Cooling system for a combustion grate in an incineration plant

A technology for cooling fluid, circulating system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

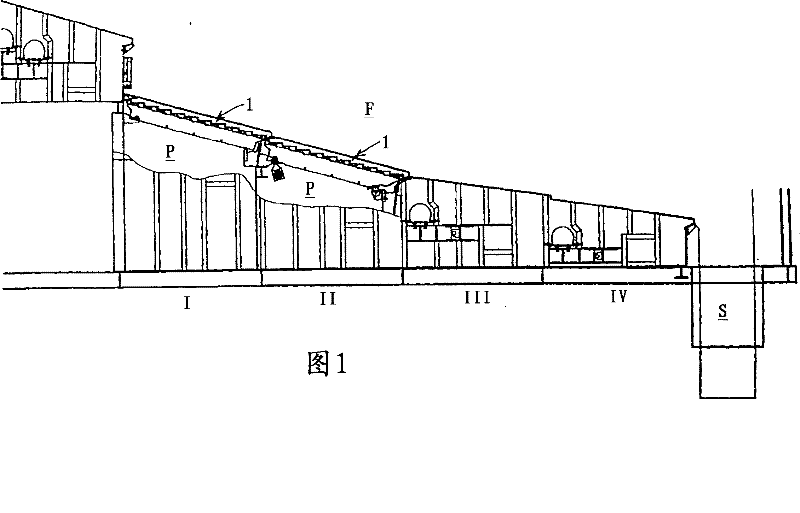

[0010] like figure 1 The waste heat incineration plant shown comprises several grate sections I-IV, each grate section comprising a grate beam 1 stepped downwards and a stationary grate beam in transverse direction, downwards The walking grate beams 1 extend in the direction of movement of the fuel over the top of the grate section and are arranged to move alternately. Thus, each grate section comprises a number of grate beams 1 arranged above the primary air chamber P in order to guide the primary air through the primary air openings in the grate.

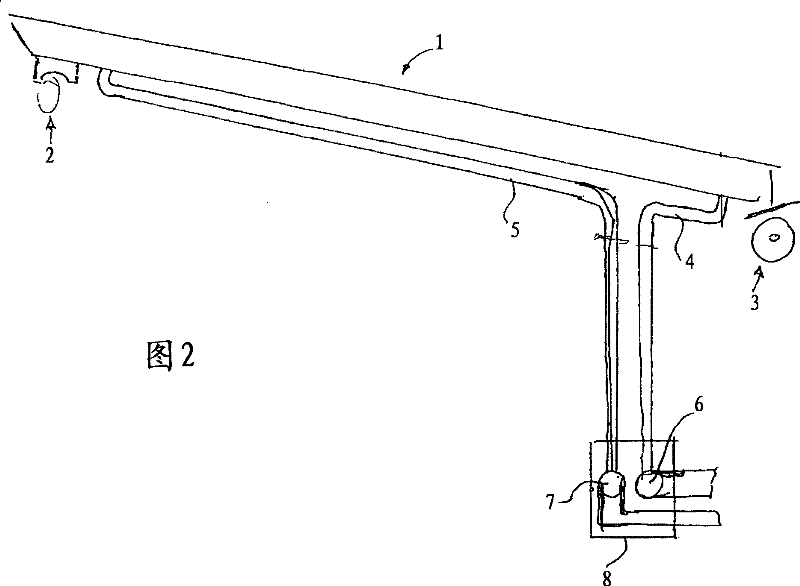

[0011] like figure 2 As shown, the movable grate beam 1 is provided with a moving mechanism 2 at one end and a supporting roller 3 at the opposite end, whereby the movable grate beam 1 can move in the longitudinal direction. The grate beam 1 is provided with cooling fluid channels (not shown in detail) which are supplied with cooling fluid through rigid tubes 4 which leave the grate beam through rigid tubes 5 . The pipelines 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com