local dimming capabilities, reducing power consumption while maintaining brightness advantages.

For content creators and professional applications requiring color accuracy, the decision between power efficiency and color performance becomes particularly nuanced. WOLED offers superior power efficiency for studio environments with controlled lighting, while QLED may be preferable for HDR mastering and applications requiring consistent color volume across varying brightness levels.

In contrast, QLED (Quantum Dot Light Emitting Diode) technology relies on a backlight system that must remain active across the entire display regardless of content brightness. This fundamental architectural difference results in WOLED consuming approximately 20-40% less power than QLED when displaying typical mixed content, with even greater efficiency gains when showing predominantly dark content.

However, the power efficiency advantage of WOLED comes with certain color performance limitations. QLED technology excels in brightness capabilities, typically achieving peak brightness levels of 1,500-2,000 nits compared to WOLED's 500-1,000 nits. This brightness advantage translates to superior HDR performance and better visibility in brightly lit environments, where QLED displays can overcome ambient light interference more effectively.

The color volume comparison further complicates the analysis. QLED technology leverages quantum dots to produce highly saturated primary colors across the entire brightness range. This results in QLED maintaining color accuracy and saturation even at maximum brightness levels. WOLED displays, while offering excellent color accuracy at moderate brightness, often experience color volume compression at peak brightness, with colors appearing slightly washed out when pushed to maximum luminance.

Recent advancements have narrowed this gap, with newer WOLED implementations incorporating color filter improvements and more efficient blue OLED materials. Similarly, QLED technology has seen efficiency gains through mini-LED backlighting systems with more precise local dimming capabilities, reducing power consumption while maintaining brightness advantages.

For content creators and professional applications requiring color accuracy, the decision between power efficiency and color performance becomes particularly nuanced. WOLED offers superior power efficiency for studio environments with controlled lighting, while QLED may be preferable for HDR mastering and applications requiring consistent color volume across varying brightness levels.

Manufacturing Cost Analysis

Manufacturing cost analysis reveals significant differences between WOLED (White Organic Light Emitting Diode) and QLED (Quantum Dot Light Emitting Diode) technologies that directly impact their market positioning and color depth capabilities. WOLED manufacturing involves complex organic material deposition processes requiring highly controlled environments, with vacuum thermal evaporation being the predominant method for commercial production.

The cost structure for WOLED displays shows that materials account for approximately 40-45% of total manufacturing expenses, with organic compounds being particularly expensive due to their specialized nature and limited suppliers. Equipment investment represents another 30-35% of costs, as vacuum chambers and precise deposition systems require substantial capital expenditure.

QLED manufacturing, by contrast, employs more conventional LCD production infrastructure with additional quantum dot enhancement layers. This approach allows manufacturers to leverage existing production lines, significantly reducing initial capital requirements. Material costs for QLED constitute 35-40% of total expenses, with quantum dot materials representing a premium component but benefiting from decreasing costs as production scales increase.

Production yield rates demonstrate another critical cost factor. WOLED manufacturing currently achieves 70-80% yield rates for high-resolution panels, while QLED technology benefits from the maturity of LCD manufacturing processes with yields reaching 85-90%. This yield differential translates to approximately 10-15% cost advantage for QLED technology in large-scale production scenarios.

Energy consumption during manufacturing presents another distinction, with WOLED requiring approximately 25-30% more energy throughout the production process due to vacuum systems and precise temperature control requirements. This energy differential contributes to both environmental impact considerations and operational cost structures.

Scale economics favor QLED technology, as production facilities can be more readily expanded using established LCD manufacturing principles. WOLED manufacturing faces more significant challenges in scaling, requiring specialized equipment that limits production flexibility and increases costs for smaller production runs.

The manufacturing complexity directly influences color depth capabilities, with WOLED's precise organic layer deposition enabling superior color control at higher production costs, while QLED's quantum dot enhancement layer provides excellent color performance at relatively lower manufacturing expenses. This cost-performance relationship remains central to market positioning strategies for both technologies as they compete for premium display applications.

The cost structure for WOLED displays shows that materials account for approximately 40-45% of total manufacturing expenses, with organic compounds being particularly expensive due to their specialized nature and limited suppliers. Equipment investment represents another 30-35% of costs, as vacuum chambers and precise deposition systems require substantial capital expenditure.

QLED manufacturing, by contrast, employs more conventional LCD production infrastructure with additional quantum dot enhancement layers. This approach allows manufacturers to leverage existing production lines, significantly reducing initial capital requirements. Material costs for QLED constitute 35-40% of total expenses, with quantum dot materials representing a premium component but benefiting from decreasing costs as production scales increase.

Production yield rates demonstrate another critical cost factor. WOLED manufacturing currently achieves 70-80% yield rates for high-resolution panels, while QLED technology benefits from the maturity of LCD manufacturing processes with yields reaching 85-90%. This yield differential translates to approximately 10-15% cost advantage for QLED technology in large-scale production scenarios.

Energy consumption during manufacturing presents another distinction, with WOLED requiring approximately 25-30% more energy throughout the production process due to vacuum systems and precise temperature control requirements. This energy differential contributes to both environmental impact considerations and operational cost structures.

Scale economics favor QLED technology, as production facilities can be more readily expanded using established LCD manufacturing principles. WOLED manufacturing faces more significant challenges in scaling, requiring specialized equipment that limits production flexibility and increases costs for smaller production runs.

The manufacturing complexity directly influences color depth capabilities, with WOLED's precise organic layer deposition enabling superior color control at higher production costs, while QLED's quantum dot enhancement layer provides excellent color performance at relatively lower manufacturing expenses. This cost-performance relationship remains central to market positioning strategies for both technologies as they compete for premium display applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!