A transformer moisture absorber transfer valve

A technology of moisture absorber and transfer valve, applied in the field of transformers, can solve the problems of few spare parts, mismatched installation size, low quality of elimination, etc., and achieve the effect of improving service life, good sealing performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

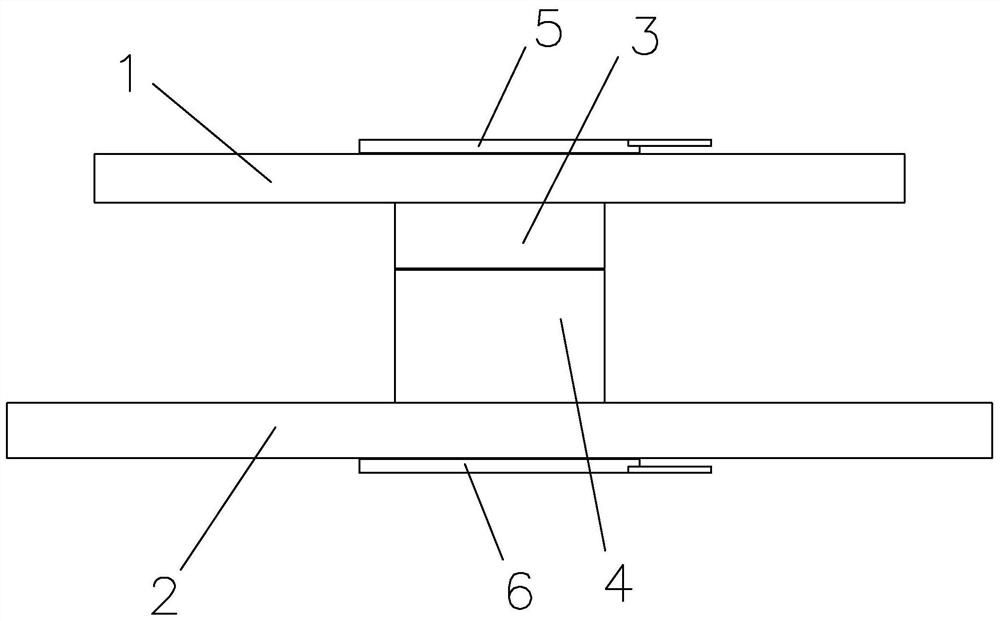

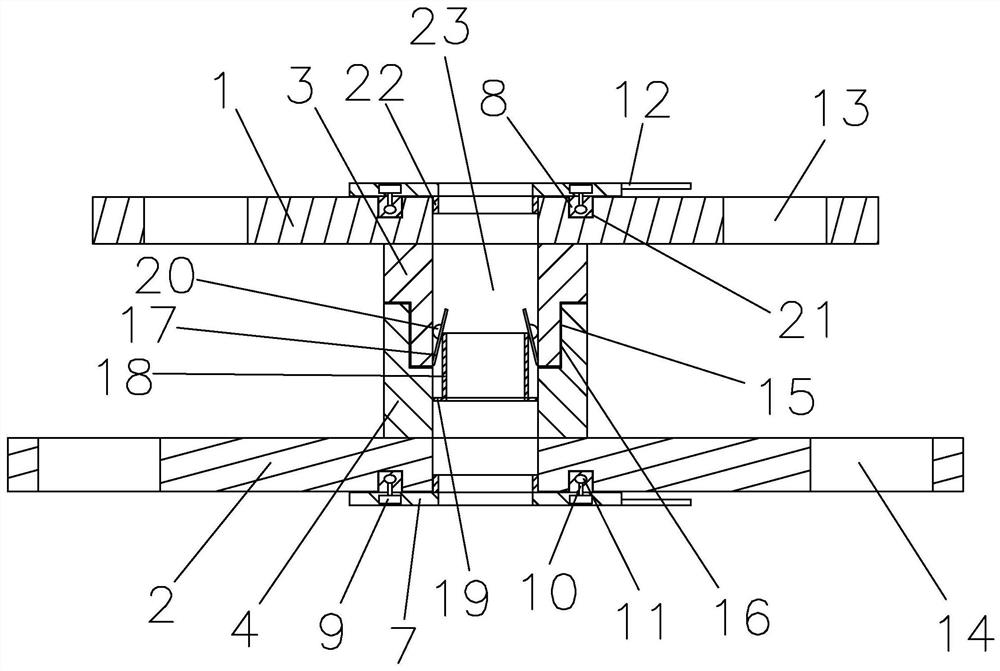

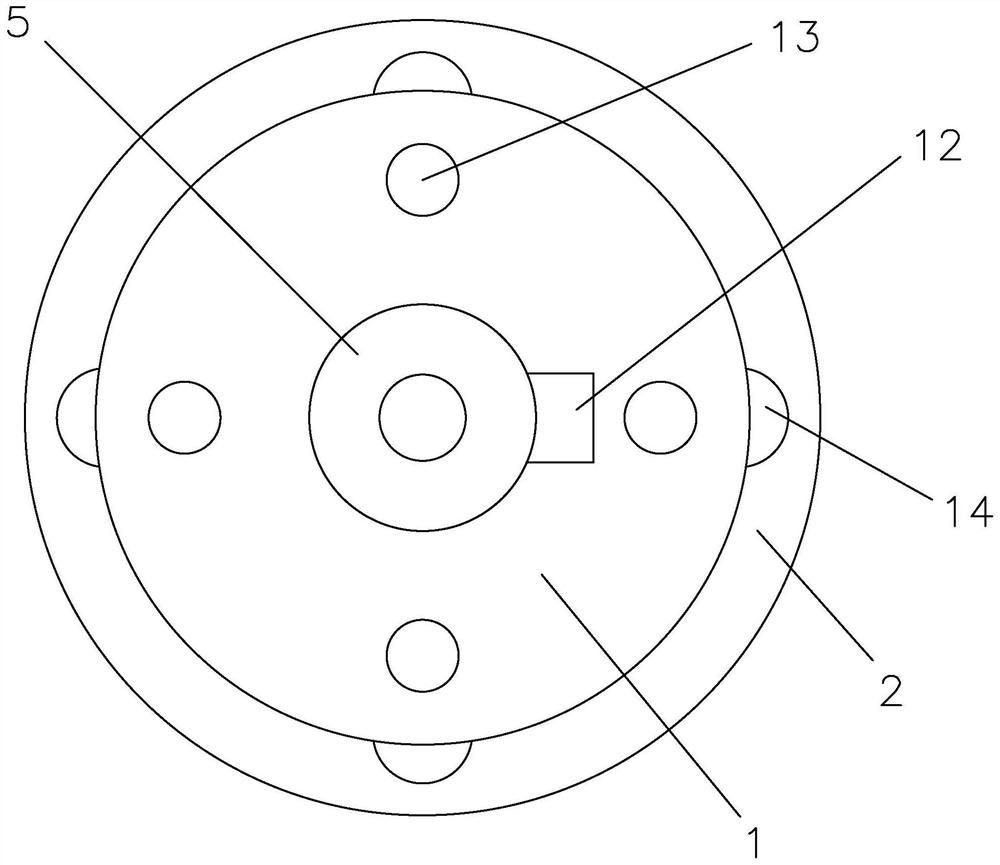

[0023] Such as figure 1 , 2 , 3, a transformer moisture absorber transfer valve, including the first connection plate 1 for connecting with the flange on the moisture absorber and the second connection plate 2 for connecting with the flange on the connecting pipe, the first A connecting plate 1 is provided with a first connecting hole 13 matching with the flange hole on the dehumidifier, and a second connecting plate 2 is provided with a second connecting hole 14 matching with the flange hole on the connecting pipe. The first connecting plate 1 is consistent with the design standard of the flange of the dehumidifier, and the second connecting plate 2 is consistent with the design standard of the connecting pipe flange, so that after two-two connection, the installation of the new dehumidifier is realized. The first connecting plate 1 and the second connecting plate The two connection plates 2 are connected through the main connection cylinder, and the main connection cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com