Bearing ring reject device

A technology for removing devices and bearing rings, applied in the field of device structure, can solve the problems of large area occupied by measuring devices, low utilization rate of resources, and high cost of land for placing equipment, so as to achieve high utilization rate of resources and low cost of land , small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

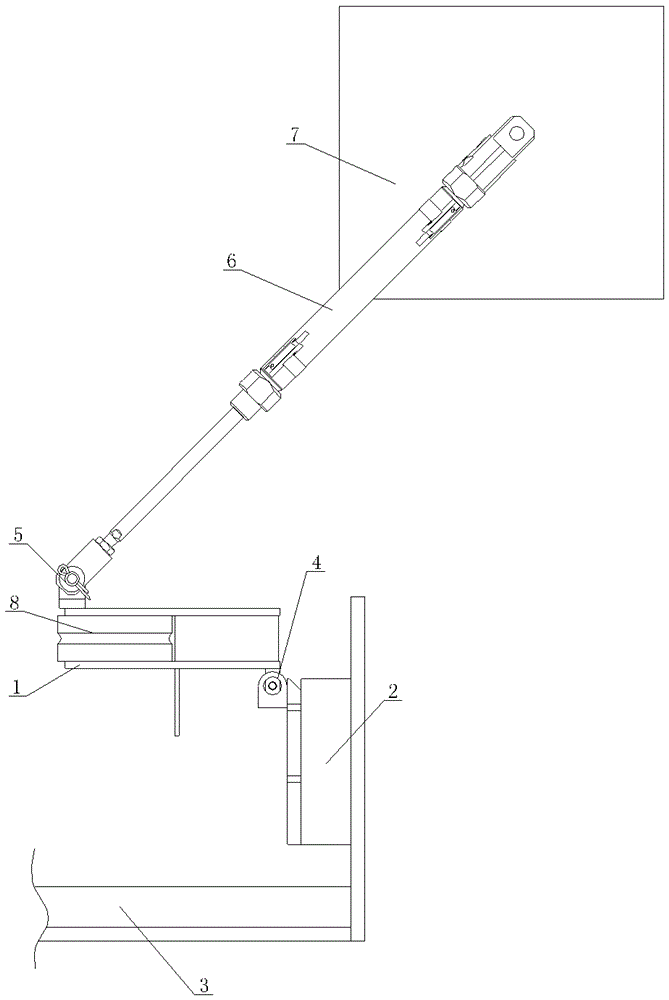

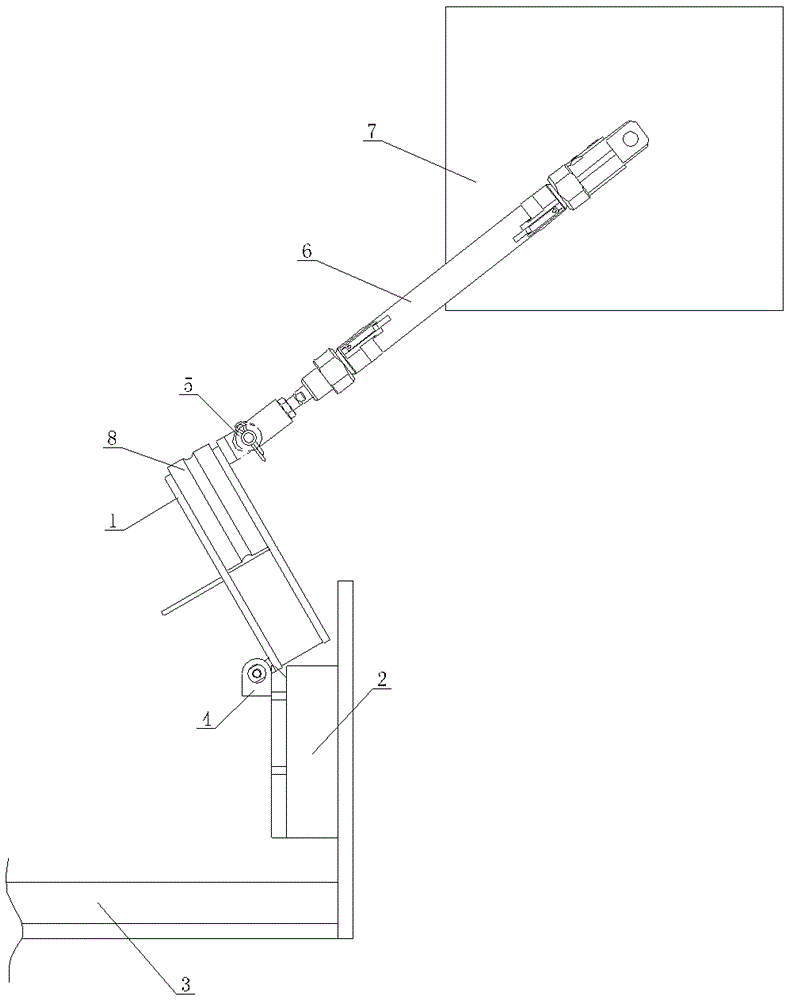

[0008] See figure 1 , figure 2 , which includes a measuring workbench 1 and a feeder, the feeder includes a vertical feeder 2 and a bottom row of feeders 3, the bottom of one end of the measuring workbench 1 is supported on the vertical wall of the vertical feeder 2 through a hinge structure 4, and the measurement The upper part of the other end of the workbench 1 is connected to the movable end of the cylinder 6 through the pin shaft 5, and the cylinder seat of the cylinder 6 is fastened to the frame 7, and the outlet of the vertical material channel 2 is arranged towards the bottom of the material channel 3. The outlet side of the measuring table 1 faces the inlet of the vertical material channel 2 . 8 is the workpiece among the figure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com