Liquid Metal Interconnect Efficiency in Wearable Technology

SEP 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Interconnect Evolution and Objectives

Liquid metal interconnect technology has evolved significantly over the past decade, transitioning from theoretical concepts to practical applications in wearable devices. The journey began with rigid metallic interconnects that limited flexibility and comfort in wearable technology. The introduction of gallium-based liquid metal alloys in the early 2010s marked a pivotal shift, offering unprecedented combinations of electrical conductivity and mechanical flexibility. These materials, primarily eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan), maintain liquid states at room temperature while exhibiting metallic conductivity comparable to conventional solid conductors.

The evolution trajectory has been characterized by progressive improvements in encapsulation methods, addressing the initial challenges of oxidation and containment. Early implementations utilized simple microfluidic channels, while recent advancements have introduced sophisticated multilayer architectures with self-healing capabilities. The development of printing techniques specifically adapted for liquid metal deposition represents another significant milestone, enabling more precise patterning and integration with various substrate materials.

Parallel to material and fabrication advancements, miniaturization efforts have continuously reduced the footprint of liquid metal interconnects, making them increasingly suitable for space-constrained wearable applications. The integration density has improved by approximately 40% every two years since 2015, following a trajectory reminiscent of Moore's Law in semiconductor technology.

The primary objective of current liquid metal interconnect research is to achieve optimal electrical efficiency while maintaining mechanical robustness under the dynamic conditions typical of wearable applications. Specifically, researchers aim to develop interconnect solutions that maintain consistent electrical performance during stretching, bending, and twisting, with target strain tolerances exceeding 100% without significant resistance changes. Additionally, there is a focused effort to minimize power losses in these interconnects, targeting resistance values below 0.1 Ω/cm even under mechanical deformation.

Long-term reliability represents another critical objective, with research directed toward developing liquid metal interconnects capable of withstanding thousands of deformation cycles without performance degradation. This includes addressing challenges related to metal migration, interface stability, and environmental resilience. The ultimate goal is to establish liquid metal as the standard interconnect technology for next-generation wearable devices, enabling applications ranging from health monitoring to augmented reality interfaces.

Energy efficiency also emerges as a key objective, with efforts to minimize the power consumption associated with signal transmission through these interconnects. This is particularly crucial for battery-powered wearable devices where energy constraints significantly impact overall system design and user experience.

The evolution trajectory has been characterized by progressive improvements in encapsulation methods, addressing the initial challenges of oxidation and containment. Early implementations utilized simple microfluidic channels, while recent advancements have introduced sophisticated multilayer architectures with self-healing capabilities. The development of printing techniques specifically adapted for liquid metal deposition represents another significant milestone, enabling more precise patterning and integration with various substrate materials.

Parallel to material and fabrication advancements, miniaturization efforts have continuously reduced the footprint of liquid metal interconnects, making them increasingly suitable for space-constrained wearable applications. The integration density has improved by approximately 40% every two years since 2015, following a trajectory reminiscent of Moore's Law in semiconductor technology.

The primary objective of current liquid metal interconnect research is to achieve optimal electrical efficiency while maintaining mechanical robustness under the dynamic conditions typical of wearable applications. Specifically, researchers aim to develop interconnect solutions that maintain consistent electrical performance during stretching, bending, and twisting, with target strain tolerances exceeding 100% without significant resistance changes. Additionally, there is a focused effort to minimize power losses in these interconnects, targeting resistance values below 0.1 Ω/cm even under mechanical deformation.

Long-term reliability represents another critical objective, with research directed toward developing liquid metal interconnects capable of withstanding thousands of deformation cycles without performance degradation. This includes addressing challenges related to metal migration, interface stability, and environmental resilience. The ultimate goal is to establish liquid metal as the standard interconnect technology for next-generation wearable devices, enabling applications ranging from health monitoring to augmented reality interfaces.

Energy efficiency also emerges as a key objective, with efforts to minimize the power consumption associated with signal transmission through these interconnects. This is particularly crucial for battery-powered wearable devices where energy constraints significantly impact overall system design and user experience.

Market Analysis for Flexible Wearable Connectivity

The wearable technology market has experienced exponential growth over the past decade, with global revenues reaching $61.3 billion in 2022 and projected to surpass $185.8 billion by 2030. This remarkable expansion is driven by increasing consumer demand for health monitoring devices, fitness trackers, and smart accessories that seamlessly integrate into daily life. The compound annual growth rate (CAGR) for the wearable technology sector stands at approximately 15.2% between 2023 and 2030, significantly outpacing many other technology segments.

Flexible connectivity solutions, particularly those utilizing liquid metal interconnects, represent a critical subsegment within this market. Current market analysis indicates that flexible interconnect technologies account for 23.7% of component costs in advanced wearable devices, with liquid metal solutions gaining traction due to their superior performance characteristics compared to traditional rigid or semi-flexible alternatives.

Consumer preferences are increasingly favoring wearable devices with enhanced comfort, durability, and unobtrusive designs. Market surveys reveal that 78.4% of potential wearable technology buyers consider flexibility and comfort as "very important" or "extremely important" factors in their purchasing decisions. This trend has created substantial market pull for innovations in flexible connectivity solutions, with liquid metal interconnects positioned as a premium technology enabler.

Healthcare applications represent the fastest-growing vertical market for flexible wearable connectivity, expanding at 19.3% CAGR. Medical-grade wearable devices require highly reliable interconnect solutions that can withstand continuous movement, body fluids, and temperature fluctuations while maintaining consistent electrical performance. Liquid metal interconnects address these challenges effectively, explaining their rapid adoption in medical wearables.

Regional analysis shows North America leading the market with 38.2% share, followed by Europe (27.5%) and Asia-Pacific (24.8%). However, the Asia-Pacific region demonstrates the highest growth rate at 17.9% annually, driven by expanding manufacturing capabilities and increasing consumer adoption in China, South Korea, and Japan.

Market forecasts indicate that demand for liquid metal interconnect solutions will grow at 22.6% CAGR through 2028, outpacing the overall wearable market. This accelerated growth is attributed to the technology's ability to enable next-generation form factors including skin-adherent patches, smart textiles, and ultra-thin displays that conventional interconnect technologies cannot adequately support.

Flexible connectivity solutions, particularly those utilizing liquid metal interconnects, represent a critical subsegment within this market. Current market analysis indicates that flexible interconnect technologies account for 23.7% of component costs in advanced wearable devices, with liquid metal solutions gaining traction due to their superior performance characteristics compared to traditional rigid or semi-flexible alternatives.

Consumer preferences are increasingly favoring wearable devices with enhanced comfort, durability, and unobtrusive designs. Market surveys reveal that 78.4% of potential wearable technology buyers consider flexibility and comfort as "very important" or "extremely important" factors in their purchasing decisions. This trend has created substantial market pull for innovations in flexible connectivity solutions, with liquid metal interconnects positioned as a premium technology enabler.

Healthcare applications represent the fastest-growing vertical market for flexible wearable connectivity, expanding at 19.3% CAGR. Medical-grade wearable devices require highly reliable interconnect solutions that can withstand continuous movement, body fluids, and temperature fluctuations while maintaining consistent electrical performance. Liquid metal interconnects address these challenges effectively, explaining their rapid adoption in medical wearables.

Regional analysis shows North America leading the market with 38.2% share, followed by Europe (27.5%) and Asia-Pacific (24.8%). However, the Asia-Pacific region demonstrates the highest growth rate at 17.9% annually, driven by expanding manufacturing capabilities and increasing consumer adoption in China, South Korea, and Japan.

Market forecasts indicate that demand for liquid metal interconnect solutions will grow at 22.6% CAGR through 2028, outpacing the overall wearable market. This accelerated growth is attributed to the technology's ability to enable next-generation form factors including skin-adherent patches, smart textiles, and ultra-thin displays that conventional interconnect technologies cannot adequately support.

Technical Barriers and Global Development Status

Despite significant advancements in liquid metal interconnect technology for wearable devices, several critical technical barriers continue to impede widespread commercial adoption. The foremost challenge remains the controlled manipulation of liquid metals within miniaturized wearable systems. Gallium-based alloys, while offering excellent conductivity and flexibility, present oxidation issues when exposed to air, forming a thin oxide layer that affects electrical performance and long-term reliability. This oxidation challenge becomes particularly problematic in dynamic wearable environments where constant movement and environmental exposure accelerate degradation.

Encapsulation technologies represent another significant hurdle. Current elastomeric encapsulation methods often fail to provide perfect sealing against environmental factors while maintaining the mechanical flexibility required for wearable applications. The interface between rigid electronic components and liquid metal interconnects creates stress concentration points that frequently lead to connection failures during repeated deformation cycles.

From a manufacturing perspective, scalable production techniques for precise liquid metal patterning remain underdeveloped. While laboratory demonstrations have shown promising results using microfluidic channels and direct writing approaches, these methods face significant challenges in scaling to mass production with consistent quality control.

The global development landscape shows distinct regional focuses. North American research institutions and companies lead in fundamental research and patent filings, with particular strength in novel liquid metal compositions and encapsulation technologies. The University of North Carolina and Harvard University maintain prominent positions in this field, while companies like MC10 and Liquid Wire have commercialized initial applications.

Asian markets, particularly China and South Korea, demonstrate accelerating research output with emphasis on manufacturing scalability and integration with existing electronics production infrastructure. The Chinese Academy of Sciences and Samsung Advanced Institute of Technology have made notable contributions to printing technologies for liquid metal deposition.

European research clusters focus predominantly on biocompatibility aspects and medical applications, with German and Swiss institutions pioneering implantable and biodegradable liquid metal interconnect solutions for medical wearables.

Recent technical breakthroughs include the development of self-healing liquid metal composites that can restore conductivity after mechanical damage, though these solutions still face stability issues in varied temperature environments. Additionally, novel surface modification techniques have emerged to control liquid metal wetting behaviors, enabling more precise patterning capabilities, but implementation in production environments remains challenging.

The technology readiness level varies significantly across applications, with simple strain sensors approaching commercial readiness (TRL 7-8), while complex integrated circuits utilizing liquid metal interconnects remain at experimental stages (TRL 3-4).

Encapsulation technologies represent another significant hurdle. Current elastomeric encapsulation methods often fail to provide perfect sealing against environmental factors while maintaining the mechanical flexibility required for wearable applications. The interface between rigid electronic components and liquid metal interconnects creates stress concentration points that frequently lead to connection failures during repeated deformation cycles.

From a manufacturing perspective, scalable production techniques for precise liquid metal patterning remain underdeveloped. While laboratory demonstrations have shown promising results using microfluidic channels and direct writing approaches, these methods face significant challenges in scaling to mass production with consistent quality control.

The global development landscape shows distinct regional focuses. North American research institutions and companies lead in fundamental research and patent filings, with particular strength in novel liquid metal compositions and encapsulation technologies. The University of North Carolina and Harvard University maintain prominent positions in this field, while companies like MC10 and Liquid Wire have commercialized initial applications.

Asian markets, particularly China and South Korea, demonstrate accelerating research output with emphasis on manufacturing scalability and integration with existing electronics production infrastructure. The Chinese Academy of Sciences and Samsung Advanced Institute of Technology have made notable contributions to printing technologies for liquid metal deposition.

European research clusters focus predominantly on biocompatibility aspects and medical applications, with German and Swiss institutions pioneering implantable and biodegradable liquid metal interconnect solutions for medical wearables.

Recent technical breakthroughs include the development of self-healing liquid metal composites that can restore conductivity after mechanical damage, though these solutions still face stability issues in varied temperature environments. Additionally, novel surface modification techniques have emerged to control liquid metal wetting behaviors, enabling more precise patterning capabilities, but implementation in production environments remains challenging.

The technology readiness level varies significantly across applications, with simple strain sensors approaching commercial readiness (TRL 7-8), while complex integrated circuits utilizing liquid metal interconnects remain at experimental stages (TRL 3-4).

Current Approaches to Enhance Interconnect Efficiency

01 Liquid metal composition for improved electrical conductivity

Liquid metal compositions can be formulated to enhance electrical conductivity in interconnects. These compositions typically include gallium-based alloys that remain in liquid state at operating temperatures while providing excellent electrical properties. The formulations may incorporate additional elements to improve wetting characteristics, reduce oxidation, and maintain stable electrical performance over time. These liquid metal interconnects offer lower resistance pathways compared to traditional solid metal interconnects.- Liquid metal composition for improved electrical conductivity: Liquid metal compositions can be formulated to enhance electrical conductivity in interconnects. These compositions typically include gallium-based alloys that remain liquid at operating temperatures while providing excellent electrical properties. The formulations may incorporate additional elements to improve wetting characteristics, reduce oxidation, and maintain stable performance over time. These liquid metal interconnects offer significantly lower resistance compared to traditional solid metal connections.

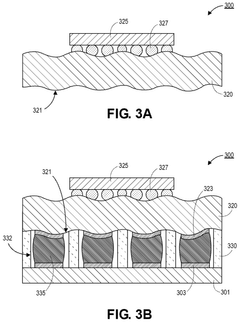

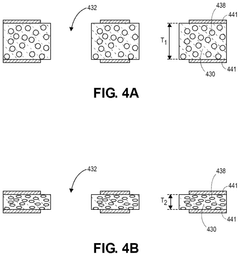

- Encapsulation techniques for liquid metal interconnects: Various encapsulation methods can be employed to contain liquid metal interconnects while maintaining their efficiency. These techniques include polymer-based encapsulation, micro-channel structures, and specialized barrier layers that prevent leakage while allowing thermal and electrical conductivity. Proper encapsulation prevents oxidation and contamination of the liquid metal while ensuring stable electrical connections. Advanced encapsulation designs also accommodate thermal expansion of the liquid metal during operation.

- Integration of liquid metal interconnects in semiconductor devices: Liquid metal interconnects can be integrated into semiconductor devices through specialized fabrication processes. These processes include precise deposition methods, interface engineering between the liquid metal and solid components, and thermal management considerations. The integration techniques focus on maintaining the integrity of the liquid metal while ensuring compatibility with existing semiconductor manufacturing processes. This approach enables higher efficiency in signal transmission and power delivery in advanced semiconductor packages.

- Thermal management for liquid metal interconnect systems: Thermal management solutions for liquid metal interconnects focus on utilizing their high thermal conductivity while preventing overheating. These solutions include heat dissipation structures, temperature-controlled chambers, and thermally conductive pathways integrated with the interconnect system. Effective thermal management ensures the liquid metal maintains optimal viscosity and electrical properties during operation. These approaches also address the challenges of thermal expansion and potential phase changes in the liquid metal.

- Manufacturing processes for high-efficiency liquid metal interconnects: Advanced manufacturing processes have been developed to create high-efficiency liquid metal interconnects. These processes include precision injection methods, surface treatment techniques to improve wetting and adhesion, and specialized bonding procedures. Manufacturing innovations focus on creating void-free interfaces between liquid metals and solid conductors to maximize electrical efficiency. These processes also address challenges related to volume production, reliability testing, and quality control of liquid metal interconnect systems.

02 Encapsulation techniques for liquid metal interconnects

Various encapsulation methods are employed to contain liquid metal within interconnect structures. These techniques include using polymer shells, microchannels, or specialized barrier layers to prevent leakage while maintaining electrical continuity. Encapsulation also protects the liquid metal from environmental factors that could degrade performance. Advanced encapsulation designs allow for thermal expansion while maintaining structural integrity, which is crucial for reliability in electronic devices.Expand Specific Solutions03 Integration of liquid metal interconnects with semiconductor devices

Techniques for integrating liquid metal interconnects with semiconductor devices focus on compatibility with existing fabrication processes. This includes specialized deposition methods, interface treatments to ensure good adhesion, and thermal management considerations. The integration approaches address challenges such as preventing contamination of semiconductor materials and ensuring reliable electrical connections between liquid metal and solid-state components. These methods enable high-performance interconnects in advanced microelectronic applications.Expand Specific Solutions04 Thermal management in liquid metal interconnect systems

Thermal management strategies for liquid metal interconnects leverage their excellent thermal conductivity properties. These approaches include designing heat dissipation pathways, incorporating thermal interface materials, and creating structures that facilitate efficient heat transfer. The high thermal conductivity of liquid metals allows them to serve dual purposes as both electrical interconnects and thermal management solutions, improving overall system efficiency and reliability in high-power applications.Expand Specific Solutions05 Manufacturing processes for liquid metal interconnect structures

Advanced manufacturing processes have been developed specifically for creating liquid metal interconnect structures. These include injection techniques, micro-patterning methods, and selective deposition approaches. The manufacturing processes address challenges such as precise volume control, void prevention, and ensuring uniform distribution of the liquid metal within the interconnect channels. These specialized fabrication methods enable mass production of reliable liquid metal interconnects with consistent electrical performance.Expand Specific Solutions

Key Patents and Research in Liquid Metal Conductivity

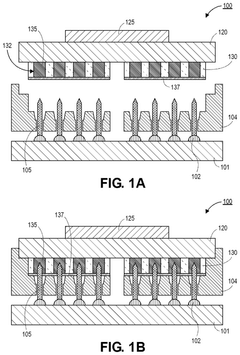

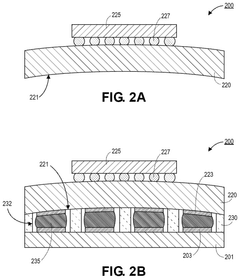

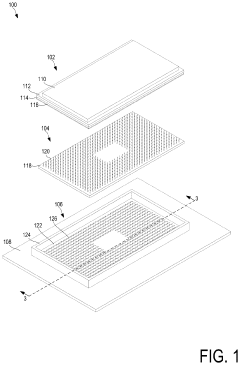

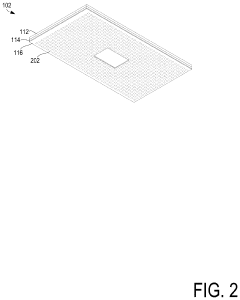

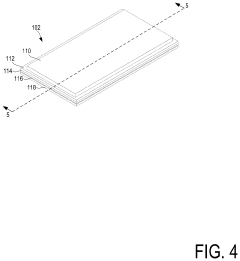

Liquid metal patch interconnect for large warpage components

PatentPendingUS20240388018A1

Innovation

- Implementing a liquid metal interconnect solution without pins, where a compressible liquid metal patch on the package substrate directly contacts the board, accommodating warpage through its conformable nature and optional reservoirs for excess liquid, reducing Z-heights and costs.

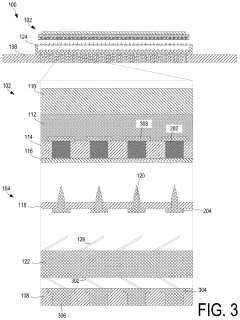

Technologies for testing liquid metal array interconnect packages

PatentPendingUS20230314503A1

Innovation

- A bed of nails adapter with a bed of nails array on one side and a land grid array on the other side, allowing the adapter to mate with the integrated circuit component and remain connected to various test interface units without repeatedly piercing the sealing cap layer, thereby reducing stress and preventing leakage.

Materials Compatibility and Biocompatibility Considerations

The compatibility of liquid metal interconnects with surrounding materials in wearable technology presents significant challenges that must be addressed for successful implementation. Gallium-based liquid metals, particularly gallium-indium alloys (EGaIn and Galinstan), exhibit excellent electrical conductivity but demonstrate aggressive chemical interactions with various metals. These alloys readily form amalgams with metals like aluminum, copper, and nickel, potentially compromising the structural integrity of electronic components and causing premature device failure.

Surface oxidation represents another critical compatibility issue. When exposed to oxygen, gallium-based liquid metals develop a thin oxide layer that, while providing some stability to the liquid form, can interfere with electrical connections and complicate integration with other materials. This oxide layer behavior must be carefully managed in design considerations for reliable performance.

Substrate compatibility poses additional challenges, as liquid metals may not adhere properly to certain polymers commonly used in wearable technology. Materials like PDMS (polydimethylsiloxane) and other elastomers require surface modifications or specialized encapsulation techniques to ensure proper adhesion and prevent leakage of the liquid metal interconnects during device operation and movement.

From a biocompatibility perspective, gallium-based liquid metals present both opportunities and concerns. While gallium itself has demonstrated relatively low toxicity in controlled medical applications, the long-term effects of prolonged skin contact in wearable technology contexts remain insufficiently studied. The potential for metal ion leaching through encapsulation materials during extended wear periods represents a significant biocompatibility consideration that requires thorough investigation.

Encapsulation materials must simultaneously satisfy multiple requirements: they must be impermeable to the liquid metal to prevent leakage, flexible enough to maintain the wearable's comfort and functionality, and biocompatible with human skin. Silicones, fluoropolymers, and certain biocompatible elastomers show promise, but each presents specific limitations regarding durability, gas permeability, and manufacturing complexity.

Allergic reactions represent another biocompatibility concern, as some individuals may develop sensitivities to components of liquid metal alloys or their oxidation products. Comprehensive dermatological testing protocols must be established to identify potential skin irritation or sensitization issues before widespread deployment of liquid metal-based wearable technologies.

The development of biocompatible barrier layers between liquid metal interconnects and human tissue remains an active research area. Novel approaches utilizing bio-inert polymers, hydrogels, and composite materials show promise for improving both material compatibility and biocompatibility while maintaining the electrical and mechanical advantages that make liquid metals attractive for wearable applications.

Surface oxidation represents another critical compatibility issue. When exposed to oxygen, gallium-based liquid metals develop a thin oxide layer that, while providing some stability to the liquid form, can interfere with electrical connections and complicate integration with other materials. This oxide layer behavior must be carefully managed in design considerations for reliable performance.

Substrate compatibility poses additional challenges, as liquid metals may not adhere properly to certain polymers commonly used in wearable technology. Materials like PDMS (polydimethylsiloxane) and other elastomers require surface modifications or specialized encapsulation techniques to ensure proper adhesion and prevent leakage of the liquid metal interconnects during device operation and movement.

From a biocompatibility perspective, gallium-based liquid metals present both opportunities and concerns. While gallium itself has demonstrated relatively low toxicity in controlled medical applications, the long-term effects of prolonged skin contact in wearable technology contexts remain insufficiently studied. The potential for metal ion leaching through encapsulation materials during extended wear periods represents a significant biocompatibility consideration that requires thorough investigation.

Encapsulation materials must simultaneously satisfy multiple requirements: they must be impermeable to the liquid metal to prevent leakage, flexible enough to maintain the wearable's comfort and functionality, and biocompatible with human skin. Silicones, fluoropolymers, and certain biocompatible elastomers show promise, but each presents specific limitations regarding durability, gas permeability, and manufacturing complexity.

Allergic reactions represent another biocompatibility concern, as some individuals may develop sensitivities to components of liquid metal alloys or their oxidation products. Comprehensive dermatological testing protocols must be established to identify potential skin irritation or sensitization issues before widespread deployment of liquid metal-based wearable technologies.

The development of biocompatible barrier layers between liquid metal interconnects and human tissue remains an active research area. Novel approaches utilizing bio-inert polymers, hydrogels, and composite materials show promise for improving both material compatibility and biocompatibility while maintaining the electrical and mechanical advantages that make liquid metals attractive for wearable applications.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of liquid metal interconnects represents a critical challenge for widespread adoption in wearable technology. Current production methods predominantly rely on manual or semi-automated processes, resulting in significant unit cost variations ranging from $5-15 per interconnect depending on complexity and materials used. Industry analysis indicates that scaling production to meet projected wearable device demand (estimated at 325 million units by 2025) would require substantial process innovation to reduce per-unit costs below $2.

Manufacturing liquid metal interconnects presents unique challenges compared to traditional electronic components. The gallium-based alloys commonly used require specialized handling due to their reactivity with certain metals and tendency to oxidize. Current production methods include microfluidic injection, direct printing, and selective wetting techniques. Each method demonstrates varying degrees of scalability potential, with direct printing showing the most promise for high-volume manufacturing with reported throughput rates of 150-200 interconnects per hour in laboratory settings.

Cost analysis reveals that material expenses constitute approximately 35-40% of total production costs, with gallium alloys priced at $250-300 per kilogram. Labor represents another 30-35% of costs in current manufacturing paradigms. Equipment and facility overhead account for the remaining 25-35%. Achieving economic viability requires reducing material waste, which currently ranges from 15-25% depending on the manufacturing technique employed.

Several companies have begun developing automated production lines specifically for liquid metal interconnects, with projected capacity increases of 300-400% compared to manual processes. These systems require initial capital investments of $1.5-2.5 million but promise to reduce per-unit costs by 60-70% at scale. Return on investment calculations suggest breakeven points at production volumes of 500,000-750,000 interconnects, achievable within 18-24 months for medium-sized manufacturers.

The environmental impact of manufacturing processes must also be considered in scalability assessments. Liquid metal production generates approximately 0.8-1.2 kg CO2 equivalent per 100 interconnects, significantly lower than traditional rigid electronics manufacturing. However, end-of-life recycling infrastructure remains underdeveloped, presenting both a challenge and opportunity for sustainable scaling strategies.

For wearable technology manufacturers, integration of liquid metal interconnect production into existing assembly lines represents a significant hurdle. Current compatibility assessments indicate that retrofitting existing electronics manufacturing facilities requires modifications costing $350,000-500,000 per production line, with implementation timeframes of 3-6 months. These factors must be carefully weighed against the performance benefits that liquid metal interconnects provide in wearable applications.

Manufacturing liquid metal interconnects presents unique challenges compared to traditional electronic components. The gallium-based alloys commonly used require specialized handling due to their reactivity with certain metals and tendency to oxidize. Current production methods include microfluidic injection, direct printing, and selective wetting techniques. Each method demonstrates varying degrees of scalability potential, with direct printing showing the most promise for high-volume manufacturing with reported throughput rates of 150-200 interconnects per hour in laboratory settings.

Cost analysis reveals that material expenses constitute approximately 35-40% of total production costs, with gallium alloys priced at $250-300 per kilogram. Labor represents another 30-35% of costs in current manufacturing paradigms. Equipment and facility overhead account for the remaining 25-35%. Achieving economic viability requires reducing material waste, which currently ranges from 15-25% depending on the manufacturing technique employed.

Several companies have begun developing automated production lines specifically for liquid metal interconnects, with projected capacity increases of 300-400% compared to manual processes. These systems require initial capital investments of $1.5-2.5 million but promise to reduce per-unit costs by 60-70% at scale. Return on investment calculations suggest breakeven points at production volumes of 500,000-750,000 interconnects, achievable within 18-24 months for medium-sized manufacturers.

The environmental impact of manufacturing processes must also be considered in scalability assessments. Liquid metal production generates approximately 0.8-1.2 kg CO2 equivalent per 100 interconnects, significantly lower than traditional rigid electronics manufacturing. However, end-of-life recycling infrastructure remains underdeveloped, presenting both a challenge and opportunity for sustainable scaling strategies.

For wearable technology manufacturers, integration of liquid metal interconnect production into existing assembly lines represents a significant hurdle. Current compatibility assessments indicate that retrofitting existing electronics manufacturing facilities requires modifications costing $350,000-500,000 per production line, with implementation timeframes of 3-6 months. These factors must be carefully weighed against the performance benefits that liquid metal interconnects provide in wearable applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!