Analysis of Coating Durability on Quantum Dot Stability

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Coating Evolution and Objectives

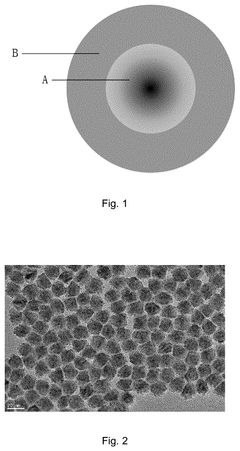

Quantum dots (QDs) have emerged as revolutionary nanomaterials since their initial discovery in the 1980s. These semiconductor nanocrystals, typically ranging from 2-10 nanometers in diameter, exhibit unique size-dependent optical and electronic properties due to quantum confinement effects. The evolution of quantum dot technology has been significantly influenced by advancements in coating methodologies, which directly impact their stability, functionality, and commercial viability.

Early quantum dot research focused primarily on core structures, with cadmium-based materials (CdSe, CdS, CdTe) dominating the landscape. However, these bare core structures suffered from poor photoluminescence quantum yields, chemical instability, and cytotoxicity concerns. The introduction of core-shell architectures in the 1990s marked a pivotal advancement, with ZnS emerging as a preferred shell material that enhanced quantum yield and reduced environmental sensitivity.

The subsequent development trajectory has been characterized by increasingly sophisticated coating strategies. Single-shell structures evolved into multi-shell configurations, gradient alloy interfaces, and hybrid organic-inorganic coating systems. Each evolutionary step has addressed specific stability challenges, including photo-oxidation, thermal degradation, and chemical leaching that previously limited practical applications.

Current coating technology focuses on achieving multifunctional protection layers that simultaneously enhance photostability, prevent ion leakage, maintain quantum confinement, and enable specific surface functionalization. The transition from purely inorganic passivation layers to hybrid systems incorporating polymers, silica encapsulation, and biomolecules represents a significant paradigm shift in quantum dot engineering.

The primary technical objectives in quantum dot coating development now center on several critical parameters: long-term stability under diverse environmental conditions, retention of high quantum yield, prevention of heavy metal leaching, compatibility with various solvents and matrices, and scalable manufacturing processes. Particular emphasis is placed on developing coatings that maintain quantum dot performance under elevated temperatures (>150°C) and prolonged UV exposure, which are essential requirements for display, lighting, and photovoltaic applications.

Looking forward, the field is moving toward environmentally benign coating materials that eliminate the need for toxic precursors while maintaining or enhancing performance metrics. Additionally, there is growing interest in stimuli-responsive coating systems that can adapt to environmental changes or enable controlled interactions with surrounding materials. The ultimate goal remains the development of universal coating strategies that can be applied across different quantum dot compositions while providing application-specific surface properties without compromising the intrinsic advantages of the quantum dot core.

Early quantum dot research focused primarily on core structures, with cadmium-based materials (CdSe, CdS, CdTe) dominating the landscape. However, these bare core structures suffered from poor photoluminescence quantum yields, chemical instability, and cytotoxicity concerns. The introduction of core-shell architectures in the 1990s marked a pivotal advancement, with ZnS emerging as a preferred shell material that enhanced quantum yield and reduced environmental sensitivity.

The subsequent development trajectory has been characterized by increasingly sophisticated coating strategies. Single-shell structures evolved into multi-shell configurations, gradient alloy interfaces, and hybrid organic-inorganic coating systems. Each evolutionary step has addressed specific stability challenges, including photo-oxidation, thermal degradation, and chemical leaching that previously limited practical applications.

Current coating technology focuses on achieving multifunctional protection layers that simultaneously enhance photostability, prevent ion leakage, maintain quantum confinement, and enable specific surface functionalization. The transition from purely inorganic passivation layers to hybrid systems incorporating polymers, silica encapsulation, and biomolecules represents a significant paradigm shift in quantum dot engineering.

The primary technical objectives in quantum dot coating development now center on several critical parameters: long-term stability under diverse environmental conditions, retention of high quantum yield, prevention of heavy metal leaching, compatibility with various solvents and matrices, and scalable manufacturing processes. Particular emphasis is placed on developing coatings that maintain quantum dot performance under elevated temperatures (>150°C) and prolonged UV exposure, which are essential requirements for display, lighting, and photovoltaic applications.

Looking forward, the field is moving toward environmentally benign coating materials that eliminate the need for toxic precursors while maintaining or enhancing performance metrics. Additionally, there is growing interest in stimuli-responsive coating systems that can adapt to environmental changes or enable controlled interactions with surrounding materials. The ultimate goal remains the development of universal coating strategies that can be applied across different quantum dot compositions while providing application-specific surface properties without compromising the intrinsic advantages of the quantum dot core.

Market Analysis for Durable Quantum Dot Applications

The quantum dot (QD) market has experienced significant growth in recent years, with the global market value reaching $4.6 billion in 2021 and projected to exceed $16 billion by 2028, representing a compound annual growth rate of approximately 19.8%. This robust expansion is primarily driven by increasing adoption in display technologies, where quantum dots offer superior color gamut and energy efficiency compared to traditional display materials.

Consumer electronics represents the largest application segment, accounting for over 60% of the current market share. Major manufacturers like Samsung, LG, and TCL have incorporated quantum dot technology into their premium television lines, marketing them as QLED displays. The enhanced durability of quantum dot coatings directly correlates with consumer satisfaction metrics, as longer-lasting displays command premium pricing and strengthen brand loyalty.

Healthcare applications constitute a rapidly growing segment, particularly in bioimaging and diagnostic tools. The market for QD-based medical imaging devices is expected to grow at 24% annually through 2027, contingent upon improvements in coating stability that prevent leaching of potentially toxic core materials in biological environments. Regulatory approval pathways are becoming increasingly dependent on demonstrated coating durability under physiological conditions.

The automotive sector presents an emerging opportunity, with QD-enhanced displays for dashboards and entertainment systems gaining traction. Industry analysts predict that by 2025, approximately 30% of premium vehicles will incorporate quantum dot display technology, provided that coating durability meets the stringent temperature and vibration requirements of automotive environments.

Lighting applications represent another significant growth vector, with QD-enhanced LED lighting solutions offering tunable color temperatures and improved energy efficiency. The commercial building sector has shown particular interest, with energy savings of 15-20% reported in early implementations. However, widespread adoption hinges on coating stability that can maintain performance over the 50,000+ hour operational lifetimes expected in commercial lighting applications.

Regional analysis indicates North America currently leads in QD technology adoption, followed closely by East Asia. However, the fastest growth is projected in emerging economies, particularly India and Southeast Asian nations, where expanding consumer electronics manufacturing and lower production costs are creating favorable market conditions for quantum dot applications.

The market demonstrates clear price sensitivity to durability metrics, with premium pricing directly correlated to guaranteed operational lifetimes. Market research indicates consumers are willing to pay up to 40% more for display technologies with demonstrated longevity advantages, highlighting the commercial importance of advances in coating stability technology.

Consumer electronics represents the largest application segment, accounting for over 60% of the current market share. Major manufacturers like Samsung, LG, and TCL have incorporated quantum dot technology into their premium television lines, marketing them as QLED displays. The enhanced durability of quantum dot coatings directly correlates with consumer satisfaction metrics, as longer-lasting displays command premium pricing and strengthen brand loyalty.

Healthcare applications constitute a rapidly growing segment, particularly in bioimaging and diagnostic tools. The market for QD-based medical imaging devices is expected to grow at 24% annually through 2027, contingent upon improvements in coating stability that prevent leaching of potentially toxic core materials in biological environments. Regulatory approval pathways are becoming increasingly dependent on demonstrated coating durability under physiological conditions.

The automotive sector presents an emerging opportunity, with QD-enhanced displays for dashboards and entertainment systems gaining traction. Industry analysts predict that by 2025, approximately 30% of premium vehicles will incorporate quantum dot display technology, provided that coating durability meets the stringent temperature and vibration requirements of automotive environments.

Lighting applications represent another significant growth vector, with QD-enhanced LED lighting solutions offering tunable color temperatures and improved energy efficiency. The commercial building sector has shown particular interest, with energy savings of 15-20% reported in early implementations. However, widespread adoption hinges on coating stability that can maintain performance over the 50,000+ hour operational lifetimes expected in commercial lighting applications.

Regional analysis indicates North America currently leads in QD technology adoption, followed closely by East Asia. However, the fastest growth is projected in emerging economies, particularly India and Southeast Asian nations, where expanding consumer electronics manufacturing and lower production costs are creating favorable market conditions for quantum dot applications.

The market demonstrates clear price sensitivity to durability metrics, with premium pricing directly correlated to guaranteed operational lifetimes. Market research indicates consumers are willing to pay up to 40% more for display technologies with demonstrated longevity advantages, highlighting the commercial importance of advances in coating stability technology.

Current Challenges in Quantum Dot Coating Technology

Despite significant advancements in quantum dot (QD) technology, coating durability remains a critical challenge that impedes widespread commercial adoption. Current QD coating technologies face several persistent issues that directly impact quantum dot stability and performance longevity. The primary challenge lies in the susceptibility of quantum dots to environmental degradation factors, including oxygen, moisture, heat, and UV radiation, which can rapidly compromise their optoelectronic properties.

Surface oxidation represents one of the most significant challenges, as exposure to atmospheric oxygen leads to the formation of surface trap states that quench photoluminescence and reduce quantum yield. Conventional coating materials often provide insufficient oxygen barrier properties, particularly over extended periods or under harsh operating conditions. This limitation is especially problematic for applications requiring long-term stability, such as displays and lighting solutions.

Moisture penetration through coating layers presents another major hurdle. Water molecules can interact with the QD surface, causing ligand displacement and subsequent aggregation of quantum dots. Current hydrophobic coating technologies demonstrate limited effectiveness in high-humidity environments or during temperature cycling, where coating integrity may be compromised through microscopic crack formation.

Thermal stability of coatings represents a significant technical barrier, as many applications subject QDs to elevated temperatures during both manufacturing and operation. Existing coating materials often exhibit thermal expansion coefficient mismatches with the QD core materials, leading to coating delamination or cracking during thermal cycling. Additionally, high-temperature processing required for device integration can degrade coating integrity before the product even reaches end-users.

Photostability under continuous illumination remains problematic, as UV exposure can degrade both the coating materials and the QD-ligand interface. This photo-oxidation process accelerates performance degradation, particularly in display and lighting applications where QDs are continuously exposed to high-energy photons.

Scalable manufacturing of uniform, defect-free coatings presents significant engineering challenges. Current industrial coating processes often result in batch-to-batch variations and coating thickness inconsistencies that affect quantum yield and emission wavelength uniformity. The trade-off between coating thickness (for better protection) and charge transport efficiency (for device performance) remains difficult to optimize.

Biocompatibility of coatings is another emerging challenge, particularly for biomedical applications. Many effective coating materials that provide excellent environmental protection contain toxic elements or demonstrate poor compatibility with biological systems, limiting their utility in medical imaging or therapeutic applications.

Surface oxidation represents one of the most significant challenges, as exposure to atmospheric oxygen leads to the formation of surface trap states that quench photoluminescence and reduce quantum yield. Conventional coating materials often provide insufficient oxygen barrier properties, particularly over extended periods or under harsh operating conditions. This limitation is especially problematic for applications requiring long-term stability, such as displays and lighting solutions.

Moisture penetration through coating layers presents another major hurdle. Water molecules can interact with the QD surface, causing ligand displacement and subsequent aggregation of quantum dots. Current hydrophobic coating technologies demonstrate limited effectiveness in high-humidity environments or during temperature cycling, where coating integrity may be compromised through microscopic crack formation.

Thermal stability of coatings represents a significant technical barrier, as many applications subject QDs to elevated temperatures during both manufacturing and operation. Existing coating materials often exhibit thermal expansion coefficient mismatches with the QD core materials, leading to coating delamination or cracking during thermal cycling. Additionally, high-temperature processing required for device integration can degrade coating integrity before the product even reaches end-users.

Photostability under continuous illumination remains problematic, as UV exposure can degrade both the coating materials and the QD-ligand interface. This photo-oxidation process accelerates performance degradation, particularly in display and lighting applications where QDs are continuously exposed to high-energy photons.

Scalable manufacturing of uniform, defect-free coatings presents significant engineering challenges. Current industrial coating processes often result in batch-to-batch variations and coating thickness inconsistencies that affect quantum yield and emission wavelength uniformity. The trade-off between coating thickness (for better protection) and charge transport efficiency (for device performance) remains difficult to optimize.

Biocompatibility of coatings is another emerging challenge, particularly for biomedical applications. Many effective coating materials that provide excellent environmental protection contain toxic elements or demonstrate poor compatibility with biological systems, limiting their utility in medical imaging or therapeutic applications.

Existing Coating Solutions for Quantum Dot Stability

01 Encapsulation techniques for quantum dot stability

Various encapsulation methods are used to enhance the durability and stability of quantum dots. These include silica encapsulation, polymer coating, and core-shell structures that protect the quantum dots from environmental factors such as oxygen, moisture, and heat. These protective layers prevent degradation while maintaining the optical properties of the quantum dots, significantly extending their operational lifetime and stability under various conditions.- Encapsulation techniques for quantum dot stability: Various encapsulation methods are employed to enhance quantum dot durability and stability. These include silica encapsulation, polymer coating, and core-shell structures that protect quantum dots from environmental factors such as oxygen, moisture, and heat. These protective layers prevent degradation of optical properties while maintaining quantum yield and extending the operational lifetime of quantum dot-based devices.

- Surface modification for improved durability: Surface modification strategies involve functionalizing quantum dot surfaces with ligands, organic molecules, or inorganic materials to improve stability. These modifications create stronger bonds between quantum dots and surrounding matrices, reduce surface defects, and prevent aggregation. Such treatments enhance resistance to photo-oxidation and thermal degradation while improving compatibility with various host materials.

- Environmental protection coatings: Specialized barrier coatings are developed to shield quantum dots from environmental stressors. These multi-layer protection systems include moisture barriers, oxygen scavengers, and UV-blocking components that work together to prevent degradation. Advanced barrier films with low permeability to oxygen and water vapor significantly extend quantum dot lifetime in various applications including displays, lighting, and photovoltaics.

- Matrix integration for enhanced stability: Quantum dots can be integrated into various matrix materials such as polymers, glasses, or ceramics to improve their stability. These matrices provide physical protection and reduce exposure to degradation factors. The selection of appropriate host materials with compatible chemical properties ensures better dispersion of quantum dots and prevents agglomeration, resulting in more durable quantum dot-based devices with consistent optical performance.

- Thermal and photo-stability enhancement: Specific formulations and additives are developed to enhance quantum dot resistance to thermal and photo-degradation. These include heat-stabilizing compounds, antioxidants, and photo-stabilizers that prevent luminescence quenching under high-temperature or high-intensity light conditions. Advanced thermal management strategies and photonic structures help maintain quantum dot performance in demanding operational environments such as high-brightness displays and solar concentrators.

02 Surface modification for improved environmental resistance

Surface modification techniques involve the attachment of functional groups or ligands to quantum dot surfaces to improve their resistance to environmental stressors. These modifications can include ligand exchange processes, surface passivation, and functionalization with specific molecules that enhance stability against oxidation, photo-degradation, and thermal stress. Such treatments significantly improve the durability of quantum dot coatings in various applications while maintaining their optical and electronic properties.Expand Specific Solutions03 Matrix integration for enhanced durability

Incorporating quantum dots into specialized matrices such as polymers, glasses, or ceramic materials provides physical protection and improves their overall stability. These matrices act as protective environments that shield quantum dots from oxygen, moisture, and mechanical stress. The integration methods include in-situ synthesis, melt processing, and solution blending techniques that result in uniform distribution of quantum dots within the matrix while maintaining their optical properties and extending their usable lifetime.Expand Specific Solutions04 Barrier layer technologies

Multilayer barrier technologies protect quantum dot films from environmental degradation. These systems typically consist of alternating organic and inorganic layers that effectively block moisture and oxygen penetration while remaining optically transparent. Advanced barrier films with low water vapor transmission rates and oxygen transmission rates significantly extend the lifetime of quantum dot coatings in displays, lighting, and photovoltaic applications by preventing degradation mechanisms that lead to luminescence quenching.Expand Specific Solutions05 Thermal and photo-stability enhancement methods

Specialized additives and structural modifications are employed to enhance the thermal and photo-stability of quantum dot coatings. These include the incorporation of antioxidants, UV stabilizers, and radical scavengers that prevent degradation under high-temperature conditions or prolonged light exposure. Additionally, specific synthesis methods that create defect-free quantum dot structures with robust interfaces between core and shell materials significantly improve stability under operational conditions in display, lighting, and solar applications.Expand Specific Solutions

Leading Companies in Quantum Dot Coating Industry

The quantum dot coating durability market is in a growth phase, with increasing demand driven by applications in displays, lighting, and solar cells. The market size is expanding rapidly, projected to reach significant value as quantum dot technology becomes more mainstream. Technologically, the field is advancing from early-stage development toward maturity, with several key players making substantial progress. Companies like Samsung Display, Nanoco Technologies, and BOE Technology lead in commercial applications, while Shin-Etsu Chemical, 3M Innovative Properties, and Applied Materials focus on coating material innovations. Research institutions such as Xiamen University contribute fundamental advancements. The competition centers around developing stable, environmentally friendly quantum dot coatings that maintain optical performance while extending device lifetimes under various environmental conditions.

3M Innovative Properties Co.

Technical Solution: 3M has developed a sophisticated quantum dot coating technology called "Quantum Dot Enhancement Film" (QDEF) that addresses stability challenges through a multi-layered protection approach. Their technology encapsulates quantum dots within a specialized polymer matrix that provides both mechanical protection and barrier properties against environmental degradation factors. The 3M approach utilizes proprietary barrier films with extremely low oxygen and water vapor transmission rates (WVTR < 10^-6 g/m²/day), effectively isolating quantum dots from key degradation triggers. Their coating system incorporates specialized UV absorbers and antioxidants strategically distributed throughout the polymer matrix to neutralize any penetrating oxidative species before they can reach the quantum dots. 3M's research has demonstrated that this comprehensive protection system can maintain quantum dot performance with minimal degradation over extended periods, even under accelerated aging conditions. Additionally, their technology includes thermal stabilization components that prevent quantum dot degradation during high-temperature processing steps in display manufacturing, allowing for integration with existing production lines while maintaining quantum dot integrity.

Strengths: Industry-leading barrier properties against oxygen and moisture with proven performance in commercial display products. The film-based approach allows for easy integration with existing LCD manufacturing infrastructure. Weaknesses: The polymer-based encapsulation may have limitations in extremely high-temperature applications, and the additional film layer in displays may impact overall device thickness compared to direct quantum dot integration approaches.

Nanoco Technologies Ltd.

Technical Solution: Nanoco Technologies has developed proprietary CFQD® (cadmium-free quantum dot) technology with specialized coating methodologies to enhance quantum dot stability. Their approach involves encapsulating quantum dots with multiple shell layers using proprietary ligand chemistry that creates strong covalent bonds between the quantum dot core and the coating materials. This multi-layer coating strategy provides effective protection against oxidation, moisture, and heat degradation. Nanoco's process includes a controlled synthesis environment where inorganic shells are precisely deposited around the quantum dot core, followed by surface functionalization with organic ligands that provide additional stability while maintaining quantum yield. Their patented technology allows for tunable emission wavelengths while maintaining coating integrity under various environmental stressors, significantly extending the operational lifetime of quantum dot displays and lighting applications.

Strengths: Industry-leading cadmium-free formulations provide environmental advantages while maintaining high quantum yields. Their multi-layer coating approach offers superior protection against multiple degradation pathways simultaneously. Weaknesses: The complex multi-layer coating process may increase manufacturing costs and complexity compared to simpler coating technologies, potentially limiting mass production scalability.

Key Innovations in Quantum Dot Protection Mechanisms

Stable INP quantum dots with thick shell coating and method of producing the same

PatentWO2017189666A1

Innovation

- A multi-layered nanostructure with a core and multiple shells, where at least two shells comprise different materials, such as ZnS and ZnSe, with specific thicknesses between 0.7 nm and 3.5 nm, is synthesized using a high-temperature method involving zinc and selenium sources, sulfur sources, and precise control of shell precursors to enhance stability and optical properties.

Quantum Dot Coating Material and Preparation Method Therefor, and Quantum Dot Optical Device

PatentPendingUS20240352308A1

Innovation

- A quantum dot coating material comprising an oil-soluble quantum dot core and an inorganic salt coating agent with specific solubility and thermal decomposition properties, where the mass ratio of the quantum dot to the inorganic salt is optimized to form a dense coating layer, enhancing thermal, light, water, and oxygen resistance.

Environmental Impact of Quantum Dot Materials

The environmental implications of quantum dot materials represent a critical consideration in their development and application. Quantum dots, while offering revolutionary advancements in display technology, lighting, and biomedical applications, pose significant environmental concerns throughout their lifecycle. These nanomaterials typically contain heavy metals such as cadmium, lead, or indium, which are known environmental toxins with potential for bioaccumulation.

When quantum dot coatings degrade, these toxic elements can leach into the environment, contaminating soil and water systems. Research indicates that quantum dots with compromised coating integrity can release heavy metals at rates up to 30% higher than those with stable encapsulation. This degradation process accelerates under environmental stressors such as UV radiation, humidity, and temperature fluctuations, which are precisely the conditions many quantum dot applications encounter during normal use.

Aquatic ecosystems appear particularly vulnerable to quantum dot pollution. Studies demonstrate that certain fish species exposed to degraded quantum dot materials show developmental abnormalities and reduced reproductive capacity at concentrations as low as 5 parts per billion. The small size of quantum dots enables them to penetrate cellular barriers in organisms, potentially disrupting biological processes at the molecular level.

The manufacturing process of quantum dots also presents environmental challenges. Production typically involves energy-intensive processes and hazardous chemicals, including organic solvents that contribute to air pollution and greenhouse gas emissions. Estimates suggest that producing one kilogram of high-quality quantum dots generates approximately 2,000 kilograms of CO2 equivalent emissions, significantly higher than conventional materials used in similar applications.

Recycling quantum dot-containing products presents additional complications. The integration of quantum dots into complex electronic devices makes material separation and recovery difficult, resulting in most quantum dot materials ending up in landfills or incinerators. This disposal pathway further increases the risk of environmental contamination through leaching or atmospheric release.

Recent regulatory frameworks, including the European Union's Restriction of Hazardous Substances (RoHS) directive, have begun addressing these concerns by limiting the use of certain heavy metals in electronic applications. This has accelerated research into "green" quantum dots using less toxic elements such as zinc, copper, or silicon. These alternative materials show promising environmental profiles while maintaining acceptable optical performance, though often with reduced efficiency compared to their heavy metal counterparts.

When quantum dot coatings degrade, these toxic elements can leach into the environment, contaminating soil and water systems. Research indicates that quantum dots with compromised coating integrity can release heavy metals at rates up to 30% higher than those with stable encapsulation. This degradation process accelerates under environmental stressors such as UV radiation, humidity, and temperature fluctuations, which are precisely the conditions many quantum dot applications encounter during normal use.

Aquatic ecosystems appear particularly vulnerable to quantum dot pollution. Studies demonstrate that certain fish species exposed to degraded quantum dot materials show developmental abnormalities and reduced reproductive capacity at concentrations as low as 5 parts per billion. The small size of quantum dots enables them to penetrate cellular barriers in organisms, potentially disrupting biological processes at the molecular level.

The manufacturing process of quantum dots also presents environmental challenges. Production typically involves energy-intensive processes and hazardous chemicals, including organic solvents that contribute to air pollution and greenhouse gas emissions. Estimates suggest that producing one kilogram of high-quality quantum dots generates approximately 2,000 kilograms of CO2 equivalent emissions, significantly higher than conventional materials used in similar applications.

Recycling quantum dot-containing products presents additional complications. The integration of quantum dots into complex electronic devices makes material separation and recovery difficult, resulting in most quantum dot materials ending up in landfills or incinerators. This disposal pathway further increases the risk of environmental contamination through leaching or atmospheric release.

Recent regulatory frameworks, including the European Union's Restriction of Hazardous Substances (RoHS) directive, have begun addressing these concerns by limiting the use of certain heavy metals in electronic applications. This has accelerated research into "green" quantum dots using less toxic elements such as zinc, copper, or silicon. These alternative materials show promising environmental profiles while maintaining acceptable optical performance, though often with reduced efficiency compared to their heavy metal counterparts.

Standardization and Testing Protocols for Coating Performance

The standardization of testing protocols for quantum dot coating performance represents a critical challenge in the advancement of quantum dot technology. Currently, the industry lacks universally accepted methodologies for evaluating coating durability and its impact on quantum dot stability. This fragmentation in testing approaches has led to difficulties in comparing research results across different laboratories and manufacturers, ultimately hindering technological progress.

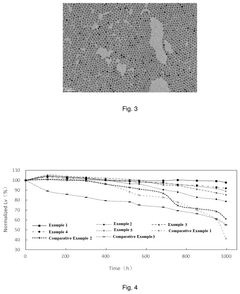

Accelerated aging tests have emerged as the primary method for assessing coating durability, typically involving exposure to elevated temperatures, high humidity, UV radiation, and oxidizing environments. However, the specific parameters—such as temperature ranges, exposure durations, and humidity levels—vary significantly between research institutions. For instance, temperature stress tests may range from 60°C to 120°C, with exposure periods spanning from 24 hours to several weeks.

Photoluminescence quantum yield (PLQY) measurements serve as a key indicator of quantum dot stability, with decreases in PLQY directly correlating to coating degradation. Complementary analytical techniques include spectroscopic methods (FTIR, XPS, Raman) for monitoring chemical changes in coating materials, and microscopy techniques (TEM, SEM) for visualizing physical alterations to the coating structure.

Recent efforts by organizations such as the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO) have begun addressing this standardization gap. The IEC Technical Committee 113 has initiated work on standardized testing protocols specifically for quantum dot materials, while several industry consortia are developing reference materials and benchmark tests.

The establishment of round-robin testing programs, where identical samples are evaluated across multiple laboratories using standardized protocols, represents a promising approach to validation. These programs have successfully identified measurement variabilities and methodological inconsistencies, leading to refined protocols with improved reproducibility.

Future standardization efforts must address several key challenges, including the development of accelerated testing methods that accurately predict real-world performance, the establishment of minimum performance thresholds for different application categories, and the creation of application-specific testing protocols that reflect the diverse environments quantum dots encounter in commercial products.

The implementation of standardized testing protocols would significantly benefit the quantum dot industry by enabling meaningful comparisons between different coating technologies, accelerating the qualification process for new materials, and providing consumers with reliable performance metrics for quantum dot-based products.

Accelerated aging tests have emerged as the primary method for assessing coating durability, typically involving exposure to elevated temperatures, high humidity, UV radiation, and oxidizing environments. However, the specific parameters—such as temperature ranges, exposure durations, and humidity levels—vary significantly between research institutions. For instance, temperature stress tests may range from 60°C to 120°C, with exposure periods spanning from 24 hours to several weeks.

Photoluminescence quantum yield (PLQY) measurements serve as a key indicator of quantum dot stability, with decreases in PLQY directly correlating to coating degradation. Complementary analytical techniques include spectroscopic methods (FTIR, XPS, Raman) for monitoring chemical changes in coating materials, and microscopy techniques (TEM, SEM) for visualizing physical alterations to the coating structure.

Recent efforts by organizations such as the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO) have begun addressing this standardization gap. The IEC Technical Committee 113 has initiated work on standardized testing protocols specifically for quantum dot materials, while several industry consortia are developing reference materials and benchmark tests.

The establishment of round-robin testing programs, where identical samples are evaluated across multiple laboratories using standardized protocols, represents a promising approach to validation. These programs have successfully identified measurement variabilities and methodological inconsistencies, leading to refined protocols with improved reproducibility.

Future standardization efforts must address several key challenges, including the development of accelerated testing methods that accurately predict real-world performance, the establishment of minimum performance thresholds for different application categories, and the creation of application-specific testing protocols that reflect the diverse environments quantum dots encounter in commercial products.

The implementation of standardized testing protocols would significantly benefit the quantum dot industry by enabling meaningful comparisons between different coating technologies, accelerating the qualification process for new materials, and providing consumers with reliable performance metrics for quantum dot-based products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!