What Factors Drive Liquid Metal Interconnect Adoption in Robotics?

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Interconnect Evolution and Objectives

Liquid metal interconnects represent a revolutionary approach to creating flexible, stretchable connections in robotic systems. The evolution of this technology can be traced back to the early 2000s when researchers began exploring gallium-based alloys as alternatives to traditional rigid copper wiring. These early investigations focused primarily on the unique properties of liquid metals, particularly their ability to maintain electrical conductivity while undergoing significant mechanical deformation.

The field gained significant momentum around 2010-2015 with the development of more sophisticated fabrication techniques, including microfluidic channels, direct writing methods, and 3D printing approaches for liquid metal integration. This period marked a transition from purely academic research to more application-focused development, with increasing attention on addressing challenges related to oxidation, adhesion, and integration with existing electronic components.

Recent years have witnessed an acceleration in liquid metal interconnect research specifically targeting robotics applications. The growing demand for soft robotics, wearable technology, and human-machine interfaces has created a compelling need for electrical connections that can withstand repeated bending, stretching, and compression without performance degradation. This has led to innovations in encapsulation materials, interface engineering, and hybrid approaches combining liquid metals with conventional electronics.

The primary technical objectives driving liquid metal interconnect development in robotics include achieving mechanical compliance matching that of biological tissues, maintaining stable electrical performance under extreme deformation conditions, and ensuring long-term reliability in dynamic environments. Researchers aim to develop interconnects capable of withstanding strains exceeding 300% while maintaining consistent conductivity and minimizing hysteresis effects during repeated deformation cycles.

Another critical objective is overcoming the inherent challenges of liquid metal handling and integration. This includes developing methods to control oxidation, prevent leakage, ensure compatibility with manufacturing processes, and create reliable interfaces with conventional rigid electronics. The field is increasingly focused on scalable fabrication techniques that can transition from laboratory demonstrations to commercial production.

Looking forward, the evolution of liquid metal interconnects is expected to continue along several trajectories: miniaturization for microscale robotic applications, development of self-healing capabilities to enhance reliability, integration with sensing functionalities to create multifunctional components, and exploration of environmentally friendly alternatives to gallium-indium alloys. The ultimate goal remains creating interconnect technologies that can enable truly biomimetic robotic systems with human-like flexibility, resilience, and sensory capabilities.

The field gained significant momentum around 2010-2015 with the development of more sophisticated fabrication techniques, including microfluidic channels, direct writing methods, and 3D printing approaches for liquid metal integration. This period marked a transition from purely academic research to more application-focused development, with increasing attention on addressing challenges related to oxidation, adhesion, and integration with existing electronic components.

Recent years have witnessed an acceleration in liquid metal interconnect research specifically targeting robotics applications. The growing demand for soft robotics, wearable technology, and human-machine interfaces has created a compelling need for electrical connections that can withstand repeated bending, stretching, and compression without performance degradation. This has led to innovations in encapsulation materials, interface engineering, and hybrid approaches combining liquid metals with conventional electronics.

The primary technical objectives driving liquid metal interconnect development in robotics include achieving mechanical compliance matching that of biological tissues, maintaining stable electrical performance under extreme deformation conditions, and ensuring long-term reliability in dynamic environments. Researchers aim to develop interconnects capable of withstanding strains exceeding 300% while maintaining consistent conductivity and minimizing hysteresis effects during repeated deformation cycles.

Another critical objective is overcoming the inherent challenges of liquid metal handling and integration. This includes developing methods to control oxidation, prevent leakage, ensure compatibility with manufacturing processes, and create reliable interfaces with conventional rigid electronics. The field is increasingly focused on scalable fabrication techniques that can transition from laboratory demonstrations to commercial production.

Looking forward, the evolution of liquid metal interconnects is expected to continue along several trajectories: miniaturization for microscale robotic applications, development of self-healing capabilities to enhance reliability, integration with sensing functionalities to create multifunctional components, and exploration of environmentally friendly alternatives to gallium-indium alloys. The ultimate goal remains creating interconnect technologies that can enable truly biomimetic robotic systems with human-like flexibility, resilience, and sensory capabilities.

Market Demand Analysis for Flexible Robotics Connections

The robotics industry is witnessing unprecedented growth, with the global market projected to reach $260 billion by 2030. Within this expanding ecosystem, flexible connection technologies have emerged as a critical component, particularly for advanced robotic systems requiring adaptable and resilient interconnects. Market research indicates that traditional rigid wiring solutions are increasingly inadequate for modern robotics applications that demand high degrees of movement, durability, and reliability.

Liquid metal interconnects represent a revolutionary solution addressing these market needs. The demand for these advanced connections is primarily driven by four key market segments: industrial automation, medical robotics, soft robotics, and consumer robotics. Each segment presents unique requirements and growth trajectories that collectively fuel the adoption of liquid metal technology.

Industrial automation, the largest segment by market value, requires connections that can withstand millions of movement cycles in harsh environments. Manufacturing facilities are increasingly deploying collaborative robots that work alongside humans, necessitating flexible connections that maintain performance despite constant articulation. Market surveys indicate that downtime due to connection failures costs manufacturers billions annually, creating strong economic incentives for more reliable solutions.

The medical robotics sector demonstrates the highest growth rate for flexible connection technologies, with surgical robots and rehabilitation devices leading adoption. These applications demand biocompatible materials with exceptional reliability, as connection failures during medical procedures could have severe consequences. The market for surgical robots alone is growing at 15% annually, creating substantial demand for advanced interconnect solutions.

Soft robotics represents an emerging but rapidly expanding market segment. These biomimetic systems require entirely new approaches to electrical connections that can stretch, compress, and twist while maintaining conductivity. Research institutions and startups focusing on soft robotics report that connection limitations currently represent their primary technical constraint, indicating significant unmet market demand.

Consumer robotics, including entertainment, education, and household applications, is driving volume demand for cost-effective flexible connections. As these devices become more sophisticated and interactive, manufacturers seek connections that can withstand daily user handling while remaining affordable for mass-market products.

Market analysis reveals that end-users across all segments are willing to pay premium prices for connection technologies that demonstrably improve reliability, extend product lifespan, and enable new functionality. This price elasticity creates favorable conditions for liquid metal interconnect adoption despite higher initial costs compared to conventional solutions.

Liquid metal interconnects represent a revolutionary solution addressing these market needs. The demand for these advanced connections is primarily driven by four key market segments: industrial automation, medical robotics, soft robotics, and consumer robotics. Each segment presents unique requirements and growth trajectories that collectively fuel the adoption of liquid metal technology.

Industrial automation, the largest segment by market value, requires connections that can withstand millions of movement cycles in harsh environments. Manufacturing facilities are increasingly deploying collaborative robots that work alongside humans, necessitating flexible connections that maintain performance despite constant articulation. Market surveys indicate that downtime due to connection failures costs manufacturers billions annually, creating strong economic incentives for more reliable solutions.

The medical robotics sector demonstrates the highest growth rate for flexible connection technologies, with surgical robots and rehabilitation devices leading adoption. These applications demand biocompatible materials with exceptional reliability, as connection failures during medical procedures could have severe consequences. The market for surgical robots alone is growing at 15% annually, creating substantial demand for advanced interconnect solutions.

Soft robotics represents an emerging but rapidly expanding market segment. These biomimetic systems require entirely new approaches to electrical connections that can stretch, compress, and twist while maintaining conductivity. Research institutions and startups focusing on soft robotics report that connection limitations currently represent their primary technical constraint, indicating significant unmet market demand.

Consumer robotics, including entertainment, education, and household applications, is driving volume demand for cost-effective flexible connections. As these devices become more sophisticated and interactive, manufacturers seek connections that can withstand daily user handling while remaining affordable for mass-market products.

Market analysis reveals that end-users across all segments are willing to pay premium prices for connection technologies that demonstrably improve reliability, extend product lifespan, and enable new functionality. This price elasticity creates favorable conditions for liquid metal interconnect adoption despite higher initial costs compared to conventional solutions.

Technical Barriers and Global Development Status

Despite significant advancements in liquid metal (LM) interconnect technology for robotics applications, several technical barriers continue to impede widespread adoption. The inherent oxidation of gallium-based liquid metals remains a primary challenge, as surface oxidation affects electrical conductivity and can lead to performance degradation over time. This oxidation layer, while providing mechanical stability in certain applications, creates unpredictable electrical resistance that complicates circuit design and reliability.

Material compatibility presents another significant hurdle, as gallium-based LMs exhibit corrosive properties when in contact with many metals, particularly aluminum. This corrosivity limits substrate and encapsulation material options, necessitating specialized designs that increase manufacturing complexity and cost. The development of effective encapsulation techniques that maintain flexibility while preventing leakage continues to challenge researchers globally.

Manufacturing scalability represents a critical barrier to commercial adoption. Current fabrication methods for LM-based circuits often involve manual injection or patterning techniques that are difficult to scale for mass production. The lack of standardized manufacturing processes comparable to traditional PCB fabrication significantly impacts production efficiency and cost-effectiveness.

From a global development perspective, research into LM interconnects for robotics applications has gained momentum primarily in North America, East Asia, and Europe. The United States leads in fundamental research through institutions like Purdue University, Carnegie Mellon University, and North Carolina State University, focusing on novel fabrication methods and material formulations. Chinese research institutions have made significant progress in developing practical applications, particularly in soft robotics and wearable technology integration.

European contributions have centered on materials science innovations, with German and Swiss research groups developing advanced encapsulation materials and exploring alternative liquid metal alloys with improved properties. South Korean research teams have demonstrated notable advancements in manufacturing techniques for stretchable electronics incorporating liquid metal interconnects.

Industry engagement varies significantly by region, with North American startups showing greater commercialization efforts compared to their Asian counterparts. However, Japanese electronics manufacturers have recently increased investment in LM technology for next-generation flexible electronics applications, including robotics.

Regulatory frameworks for liquid metal technologies remain underdeveloped globally, creating uncertainty regarding safety standards and environmental considerations. This regulatory gap, combined with the technical challenges, has resulted in most liquid metal interconnect applications remaining at the prototype or small-scale production stage rather than achieving widespread commercial deployment in robotics systems.

Material compatibility presents another significant hurdle, as gallium-based LMs exhibit corrosive properties when in contact with many metals, particularly aluminum. This corrosivity limits substrate and encapsulation material options, necessitating specialized designs that increase manufacturing complexity and cost. The development of effective encapsulation techniques that maintain flexibility while preventing leakage continues to challenge researchers globally.

Manufacturing scalability represents a critical barrier to commercial adoption. Current fabrication methods for LM-based circuits often involve manual injection or patterning techniques that are difficult to scale for mass production. The lack of standardized manufacturing processes comparable to traditional PCB fabrication significantly impacts production efficiency and cost-effectiveness.

From a global development perspective, research into LM interconnects for robotics applications has gained momentum primarily in North America, East Asia, and Europe. The United States leads in fundamental research through institutions like Purdue University, Carnegie Mellon University, and North Carolina State University, focusing on novel fabrication methods and material formulations. Chinese research institutions have made significant progress in developing practical applications, particularly in soft robotics and wearable technology integration.

European contributions have centered on materials science innovations, with German and Swiss research groups developing advanced encapsulation materials and exploring alternative liquid metal alloys with improved properties. South Korean research teams have demonstrated notable advancements in manufacturing techniques for stretchable electronics incorporating liquid metal interconnects.

Industry engagement varies significantly by region, with North American startups showing greater commercialization efforts compared to their Asian counterparts. However, Japanese electronics manufacturers have recently increased investment in LM technology for next-generation flexible electronics applications, including robotics.

Regulatory frameworks for liquid metal technologies remain underdeveloped globally, creating uncertainty regarding safety standards and environmental considerations. This regulatory gap, combined with the technical challenges, has resulted in most liquid metal interconnect applications remaining at the prototype or small-scale production stage rather than achieving widespread commercial deployment in robotics systems.

Current Liquid Metal Implementation Approaches

01 Liquid metal interconnect materials and compositions

Liquid metals, particularly gallium-based alloys, are used as interconnect materials in electronic devices due to their excellent electrical conductivity and low melting points. These materials can flow and maintain electrical connections even during mechanical deformation, making them ideal for flexible electronics. Various compositions and formulations have been developed to optimize properties such as viscosity, adhesion, and oxidation resistance while maintaining high conductivity.- Liquid metal interconnect materials and compositions: Liquid metals, such as gallium-based alloys, can be used as interconnect materials in electronic devices due to their excellent electrical conductivity and mechanical flexibility. These materials remain in a liquid state at operating temperatures, allowing for self-healing properties and resistance to mechanical fatigue. The composition can be tailored to achieve specific melting points, viscosity, and adhesion properties suitable for different applications in semiconductor packaging and flexible electronics.

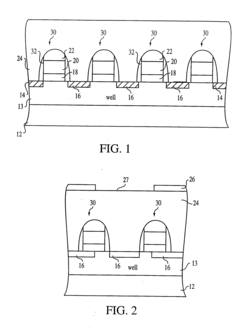

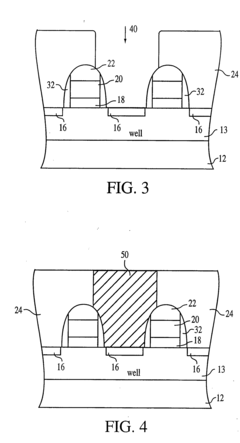

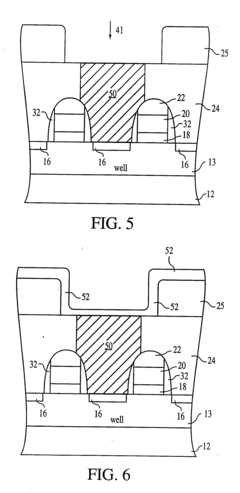

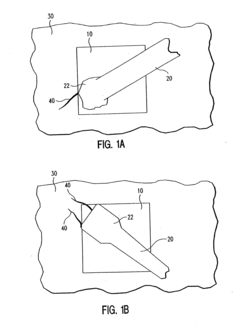

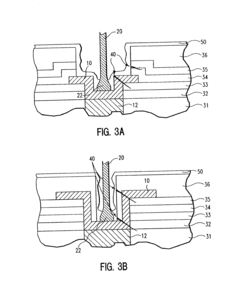

- Manufacturing processes for liquid metal interconnects: Various manufacturing techniques are employed to create liquid metal interconnects, including injection molding, printing, and deposition methods. These processes involve precise control of temperature and pressure to ensure proper flow and placement of the liquid metal. Surface treatments may be applied to improve wetting and adhesion characteristics. Advanced patterning techniques allow for the creation of complex interconnect geometries with high precision and reliability.

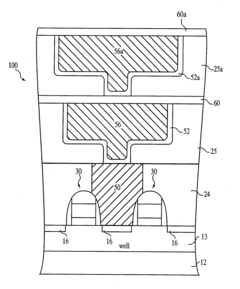

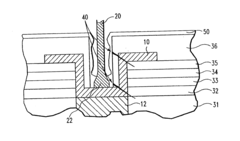

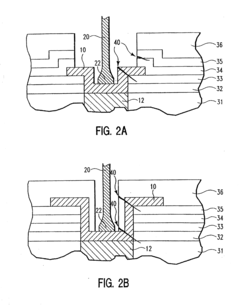

- Integration of liquid metal interconnects in semiconductor devices: Liquid metal interconnects can be integrated into semiconductor devices to provide electrical connections between components. This integration requires specialized packaging techniques to contain the liquid metal while maintaining electrical continuity. Barrier layers are often employed to prevent diffusion of the liquid metal into surrounding materials. The integration process must address thermal management considerations to maintain the desired physical state of the interconnect material throughout the device's operational range.

- Reliability and performance characteristics of liquid metal interconnects: Liquid metal interconnects offer unique reliability advantages including resistance to thermal cycling fatigue and mechanical stress. Their self-healing properties allow them to recover from physical damage that would permanently impair traditional solid interconnects. Performance characteristics include low electrical resistance, excellent thermal conductivity, and the ability to maintain connectivity during mechanical deformation. Testing methodologies have been developed to evaluate the long-term stability and performance of these interconnects under various environmental conditions.

- Applications in flexible and stretchable electronics: Liquid metal interconnects are particularly valuable in flexible and stretchable electronic applications where traditional rigid interconnects would fail under deformation. These interconnects enable the development of wearable devices, soft robotics, and conformable sensors that can maintain functionality while being bent, twisted, or stretched. The ability of liquid metals to flow and redistribute under strain while maintaining electrical continuity makes them ideal for applications requiring mechanical flexibility without sacrificing electrical performance.

02 Fabrication methods for liquid metal interconnects

Various techniques have been developed for fabricating liquid metal interconnects, including microfluidic injection, printing, and patterning methods. These processes involve precise deposition of liquid metal into channels or vias, often requiring specialized equipment to control the flow and placement of the material. Surface treatments may be applied to improve wetting characteristics and adhesion to substrates, while encapsulation techniques prevent leakage and oxidation of the liquid metal.Expand Specific Solutions03 Flexible and stretchable interconnect applications

Liquid metal interconnects are particularly valuable in flexible and stretchable electronics, where traditional solid metal connections would fail under mechanical stress. These interconnects can maintain electrical conductivity while being stretched, bent, or twisted, enabling applications in wearable devices, soft robotics, and biomedical implants. Special design considerations include channel geometries that accommodate deformation and interface materials that ensure stable connections with rigid components.Expand Specific Solutions04 Integration with semiconductor devices

Integrating liquid metal interconnects with conventional semiconductor devices presents unique challenges and opportunities. Techniques have been developed to create reliable interfaces between liquid metals and solid-state components, including specialized bonding methods and transition structures. These approaches enable the combination of high-performance semiconductor devices with the mechanical flexibility of liquid metal interconnects, creating hybrid systems with enhanced functionality.Expand Specific Solutions05 Reliability and packaging solutions

Ensuring the long-term reliability of liquid metal interconnects requires specialized packaging and encapsulation techniques. Methods have been developed to prevent leakage, oxidation, and corrosion of liquid metals while maintaining their electrical and mechanical properties. These include barrier layers, hermetic sealing approaches, and composite encapsulants that accommodate the unique characteristics of liquid metals while protecting surrounding components from potential contamination.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The liquid metal interconnect market in robotics is currently in an early growth phase, characterized by increasing adoption driven by demands for flexible, durable connections in dynamic robotic systems. The global market size remains relatively modest but is expanding rapidly as robotics applications diversify across industrial, medical, and consumer sectors. From a technological maturity perspective, the field shows promising development with key players emerging across different specialization areas. Research institutions like Tsinghua University, Harbin Institute of Technology, and Carnegie Mellon University are advancing fundamental technologies, while established semiconductor companies including Intel, Texas Instruments, and QUALCOMM are developing commercial applications. Specialized firms such as Beijing Zhongke Tailong Electronic Technology are creating niche solutions, indicating a maturing ecosystem with diverse technological approaches to liquid metal implementation in robotic systems.

Tsinghua University

Technical Solution: Tsinghua University has developed advanced liquid metal interconnect solutions focusing on room-temperature liquid metals (RTLMs) for next-generation robotics. Their proprietary technology utilizes eutectic gallium-indium (EGaIn) alloys with modified surface properties to overcome oxidation challenges. Researchers have created novel composite materials by incorporating liquid metals into polymer matrices, achieving both electrical conductivity and mechanical flexibility. Their patented microfluidic delivery system enables precise control of liquid metal distribution within complex robotic structures. Tsinghua's approach includes innovative surface modification techniques that enhance wetting properties of liquid metals on various substrates, improving adhesion and electrical contact reliability. The university has demonstrated practical applications in soft actuators and tactile sensors for humanoid robots, where their liquid metal interconnects provide superior performance under repeated mechanical stress compared to conventional wiring solutions.

Strengths: Superior integration with soft materials and excellent performance under mechanical deformation make this technology ideal for biomimetic robotics. Their surface modification techniques significantly improve reliability and manufacturing scalability. Weaknesses: Current implementations still face challenges with long-term stability in varying environmental conditions, and the higher cost of gallium-based alloys compared to conventional wiring remains a barrier to widespread commercial adoption.

Technical Institute of Physics & Chemistry CAS

Technical Solution: The Technical Institute of Physics & Chemistry of the Chinese Academy of Sciences has developed a comprehensive liquid metal interconnect platform specifically designed for extreme robotic environments. Their technology centers on bismuth-based liquid metal alloys with customized additives that significantly lower melting points while maintaining excellent electrical conductivity. The institute has pioneered microencapsulation techniques that prevent oxidation and leakage, extending operational lifetimes of liquid metal interconnects in industrial robotics applications. Their research includes novel printing methodologies using specially formulated liquid metal inks compatible with standard manufacturing processes, enabling direct integration with existing robotic production lines. The institute has demonstrated functional prototypes of robots operating in high-temperature environments where conventional electronics would fail, utilizing their liquid metal interconnect technology to maintain signal integrity under thermal stress. Recent innovations include self-healing circuits that can automatically restore electrical connections after mechanical damage.

Strengths: Exceptional thermal stability and resistance to harsh environmental conditions make this technology particularly valuable for industrial and exploration robotics. Their manufacturing techniques are compatible with existing production equipment, lowering barriers to adoption. Weaknesses: The specialized formulations require precise environmental controls during manufacturing, and current implementations have higher electrical resistance compared to solid conductors, creating potential efficiency challenges for high-power applications.

Critical Patents and Research Breakthroughs

Use of AIN as cooper passivation layer and thermal conductor

PatentInactiveUS20070164442A1

Innovation

- A copper interconnect structure incorporating an aluminum nitride (AlN) barrier layer that enhances thermal conductivity, improves adhesion, and suppresses oxide growth, while also serving as a thermally conductive dielectric barrier to manage heat and prevent temperature rise.

Method and structure to enhance temperature/humidity/bias performance of semiconductor devices by surface modification

PatentInactiveUS20080079176A1

Innovation

- A method involving the application of a silicon-containing conformal encapsulant precursor as a reactive liquid reagent to seal microcracks and delaminations, which reacts with moisture or a secondary initiator to form a dielectric barrier, thereby enhancing the temperature/humidity/bias performance of semiconductor chips without adding extra materials or metal layers.

Material Safety and Environmental Considerations

The safety profile of liquid metal materials represents a critical consideration for their adoption in robotic applications. Gallium-based liquid metals, particularly gallium-indium-tin alloys (Galinstan) and eutectic gallium-indium (EGaIn), demonstrate significantly lower toxicity compared to mercury-based alternatives. These materials maintain liquid states at room temperature while posing minimal health risks during normal handling procedures. However, proper containment remains essential as prolonged skin contact may cause temporary irritation, and ingestion could potentially lead to gastrointestinal distress.

Manufacturing processes for liquid metal interconnects require careful management of material waste streams. Unlike traditional electronic components that often contain lead, arsenic, or other hazardous substances, gallium-based liquid metals present reduced environmental persistence and bioaccumulation concerns. Nevertheless, comprehensive end-of-life management protocols must be established to prevent inappropriate disposal and potential environmental contamination.

The oxidation behavior of liquid metals presents both challenges and opportunities from an environmental perspective. When exposed to oxygen, gallium-based alloys develop a thin oxide skin that can contain the material and prevent leakage. This self-passivation characteristic enhances safety during handling but necessitates controlled manufacturing environments to maintain optimal electrical properties. Manufacturers must implement appropriate ventilation systems and handling protocols to manage oxide formation during production processes.

Regulatory frameworks governing liquid metal usage in robotics continue to evolve as these materials gain wider adoption. Current regulations typically classify gallium-based liquid metals more favorably than mercury-based alternatives, though specific requirements vary by jurisdiction. Companies implementing liquid metal interconnect technologies must navigate these regulatory landscapes while anticipating potential future restrictions or reporting requirements related to material sourcing, usage, and disposal.

Lifecycle assessment studies indicate that liquid metal interconnects may offer sustainability advantages through extended product lifespans and enhanced repairability of robotic systems. The self-healing properties of these materials can reduce electronic waste by allowing components to maintain functionality despite mechanical stress. Additionally, the recyclability of gallium-based alloys presents opportunities for closed-loop material systems, though commercial-scale recovery infrastructure remains underdeveloped in most regions.

Manufacturing processes for liquid metal interconnects require careful management of material waste streams. Unlike traditional electronic components that often contain lead, arsenic, or other hazardous substances, gallium-based liquid metals present reduced environmental persistence and bioaccumulation concerns. Nevertheless, comprehensive end-of-life management protocols must be established to prevent inappropriate disposal and potential environmental contamination.

The oxidation behavior of liquid metals presents both challenges and opportunities from an environmental perspective. When exposed to oxygen, gallium-based alloys develop a thin oxide skin that can contain the material and prevent leakage. This self-passivation characteristic enhances safety during handling but necessitates controlled manufacturing environments to maintain optimal electrical properties. Manufacturers must implement appropriate ventilation systems and handling protocols to manage oxide formation during production processes.

Regulatory frameworks governing liquid metal usage in robotics continue to evolve as these materials gain wider adoption. Current regulations typically classify gallium-based liquid metals more favorably than mercury-based alternatives, though specific requirements vary by jurisdiction. Companies implementing liquid metal interconnect technologies must navigate these regulatory landscapes while anticipating potential future restrictions or reporting requirements related to material sourcing, usage, and disposal.

Lifecycle assessment studies indicate that liquid metal interconnects may offer sustainability advantages through extended product lifespans and enhanced repairability of robotic systems. The self-healing properties of these materials can reduce electronic waste by allowing components to maintain functionality despite mechanical stress. Additionally, the recyclability of gallium-based alloys presents opportunities for closed-loop material systems, though commercial-scale recovery infrastructure remains underdeveloped in most regions.

Reliability Testing and Performance Metrics

Reliability testing and performance metrics for liquid metal interconnects in robotics require comprehensive evaluation frameworks that address the unique challenges of this emerging technology. Standard testing protocols have been adapted from traditional electronics testing but must account for the fluid nature of liquid metals and their interaction with robotic movement dynamics.

Cyclic mechanical testing represents a cornerstone of reliability assessment, with most research groups subjecting liquid metal interconnects to between 10,000 and 1,000,000 cycles of stretching, bending, or twisting. These tests typically measure resistance changes during deformation, with high-performance interconnects maintaining less than 5% resistance variation throughout testing. Temperature cycling tests (-40°C to 85°C) further evaluate thermal stability, as liquid metal alloys may experience phase changes or oxidation at temperature extremes.

Environmental resistance testing has emerged as particularly critical for robotics applications. Exposure chambers simulating humidity (85% RH), salt spray, and industrial contaminants help quantify degradation rates under adverse conditions. Recent studies indicate that encapsulation materials significantly influence environmental durability, with fluoropolymer and silicone elastomer composites demonstrating superior protection against oxidation and leakage.

Impact and vibration resistance metrics have been standardized using modified drop tests (MIL-STD-810G) and vibration profiles matching robotic operational environments. High-frequency vibration (50-500 Hz) testing reveals that liquid metal interconnects often outperform solid conductors, showing 30-40% less performance degradation after extended vibration exposure.

Electrical performance metrics focus on current-carrying capacity, signal integrity, and electromagnetic interference (EMI) shielding. Benchmark standards now include maximum current density (typically 3-5 A/mm²), frequency response up to 5 GHz, and insertion loss measurements. Advanced interconnect designs incorporating engineered channel geometries have demonstrated up to 40% improvement in high-frequency signal transmission compared to conventional flexible electronics.

Accelerated aging protocols have been developed to predict long-term reliability, with most testing regimes combining elevated temperature (60-85°C), humidity cycling, and mechanical stress. Statistical models derived from these tests suggest that properly engineered liquid metal interconnects can maintain functional performance for 5-7 years in demanding robotic applications, though real-world validation of these projections remains limited.

Standardization efforts are underway through IEEE and IEC working groups to establish industry-wide testing protocols specifically for stretchable liquid metal electronics, addressing the current fragmentation in testing methodologies that complicates direct comparison between different research results and commercial solutions.

Cyclic mechanical testing represents a cornerstone of reliability assessment, with most research groups subjecting liquid metal interconnects to between 10,000 and 1,000,000 cycles of stretching, bending, or twisting. These tests typically measure resistance changes during deformation, with high-performance interconnects maintaining less than 5% resistance variation throughout testing. Temperature cycling tests (-40°C to 85°C) further evaluate thermal stability, as liquid metal alloys may experience phase changes or oxidation at temperature extremes.

Environmental resistance testing has emerged as particularly critical for robotics applications. Exposure chambers simulating humidity (85% RH), salt spray, and industrial contaminants help quantify degradation rates under adverse conditions. Recent studies indicate that encapsulation materials significantly influence environmental durability, with fluoropolymer and silicone elastomer composites demonstrating superior protection against oxidation and leakage.

Impact and vibration resistance metrics have been standardized using modified drop tests (MIL-STD-810G) and vibration profiles matching robotic operational environments. High-frequency vibration (50-500 Hz) testing reveals that liquid metal interconnects often outperform solid conductors, showing 30-40% less performance degradation after extended vibration exposure.

Electrical performance metrics focus on current-carrying capacity, signal integrity, and electromagnetic interference (EMI) shielding. Benchmark standards now include maximum current density (typically 3-5 A/mm²), frequency response up to 5 GHz, and insertion loss measurements. Advanced interconnect designs incorporating engineered channel geometries have demonstrated up to 40% improvement in high-frequency signal transmission compared to conventional flexible electronics.

Accelerated aging protocols have been developed to predict long-term reliability, with most testing regimes combining elevated temperature (60-85°C), humidity cycling, and mechanical stress. Statistical models derived from these tests suggest that properly engineered liquid metal interconnects can maintain functional performance for 5-7 years in demanding robotic applications, though real-world validation of these projections remains limited.

Standardization efforts are underway through IEEE and IEC working groups to establish industry-wide testing protocols specifically for stretchable liquid metal electronics, addressing the current fragmentation in testing methodologies that complicates direct comparison between different research results and commercial solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!