Method for preparing non-noble metal molybdenum carbide catalyst by cold plasma

A precious metal molybdenum carbide, cold plasma technology, applied in physical/chemical process catalysts, non-metallic elements, chemical instruments and methods, etc., can solve the problems of agglomeration of molybdenum carbide materials, complex preparation process, difficult to control, etc., to achieve crystal perfection , the operation process is simple, the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 46mg of ammonium molybdate, 0.5g of glucose and 90mg of polystyrene balls in 40mL of deionized water, mix them evenly and fully dissolve, add the obtained clear solution into a 50mL polytetrafluoroethylene reactor, and place the reactor in Hydrothermal reaction in an oven at 180°C for 12 hours, then naturally cooled to room temperature, and the product was centrifuged, washed and dried to obtain the precursor;

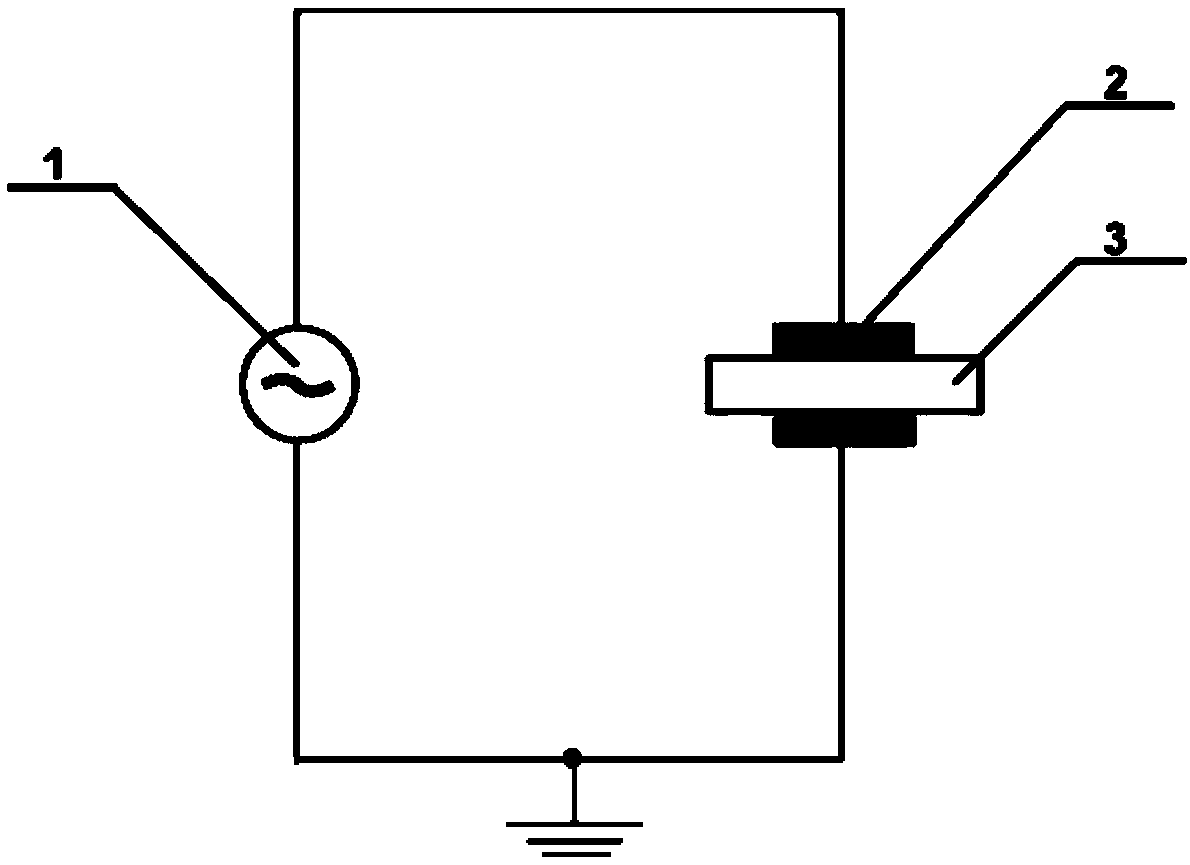

[0027] Put the precursor into an open quartz boat, and place the quartz boat between the two electrodes in the cold plasma processing equipment; fill the cold plasma processing equipment with argon as an initiating gas, and place the A voltage of 500V is applied between them and treated for 10 minutes to obtain a non-noble metal molybdenum carbide catalyst.

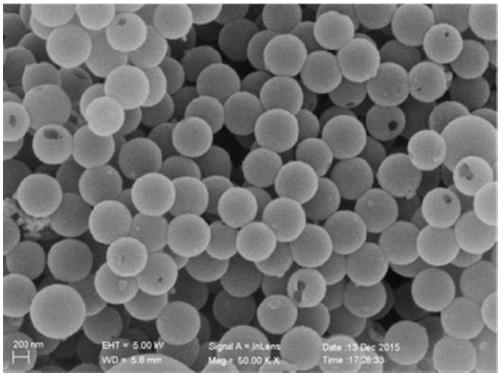

[0028] figure 2 and image 3 They are scanning electron micrographs and X-ray diffraction spectra of the product, respectively. from figure 2 It can be seen that the molybdenum carbide catalyst ...

Embodiment 2

[0031] Weigh 46mg of ammonium molybdate, 0.5g of glucose and 90mg of polystyrene balls in 40mL of deionized water, mix them evenly and fully dissolve, add the obtained clear solution into a 50mL polytetrafluoroethylene reactor, and place the reactor in Hydrothermal reaction was carried out in an oven at 180°C for 12 hours, then naturally cooled to room temperature, and the product was centrifuged, washed and dried to obtain a precursor.

[0032] Put the precursor into an open quartz boat, and place the quartz boat between the two electrodes in the cold plasma processing equipment; fill the cold plasma processing equipment with argon as an initiating gas, and place the A voltage of 1000V was applied between them, and the non-noble metal molybdenum carbide catalyst was prepared after treatment for 20 minutes.

[0033] The morphology of the samples obtained in this example is similar to that of Example 1, with uniform particle size, good dispersion and perfect crystals.

[0034]...

Embodiment 3

[0036] Weigh 46mg of ammonium molybdate, 0.5g of glucose and 90mg of polystyrene balls in 40mL of deionized water, mix them evenly and fully dissolve, add the obtained clear solution into a 50mL polytetrafluoroethylene reactor, and place the reactor in Hydrothermal reaction was carried out in an oven at 180°C for 12 hours, then naturally cooled to room temperature, and the product was centrifuged, washed and dried to obtain a precursor.

[0037] Put the precursor into an open quartz boat, and place the quartz boat between the two electrodes in the cold plasma processing equipment; fill the cold plasma processing equipment with argon as an initiating gas, and place the A voltage of 1000V was applied between them, and the non-noble metal molybdenum carbide catalyst was prepared after treatment for 30 minutes.

[0038] The morphology of the samples obtained in this example is similar to that of Example 1, with uniform particle size, good dispersion and perfect crystals.

[0039]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com