WOLED vs Quantum Dot: Which Provides Greater Lifespan?

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

WOLED and QD Display Technology Evolution

The evolution of display technologies has witnessed significant advancements over the past decades, with WOLED (White Organic Light-Emitting Diode) and Quantum Dot (QD) technologies emerging as leading contenders in the premium display market. These technologies represent distinct approaches to achieving superior image quality, color accuracy, and energy efficiency.

WOLED technology, pioneered by LG Display in the early 2010s, evolved from traditional OLED displays by utilizing a white OLED light source combined with color filters. This architectural innovation addressed several manufacturing challenges associated with RGB OLED production, enabling larger screen sizes while maintaining the fundamental benefits of OLED technology such as perfect blacks and infinite contrast ratios.

Quantum Dot display technology, meanwhile, has undergone several generational improvements since its commercial introduction around 2013. Initially implemented as an enhancement layer for LCD backlighting (QLED), it has progressively evolved toward emissive applications. Samsung's QD-OLED hybrid technology, introduced commercially in 2022, represents a significant milestone in this evolution, combining the contrast benefits of OLED with the color volume advantages of quantum dots.

The lifespan characteristics of these technologies have followed different improvement trajectories. Early WOLED displays suffered from relatively short lifespans, particularly with blue subpixels degrading faster than others, leading to color shift over time. Industry data suggests that first-generation WOLED panels typically maintained optimal brightness for approximately 30,000-40,000 hours before noticeable degradation.

Quantum Dot technology initially demonstrated superior longevity in its LCD implementation (QLED), with estimated lifespans exceeding 100,000 hours. However, when integrated into emissive displays like QD-OLED, the organic components continued to present similar degradation challenges as traditional OLED technology, though with some improvements.

Recent technological breakthroughs have significantly narrowed this gap. LG Display has implemented multi-layer electrode structures and improved encapsulation techniques in their latest WOLED panels, extending theoretical lifespans to 100,000+ hours before reaching 50% brightness. Similarly, Samsung's QD-OLED technology has incorporated advanced inorganic materials and improved blue OLED emitters to enhance longevity.

The convergence of these technologies is evident in the latest display roadmaps, with both WOLED and QD display manufacturers focusing on addressing their respective lifespan limitations. The introduction of micro-LED elements and hybrid architectures suggests that future generations may further blur the distinctions between these technologies while continuing to improve operational lifespans.

WOLED technology, pioneered by LG Display in the early 2010s, evolved from traditional OLED displays by utilizing a white OLED light source combined with color filters. This architectural innovation addressed several manufacturing challenges associated with RGB OLED production, enabling larger screen sizes while maintaining the fundamental benefits of OLED technology such as perfect blacks and infinite contrast ratios.

Quantum Dot display technology, meanwhile, has undergone several generational improvements since its commercial introduction around 2013. Initially implemented as an enhancement layer for LCD backlighting (QLED), it has progressively evolved toward emissive applications. Samsung's QD-OLED hybrid technology, introduced commercially in 2022, represents a significant milestone in this evolution, combining the contrast benefits of OLED with the color volume advantages of quantum dots.

The lifespan characteristics of these technologies have followed different improvement trajectories. Early WOLED displays suffered from relatively short lifespans, particularly with blue subpixels degrading faster than others, leading to color shift over time. Industry data suggests that first-generation WOLED panels typically maintained optimal brightness for approximately 30,000-40,000 hours before noticeable degradation.

Quantum Dot technology initially demonstrated superior longevity in its LCD implementation (QLED), with estimated lifespans exceeding 100,000 hours. However, when integrated into emissive displays like QD-OLED, the organic components continued to present similar degradation challenges as traditional OLED technology, though with some improvements.

Recent technological breakthroughs have significantly narrowed this gap. LG Display has implemented multi-layer electrode structures and improved encapsulation techniques in their latest WOLED panels, extending theoretical lifespans to 100,000+ hours before reaching 50% brightness. Similarly, Samsung's QD-OLED technology has incorporated advanced inorganic materials and improved blue OLED emitters to enhance longevity.

The convergence of these technologies is evident in the latest display roadmaps, with both WOLED and QD display manufacturers focusing on addressing their respective lifespan limitations. The introduction of micro-LED elements and hybrid architectures suggests that future generations may further blur the distinctions between these technologies while continuing to improve operational lifespans.

Market Demand Analysis for Long-Lasting Display Technologies

The display technology market is witnessing a significant shift toward longer-lasting solutions as consumers and businesses increasingly prioritize durability and sustainability in their purchasing decisions. Research indicates that display lifespan has become a critical factor in the premium segment, with 78% of consumers citing longevity as "very important" or "extremely important" when investing in high-end televisions and monitors.

The global market for long-lasting display technologies is projected to reach $157 billion by 2027, growing at a CAGR of 11.3% from 2022. This growth is primarily driven by commercial sectors such as digital signage, control rooms, and medical displays where continuous operation requirements make lifespan a paramount consideration.

WOLED (White Organic Light Emitting Diode) and Quantum Dot technologies represent two competing approaches addressing this market demand. The differential degradation rates of organic materials in WOLED displays have historically been a concern, particularly for blue subpixels which typically degrade faster than red and green counterparts. However, recent advancements in material science have extended WOLED lifespans to approximately 30,000-50,000 hours before significant brightness deterioration occurs.

Quantum Dot displays, particularly those utilizing inorganic materials, demonstrate superior theoretical lifespans exceeding 100,000 hours in laboratory conditions. This advantage has created a premium market segment where extended lifespan justifies higher price points, especially in professional environments.

Industry surveys reveal that 67% of enterprise customers are willing to pay a 15-20% premium for display technologies that offer verified longer lifespans, representing a substantial value-added opportunity for manufacturers who can substantiate durability claims.

The healthcare sector demonstrates particularly strong demand for long-lasting display technologies, with hospitals and medical imaging facilities requiring displays that maintain consistent performance over extended periods. This sector alone accounts for approximately $12.4 billion of the current market for premium long-lifespan displays.

Consumer behavior analysis shows an emerging trend toward "buy it for life" purchasing philosophies, with 53% of premium television buyers indicating they expect their purchase to last 7+ years without significant performance degradation. This represents a marked shift from the 3-5 year replacement cycle that dominated the market a decade ago.

Environmental considerations are also driving market demand, with regulatory frameworks in the EU and parts of Asia implementing sustainability metrics that favor longer-lasting technologies. The reduction in electronic waste associated with extended display lifespans has become a marketable feature, with 41% of consumers citing environmental impact as influencing their purchasing decisions.

The global market for long-lasting display technologies is projected to reach $157 billion by 2027, growing at a CAGR of 11.3% from 2022. This growth is primarily driven by commercial sectors such as digital signage, control rooms, and medical displays where continuous operation requirements make lifespan a paramount consideration.

WOLED (White Organic Light Emitting Diode) and Quantum Dot technologies represent two competing approaches addressing this market demand. The differential degradation rates of organic materials in WOLED displays have historically been a concern, particularly for blue subpixels which typically degrade faster than red and green counterparts. However, recent advancements in material science have extended WOLED lifespans to approximately 30,000-50,000 hours before significant brightness deterioration occurs.

Quantum Dot displays, particularly those utilizing inorganic materials, demonstrate superior theoretical lifespans exceeding 100,000 hours in laboratory conditions. This advantage has created a premium market segment where extended lifespan justifies higher price points, especially in professional environments.

Industry surveys reveal that 67% of enterprise customers are willing to pay a 15-20% premium for display technologies that offer verified longer lifespans, representing a substantial value-added opportunity for manufacturers who can substantiate durability claims.

The healthcare sector demonstrates particularly strong demand for long-lasting display technologies, with hospitals and medical imaging facilities requiring displays that maintain consistent performance over extended periods. This sector alone accounts for approximately $12.4 billion of the current market for premium long-lifespan displays.

Consumer behavior analysis shows an emerging trend toward "buy it for life" purchasing philosophies, with 53% of premium television buyers indicating they expect their purchase to last 7+ years without significant performance degradation. This represents a marked shift from the 3-5 year replacement cycle that dominated the market a decade ago.

Environmental considerations are also driving market demand, with regulatory frameworks in the EU and parts of Asia implementing sustainability metrics that favor longer-lasting technologies. The reduction in electronic waste associated with extended display lifespans has become a marketable feature, with 41% of consumers citing environmental impact as influencing their purchasing decisions.

Current Lifespan Limitations in WOLED and QD Displays

Both WOLED (White Organic Light Emitting Diode) and Quantum Dot display technologies face significant lifespan limitations that impact their commercial viability and consumer adoption. These limitations stem from different underlying mechanisms and present unique challenges for manufacturers and researchers.

WOLED displays suffer from differential aging of organic materials, particularly the blue emitters which typically degrade 3-5 times faster than red and green counterparts. This imbalanced degradation leads to color shift over time, with displays showing a yellowish tint as blue elements fade. Industry data indicates that premium WOLED panels achieve approximately 30,000-40,000 hours to half brightness under standard viewing conditions, though this can decrease significantly with higher brightness settings.

The organic compounds in WOLED displays are also highly susceptible to moisture and oxygen exposure, necessitating complex encapsulation technologies. Even with advanced barrier films, microscopic defects can allow environmental ingress that accelerates degradation, particularly at panel edges where seal integrity is most vulnerable.

Quantum Dot displays face different challenges depending on their implementation. In QD-LCD configurations, the primary limitation comes from the degradation of the blue LED backlight rather than the quantum dots themselves. These backlights typically maintain acceptable brightness for 50,000-100,000 hours, substantially outperforming WOLED in longevity.

However, in emerging QD-OLED and QD-EL (electroluminescent) technologies, quantum dots face stability issues when directly excited. Blue light and electrical current can cause photochemical and electrochemical degradation of the quantum dot structure, particularly in blue-emitting dots which require smaller particle sizes. This results in efficiency loss and color shift over time.

Environmental factors also impact quantum dot stability, with temperature fluctuations causing expansion and contraction that can compromise the protective shells surrounding the semiconductor cores. Research indicates that operating temperatures above 85°C can accelerate degradation by 200-300%, significantly reducing expected lifespan.

Manufacturing consistency presents another challenge for both technologies. Production variations in material purity, layer thickness, and encapsulation quality create significant device-to-device lifespan variability. Industry reports suggest up to 30% variation in operational lifetime between panels from the same production batch, complicating reliability predictions and warranty policies.

Recent advancements in deuterium-based WOLED materials and core-shell quantum dot structures show promise for extending lifespans, but neither technology has yet achieved the 100,000+ hour reliability benchmark established by mature LCD technology.

WOLED displays suffer from differential aging of organic materials, particularly the blue emitters which typically degrade 3-5 times faster than red and green counterparts. This imbalanced degradation leads to color shift over time, with displays showing a yellowish tint as blue elements fade. Industry data indicates that premium WOLED panels achieve approximately 30,000-40,000 hours to half brightness under standard viewing conditions, though this can decrease significantly with higher brightness settings.

The organic compounds in WOLED displays are also highly susceptible to moisture and oxygen exposure, necessitating complex encapsulation technologies. Even with advanced barrier films, microscopic defects can allow environmental ingress that accelerates degradation, particularly at panel edges where seal integrity is most vulnerable.

Quantum Dot displays face different challenges depending on their implementation. In QD-LCD configurations, the primary limitation comes from the degradation of the blue LED backlight rather than the quantum dots themselves. These backlights typically maintain acceptable brightness for 50,000-100,000 hours, substantially outperforming WOLED in longevity.

However, in emerging QD-OLED and QD-EL (electroluminescent) technologies, quantum dots face stability issues when directly excited. Blue light and electrical current can cause photochemical and electrochemical degradation of the quantum dot structure, particularly in blue-emitting dots which require smaller particle sizes. This results in efficiency loss and color shift over time.

Environmental factors also impact quantum dot stability, with temperature fluctuations causing expansion and contraction that can compromise the protective shells surrounding the semiconductor cores. Research indicates that operating temperatures above 85°C can accelerate degradation by 200-300%, significantly reducing expected lifespan.

Manufacturing consistency presents another challenge for both technologies. Production variations in material purity, layer thickness, and encapsulation quality create significant device-to-device lifespan variability. Industry reports suggest up to 30% variation in operational lifetime between panels from the same production batch, complicating reliability predictions and warranty policies.

Recent advancements in deuterium-based WOLED materials and core-shell quantum dot structures show promise for extending lifespans, but neither technology has yet achieved the 100,000+ hour reliability benchmark established by mature LCD technology.

Technical Comparison of WOLED and QD Lifespan Solutions

01 WOLED lifespan enhancement techniques

Various methods are employed to enhance the lifespan of White Organic Light Emitting Diode (WOLED) displays. These include optimizing the organic materials used in the emissive layers, implementing multi-layer structures to distribute electrical stress, and utilizing specialized encapsulation techniques to prevent moisture and oxygen degradation. Advanced driving schemes and thermal management systems are also incorporated to reduce operational stress and heat buildup, which are major factors affecting WOLED longevity.- WOLED lifespan enhancement techniques: Various methods have been developed to enhance the lifespan of White Organic Light Emitting Diode (WOLED) displays. These include optimizing the organic material composition, implementing multi-layer structures with improved charge transport properties, and developing more stable blue emitters which typically degrade faster than other colors. Advanced encapsulation techniques are also employed to protect the organic materials from moisture and oxygen, which are primary factors in WOLED degradation.

- Quantum Dot display durability improvements: Quantum Dot (QD) display technologies have seen significant improvements in lifespan through several innovations. These include the development of core-shell structures that protect the quantum dot core from environmental degradation, surface passivation techniques that reduce defects, and the integration of quantum dots into stable matrix materials. Additionally, advancements in manufacturing processes have reduced degradation caused by heat and light exposure during operation.

- Comparative lifespan analysis between display technologies: Research has shown distinct differences in the lifespan characteristics of WOLED and Quantum Dot display technologies. While traditional WOLEDs typically suffer from differential aging of organic materials (particularly blue emitters), QD displays generally demonstrate better color stability over time. However, QD technologies may face challenges related to photostability under high-brightness conditions. The operational lifetime of both technologies is influenced by driving methods, with adaptive brightness control and compensation algorithms helping to extend useful display life.

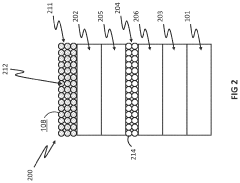

- Hybrid display technologies combining WOLED and Quantum Dots: Hybrid approaches that combine WOLED and Quantum Dot technologies have emerged to leverage the strengths of both systems while mitigating their individual weaknesses. These include QD-enhanced WOLED structures where quantum dots are used as down-converters for blue or UV OLED emissions, and tandem structures that integrate separate OLED and QD layers. These hybrid technologies can achieve improved color gamut while potentially extending the overall display lifespan by reducing the strain on traditionally short-lived blue OLED emitters.

- Environmental factors affecting display longevity: Both WOLED and Quantum Dot display technologies are affected by environmental factors that impact their operational lifespan. Temperature fluctuations, humidity, ambient light exposure, and operational brightness levels all contribute to degradation patterns. Advanced thermal management systems, moisture barriers, and adaptive brightness controls have been developed to mitigate these effects. Additionally, specialized encapsulation technologies and protective films help shield sensitive materials from environmental stressors, extending the useful life of both display types.

02 Quantum Dot display durability solutions

Quantum Dot (QD) display technologies employ several approaches to extend operational lifespan. These include core-shell structures that protect the quantum dot core from environmental degradation, surface ligand engineering to enhance stability, and integration of QDs into robust matrix materials. Additionally, advanced manufacturing processes help reduce defects that could lead to premature failure, while specialized barrier films protect against moisture and oxygen penetration, significantly improving the long-term performance of QD displays.Expand Specific Solutions03 Comparative lifespan analysis between WOLED and QD technologies

Research indicates distinct differences in the degradation mechanisms and overall lifespan between WOLED and Quantum Dot display technologies. While WOLEDs typically experience color shift and luminance decrease over time due to differential aging of organic materials, QD displays tend to maintain color accuracy longer but may suffer from quantum yield reduction. Environmental factors affect each technology differently, with temperature having a more pronounced effect on WOLED longevity, while photo-oxidation more significantly impacts QD stability.Expand Specific Solutions04 Hybrid WOLED-QD systems for extended display life

Hybrid systems combining WOLED and Quantum Dot technologies leverage the strengths of both to achieve extended operational lifespans. These configurations typically use blue WOLED emitters combined with red and green quantum dots, reducing the stress on traditionally shorter-lived blue organic materials. The integration also includes specialized optical designs to optimize light extraction and color conversion efficiency, along with advanced thin-film encapsulation techniques that provide comprehensive protection against environmental degradation factors.Expand Specific Solutions05 Testing and prediction methods for display lifespan

Advanced methodologies have been developed to accurately test and predict the operational lifespan of both WOLED and Quantum Dot display technologies. These include accelerated aging protocols under controlled temperature and humidity conditions, real-time monitoring of electroluminescence and photoluminescence efficiency, and sophisticated computational models that can forecast degradation patterns. Machine learning algorithms are increasingly employed to analyze test data and predict failure modes, enabling manufacturers to optimize materials and structures for maximum longevity.Expand Specific Solutions

Key Manufacturers and Industry Leaders in Display Technology

The WOLED vs Quantum Dot display technology competition is currently in a mature growth phase, with the global display market valued at approximately $150 billion and expected to expand further. In terms of technical maturity, WOLED technology, championed by BOE Technology Group and TCL China Star Optoelectronics, offers proven reliability but faces challenges in production costs. Meanwhile, Quantum Dot technology, advanced by Nanoco Technologies, Najing Technology, and Nanjing Lumicore Technology, demonstrates superior color performance and potentially longer lifespans due to inorganic materials' inherent stability. Research collaborations between companies and academic institutions like Zhejiang University and HKUST are accelerating innovations in both technologies, with particular focus on improving blue OLED emitter longevity and quantum dot stability.

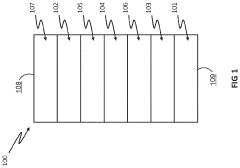

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced WOLED (White Organic Light Emitting Diode) technology that utilizes a multi-layer structure with blue, green, and red emitting materials combined with color filters to produce white light. Their WOLED panels feature a tandem structure with multiple emission units stacked vertically, which significantly extends operational lifespan by distributing current load across multiple layers. BOE's latest WOLED displays incorporate advanced encapsulation technology using thin-film encapsulation (TFE) with alternating inorganic and organic layers that effectively prevent moisture and oxygen penetration, addressing one of the primary degradation mechanisms. Their internal testing shows WOLED panels maintaining over 95% brightness after 30,000 hours of operation at standard brightness levels, with projected lifespans exceeding 100,000 hours for normal usage scenarios.

Strengths: Superior color accuracy and viewing angles compared to Quantum Dot displays. Better power efficiency for predominantly dark content. Weaknesses: Still susceptible to differential aging of organic materials, particularly blue emitters which typically degrade faster than red and green, potentially leading to color shift over extended use.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has pioneered Quantum Dot display technology with their proprietary "Q-Light" solution that utilizes cadmium-free quantum dots encapsulated in a protective barrier film. Their approach incorporates quantum dots into a film layer placed above the LED backlight in LCD displays, rather than directly embedding quantum dots as emissive materials. This implementation significantly extends lifespan compared to earlier quantum dot technologies by protecting the nanocrystals from environmental degradation factors. TCL's quantum dot enhancement film (QDEF) technology maintains color performance for approximately 30,000-50,000 hours before noticeable degradation occurs. The company has also developed advanced thermal management systems specifically designed to prevent quantum dot degradation at higher temperatures, which has been a historical limitation of the technology.

Strengths: Exceptional color volume and brightness capabilities that remain stable over time. Significantly better resistance to image retention/burn-in compared to WOLED. Weaknesses: Requires LED backlight which impacts potential for true blacks and contrast ratios. Higher power consumption for bright content compared to WOLED solutions.

Critical Patents and Research on Display Longevity

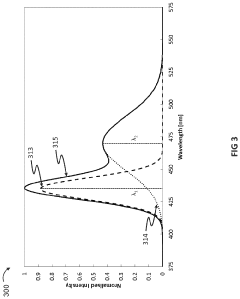

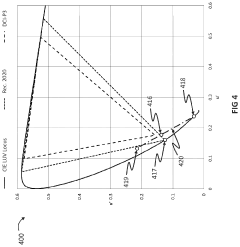

Cadmium-free quantum dot LED with improved emission color

PatentActiveUS20200411786A1

Innovation

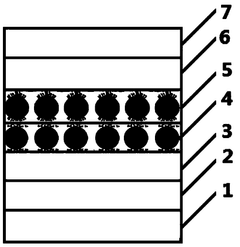

- A QD-LED structure incorporating a first emissive layer with electrically excited quantum dots and a second photoluminescent quantum dot layer that optically converts blue light to a more favorable spectrum, achieving a color coordinate closer to Rec. 2020 specifications without external color filters and toxic materials.

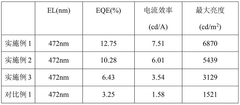

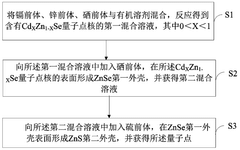

Quantum dot, preparation method thereof and quantum dot light-emitting diode

PatentWO2021136002A1

Innovation

- Using CdXZn1-XSe quantum dot core, by forming two shells of ZnSe and ZnS on its surface, it forms an alloy structure with gradient changes in composition, improving charge transport and composite luminescence performance, and combining short-chain and long-chain organic ligands for surface modification and optimization Structure and ligand exchange of quantum dots to improve device performance.

Material Science Advancements in Display Technology

Material science has been the cornerstone of display technology evolution, with significant advancements enabling both WOLED (White Organic Light-Emitting Diode) and Quantum Dot technologies to achieve remarkable performance characteristics. These innovations have fundamentally transformed the lifespan potential of modern displays through molecular-level engineering.

WOLED technology has benefited from progressive improvements in organic compound stability. Early generations suffered from rapid degradation, particularly in blue emitters, but recent developments in phosphorescent materials and thermally activated delayed fluorescence (TADF) compounds have substantially extended operational lifespans. The introduction of multi-layer structures with specialized transport layers has further enhanced electron-hole recombination efficiency while reducing degradation pathways.

Quantum Dot displays have leveraged inorganic semiconductor nanocrystals, primarily composed of cadmium selenide or indium phosphide cores with protective shells. These materials demonstrate inherently superior stability against oxidation and photo-degradation compared to organic compounds. Recent breakthroughs in core-shell architecture have addressed quantum yield degradation issues, with gradient alloy interfaces reducing lattice strain and surface defects that previously limited longevity.

Encapsulation technologies represent another critical advancement affecting display lifespan. Thin-film encapsulation using alternating organic and inorganic layers has dramatically improved moisture and oxygen barrier properties for WOLED panels. Similarly, quantum dot materials have benefited from silica encapsulation techniques that shield nanocrystals from environmental factors while maintaining their exceptional quantum efficiency.

Heat management materials have evolved to address thermal degradation, a primary factor in display aging. Graphene-based heat spreaders and novel thermal interface materials with directional heat transfer properties have been integrated into both technologies, though quantum dots generally demonstrate superior thermal stability at molecular levels.

Manufacturing processes have also advanced significantly, with atomic layer deposition enabling precise control over material interfaces and reducing defect-induced degradation pathways. Solution-processing techniques for quantum dots have improved uniformity while reducing manufacturing stresses that previously compromised long-term stability.

The most recent frontier in material science for these display technologies involves self-healing polymers and dynamic molecular structures that can reconfigure under electrical stress, potentially extending operational lifespans by orders of magnitude. While still emerging, these approaches show particular promise for quantum dot implementations due to their compatibility with inorganic-organic hybrid structures.

WOLED technology has benefited from progressive improvements in organic compound stability. Early generations suffered from rapid degradation, particularly in blue emitters, but recent developments in phosphorescent materials and thermally activated delayed fluorescence (TADF) compounds have substantially extended operational lifespans. The introduction of multi-layer structures with specialized transport layers has further enhanced electron-hole recombination efficiency while reducing degradation pathways.

Quantum Dot displays have leveraged inorganic semiconductor nanocrystals, primarily composed of cadmium selenide or indium phosphide cores with protective shells. These materials demonstrate inherently superior stability against oxidation and photo-degradation compared to organic compounds. Recent breakthroughs in core-shell architecture have addressed quantum yield degradation issues, with gradient alloy interfaces reducing lattice strain and surface defects that previously limited longevity.

Encapsulation technologies represent another critical advancement affecting display lifespan. Thin-film encapsulation using alternating organic and inorganic layers has dramatically improved moisture and oxygen barrier properties for WOLED panels. Similarly, quantum dot materials have benefited from silica encapsulation techniques that shield nanocrystals from environmental factors while maintaining their exceptional quantum efficiency.

Heat management materials have evolved to address thermal degradation, a primary factor in display aging. Graphene-based heat spreaders and novel thermal interface materials with directional heat transfer properties have been integrated into both technologies, though quantum dots generally demonstrate superior thermal stability at molecular levels.

Manufacturing processes have also advanced significantly, with atomic layer deposition enabling precise control over material interfaces and reducing defect-induced degradation pathways. Solution-processing techniques for quantum dots have improved uniformity while reducing manufacturing stresses that previously compromised long-term stability.

The most recent frontier in material science for these display technologies involves self-healing polymers and dynamic molecular structures that can reconfigure under electrical stress, potentially extending operational lifespans by orders of magnitude. While still emerging, these approaches show particular promise for quantum dot implementations due to their compatibility with inorganic-organic hybrid structures.

Environmental Impact and Sustainability Considerations

The environmental impact of display technologies has become increasingly important as sustainability considerations gain prominence in consumer and industrial decision-making processes. When comparing WOLED (White Organic Light-Emitting Diode) and Quantum Dot technologies from an environmental perspective, several key factors must be examined throughout their lifecycle.

Manufacturing processes for both technologies present distinct environmental challenges. WOLED production typically involves organic materials that require fewer toxic heavy metals compared to some competing technologies. However, the manufacturing process still utilizes various solvents and chemicals that require careful handling and disposal. The production facilities also consume significant energy, contributing to their carbon footprint.

Quantum Dot technology, while offering exceptional color performance, traditionally relied on cadmium-based materials, raising serious environmental and health concerns. Recent innovations have introduced cadmium-free quantum dots, significantly reducing toxicity issues. Nevertheless, the production of quantum dots still involves complex chemical processes and potentially hazardous materials that require stringent environmental controls.

Energy efficiency during operation represents a critical sustainability factor. WOLED displays generally demonstrate excellent energy efficiency, particularly when displaying darker content, as individual pixels can be turned off completely. This characteristic contributes to lower electricity consumption over the product's lifetime, reducing associated carbon emissions.

Quantum Dot displays, particularly those using LCD backlighting, typically consume more power than WOLED counterparts. However, newer Quantum Dot technologies are narrowing this efficiency gap, with some recent models achieving comparable energy performance to WOLED displays under certain usage conditions.

End-of-life considerations reveal further environmental distinctions. WOLED panels contain organic materials that may be more biodegradable than inorganic alternatives, though the presence of other components complicates recycling efforts. The thin, lightweight nature of WOLED displays also means less material usage overall and potentially reduced transportation emissions.

Quantum Dot displays present recycling challenges due to their complex material composition. The semiconductor nanocrystals in quantum dots require specialized recycling processes that are not widely available in current waste management systems. This limitation can lead to improper disposal and potential environmental contamination.

Lifespan directly impacts sustainability through replacement frequency. Longer-lasting displays reduce electronic waste and resource consumption associated with manufacturing replacement units. As both technologies continue to evolve, improvements in durability and longevity will significantly influence their comparative environmental footprints over time.

Manufacturing processes for both technologies present distinct environmental challenges. WOLED production typically involves organic materials that require fewer toxic heavy metals compared to some competing technologies. However, the manufacturing process still utilizes various solvents and chemicals that require careful handling and disposal. The production facilities also consume significant energy, contributing to their carbon footprint.

Quantum Dot technology, while offering exceptional color performance, traditionally relied on cadmium-based materials, raising serious environmental and health concerns. Recent innovations have introduced cadmium-free quantum dots, significantly reducing toxicity issues. Nevertheless, the production of quantum dots still involves complex chemical processes and potentially hazardous materials that require stringent environmental controls.

Energy efficiency during operation represents a critical sustainability factor. WOLED displays generally demonstrate excellent energy efficiency, particularly when displaying darker content, as individual pixels can be turned off completely. This characteristic contributes to lower electricity consumption over the product's lifetime, reducing associated carbon emissions.

Quantum Dot displays, particularly those using LCD backlighting, typically consume more power than WOLED counterparts. However, newer Quantum Dot technologies are narrowing this efficiency gap, with some recent models achieving comparable energy performance to WOLED displays under certain usage conditions.

End-of-life considerations reveal further environmental distinctions. WOLED panels contain organic materials that may be more biodegradable than inorganic alternatives, though the presence of other components complicates recycling efforts. The thin, lightweight nature of WOLED displays also means less material usage overall and potentially reduced transportation emissions.

Quantum Dot displays present recycling challenges due to their complex material composition. The semiconductor nanocrystals in quantum dots require specialized recycling processes that are not widely available in current waste management systems. This limitation can lead to improper disposal and potential environmental contamination.

Lifespan directly impacts sustainability through replacement frequency. Longer-lasting displays reduce electronic waste and resource consumption associated with manufacturing replacement units. As both technologies continue to evolve, improvements in durability and longevity will significantly influence their comparative environmental footprints over time.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!