A kind of high comprehensive performance al-zn-mg aluminum alloy material and its preparation method and application

A technology for aluminum alloy materials and raw materials, applied in the field of aluminum alloy material processing, can solve the problems of shortened service life, corrosion of components, endangering traffic safety, etc., and achieves the effects of reducing production costs, good corrosion resistance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

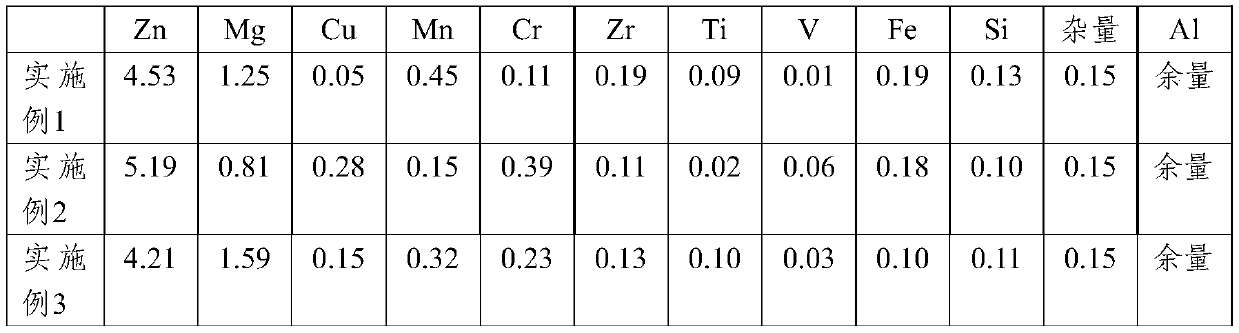

[0036] Examples 1-3 provide an Al-Zn-Mg aluminum alloy material, and the specific composition (weight percentage) is shown in Table 1.

[0037] Table 1

[0038]

[0039] Wherein, impurity represents the total amount of impurity elements (weight percent).

Embodiment 1~3

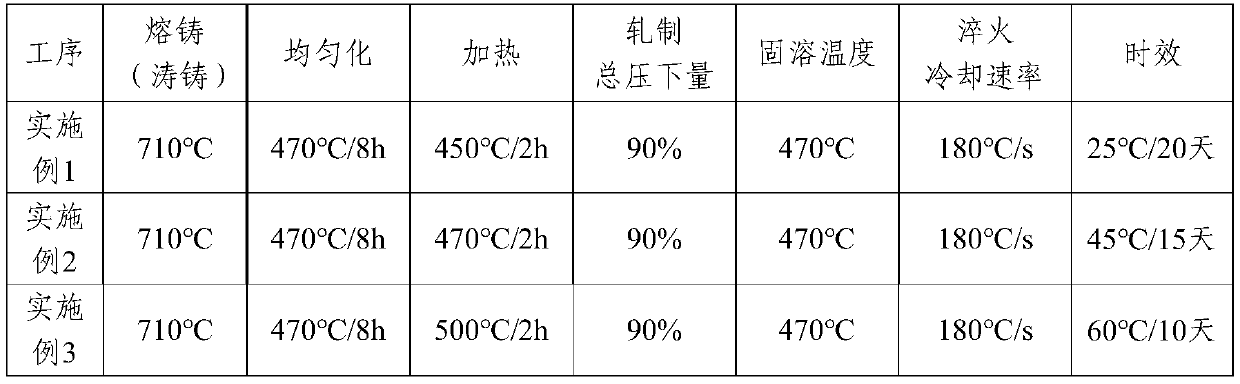

[0040] The preparation process of the Al-Zn-Mg aluminum alloy material obtained in Examples 1-3 is: melting-casting-homogenization-heating-rolling-solution-quenching-aging process; the specific characteristic parameters of each process are shown in Table 2.

[0041] Table 2

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com