Liquid Metal Interconnect Applications in Robotic Enhancements

SEP 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Technology Background and Objectives

Liquid metal technology has evolved significantly over the past decades, transitioning from theoretical concepts to practical applications in various fields. The history of liquid metals dates back to mercury applications in thermometers and electrical switches, but modern gallium-based liquid metals have revolutionized the field due to their lower toxicity and favorable mechanical properties. These materials exhibit unique combinations of electrical conductivity, thermal properties, and fluidic behavior that make them particularly suitable for advanced robotic systems requiring flexible, durable interconnections.

The evolution of liquid metal technology has been accelerated by advancements in materials science, particularly in the development of gallium-indium alloys (e.g., EGaIn, Galinstan) that remain liquid at room temperature while offering excellent electrical conductivity. These developments have coincided with the growing demand for soft robotics and wearable technology, creating a natural convergence of material capabilities and application needs.

Current research trends indicate a shift toward integrating liquid metals into complex robotic systems, focusing on creating reliable electrical pathways that can withstand mechanical deformation. This represents a departure from traditional rigid electronic components that limit the flexibility and adaptability of robotic systems. The trend is particularly evident in the development of stretchable electronics, self-healing circuits, and reconfigurable robotic components.

The primary technical objective in liquid metal interconnect applications for robotic enhancements is to develop reliable, durable connection systems that maintain electrical performance under extreme mechanical stress. This includes creating interconnects that can withstand repeated stretching, bending, and twisting without degradation of electrical properties or mechanical failure.

Secondary objectives include miniaturization of liquid metal channels for micro-robotic applications, development of manufacturing techniques for mass production, and creation of control systems for dynamically reconfigurable liquid metal pathways. These objectives align with the broader goal of creating more adaptable, resilient robotic systems capable of operating in diverse environments.

The field is also witnessing increasing interest in multi-functional liquid metal components that serve not only as electrical interconnects but also as thermal management systems, force sensors, or actuators within robotic platforms. This multifunctionality represents a significant advancement over traditional single-purpose electronic components and opens new possibilities for integrated robotic design.

Looking forward, the technology trajectory suggests continued refinement of liquid metal formulations, encapsulation techniques, and integration methods to overcome current limitations related to oxidation, pattern stability, and long-term reliability. The convergence of liquid metal technology with advances in 3D printing, microfluidics, and soft materials science is expected to accelerate progress toward fully integrated, highly adaptive robotic systems with unprecedented mechanical and electrical performance characteristics.

The evolution of liquid metal technology has been accelerated by advancements in materials science, particularly in the development of gallium-indium alloys (e.g., EGaIn, Galinstan) that remain liquid at room temperature while offering excellent electrical conductivity. These developments have coincided with the growing demand for soft robotics and wearable technology, creating a natural convergence of material capabilities and application needs.

Current research trends indicate a shift toward integrating liquid metals into complex robotic systems, focusing on creating reliable electrical pathways that can withstand mechanical deformation. This represents a departure from traditional rigid electronic components that limit the flexibility and adaptability of robotic systems. The trend is particularly evident in the development of stretchable electronics, self-healing circuits, and reconfigurable robotic components.

The primary technical objective in liquid metal interconnect applications for robotic enhancements is to develop reliable, durable connection systems that maintain electrical performance under extreme mechanical stress. This includes creating interconnects that can withstand repeated stretching, bending, and twisting without degradation of electrical properties or mechanical failure.

Secondary objectives include miniaturization of liquid metal channels for micro-robotic applications, development of manufacturing techniques for mass production, and creation of control systems for dynamically reconfigurable liquid metal pathways. These objectives align with the broader goal of creating more adaptable, resilient robotic systems capable of operating in diverse environments.

The field is also witnessing increasing interest in multi-functional liquid metal components that serve not only as electrical interconnects but also as thermal management systems, force sensors, or actuators within robotic platforms. This multifunctionality represents a significant advancement over traditional single-purpose electronic components and opens new possibilities for integrated robotic design.

Looking forward, the technology trajectory suggests continued refinement of liquid metal formulations, encapsulation techniques, and integration methods to overcome current limitations related to oxidation, pattern stability, and long-term reliability. The convergence of liquid metal technology with advances in 3D printing, microfluidics, and soft materials science is expected to accelerate progress toward fully integrated, highly adaptive robotic systems with unprecedented mechanical and electrical performance characteristics.

Market Analysis for Soft Robotics Applications

The soft robotics market has experienced significant growth in recent years, with a global market value reaching $1.5 billion in 2022 and projected to expand at a CAGR of 35% through 2028. This remarkable growth trajectory is primarily driven by increasing demand across healthcare, manufacturing, and consumer electronics sectors, where traditional rigid robots face limitations in human interaction and delicate object manipulation.

Liquid metal interconnects represent a transformative technology within the soft robotics ecosystem, addressing critical challenges related to flexibility, durability, and electrical conductivity. Market research indicates that approximately 40% of soft robotics applications require advanced interconnect solutions that maintain conductivity during extreme deformation—a requirement perfectly aligned with liquid metal capabilities.

Healthcare applications currently dominate the market demand, accounting for roughly 45% of liquid metal interconnect implementations in soft robotics. Wearable health monitoring devices, rehabilitation exoskeletons, and surgical assistants represent the fastest-growing application segments, with hospitals and rehabilitation centers serving as primary end-users. The aging population in developed economies further accelerates this demand, with projections suggesting the medical soft robotics market will double in size by 2026.

Manufacturing represents the second-largest application sector at 30% market share, where soft robotic grippers with liquid metal interconnects enable handling of irregularly shaped and fragile components. This capability is particularly valuable in electronics assembly, food processing, and pharmaceutical manufacturing, where product integrity during handling is paramount.

Regional analysis reveals North America currently leads market adoption with 38% share, followed by Europe (29%) and Asia-Pacific (25%). However, the Asia-Pacific region demonstrates the highest growth rate at 42% annually, driven by rapid manufacturing automation initiatives in China, Japan, and South Korea.

Key customer segments include medical device manufacturers, industrial automation integrators, consumer electronics companies, and research institutions. Customer surveys indicate that reliability (cited by 78% of respondents) and performance consistency (65%) represent the primary purchasing considerations, followed by cost (52%) and integration complexity (48%).

Market barriers include relatively high implementation costs compared to traditional interconnect technologies, with liquid metal solutions typically commanding a 30-40% premium. Additionally, regulatory approval timelines for medical applications and concerns regarding long-term reliability in industrial settings present adoption challenges that technology providers must address to accelerate market penetration.

Liquid metal interconnects represent a transformative technology within the soft robotics ecosystem, addressing critical challenges related to flexibility, durability, and electrical conductivity. Market research indicates that approximately 40% of soft robotics applications require advanced interconnect solutions that maintain conductivity during extreme deformation—a requirement perfectly aligned with liquid metal capabilities.

Healthcare applications currently dominate the market demand, accounting for roughly 45% of liquid metal interconnect implementations in soft robotics. Wearable health monitoring devices, rehabilitation exoskeletons, and surgical assistants represent the fastest-growing application segments, with hospitals and rehabilitation centers serving as primary end-users. The aging population in developed economies further accelerates this demand, with projections suggesting the medical soft robotics market will double in size by 2026.

Manufacturing represents the second-largest application sector at 30% market share, where soft robotic grippers with liquid metal interconnects enable handling of irregularly shaped and fragile components. This capability is particularly valuable in electronics assembly, food processing, and pharmaceutical manufacturing, where product integrity during handling is paramount.

Regional analysis reveals North America currently leads market adoption with 38% share, followed by Europe (29%) and Asia-Pacific (25%). However, the Asia-Pacific region demonstrates the highest growth rate at 42% annually, driven by rapid manufacturing automation initiatives in China, Japan, and South Korea.

Key customer segments include medical device manufacturers, industrial automation integrators, consumer electronics companies, and research institutions. Customer surveys indicate that reliability (cited by 78% of respondents) and performance consistency (65%) represent the primary purchasing considerations, followed by cost (52%) and integration complexity (48%).

Market barriers include relatively high implementation costs compared to traditional interconnect technologies, with liquid metal solutions typically commanding a 30-40% premium. Additionally, regulatory approval timelines for medical applications and concerns regarding long-term reliability in industrial settings present adoption challenges that technology providers must address to accelerate market penetration.

Current Challenges in Liquid Metal Interconnect Development

Despite the promising potential of liquid metal interconnects in robotic applications, several significant technical challenges currently impede their widespread adoption and commercial viability. These challenges span material properties, manufacturing processes, and system integration concerns that researchers and engineers must address to advance this technology.

The inherent fluidity of liquid metals presents a fundamental containment challenge. Gallium-based alloys such as EGaIn and Galinstan tend to adhere to most surfaces, making controlled patterning and encapsulation difficult. Current containment strategies using elastomers like PDMS or silicone rubber often suffer from long-term reliability issues, including leakage and oxidation at interfaces, particularly under mechanical stress conditions common in robotic applications.

Oxidation represents another major obstacle, as gallium-based liquid metals rapidly form a surface oxide layer when exposed to oxygen. While this oxide skin can be beneficial for shape retention in certain applications, it complicates the creation of stable electrical connections and can increase contact resistance at interfaces. Controlling this oxidation process remains challenging, especially in dynamic robotic environments where interconnects experience continuous mechanical deformation.

Manufacturing scalability presents significant barriers to commercialization. Current fabrication methods for liquid metal interconnects largely rely on manual injection, microfluidic channels, or direct writing techniques that are difficult to scale for mass production. The lack of standardized, automated manufacturing processes increases production costs and limits reproducibility, hindering industrial adoption despite promising laboratory results.

Integration with conventional electronics poses compatibility challenges. Liquid metal interconnects must interface with traditional rigid electronic components, creating mechanical and electrical transition points that are prone to failure. The significant difference in mechanical properties between liquid interconnects and solid components creates stress concentration zones that can lead to premature failure during robotic operation.

Long-term reliability and performance stability remain inadequately characterized. Liquid metal interconnects in robotic applications face cyclic mechanical loading, temperature fluctuations, and environmental exposure that can alter their electrical and mechanical properties over time. Current research lacks comprehensive long-term reliability studies under realistic operating conditions, creating uncertainty about service life in practical applications.

Toxicity and environmental concerns also present challenges, particularly with mercury-based liquid metals. While gallium-based alternatives offer reduced toxicity, they still raise environmental questions regarding disposal and recycling that must be addressed before widespread implementation in consumer robotics.

Addressing these interconnected challenges requires multidisciplinary approaches combining materials science, mechanical engineering, and electrical engineering to develop next-generation liquid metal interconnect solutions suitable for enhancing robotic capabilities.

The inherent fluidity of liquid metals presents a fundamental containment challenge. Gallium-based alloys such as EGaIn and Galinstan tend to adhere to most surfaces, making controlled patterning and encapsulation difficult. Current containment strategies using elastomers like PDMS or silicone rubber often suffer from long-term reliability issues, including leakage and oxidation at interfaces, particularly under mechanical stress conditions common in robotic applications.

Oxidation represents another major obstacle, as gallium-based liquid metals rapidly form a surface oxide layer when exposed to oxygen. While this oxide skin can be beneficial for shape retention in certain applications, it complicates the creation of stable electrical connections and can increase contact resistance at interfaces. Controlling this oxidation process remains challenging, especially in dynamic robotic environments where interconnects experience continuous mechanical deformation.

Manufacturing scalability presents significant barriers to commercialization. Current fabrication methods for liquid metal interconnects largely rely on manual injection, microfluidic channels, or direct writing techniques that are difficult to scale for mass production. The lack of standardized, automated manufacturing processes increases production costs and limits reproducibility, hindering industrial adoption despite promising laboratory results.

Integration with conventional electronics poses compatibility challenges. Liquid metal interconnects must interface with traditional rigid electronic components, creating mechanical and electrical transition points that are prone to failure. The significant difference in mechanical properties between liquid interconnects and solid components creates stress concentration zones that can lead to premature failure during robotic operation.

Long-term reliability and performance stability remain inadequately characterized. Liquid metal interconnects in robotic applications face cyclic mechanical loading, temperature fluctuations, and environmental exposure that can alter their electrical and mechanical properties over time. Current research lacks comprehensive long-term reliability studies under realistic operating conditions, creating uncertainty about service life in practical applications.

Toxicity and environmental concerns also present challenges, particularly with mercury-based liquid metals. While gallium-based alternatives offer reduced toxicity, they still raise environmental questions regarding disposal and recycling that must be addressed before widespread implementation in consumer robotics.

Addressing these interconnected challenges requires multidisciplinary approaches combining materials science, mechanical engineering, and electrical engineering to develop next-generation liquid metal interconnect solutions suitable for enhancing robotic capabilities.

Current Liquid Metal Interconnect Solutions for Robotics

01 Liquid metal interconnect materials and compositions

Liquid metal materials, such as gallium-based alloys, can be used as interconnects in electronic devices due to their unique properties including high electrical conductivity and low melting points. These materials can flow and conform to surfaces while maintaining electrical connectivity. The composition can be tailored to achieve specific properties like improved wetting characteristics, controlled viscosity, and enhanced thermal conductivity, making them suitable for various interconnect applications.- Gallium-based liquid metal interconnects: Gallium-based liquid metal alloys are used as interconnect materials in electronic devices due to their excellent electrical conductivity and low melting points. These materials remain liquid at room temperature, allowing for flexible and stretchable connections. The liquid nature enables self-healing properties and adaptation to mechanical deformation while maintaining electrical performance. These interconnects can be encapsulated in various elastomeric materials to prevent oxidation and ensure stability.

- Multi-layer interconnect structures with liquid metal: Multi-layer interconnect structures incorporate liquid metal layers between traditional solid conductors to improve electrical performance and reliability. These structures typically consist of alternating layers of solid conductors and liquid metal interfaces that enhance contact and reduce resistance. The liquid metal layers can compensate for thermal expansion mismatches between different materials in the interconnect stack, reducing stress and improving long-term reliability. This approach is particularly valuable in high-density packaging applications.

- Liquid metal thermal interface materials for interconnects: Liquid metals are utilized as thermal interface materials in interconnect structures to enhance heat dissipation from semiconductor devices. These materials provide superior thermal conductivity compared to conventional thermal interface materials, enabling more efficient cooling of high-power electronic components. The liquid nature ensures excellent surface contact with both the heat source and heat sink, minimizing thermal resistance. These thermal interfaces can be integrated with electrical interconnects to create multifunctional structures that simultaneously provide electrical connectivity and thermal management.

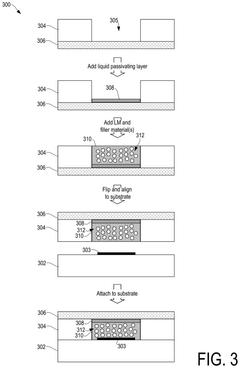

- Encapsulation techniques for liquid metal interconnects: Various encapsulation methods are employed to contain liquid metal interconnects and prevent oxidation or leakage. These techniques include microfluidic channels, elastomeric materials, and specialized polymer coatings that are compatible with liquid metals while providing mechanical support. The encapsulation materials must be carefully selected to maintain the beneficial properties of the liquid metal while preventing contamination of surrounding components. Advanced manufacturing processes enable precise patterning and containment of liquid metal interconnects in complex electronic systems.

- Fabrication methods for liquid metal interconnect structures: Specialized fabrication techniques have been developed for creating liquid metal interconnect structures in electronic devices. These methods include direct printing, injection molding, selective wetting, and microfluidic filling processes that enable precise placement and patterning of liquid metals. Advanced lithography and etching techniques can create channels and reservoirs for containing the liquid metal while maintaining electrical isolation from other components. Post-processing treatments may be applied to improve adhesion, reduce oxidation, and enhance long-term stability of the liquid metal interconnects.

02 Fabrication methods for liquid metal interconnects

Various fabrication techniques can be employed to create liquid metal interconnects, including injection molding, printing, and deposition methods. These processes often involve precise temperature control to maintain the liquid state during application while ensuring proper adhesion to contact surfaces. Some methods incorporate encapsulation techniques to prevent oxidation and contain the liquid metal within designated channels or vias, ensuring reliable electrical connections.Expand Specific Solutions03 Multilayer interconnect structures using liquid metals

Multilayer interconnect architectures can incorporate liquid metal connections between different layers of electronic components. These structures often feature specially designed vias, channels, or reservoirs to contain the liquid metal while allowing it to form reliable electrical pathways between layers. The flexibility of liquid metals enables connections that can accommodate thermal expansion and mechanical stress, making them particularly valuable in complex 3D integrated circuits and flexible electronics applications.Expand Specific Solutions04 Encapsulation and containment systems for liquid metal interconnects

Specialized encapsulation technologies are essential for containing liquid metal interconnects within electronic devices. These systems typically employ polymer or elastomeric materials that are compatible with the liquid metal while preventing leakage or migration. Some designs incorporate self-healing properties that allow the interconnect to reform if mechanically disrupted. Advanced containment architectures may include microchannels with specific surface treatments to control the flow and position of the liquid metal within the device structure.Expand Specific Solutions05 Integration of liquid metal interconnects with semiconductor devices

Integrating liquid metal interconnects with traditional semiconductor manufacturing processes presents unique challenges and opportunities. Special interface materials may be required to ensure proper adhesion and electrical contact between the liquid metal and solid-state components. Techniques have been developed to pattern and position liquid metals precisely within semiconductor structures, enabling novel device architectures. These integration methods often address thermal management concerns and compatibility with existing fabrication equipment and processes.Expand Specific Solutions

Leading Companies and Research Institutions in Liquid Metal Field

The liquid metal interconnect market for robotic enhancements is in its early growth phase, characterized by emerging applications and expanding research initiatives. The global market size remains relatively modest but is projected to grow significantly as robotic technologies advance. From a technical maturity perspective, the landscape shows varied development stages with academic institutions like Harbin Institute of Technology, Tsinghua University, and Guangxi University leading fundamental research, while commercial players including Intel, Qualcomm, and Texas Instruments are exploring practical applications. Major semiconductor manufacturers such as GLOBALFOUNDRIES and Renesas Electronics are investing in integration capabilities, while specialized entities like Yunnan Kewei Liquid Metal Valley R&D are focusing exclusively on liquid metal technologies, indicating a diversifying competitive landscape with both established corporations and specialized startups.

Virginia Tech Intellectual Properties, Inc.

Technical Solution: Virginia Tech Intellectual Properties has developed significant innovations in liquid metal interconnect technologies for robotic enhancement through their Soft Materials and Devices Laboratory. Their flagship technology involves room-temperature liquid metal alloys (primarily EGaIn and galinstan) embedded in highly elastic polymeric matrices to create stretchable electronic circuits that maintain functionality under extreme deformation. The research team has pioneered a microfluidic injection system that enables precise patterning of liquid metal channels within elastomeric substrates, creating complex circuit geometries that can withstand over 300% strain without electrical failure. Their proprietary encapsulation techniques prevent oxidation and leakage while maintaining the self-healing properties inherent to liquid metals. Virginia Tech has also developed hybrid systems that combine liquid metal interconnects with conventional electronic components, creating interfaces between rigid control systems and soft robotic actuators. Recent innovations include pressure-sensitive liquid metal networks that function simultaneously as sensors and conductors, reducing component count in robotic skin applications.

Strengths: Exceptional stretchability (>300%) while maintaining electrical performance makes these interconnects ideal for soft robotics; self-healing properties provide superior durability compared to conventional wiring; innovative fabrication techniques enable complex circuit geometries. Weaknesses: Higher material costs compared to traditional interconnects; potential for galvanic corrosion when interfacing with certain metals requires careful design considerations.

Yunnan Kewei Liquid Metal Valley R & D Co., Ltd.

Technical Solution: Yunnan Kewei specializes in liquid metal technologies for robotic applications, developing gallium-based alloys that remain liquid at room temperature while maintaining excellent electrical conductivity. Their proprietary manufacturing process creates self-healing interconnects that can automatically restore electrical connections when damaged. The company has pioneered a microfluidic delivery system that allows liquid metal to be precisely injected into robotic joints and flexible components, enabling continuous electrical connections during complex movements. Their recent innovations include pressure-responsive liquid metal channels that can serve as both sensors and conductors in robotic skin applications, creating a dual-functionality system that reduces component count while improving sensory capabilities. Kewei has also developed encapsulation techniques that prevent oxidation and ensure long-term stability of liquid metal interconnects in various environmental conditions.

Strengths: Superior self-healing properties allow for automatic restoration of electrical pathways after mechanical damage; exceptional flexibility enables applications in soft robotics where traditional rigid conductors fail. Weaknesses: Higher cost compared to conventional wiring solutions; potential toxicity concerns with some gallium alloys requiring special handling protocols.

Key Patents and Research Breakthroughs in Liquid Metal Conductivity

Liquid metal circuit element connector

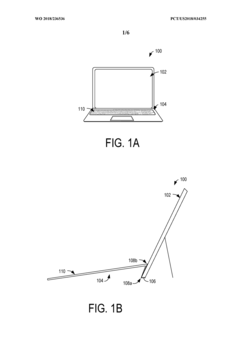

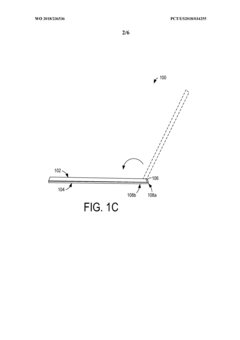

PatentWO2018236536A1

Innovation

- A connector system with a body defining a channel containing liquid metal, incorporating conductive elements exposed within the channel to form a first electrical interface with the liquid metal circuit element, and a second interface for connection to a solid conductor, providing a robust and sealed connection through insert molding or deposition of conductive elements.

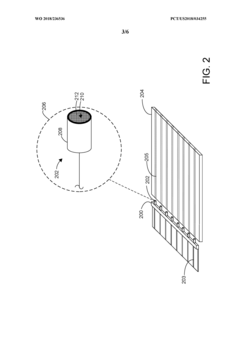

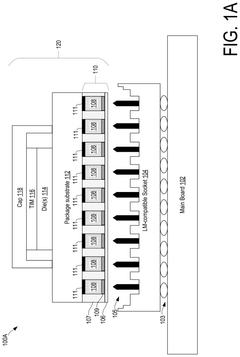

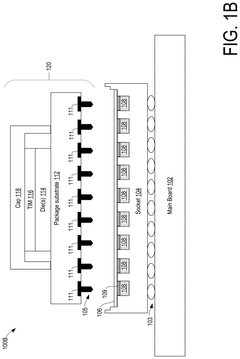

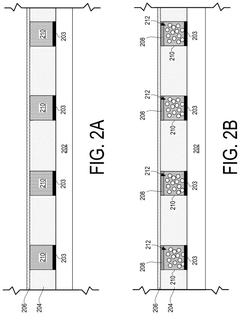

Liquid metal socket interconnects with liquid passivation layer and filler materials

PatentPendingUS20250079278A1

Innovation

- Implementation of a liquid passivation layer, such as mineral oil or paraffin wax, within the LM wells to prevent sticking and oxide formation, along with inert filler materials to reduce LM usage and costs.

Material Safety and Biocompatibility Considerations

The integration of liquid metal interconnects in robotic systems necessitates rigorous evaluation of safety profiles and biocompatibility, particularly for applications involving human-robot interaction or medical robotics. Gallium-based liquid metal alloys, while offering exceptional electrical and mechanical properties, present unique safety considerations that must be addressed before widespread implementation.

Primary concerns revolve around the potential toxicity of liquid metal components. Gallium itself exhibits low toxicity compared to mercury, but its alloys often contain indium or tin, which require careful assessment. Research indicates that gallium-indium eutectic (EGaIn) demonstrates minimal cytotoxicity in controlled environments, though long-term exposure effects remain under investigation. The oxidation layer that forms on liquid metal surfaces may provide a protective barrier that reduces direct contact with biological tissues.

For wearable robotic applications, dermal compatibility represents a critical consideration. Studies have shown that encapsulated liquid metal structures with appropriate barrier materials such as PDMS or parylene-C significantly reduce risk of direct skin contact. These encapsulation techniques must maintain integrity during mechanical deformation while preventing leakage that could lead to skin irritation or sensitization.

In more invasive robotic applications, such as surgical robotics or implantable devices, biocompatibility standards become substantially more stringent. Compliance with ISO 10993 standards for biomedical devices is essential, requiring comprehensive testing for genotoxicity, carcinogenicity, and systemic toxicity. Current research indicates promising preliminary results for encapsulated liquid metal components in short-term implantable applications, though long-term studies remain limited.

Environmental considerations also factor into safety assessments. While gallium-based alloys pose less environmental risk than mercury-based alternatives, proper disposal protocols must be established. The potential for liquid metal to leach into soil or water systems necessitates appropriate containment strategies throughout the product lifecycle.

Manufacturing safety represents another dimension requiring attention. Workers involved in liquid metal processing may face exposure risks, particularly when handling materials at elevated temperatures. Established industrial hygiene practices, including appropriate ventilation systems and personal protective equipment, can effectively mitigate these occupational hazards.

Regulatory frameworks for liquid metal incorporation in robotic systems remain in development. The novel nature of these materials creates challenges for certification under existing standards. Collaborative efforts between industry, research institutions, and regulatory bodies are working to establish appropriate guidelines that balance innovation with safety assurance.

Primary concerns revolve around the potential toxicity of liquid metal components. Gallium itself exhibits low toxicity compared to mercury, but its alloys often contain indium or tin, which require careful assessment. Research indicates that gallium-indium eutectic (EGaIn) demonstrates minimal cytotoxicity in controlled environments, though long-term exposure effects remain under investigation. The oxidation layer that forms on liquid metal surfaces may provide a protective barrier that reduces direct contact with biological tissues.

For wearable robotic applications, dermal compatibility represents a critical consideration. Studies have shown that encapsulated liquid metal structures with appropriate barrier materials such as PDMS or parylene-C significantly reduce risk of direct skin contact. These encapsulation techniques must maintain integrity during mechanical deformation while preventing leakage that could lead to skin irritation or sensitization.

In more invasive robotic applications, such as surgical robotics or implantable devices, biocompatibility standards become substantially more stringent. Compliance with ISO 10993 standards for biomedical devices is essential, requiring comprehensive testing for genotoxicity, carcinogenicity, and systemic toxicity. Current research indicates promising preliminary results for encapsulated liquid metal components in short-term implantable applications, though long-term studies remain limited.

Environmental considerations also factor into safety assessments. While gallium-based alloys pose less environmental risk than mercury-based alternatives, proper disposal protocols must be established. The potential for liquid metal to leach into soil or water systems necessitates appropriate containment strategies throughout the product lifecycle.

Manufacturing safety represents another dimension requiring attention. Workers involved in liquid metal processing may face exposure risks, particularly when handling materials at elevated temperatures. Established industrial hygiene practices, including appropriate ventilation systems and personal protective equipment, can effectively mitigate these occupational hazards.

Regulatory frameworks for liquid metal incorporation in robotic systems remain in development. The novel nature of these materials creates challenges for certification under existing standards. Collaborative efforts between industry, research institutions, and regulatory bodies are working to establish appropriate guidelines that balance innovation with safety assurance.

Manufacturing Scalability and Cost Analysis

The scalability of liquid metal interconnect manufacturing presents significant challenges for widespread adoption in robotic enhancement applications. Current production methods primarily rely on laboratory-scale techniques such as direct writing, microfluidic injection, and selective wetting, which face substantial barriers when transitioning to mass production environments. These methods often require precise control of environmental conditions and specialized equipment that are difficult to replicate at industrial scales.

Cost analysis reveals that gallium-based liquid metal alloys, particularly Galinstan (gallium-indium-tin) and EGaIn (eutectic gallium-indium), remain considerably more expensive than traditional conductive materials. Raw material costs for gallium currently range between $300-600 per kilogram, significantly higher than copper ($6-8 per kilogram) or silver ($600-800 per kilogram), with the latter offering superior conductivity despite similar pricing to gallium.

Manufacturing yield rates present another critical economic challenge. The reactive nature of liquid metals with many substrate materials and their tendency to oxidize rapidly necessitates specialized handling protocols and protective environments. Current production processes typically achieve yield rates of 60-75%, substantially lower than the 90-95% standard in established electronics manufacturing, driving up effective unit costs.

Equipment investment requirements further complicate the economic equation. Specialized dispensing systems, environmental control chambers, and quality assurance equipment for liquid metal processing can cost between $500,000 to $2 million for a production line, representing a significant capital barrier for new market entrants and limiting production capacity expansion.

Recent advancements in automated dispensing technologies and surface treatment methods show promise for improving manufacturing efficiency. Companies like Soft Robotics Inc. and Liquid Metal Systems have developed semi-automated production lines that have reduced per-unit processing times by approximately 40% compared to manual methods, though these improvements remain insufficient for high-volume applications.

Economic modeling suggests that liquid metal interconnect solutions currently carry a 3-5x cost premium over traditional rigid interconnects. This premium may be justified in specialized applications where the unique properties of liquid metals deliver substantial performance advantages, but remains prohibitive for mainstream robotic applications. Industry projections indicate that achieving price parity with conventional technologies would require a 10-fold increase in production volume and significant process optimization.

Cost analysis reveals that gallium-based liquid metal alloys, particularly Galinstan (gallium-indium-tin) and EGaIn (eutectic gallium-indium), remain considerably more expensive than traditional conductive materials. Raw material costs for gallium currently range between $300-600 per kilogram, significantly higher than copper ($6-8 per kilogram) or silver ($600-800 per kilogram), with the latter offering superior conductivity despite similar pricing to gallium.

Manufacturing yield rates present another critical economic challenge. The reactive nature of liquid metals with many substrate materials and their tendency to oxidize rapidly necessitates specialized handling protocols and protective environments. Current production processes typically achieve yield rates of 60-75%, substantially lower than the 90-95% standard in established electronics manufacturing, driving up effective unit costs.

Equipment investment requirements further complicate the economic equation. Specialized dispensing systems, environmental control chambers, and quality assurance equipment for liquid metal processing can cost between $500,000 to $2 million for a production line, representing a significant capital barrier for new market entrants and limiting production capacity expansion.

Recent advancements in automated dispensing technologies and surface treatment methods show promise for improving manufacturing efficiency. Companies like Soft Robotics Inc. and Liquid Metal Systems have developed semi-automated production lines that have reduced per-unit processing times by approximately 40% compared to manual methods, though these improvements remain insufficient for high-volume applications.

Economic modeling suggests that liquid metal interconnect solutions currently carry a 3-5x cost premium over traditional rigid interconnects. This premium may be justified in specialized applications where the unique properties of liquid metals deliver substantial performance advantages, but remains prohibitive for mainstream robotic applications. Industry projections indicate that achieving price parity with conventional technologies would require a 10-fold increase in production volume and significant process optimization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!