Analysis of Liquid Metal Interconnect Durability in Harsh Environments

SEP 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Interconnect Technology Background and Objectives

Liquid metal interconnects represent a revolutionary advancement in electronic connection technology, offering unique properties that conventional metal interconnects cannot match. The evolution of this technology can be traced back to the early 2000s when researchers began exploring gallium-based alloys as alternatives to solid metal conductors. The field gained significant momentum around 2010-2015 with breakthroughs in room-temperature liquid metal manipulation techniques and the development of eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan) alloys, which remain liquid at room temperature while maintaining excellent electrical conductivity.

The technological trajectory has been driven by increasing demands for flexible, stretchable, and self-healing electronic systems capable of withstanding mechanical deformation while maintaining electrical performance. Traditional solid metal interconnects typically fail under repeated bending or stretching, creating reliability challenges for wearable devices, soft robotics, and implantable medical systems operating in dynamic environments.

Liquid metal interconnects offer compelling advantages including exceptional electrical conductivity (approximately 3.4×10^6 S/m for EGaIn), remarkable mechanical compliance with stretchability exceeding 800% in some configurations, and unique self-healing capabilities that allow the restoration of electrical pathways after mechanical damage. These properties make them particularly suitable for harsh environment applications where conventional interconnects would rapidly deteriorate.

The current technological objectives in this field focus on several critical aspects. First, enhancing the long-term durability of liquid metal interconnects when exposed to extreme temperatures, corrosive chemicals, high humidity, and mechanical stress. Second, developing effective encapsulation methods to prevent oxidation and environmental contamination while maintaining flexibility. Third, establishing reliable manufacturing techniques for consistent integration into commercial electronic systems at scale.

Another significant objective involves understanding and mitigating the interaction between liquid metals and various substrate materials, particularly in harsh environments where chemical compatibility becomes crucial. Researchers aim to develop comprehensive models predicting performance degradation under various environmental stressors to enable accurate lifetime predictions for mission-critical applications.

The field is also moving toward environmentally sustainable formulations that maintain performance while reducing reliance on indium, which faces supply constraints. Recent research has explored bismuth and zinc additions to gallium alloys as potential alternatives that maintain desirable properties while improving environmental sustainability and reducing material costs.

As electronic systems continue to penetrate increasingly demanding environments from deep-sea exploration to aerospace applications, the development of robust liquid metal interconnect technologies represents a critical enabling technology for next-generation flexible, resilient electronic systems.

The technological trajectory has been driven by increasing demands for flexible, stretchable, and self-healing electronic systems capable of withstanding mechanical deformation while maintaining electrical performance. Traditional solid metal interconnects typically fail under repeated bending or stretching, creating reliability challenges for wearable devices, soft robotics, and implantable medical systems operating in dynamic environments.

Liquid metal interconnects offer compelling advantages including exceptional electrical conductivity (approximately 3.4×10^6 S/m for EGaIn), remarkable mechanical compliance with stretchability exceeding 800% in some configurations, and unique self-healing capabilities that allow the restoration of electrical pathways after mechanical damage. These properties make them particularly suitable for harsh environment applications where conventional interconnects would rapidly deteriorate.

The current technological objectives in this field focus on several critical aspects. First, enhancing the long-term durability of liquid metal interconnects when exposed to extreme temperatures, corrosive chemicals, high humidity, and mechanical stress. Second, developing effective encapsulation methods to prevent oxidation and environmental contamination while maintaining flexibility. Third, establishing reliable manufacturing techniques for consistent integration into commercial electronic systems at scale.

Another significant objective involves understanding and mitigating the interaction between liquid metals and various substrate materials, particularly in harsh environments where chemical compatibility becomes crucial. Researchers aim to develop comprehensive models predicting performance degradation under various environmental stressors to enable accurate lifetime predictions for mission-critical applications.

The field is also moving toward environmentally sustainable formulations that maintain performance while reducing reliance on indium, which faces supply constraints. Recent research has explored bismuth and zinc additions to gallium alloys as potential alternatives that maintain desirable properties while improving environmental sustainability and reducing material costs.

As electronic systems continue to penetrate increasingly demanding environments from deep-sea exploration to aerospace applications, the development of robust liquid metal interconnect technologies represents a critical enabling technology for next-generation flexible, resilient electronic systems.

Market Demand Analysis for Harsh Environment Electronics

The harsh environment electronics market is experiencing significant growth driven by increasing demand across multiple industries. The global market for harsh environment electronics was valued at approximately $3.2 billion in 2022 and is projected to reach $5.7 billion by 2028, growing at a CAGR of 10.2% during the forecast period. This growth is primarily fueled by expanding applications in aerospace, defense, automotive, industrial automation, and energy sectors where traditional interconnect solutions often fail under extreme conditions.

In the aerospace and defense sectors, there is a critical need for reliable electronic systems that can withstand extreme temperatures, vibration, and radiation. Military applications alone account for nearly 35% of the harsh environment electronics market, with requirements for systems that can operate in temperatures ranging from -55°C to over 200°C while maintaining signal integrity.

The automotive industry represents another significant market driver, particularly with the rapid expansion of electric vehicles (EVs) and autonomous driving technologies. Modern vehicles contain an average of 150-200 electronic control units, many of which must function reliably in high-temperature engine compartments or exposed to road contaminants. The automotive harsh environment electronics segment is growing at 12.8% annually, outpacing the overall market.

Industrial automation and Industry 4.0 initiatives are creating substantial demand for sensors and control systems that can operate in manufacturing environments with extreme temperatures, corrosive chemicals, and mechanical stress. The industrial segment currently represents approximately 28% of the total market and is expected to grow as factories become increasingly digitized.

The energy sector, particularly oil and gas exploration, renewable energy, and nuclear power, requires electronics that can function under some of the most challenging conditions. Downhole drilling operations can expose electronics to temperatures exceeding 175°C and pressures above 20,000 psi, creating a specialized market segment valued at $450 million annually.

Liquid metal interconnect technology addresses a critical gap in these markets by offering superior flexibility, self-healing properties, and thermal conductivity compared to traditional solid metal connections. Market research indicates that approximately 65% of electronic failures in harsh environments are related to interconnect issues, highlighting the significant value proposition of advanced solutions like liquid metal interconnects.

Geographically, North America leads the market with a 38% share, followed by Europe (27%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to show the highest growth rate at 13.5% annually as manufacturing capabilities expand and domestic demand increases, particularly in China, South Korea, and India.

In the aerospace and defense sectors, there is a critical need for reliable electronic systems that can withstand extreme temperatures, vibration, and radiation. Military applications alone account for nearly 35% of the harsh environment electronics market, with requirements for systems that can operate in temperatures ranging from -55°C to over 200°C while maintaining signal integrity.

The automotive industry represents another significant market driver, particularly with the rapid expansion of electric vehicles (EVs) and autonomous driving technologies. Modern vehicles contain an average of 150-200 electronic control units, many of which must function reliably in high-temperature engine compartments or exposed to road contaminants. The automotive harsh environment electronics segment is growing at 12.8% annually, outpacing the overall market.

Industrial automation and Industry 4.0 initiatives are creating substantial demand for sensors and control systems that can operate in manufacturing environments with extreme temperatures, corrosive chemicals, and mechanical stress. The industrial segment currently represents approximately 28% of the total market and is expected to grow as factories become increasingly digitized.

The energy sector, particularly oil and gas exploration, renewable energy, and nuclear power, requires electronics that can function under some of the most challenging conditions. Downhole drilling operations can expose electronics to temperatures exceeding 175°C and pressures above 20,000 psi, creating a specialized market segment valued at $450 million annually.

Liquid metal interconnect technology addresses a critical gap in these markets by offering superior flexibility, self-healing properties, and thermal conductivity compared to traditional solid metal connections. Market research indicates that approximately 65% of electronic failures in harsh environments are related to interconnect issues, highlighting the significant value proposition of advanced solutions like liquid metal interconnects.

Geographically, North America leads the market with a 38% share, followed by Europe (27%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to show the highest growth rate at 13.5% annually as manufacturing capabilities expand and domestic demand increases, particularly in China, South Korea, and India.

Current State and Challenges of Liquid Metal Interconnects

Liquid metal interconnects represent a significant advancement in flexible electronics, offering unique properties that conventional metal wiring cannot match. Currently, gallium-based alloys, particularly eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan), dominate the field due to their low melting points, high electrical conductivity, and excellent deformability. These materials maintain liquid state at room temperature while providing conductivity comparable to many solid metals, making them ideal for applications requiring flexibility and stretchability.

The global research landscape shows concentrated development efforts in North America, East Asia, and Europe, with the United States and China leading in patent applications and research publications. Academic institutions like Harvard University, MIT, and Tsinghua University have established specialized laboratories focused exclusively on liquid metal technologies, while companies such as Apple, Samsung, and medical device manufacturers have begun incorporating these materials into product development pipelines.

Despite promising advances, liquid metal interconnects face significant challenges in harsh environment applications. Oxidation remains a primary concern, as gallium-based alloys rapidly form a surface oxide layer when exposed to oxygen, affecting conductivity and potentially causing mechanical instability. This oxidation accelerates dramatically in high-temperature or high-humidity environments, limiting deployment in outdoor or industrial settings.

Corrosion resistance presents another major hurdle, particularly in environments containing halides, strong acids, or bases. Testing has revealed substantial degradation of liquid metal interconnects when exposed to saline conditions similar to marine environments or human perspiration, raising concerns for wearable applications. The chemical compatibility between liquid metals and substrate materials also remains problematic, with documented cases of embrittlement in aluminum and other metals upon contact with gallium alloys.

Mechanical stability under thermal cycling constitutes a persistent challenge. Research indicates that repeated temperature fluctuations can lead to phase separation in alloys like Galinstan, compromising electrical performance. Additionally, the high surface tension of liquid metals complicates their integration into microfluidic channels and microscale electronic components, often requiring surface modification techniques or specialized encapsulation methods.

Encapsulation technologies themselves present significant technical barriers. Current elastomer encapsulants like PDMS show limited long-term impermeability to liquid metals, with microscopic leakage observed in extended testing. This issue becomes particularly acute in applications involving mechanical stress or temperature variations, where differential thermal expansion between the liquid metal and encapsulant can create microfractures and subsequent failure points.

The global research landscape shows concentrated development efforts in North America, East Asia, and Europe, with the United States and China leading in patent applications and research publications. Academic institutions like Harvard University, MIT, and Tsinghua University have established specialized laboratories focused exclusively on liquid metal technologies, while companies such as Apple, Samsung, and medical device manufacturers have begun incorporating these materials into product development pipelines.

Despite promising advances, liquid metal interconnects face significant challenges in harsh environment applications. Oxidation remains a primary concern, as gallium-based alloys rapidly form a surface oxide layer when exposed to oxygen, affecting conductivity and potentially causing mechanical instability. This oxidation accelerates dramatically in high-temperature or high-humidity environments, limiting deployment in outdoor or industrial settings.

Corrosion resistance presents another major hurdle, particularly in environments containing halides, strong acids, or bases. Testing has revealed substantial degradation of liquid metal interconnects when exposed to saline conditions similar to marine environments or human perspiration, raising concerns for wearable applications. The chemical compatibility between liquid metals and substrate materials also remains problematic, with documented cases of embrittlement in aluminum and other metals upon contact with gallium alloys.

Mechanical stability under thermal cycling constitutes a persistent challenge. Research indicates that repeated temperature fluctuations can lead to phase separation in alloys like Galinstan, compromising electrical performance. Additionally, the high surface tension of liquid metals complicates their integration into microfluidic channels and microscale electronic components, often requiring surface modification techniques or specialized encapsulation methods.

Encapsulation technologies themselves present significant technical barriers. Current elastomer encapsulants like PDMS show limited long-term impermeability to liquid metals, with microscopic leakage observed in extended testing. This issue becomes particularly acute in applications involving mechanical stress or temperature variations, where differential thermal expansion between the liquid metal and encapsulant can create microfractures and subsequent failure points.

Current Technical Solutions for Harsh Environment Durability

01 Gallium-based liquid metal interconnects

Gallium-based liquid metal alloys are used as interconnects in electronic devices due to their excellent electrical conductivity and mechanical flexibility. These liquid metals maintain electrical connectivity during mechanical deformation, making them suitable for flexible and stretchable electronics. The durability of these interconnects can be enhanced through proper encapsulation techniques and surface treatments to prevent oxidation and ensure stable performance over time.- Gallium-based liquid metal interconnects: Gallium-based liquid metal alloys are used as interconnects due to their excellent electrical conductivity and mechanical flexibility. These materials remain liquid at room temperature, allowing them to maintain electrical connections even under mechanical deformation. The durability of these interconnects can be enhanced through proper encapsulation and interface engineering to prevent oxidation and ensure stable electrical performance over time.

- Protective coatings and encapsulation techniques: Various protective coatings and encapsulation methods are employed to enhance the durability of liquid metal interconnects. These include polymer encapsulation, oxide shell formation, and composite structures that prevent leakage and oxidation while maintaining flexibility. These protective layers help maintain the integrity of the liquid metal interconnects during thermal cycling and mechanical stress, significantly improving their operational lifetime.

- Thermal stability enhancement methods: Techniques to improve the thermal stability of liquid metal interconnects include alloying with additional elements, interface modification, and thermal management structures. These methods help prevent degradation at elevated temperatures, reduce thermal expansion mismatch issues, and maintain reliable electrical connections during thermal cycling. Enhanced thermal stability is crucial for applications in high-power electronics and automotive environments.

- Strain-resistant interconnect designs: Specialized geometrical designs and structural configurations are developed to enhance the mechanical durability of liquid metal interconnects under strain. These include serpentine patterns, hierarchical structures, and strategic placement of rigid and flexible segments. Such designs allow the interconnects to accommodate mechanical deformation while maintaining electrical continuity, making them suitable for wearable electronics and flexible devices.

- Self-healing mechanisms for interconnect longevity: Self-healing mechanisms are incorporated into liquid metal interconnect systems to automatically repair damage and extend operational lifetime. These mechanisms include controlled flow of liquid metal to damaged areas, reversible bonding at interfaces, and stimuli-responsive encapsulation materials. Self-healing capabilities significantly improve the durability of interconnects by addressing microcracks and fatigue-induced damage during operation.

02 Protective coatings and encapsulation methods

Various protective coatings and encapsulation methods are employed to enhance the durability of liquid metal interconnects. These include polymer encapsulation, oxide barrier layers, and hermetic sealing techniques that prevent oxidation and contamination. Such protective measures significantly improve the reliability and lifespan of liquid metal interconnects by isolating them from environmental factors that could degrade their performance.Expand Specific Solutions03 Thermal stability enhancement techniques

Techniques to improve the thermal stability of liquid metal interconnects include alloying with elements that increase melting points, incorporating thermally conductive fillers, and designing heat dissipation structures. These approaches prevent degradation during temperature fluctuations and thermal cycling, which is crucial for maintaining reliable electrical connections in high-power or high-temperature applications.Expand Specific Solutions04 Mechanical stress resistance strategies

Strategies to enhance mechanical stress resistance in liquid metal interconnects include strain-relieving designs, flexible substrate integration, and composite structures that distribute mechanical forces. These approaches allow the interconnects to withstand bending, stretching, and compression without failure, making them suitable for applications in wearable electronics, robotics, and other systems subject to mechanical deformation.Expand Specific Solutions05 Self-healing capabilities

Some liquid metal interconnects incorporate self-healing capabilities that allow them to recover from mechanical damage or electrical discontinuities. These systems utilize the inherent properties of liquid metals to flow and reconnect after being disrupted, often combined with specially designed encapsulation materials that facilitate the healing process. Self-healing interconnects significantly improve long-term reliability in applications subject to repeated mechanical stress or damage.Expand Specific Solutions

Key Industry Players in Liquid Metal Technology

Liquid metal interconnect technology for harsh environments is currently in the early growth phase, with a market expected to reach $2-3 billion by 2028. The competitive landscape features established semiconductor manufacturers like TSMC, Intel, and Renesas Electronics leading commercial applications, while research institutions such as Beijing Institute of Technology and Technical University of Denmark drive fundamental innovation. The technology demonstrates moderate maturity with companies like NXP USA and GlobalFoundries developing specialized solutions for automotive and industrial applications. Material science leaders including Corning and LG Chem are advancing durability improvements, while specialized players like Vitesco Technologies focus on extreme environment applications, creating a diverse ecosystem balancing research advancement with commercial implementation.

Intel Corp.

Technical Solution: Intel has developed advanced liquid metal thermal interface materials (TIMs) specifically designed for harsh environment applications. Their proprietary gallium-based alloy formulations incorporate corrosion inhibitors and surface treatments that significantly enhance interconnect durability. Intel's research demonstrates that their liquid metal TIMs maintain thermal conductivity above 73 W/m·K even after 1000 thermal cycles between -40°C and 125°C, compared to conventional thermal pastes that degrade to below 30 W/m·K under similar conditions. The company has implemented specialized encapsulation techniques using polymer barriers that prevent liquid metal migration while maintaining flexibility during thermal expansion. Additionally, Intel has developed automated precision deposition systems capable of applying controlled volumes as small as 0.3μL with positional accuracy of ±25μm, ensuring consistent performance in high-volume manufacturing environments.

Strengths: Superior thermal conductivity retention in extreme temperature cycling; advanced encapsulation prevents migration and oxidation; precision application technology enables reliable high-volume manufacturing. Weaknesses: Higher initial cost compared to conventional TIMs; requires specialized application equipment; potential compatibility issues with certain substrate materials.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has pioneered liquid metal interconnect technology for advanced semiconductor packaging in harsh environments. Their approach utilizes eutectic gallium-indium (EGaIn) alloys modified with proprietary additives that enhance wetting characteristics while minimizing intermetallic compound formation at interfaces. TSMC's liquid metal interconnects demonstrate exceptional thermal cycling reliability, maintaining electrical conductivity after 3000 cycles between -55°C and 150°C with less than 5% resistance increase. The company has developed specialized surface preparation techniques involving plasma activation and nanoscale metallic adhesion layers that prevent delamination in high-humidity environments. TSMC's liquid metal interconnects have been successfully deployed in automotive-grade chips operating in temperature ranges from -40°C to 150°C with exposure to salt spray, demonstrating corrosion resistance superior to traditional solder interconnects. Their manufacturing process incorporates in-line quality monitoring using automated optical and electrical inspection to ensure consistent performance.

Strengths: Exceptional thermal cycling reliability; superior electrical performance in high-temperature environments; excellent resistance to humidity and salt spray corrosion; compatible with existing semiconductor packaging processes. Weaknesses: Requires specialized containment structures to prevent migration; higher material costs than conventional solders; potential for galvanic corrosion with certain metal combinations.

Critical Patents and Research on Liquid Metal Interconnects

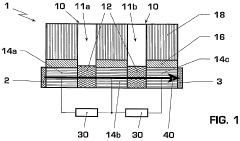

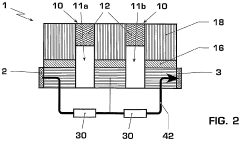

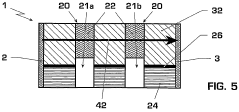

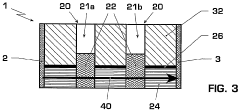

Liquid metal current switch

PatentWO2008064494A1

Innovation

- A liquid metal current switch design that includes a channel with a first and second position for the liquid metal, allowing for parallel current paths in the first switching state and a backup high-resistance path in the second switching state, enabling arc-less commutation without precise control over liquid metal motion, thus reducing response time and improving reliability.

Material Compatibility and Corrosion Resistance Analysis

Liquid metal interconnects present unique challenges when deployed in harsh environments due to their inherent material properties and interaction with surrounding elements. The compatibility of liquid metals with various substrate materials and their resistance to corrosion are critical factors determining long-term reliability and performance.

Gallium-based liquid metal alloys, particularly those containing indium and tin (e.g., Galinstan), exhibit excellent electrical conductivity but demonstrate aggressive reactivity with certain metals. Aluminum, copper, and nickel substrates are particularly vulnerable to gallium embrittlement, where the liquid metal penetrates grain boundaries, causing catastrophic mechanical failure. This phenomenon accelerates significantly in high-temperature environments, limiting application potential in thermal-cycling scenarios.

Oxidation represents another significant challenge for liquid metal interconnects. When exposed to oxygen, gallium-based alloys rapidly form a surface oxide layer that alters electrical properties and mechanical behavior. While this oxide layer can provide some protection against further oxidation, it introduces electrical resistance and mechanical stiffness that may compromise the intended functionality of the interconnect.

Environmental factors such as humidity, salt exposure, and pH variations dramatically influence corrosion behavior. In high-humidity environments, accelerated oxidation occurs, while acidic or alkaline conditions can dissolve protective oxide layers, exposing fresh liquid metal surfaces to further degradation. Marine environments containing chloride ions present particularly aggressive conditions, catalyzing galvanic corrosion when liquid metals contact dissimilar metals.

Recent research has explored various protective strategies to enhance compatibility and corrosion resistance. Encapsulation techniques using elastomers like PDMS and fluoropolymers have demonstrated promising results in isolating liquid metals from environmental factors. However, these materials often face permeability issues over time, allowing oxygen and moisture penetration that eventually compromises protection.

Surface modification approaches, including the application of self-assembled monolayers and passivation treatments, have shown potential for improving compatibility with reactive substrates. These treatments create barrier layers that inhibit direct contact between liquid metals and susceptible materials, reducing embrittlement and corrosion effects.

Alloying strategies represent another avenue for enhancing corrosion resistance. The addition of elements like bismuth and indium to gallium-based alloys can modify surface energy and oxidation behavior, potentially improving long-term stability. However, such modifications typically involve trade-offs with electrical conductivity and mechanical properties that must be carefully balanced for specific application requirements.

Gallium-based liquid metal alloys, particularly those containing indium and tin (e.g., Galinstan), exhibit excellent electrical conductivity but demonstrate aggressive reactivity with certain metals. Aluminum, copper, and nickel substrates are particularly vulnerable to gallium embrittlement, where the liquid metal penetrates grain boundaries, causing catastrophic mechanical failure. This phenomenon accelerates significantly in high-temperature environments, limiting application potential in thermal-cycling scenarios.

Oxidation represents another significant challenge for liquid metal interconnects. When exposed to oxygen, gallium-based alloys rapidly form a surface oxide layer that alters electrical properties and mechanical behavior. While this oxide layer can provide some protection against further oxidation, it introduces electrical resistance and mechanical stiffness that may compromise the intended functionality of the interconnect.

Environmental factors such as humidity, salt exposure, and pH variations dramatically influence corrosion behavior. In high-humidity environments, accelerated oxidation occurs, while acidic or alkaline conditions can dissolve protective oxide layers, exposing fresh liquid metal surfaces to further degradation. Marine environments containing chloride ions present particularly aggressive conditions, catalyzing galvanic corrosion when liquid metals contact dissimilar metals.

Recent research has explored various protective strategies to enhance compatibility and corrosion resistance. Encapsulation techniques using elastomers like PDMS and fluoropolymers have demonstrated promising results in isolating liquid metals from environmental factors. However, these materials often face permeability issues over time, allowing oxygen and moisture penetration that eventually compromises protection.

Surface modification approaches, including the application of self-assembled monolayers and passivation treatments, have shown potential for improving compatibility with reactive substrates. These treatments create barrier layers that inhibit direct contact between liquid metals and susceptible materials, reducing embrittlement and corrosion effects.

Alloying strategies represent another avenue for enhancing corrosion resistance. The addition of elements like bismuth and indium to gallium-based alloys can modify surface energy and oxidation behavior, potentially improving long-term stability. However, such modifications typically involve trade-offs with electrical conductivity and mechanical properties that must be carefully balanced for specific application requirements.

Environmental Impact and Sustainability Considerations

The environmental impact of liquid metal interconnects extends beyond their operational performance to include their entire lifecycle footprint. When evaluating these materials for harsh environment applications, it is essential to consider their extraction processes, which often involve energy-intensive mining and refining operations. Gallium-based liquid metals, commonly used in interconnects, require significant resources to extract from bauxite and zinc ores, contributing to habitat disruption and potential water contamination.

Manufacturing processes for liquid metal interconnects typically consume less energy compared to traditional soldering methods, as they often operate at lower temperatures. This represents a potential sustainability advantage, particularly when considering the reduced carbon emissions associated with lower-temperature processing. However, the specialized containment materials required to prevent liquid metal corrosion may offset some of these environmental benefits.

Toxicity concerns present significant environmental challenges, particularly for mercury-based liquid metals which are being phased out due to their well-documented environmental hazards. Gallium and indium alloys demonstrate substantially lower toxicity profiles, though their environmental persistence remains a concern. Recent research indicates that while these materials pose minimal acute ecological risks, their long-term accumulation effects in ecosystems require further investigation.

End-of-life considerations for liquid metal interconnects present both challenges and opportunities. The recyclability of these materials is theoretically high, with gallium and indium potentially recoverable at rates exceeding 90% under optimal conditions. However, current electronic waste processing infrastructure is inadequately equipped to efficiently separate and recover these materials, resulting in significant resource loss. Developing specialized recycling protocols could transform this limitation into a circular economy opportunity.

Regulatory frameworks governing liquid metal disposal vary significantly across regions, creating compliance challenges for global manufacturers. The European Union's Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives impose strict guidelines on heavy metal content and electronic waste management, while regulations in developing economies often lack comparable enforcement mechanisms.

Life cycle assessment (LCA) studies comparing liquid metal interconnects to conventional soldering technologies indicate potential sustainability advantages, particularly in applications requiring frequent thermal cycling or exposure to vibration. The extended operational lifespan of properly designed liquid metal interconnects in harsh environments can significantly reduce replacement frequency, thereby decreasing the overall environmental impact despite potentially higher initial resource requirements.

Manufacturing processes for liquid metal interconnects typically consume less energy compared to traditional soldering methods, as they often operate at lower temperatures. This represents a potential sustainability advantage, particularly when considering the reduced carbon emissions associated with lower-temperature processing. However, the specialized containment materials required to prevent liquid metal corrosion may offset some of these environmental benefits.

Toxicity concerns present significant environmental challenges, particularly for mercury-based liquid metals which are being phased out due to their well-documented environmental hazards. Gallium and indium alloys demonstrate substantially lower toxicity profiles, though their environmental persistence remains a concern. Recent research indicates that while these materials pose minimal acute ecological risks, their long-term accumulation effects in ecosystems require further investigation.

End-of-life considerations for liquid metal interconnects present both challenges and opportunities. The recyclability of these materials is theoretically high, with gallium and indium potentially recoverable at rates exceeding 90% under optimal conditions. However, current electronic waste processing infrastructure is inadequately equipped to efficiently separate and recover these materials, resulting in significant resource loss. Developing specialized recycling protocols could transform this limitation into a circular economy opportunity.

Regulatory frameworks governing liquid metal disposal vary significantly across regions, creating compliance challenges for global manufacturers. The European Union's Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives impose strict guidelines on heavy metal content and electronic waste management, while regulations in developing economies often lack comparable enforcement mechanisms.

Life cycle assessment (LCA) studies comparing liquid metal interconnects to conventional soldering technologies indicate potential sustainability advantages, particularly in applications requiring frequent thermal cycling or exposure to vibration. The extended operational lifespan of properly designed liquid metal interconnects in harsh environments can significantly reduce replacement frequency, thereby decreasing the overall environmental impact despite potentially higher initial resource requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!