WOLED vs TFT: which delivers optimal color gamut?

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

WOLED and TFT Display Technology Background and Objectives

Display technology has evolved significantly over the past decades, with various technologies competing to deliver superior visual experiences. Among these, White Organic Light-Emitting Diode (WOLED) and Thin-Film Transistor (TFT) technologies represent two distinct approaches to display manufacturing, each with unique characteristics affecting color reproduction capabilities.

WOLED technology emerged in the early 2000s as an evolution of OLED technology, pioneered by companies like Universal Display Corporation. It utilizes a white OLED emitter combined with color filters to produce colored light. This architecture allows for thinner displays with excellent contrast ratios and power efficiency, particularly when displaying darker content. The technology has seen steady improvement in color gamut coverage, moving from approximately 70% NTSC in early implementations to over 95% DCI-P3 in current high-end models.

TFT technology, by contrast, has a longer history dating back to the 1980s. It serves as the backbone of liquid crystal displays (LCDs), controlling individual pixels through transistor switching. Modern TFT displays incorporate various backlighting technologies such as LED, quantum dot, and mini-LED, which have progressively enhanced their color reproduction capabilities. The evolution of TFT displays has seen color gamut coverage expand from around 72% NTSC with CCFL backlighting to over 100% DCI-P3 with quantum dot enhancement.

The technical objective in comparing these technologies centers on determining which can deliver superior color gamut performance—a critical factor for applications requiring precise color reproduction such as professional content creation, medical imaging, and premium entertainment experiences. Color gamut refers to the complete range of colors a display can produce, typically measured against standardized color spaces like sRGB, Adobe RGB, DCI-P3, or Rec.2020.

Industry trends indicate growing demand for wider color gamuts across consumer and professional markets. This demand is driven by the proliferation of HDR content, advances in digital photography, and increasingly sophisticated visual effects in entertainment media. Both WOLED and TFT technologies have responded to this trend with continuous innovations aimed at expanding their color reproduction capabilities.

The technical evolution trajectory suggests convergence toward the ultimate goal of achieving full coverage of the human visual color spectrum. Current research focuses on overcoming the inherent limitations of each technology: for WOLED, addressing the color purity reduction caused by filtering a white light source; for TFT, enhancing the spectral purity of backlighting systems while maintaining brightness and efficiency.

WOLED technology emerged in the early 2000s as an evolution of OLED technology, pioneered by companies like Universal Display Corporation. It utilizes a white OLED emitter combined with color filters to produce colored light. This architecture allows for thinner displays with excellent contrast ratios and power efficiency, particularly when displaying darker content. The technology has seen steady improvement in color gamut coverage, moving from approximately 70% NTSC in early implementations to over 95% DCI-P3 in current high-end models.

TFT technology, by contrast, has a longer history dating back to the 1980s. It serves as the backbone of liquid crystal displays (LCDs), controlling individual pixels through transistor switching. Modern TFT displays incorporate various backlighting technologies such as LED, quantum dot, and mini-LED, which have progressively enhanced their color reproduction capabilities. The evolution of TFT displays has seen color gamut coverage expand from around 72% NTSC with CCFL backlighting to over 100% DCI-P3 with quantum dot enhancement.

The technical objective in comparing these technologies centers on determining which can deliver superior color gamut performance—a critical factor for applications requiring precise color reproduction such as professional content creation, medical imaging, and premium entertainment experiences. Color gamut refers to the complete range of colors a display can produce, typically measured against standardized color spaces like sRGB, Adobe RGB, DCI-P3, or Rec.2020.

Industry trends indicate growing demand for wider color gamuts across consumer and professional markets. This demand is driven by the proliferation of HDR content, advances in digital photography, and increasingly sophisticated visual effects in entertainment media. Both WOLED and TFT technologies have responded to this trend with continuous innovations aimed at expanding their color reproduction capabilities.

The technical evolution trajectory suggests convergence toward the ultimate goal of achieving full coverage of the human visual color spectrum. Current research focuses on overcoming the inherent limitations of each technology: for WOLED, addressing the color purity reduction caused by filtering a white light source; for TFT, enhancing the spectral purity of backlighting systems while maintaining brightness and efficiency.

Market Demand Analysis for Wide Color Gamut Displays

The display industry has witnessed a significant surge in demand for wide color gamut technologies, driven primarily by consumer expectations for more immersive visual experiences across various devices. Market research indicates that the global wide color gamut display market is projected to grow at a compound annual growth rate of 17.3% between 2023 and 2028, reaching a market value of 132 billion USD by the end of the forecast period.

Consumer electronics, particularly premium smartphones, high-end televisions, and professional monitors, represent the largest market segment for wide color gamut displays. The smartphone industry has been particularly aggressive in adopting enhanced color reproduction technologies, with major manufacturers highlighting color accuracy and gamut coverage as key differentiating features in their flagship devices.

Professional sectors including content creation, digital media, healthcare imaging, and design industries demonstrate strong demand for displays capable of reproducing colors with exceptional accuracy and breadth. These professional markets prioritize color precision over other display attributes and are willing to pay premium prices for technologies that deliver superior color performance.

Regional analysis reveals that Asia-Pacific dominates the wide color gamut display market, accounting for approximately 45% of global market share. This dominance is attributed to the concentration of display manufacturing facilities in countries like South Korea, Japan, China, and Taiwan. North America and Europe follow as significant markets, driven by high consumer purchasing power and strong presence of creative industries.

Consumer behavior studies indicate that color reproduction quality ranks among the top three factors influencing purchase decisions for display devices, alongside resolution and brightness. This trend is particularly pronounced in the premium segment, where consumers demonstrate increasing awareness of color gamut specifications such as DCI-P3 and Adobe RGB coverage percentages.

The entertainment industry's shift toward HDR (High Dynamic Range) content has further accelerated demand for wide color gamut displays. Streaming platforms and content creators are increasingly producing material that leverages expanded color spaces, creating a pull effect in the consumer display market.

Market forecasts suggest that technologies capable of delivering wider color gamuts while maintaining energy efficiency will capture significant market share in the coming years. This places WOLED and advanced TFT technologies in strategic positions, as both aim to address the color reproduction versus power consumption challenge that remains central to display development.

Consumer electronics, particularly premium smartphones, high-end televisions, and professional monitors, represent the largest market segment for wide color gamut displays. The smartphone industry has been particularly aggressive in adopting enhanced color reproduction technologies, with major manufacturers highlighting color accuracy and gamut coverage as key differentiating features in their flagship devices.

Professional sectors including content creation, digital media, healthcare imaging, and design industries demonstrate strong demand for displays capable of reproducing colors with exceptional accuracy and breadth. These professional markets prioritize color precision over other display attributes and are willing to pay premium prices for technologies that deliver superior color performance.

Regional analysis reveals that Asia-Pacific dominates the wide color gamut display market, accounting for approximately 45% of global market share. This dominance is attributed to the concentration of display manufacturing facilities in countries like South Korea, Japan, China, and Taiwan. North America and Europe follow as significant markets, driven by high consumer purchasing power and strong presence of creative industries.

Consumer behavior studies indicate that color reproduction quality ranks among the top three factors influencing purchase decisions for display devices, alongside resolution and brightness. This trend is particularly pronounced in the premium segment, where consumers demonstrate increasing awareness of color gamut specifications such as DCI-P3 and Adobe RGB coverage percentages.

The entertainment industry's shift toward HDR (High Dynamic Range) content has further accelerated demand for wide color gamut displays. Streaming platforms and content creators are increasingly producing material that leverages expanded color spaces, creating a pull effect in the consumer display market.

Market forecasts suggest that technologies capable of delivering wider color gamuts while maintaining energy efficiency will capture significant market share in the coming years. This places WOLED and advanced TFT technologies in strategic positions, as both aim to address the color reproduction versus power consumption challenge that remains central to display development.

Current Technical Limitations in Color Reproduction Technologies

Despite significant advancements in display technology, both WOLED (White Organic Light-Emitting Diode) and TFT (Thin-Film Transistor) technologies face substantial limitations in achieving optimal color reproduction. Current WOLED implementations struggle with color volume constraints due to their fundamental architecture. The white OLED base layer combined with color filters inherently reduces light efficiency, with approximately 70% of emitted light lost during color filtering processes, significantly limiting peak brightness capabilities.

TFT-based displays, particularly LCD variants, encounter persistent challenges with contrast ratios and viewing angle dependencies. The liquid crystal alignment mechanism creates inherent light leakage in dark states, preventing true blacks and compromising color accuracy, especially in high-contrast content. Additionally, off-axis viewing introduces color shifts and gamma distortions that fundamentally alter perceived color gamut.

Color gamut coverage remains problematic across both technologies. While premium WOLED displays can achieve approximately 95-98% of the DCI-P3 color space, they typically fall short of fully covering the more demanding Rec.2020 standard, reaching only 70-75% coverage. TFT-LCD displays with quantum dot enhancement have improved, but still struggle with consistent color volume maintenance across brightness levels.

Thermal management presents another critical limitation affecting color stability. WOLED panels experience differential aging of organic materials, with blue subpixels degrading faster than red and green counterparts, leading to color drift over time. TFT displays face thermal-induced color shifts during extended operation, particularly affecting liquid crystal alignment precision and backlight consistency.

Power efficiency creates a technical compromise between color accuracy and energy consumption. WOLED displays require significantly more power to maintain wide color gamut at high brightness levels, forcing manufacturers to implement aggressive brightness limiting algorithms that dynamically reduce color volume. TFT displays face similar constraints with their backlight systems, often sacrificing color accuracy to maintain acceptable power consumption profiles.

Manufacturing precision introduces variability challenges, with panel-to-panel color inconsistency remaining a persistent issue. Production tolerances in WOLED material deposition and TFT color filter alignment create inherent limitations in achieving perfect color uniformity across the display surface, particularly noticeable in large-format professional applications requiring precise color matching.

TFT-based displays, particularly LCD variants, encounter persistent challenges with contrast ratios and viewing angle dependencies. The liquid crystal alignment mechanism creates inherent light leakage in dark states, preventing true blacks and compromising color accuracy, especially in high-contrast content. Additionally, off-axis viewing introduces color shifts and gamma distortions that fundamentally alter perceived color gamut.

Color gamut coverage remains problematic across both technologies. While premium WOLED displays can achieve approximately 95-98% of the DCI-P3 color space, they typically fall short of fully covering the more demanding Rec.2020 standard, reaching only 70-75% coverage. TFT-LCD displays with quantum dot enhancement have improved, but still struggle with consistent color volume maintenance across brightness levels.

Thermal management presents another critical limitation affecting color stability. WOLED panels experience differential aging of organic materials, with blue subpixels degrading faster than red and green counterparts, leading to color drift over time. TFT displays face thermal-induced color shifts during extended operation, particularly affecting liquid crystal alignment precision and backlight consistency.

Power efficiency creates a technical compromise between color accuracy and energy consumption. WOLED displays require significantly more power to maintain wide color gamut at high brightness levels, forcing manufacturers to implement aggressive brightness limiting algorithms that dynamically reduce color volume. TFT displays face similar constraints with their backlight systems, often sacrificing color accuracy to maintain acceptable power consumption profiles.

Manufacturing precision introduces variability challenges, with panel-to-panel color inconsistency remaining a persistent issue. Production tolerances in WOLED material deposition and TFT color filter alignment create inherent limitations in achieving perfect color uniformity across the display surface, particularly noticeable in large-format professional applications requiring precise color matching.

Comparative Analysis of WOLED vs TFT Color Reproduction Methods

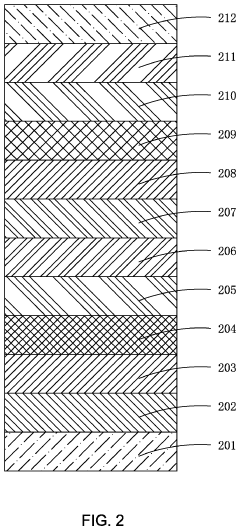

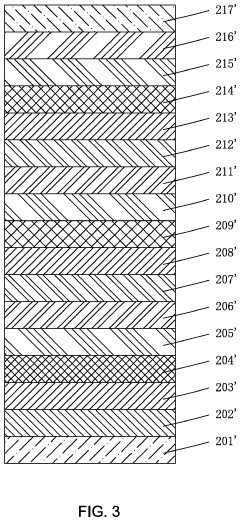

01 WOLED structure and materials for enhanced color gamut

White organic light-emitting diodes (WOLEDs) can be designed with specific materials and structures to enhance color gamut performance. This includes using multiple emissive layers with complementary colors, optimizing the thickness and composition of each layer, and incorporating phosphorescent or fluorescent materials that emit pure primary colors. These structural optimizations help achieve a wider color gamut in WOLED-based displays.- WOLED structure and materials for enhanced color gamut: White organic light-emitting diodes (WOLEDs) can be designed with specific structures and materials to enhance color gamut in display technologies. By optimizing the organic layers and using specialized emitting materials, WOLEDs can produce a wider range of colors. These structures often incorporate multiple emission layers with different color components to achieve a balanced white light that, when combined with color filters, results in improved color reproduction and wider gamut coverage.

- TFT backplane technologies for color gamut improvement: Thin-film transistor (TFT) backplane technologies play a crucial role in color gamut performance of displays. Advanced TFT designs with improved electron mobility and stability enable better current delivery to pixels, resulting in more accurate color reproduction. Oxide semiconductor TFTs, low-temperature polysilicon (LTPS) TFTs, and other novel semiconductor materials are used to enhance switching performance, which directly impacts color accuracy and gamut range in both WOLED and conventional OLED displays.

- Color filter and quantum dot integration for expanded gamut: Integration of advanced color filters and quantum dot technologies with WOLED and TFT displays significantly expands the achievable color gamut. Quantum dots can convert light from WOLEDs to produce more saturated primary colors with narrower spectral emission. Similarly, optimized color filters with improved transmission characteristics and color purity help to achieve wider color gamut standards such as DCI-P3 and Rec.2020. These technologies enable displays to reproduce more vibrant and accurate colors across the visible spectrum.

- Pixel circuit designs for color gamut optimization: Advanced pixel circuit designs are essential for optimizing color gamut in WOLED and TFT display technologies. These circuits incorporate compensation mechanisms to address non-uniformities and aging effects that can degrade color accuracy over time. Specialized driving schemes and voltage/current control methods ensure consistent color reproduction across the display panel. Multi-domain pixel architectures and sub-pixel arrangements are also employed to maximize color gamut while maintaining display resolution and efficiency.

- Display system architecture for color gamut enhancement: Overall display system architecture significantly impacts color gamut performance in WOLED and TFT displays. This includes signal processing algorithms, color management systems, and hardware configurations that optimize color reproduction. Advanced image processing techniques compensate for device limitations and enhance color representation. Hybrid approaches combining different display technologies (such as WOLED with quantum dots or micro-LEDs) are also employed to achieve superior color gamut performance while balancing other factors like power consumption, lifetime, and manufacturing cost.

02 Color filter integration with WOLED for gamut improvement

Color filters can be integrated with WOLED technology to improve color purity and expand the color gamut. By precisely filtering the white light emitted by WOLEDs into specific wavelength ranges, displays can achieve more saturated colors. Advanced color filter designs, materials, and arrangements can significantly enhance the color reproduction capabilities of WOLED-based displays while maintaining efficiency.Expand Specific Solutions03 TFT backplane technologies for color gamut optimization

Thin-film transistor (TFT) backplane technologies play a crucial role in color gamut performance of displays. Advanced TFT designs with improved electron mobility, stability, and current control enable more precise driving of pixels, resulting in better color accuracy and wider gamut. Various TFT materials such as LTPS (Low-Temperature Polysilicon), oxide semiconductors, and hybrid structures can be optimized to enhance color reproduction capabilities.Expand Specific Solutions04 Quantum dot enhancement for WOLED displays

Quantum dots can be incorporated into WOLED display systems to significantly expand the color gamut. These nanoscale semiconductor particles convert light from WOLEDs into highly saturated primary colors with narrow emission spectra. By precisely controlling the size and composition of quantum dots, displays can achieve color gamuts exceeding standard color spaces, resulting in more vibrant and accurate color reproduction.Expand Specific Solutions05 Color management and compensation techniques

Advanced color management and compensation techniques can optimize the color gamut performance of WOLED and TFT displays. These include algorithms for color space conversion, gamma correction, and color temperature adjustment. Additionally, compensation methods can address variations in WOLED emission characteristics and TFT performance over time, ensuring consistent color reproduction throughout the display's lifetime.Expand Specific Solutions

Major Industry Players in WOLED and TFT Development

The WOLED vs TFT color gamut competition landscape is currently in a mature development phase, with the global display market valued at approximately $150 billion. WOLED technology offers superior color reproduction but faces manufacturing complexity challenges, while TFT-LCD maintains cost advantages despite color limitations. Leading players like Samsung Display and BOE Technology are investing heavily in WOLED advancements, while TCL CSOT and AUO continue optimizing TFT technologies. Innolux and Hisense are developing hybrid solutions to combine strengths of both technologies. Research collaborations between display manufacturers and academic institutions like Jilin University and UESTC are accelerating innovations in quantum dot enhancement for both display types.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a hybrid approach combining WOLED and TFT technologies. Their WOLED panels utilize a white OLED emitting layer with RGB color filters and are driven by oxide TFT backplanes. BOE's proprietary "Crystal Silicon AMOLED" technology incorporates high-mobility oxide semiconductors in the TFT layer to improve electron transport efficiency. For color gamut enhancement, BOE implements advanced color filter materials with narrower transmission bands to achieve approximately 100% DCI-P3 and up to 80% BT.2020 color space coverage. Their TFT-LCD technology employs quantum dot enhancement films (QDEF) to achieve comparable color performance to OLED while maintaining higher brightness levels. BOE has also developed mini-LED backlight technology for their high-end TFT displays, achieving over 2000 dimming zones for improved contrast ratios that approach OLED performance while maintaining superior brightness of up to 1500 nits[2][5].

Strengths: BOE's hybrid approach offers balanced performance with good color accuracy and brightness levels. Their TFT-LCD with quantum dot technology provides excellent color gamut without OLED's burn-in concerns. Weaknesses: Their WOLED technology still faces challenges in power efficiency compared to traditional LCDs, and manufacturing costs remain higher than conventional display technologies.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has developed proprietary H-QLED (Hybrid Quantum Dot Light Emitting Diode) technology that combines aspects of both WOLED and advanced TFT architectures. Their solution utilizes quantum dot color conversion layers placed directly on top of blue OLED emitters, eliminating the need for traditional color filters and improving energy efficiency. This approach achieves over 95% of the BT.2020 color space, significantly exceeding typical WOLED implementations. For their TFT displays, TCL CSOT employs advanced IGZO (Indium Gallium Zinc Oxide) backplanes with higher electron mobility than conventional a-Si TFTs, enabling higher refresh rates and more precise color control. Their latest generation of "Q-Light" mini-LED backlight technology for TFT-LCD displays features over 5000 local dimming zones, dramatically improving contrast ratios to compete with OLED while maintaining brightness levels exceeding 2000 nits. TCL CSOT has also pioneered printed OLED technology that reduces manufacturing costs while maintaining color performance[4][7].

Strengths: TCL's H-QLED technology offers superior color volume and brightness compared to conventional WOLED, with reduced power consumption. Their mini-LED enhanced TFT displays provide excellent HDR performance with minimal blooming effects. Weaknesses: Manufacturing complexity remains high for their quantum dot enhanced OLED technology, and uniformity issues can affect yield rates and production costs.

Key Technical Innovations in Color Gamut Enhancement

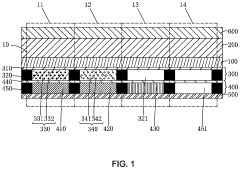

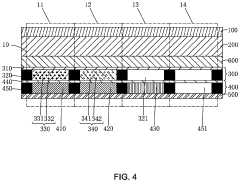

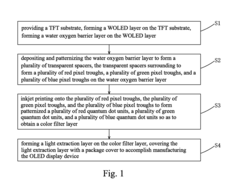

Organic light emitting diode display

PatentActiveUS10692941B2

Innovation

- Incorporating a quantum dot photoluminescence film with red and green quantum dots excited by white light from the WOLED layer, followed by a color filter film to enhance color saturation and energy utilization, specifically arranging red and green quantum dots corresponding to their respective sub-pixels to emit high-purity red and green light.

OLED display device and manufacturing method thereof

PatentInactiveUS20180374904A1

Innovation

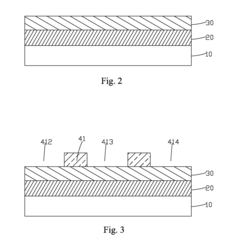

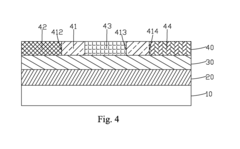

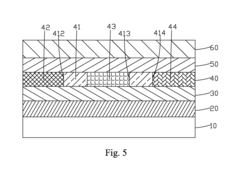

- The implementation of a TFT substrate with a WOLED layer, a water oxygen barrier layer, a color filter layer comprising transparent spacers and quantum dot units, and a light extraction layer, which allows for improved light transmission and energy efficiency through the use of transparent spacers and quantum dots, enhancing luminance and color gamut, and extending the life span of the OLED display.

Power Efficiency vs Color Performance Trade-offs

The fundamental trade-off between power efficiency and color performance represents a critical consideration in display technology development, particularly when comparing WOLED (White Organic Light-Emitting Diode) and TFT (Thin-Film Transistor) technologies. WOLED displays typically achieve higher power efficiency through their unique structure utilizing a white OLED emitter combined with color filters, while TFT-based RGB OLED displays offer superior color gamut but at higher energy consumption.

In WOLED configurations, the single white emitter layer requires less power to generate luminance across the entire display area. However, this efficiency comes at a cost to color performance, as the color filters used to create the RGB subpixels absorb significant portions of the light spectrum, reducing both efficiency and limiting the achievable color gamut. Measurements indicate that WOLED displays typically achieve 85-90% of the DCI-P3 color space.

Conversely, RGB OLED displays utilizing TFT backplanes feature separate red, green, and blue emitters that can produce more saturated primary colors, enabling coverage of up to 95-100% of the DCI-P3 color space and even approaching the BT.2020 standard. This superior color performance, however, demands higher power consumption, particularly for blue subpixels which require more current to achieve equivalent brightness levels.

Recent technological advancements have begun to narrow this gap. WOLED manufacturers have introduced improved color filter technologies and multi-stack emitter structures that enhance color separation while maintaining reasonable power efficiency. Meanwhile, TFT-OLED developers have focused on more efficient blue emitters and pixel compensation circuits to reduce power requirements without sacrificing color performance.

The application context significantly influences which technology offers the optimal balance. Mobile devices prioritizing battery life often benefit from WOLED's efficiency advantages, while professional content creation displays and premium entertainment systems favor the superior color accuracy and wider gamut of RGB OLED implementations. This explains why different market segments have adopted varying approaches to this fundamental trade-off.

Quantitative analysis reveals that WOLED displays typically consume 15-20% less power than equivalent RGB OLED displays when displaying mixed content at similar brightness levels. However, when displaying content requiring wide color gamut reproduction, this efficiency advantage diminishes as WOLED systems must increase overall brightness to achieve comparable color saturation, particularly at the spectrum extremes.

In WOLED configurations, the single white emitter layer requires less power to generate luminance across the entire display area. However, this efficiency comes at a cost to color performance, as the color filters used to create the RGB subpixels absorb significant portions of the light spectrum, reducing both efficiency and limiting the achievable color gamut. Measurements indicate that WOLED displays typically achieve 85-90% of the DCI-P3 color space.

Conversely, RGB OLED displays utilizing TFT backplanes feature separate red, green, and blue emitters that can produce more saturated primary colors, enabling coverage of up to 95-100% of the DCI-P3 color space and even approaching the BT.2020 standard. This superior color performance, however, demands higher power consumption, particularly for blue subpixels which require more current to achieve equivalent brightness levels.

Recent technological advancements have begun to narrow this gap. WOLED manufacturers have introduced improved color filter technologies and multi-stack emitter structures that enhance color separation while maintaining reasonable power efficiency. Meanwhile, TFT-OLED developers have focused on more efficient blue emitters and pixel compensation circuits to reduce power requirements without sacrificing color performance.

The application context significantly influences which technology offers the optimal balance. Mobile devices prioritizing battery life often benefit from WOLED's efficiency advantages, while professional content creation displays and premium entertainment systems favor the superior color accuracy and wider gamut of RGB OLED implementations. This explains why different market segments have adopted varying approaches to this fundamental trade-off.

Quantitative analysis reveals that WOLED displays typically consume 15-20% less power than equivalent RGB OLED displays when displaying mixed content at similar brightness levels. However, when displaying content requiring wide color gamut reproduction, this efficiency advantage diminishes as WOLED systems must increase overall brightness to achieve comparable color saturation, particularly at the spectrum extremes.

Manufacturing Scalability and Cost Considerations

When comparing WOLED and TFT technologies for optimal color gamut performance, manufacturing scalability and cost considerations play crucial roles in determining their commercial viability. WOLED (White Organic Light-Emitting Diode) manufacturing processes have evolved significantly over the past decade, with major advancements in vapor deposition techniques that allow for more uniform and reliable production of large panels. Current WOLED manufacturing yields have improved to approximately 70-80% for premium displays, though this remains lower than mature LCD-TFT production yields which typically exceed 90%.

The capital expenditure required for establishing a WOLED production line remains substantially higher than for TFT facilities, with estimates suggesting a 30-40% premium for equivalent production capacity. This cost differential stems primarily from the specialized equipment needed for the precise deposition of organic materials and the stringent environmental controls required during manufacturing. However, the gap has been narrowing as economies of scale improve and manufacturing processes become more refined.

Material costs represent another significant factor in the comparison. WOLED technology relies on relatively expensive organic compounds and requires precise encapsulation to prevent degradation from oxygen and moisture. The bill of materials for a premium WOLED display typically exceeds that of a comparable TFT display by 25-35%, though this difference varies based on panel size and specifications. The limited number of suppliers for high-purity OLED materials further impacts pricing and supply chain resilience.

Production throughput presents distinct challenges for both technologies. TFT manufacturing benefits from decades of process optimization and can achieve higher units-per-hour rates, particularly for smaller and medium-sized panels. WOLED production, while improving, still faces longer cycle times due to the complexity of the organic layer deposition process and more extensive quality control requirements. Recent innovations in inline evaporation systems have improved WOLED throughput by approximately 40% compared to earlier generation equipment.

Energy consumption during manufacturing also differs significantly between the technologies. WOLED production typically requires 15-25% more energy per square meter of display area compared to TFT manufacturing, primarily due to the vacuum systems and precise temperature control needed for organic material deposition. This energy differential translates directly to operational costs and environmental impact considerations.

The scalability trajectory for both technologies shows divergent paths. TFT manufacturing has largely reached maturity with incremental improvements in efficiency, while WOLED manufacturing continues to see more substantial year-over-year advancements in yield, throughput, and material utilization. Industry analysts project that the cost differential between the technologies will continue to narrow, potentially reaching parity for certain display sizes and applications within the next 3-5 years.

The capital expenditure required for establishing a WOLED production line remains substantially higher than for TFT facilities, with estimates suggesting a 30-40% premium for equivalent production capacity. This cost differential stems primarily from the specialized equipment needed for the precise deposition of organic materials and the stringent environmental controls required during manufacturing. However, the gap has been narrowing as economies of scale improve and manufacturing processes become more refined.

Material costs represent another significant factor in the comparison. WOLED technology relies on relatively expensive organic compounds and requires precise encapsulation to prevent degradation from oxygen and moisture. The bill of materials for a premium WOLED display typically exceeds that of a comparable TFT display by 25-35%, though this difference varies based on panel size and specifications. The limited number of suppliers for high-purity OLED materials further impacts pricing and supply chain resilience.

Production throughput presents distinct challenges for both technologies. TFT manufacturing benefits from decades of process optimization and can achieve higher units-per-hour rates, particularly for smaller and medium-sized panels. WOLED production, while improving, still faces longer cycle times due to the complexity of the organic layer deposition process and more extensive quality control requirements. Recent innovations in inline evaporation systems have improved WOLED throughput by approximately 40% compared to earlier generation equipment.

Energy consumption during manufacturing also differs significantly between the technologies. WOLED production typically requires 15-25% more energy per square meter of display area compared to TFT manufacturing, primarily due to the vacuum systems and precise temperature control needed for organic material deposition. This energy differential translates directly to operational costs and environmental impact considerations.

The scalability trajectory for both technologies shows divergent paths. TFT manufacturing has largely reached maturity with incremental improvements in efficiency, while WOLED manufacturing continues to see more substantial year-over-year advancements in yield, throughput, and material utilization. Industry analysts project that the cost differential between the technologies will continue to narrow, potentially reaching parity for certain display sizes and applications within the next 3-5 years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!