Attitude control device for combine harvester and work machine

A combine harvester and machine body technology, applied to the chassis of harvesters, agricultural machinery, agricultural machinery and machinery, etc., can solve problems such as complex structures, and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

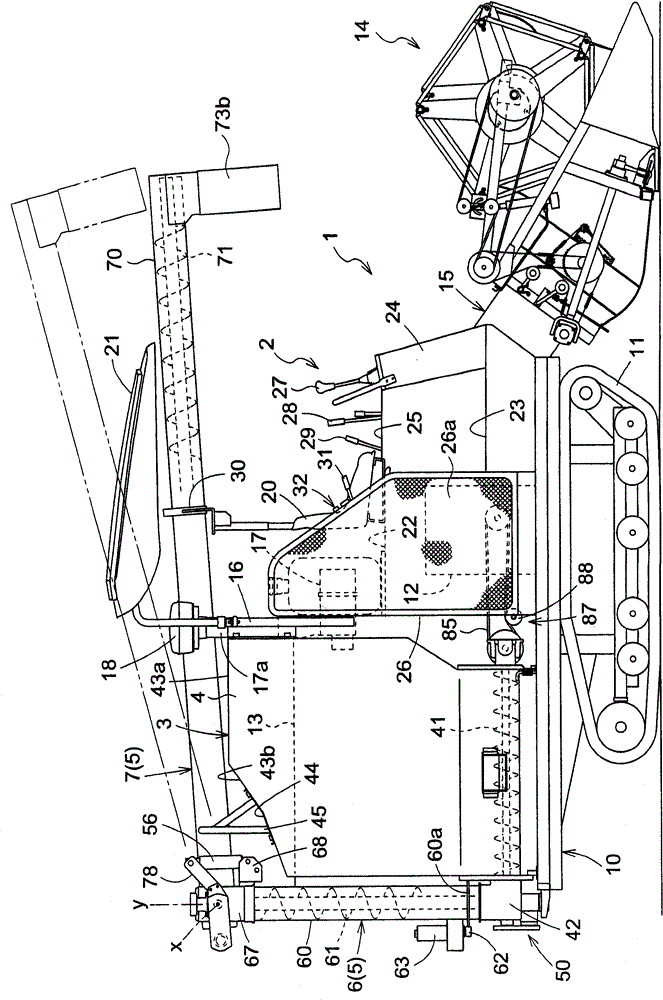

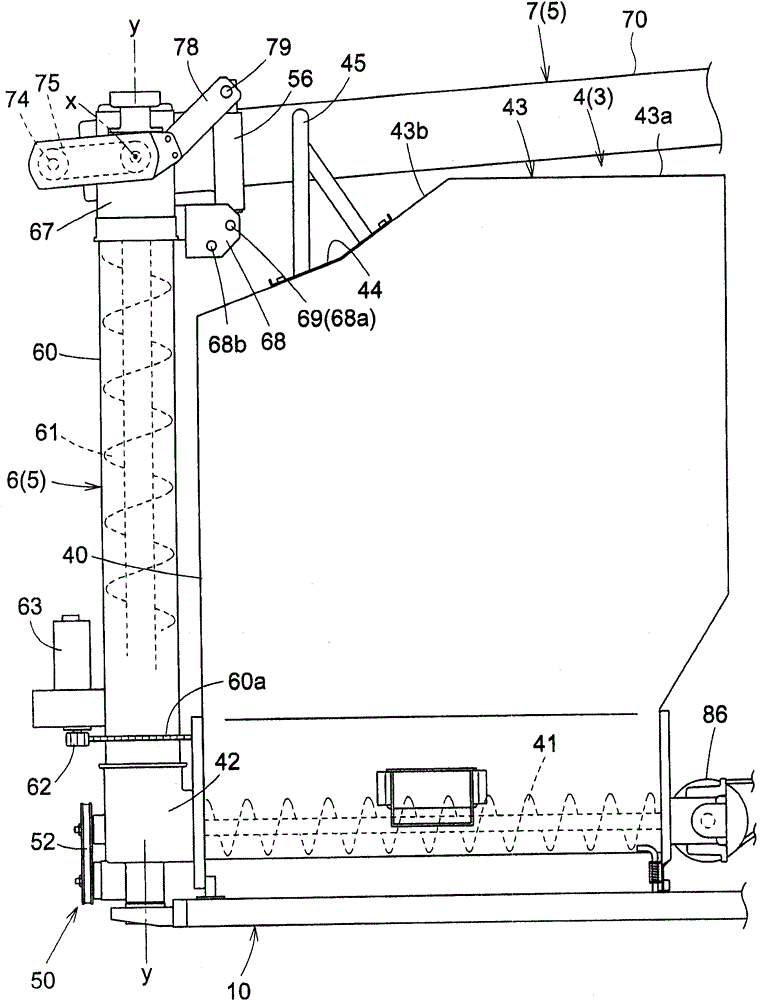

[0067] Hereinafter, embodiments of the present invention will be described based on the description of the drawings.

[0068] [the whole frame]

[0069] exist figure 1 and figure 2 In the figure, the common type combine which is an example of the combine described in this invention is shown.

[0070] In this common type combine harvester, the body frame 10 is mounted on a pair of left and right crawler belt traveling devices 11, 11 to form a self-propelled body 1. On the self-propelled body 1, it is equipped with: a driver's seat 20 and a cover for the driver's seat. The seat 20 above the canopy 21 rides the driver's part 2, the engine 12 located below the above-mentioned driver's seat 20, the threshing device 13 that throws in the processed object of the threshing object and performs threshing and sorting, and a threshing device 13 for Grain recovering device 3 for recovering processed material after threshing.

[0071] And, on the front side of the body of the self-prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com