Liquid Metal Interconnect Usage in High-Temperature Systems

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Interconnect Technology Background and Objectives

Liquid metal interconnects represent a revolutionary approach to electrical connections in extreme temperature environments, evolving from traditional solid metal connectors that face significant limitations under thermal stress. The development of these interconnects traces back to early metallurgical research on gallium-based alloys in the mid-20th century, but their application in electronic systems has gained momentum only in the past two decades with advancements in materials science and nanotechnology.

The technological evolution of liquid metal interconnects has been driven by increasing demands in aerospace, nuclear, and industrial sectors where conventional interconnects fail due to thermal expansion, oxidation, and mechanical fatigue. Early implementations primarily utilized mercury, which presented significant toxicity concerns. Modern liquid metal interconnects predominantly employ gallium-based alloys such as Galinstan (gallium-indium-tin) and EGaIn (eutectic gallium-indium), offering superior thermal conductivity while maintaining electrical performance at temperatures exceeding 400°C.

The primary objective of liquid metal interconnect technology in high-temperature systems is to maintain reliable electrical connections under extreme thermal conditions while addressing the limitations of conventional solid interconnects. Specifically, these technologies aim to achieve stable electrical resistance across wide temperature ranges (-40°C to 800°C), minimize thermal expansion-induced mechanical stress, and provide self-healing capabilities for enhanced durability in harsh operating environments.

Current research focuses on overcoming key challenges including metal oxidation, containment strategies, and integration with existing electronic packaging technologies. The field is progressing toward developing encapsulation methods that prevent gallium diffusion into adjacent materials while maintaining the liquid state necessary for thermal compliance. Additionally, researchers are exploring novel alloy compositions to optimize electrical conductivity, wettability, and thermal stability.

The technology roadmap for liquid metal interconnects envisions progression from current laboratory demonstrations to commercial deployment in critical high-temperature applications within the next five years. This transition requires addressing manufacturing scalability, long-term reliability verification, and standardization of implementation methodologies across different electronic packaging platforms.

Emerging trends in this field include the integration of liquid metal interconnects with flexible electronics for wearable high-temperature sensors, development of self-healing interconnect systems utilizing controlled oxidation mechanisms, and exploration of hybrid solid-liquid interconnect architectures that combine the advantages of both approaches for optimal performance across varying thermal conditions.

The technological evolution of liquid metal interconnects has been driven by increasing demands in aerospace, nuclear, and industrial sectors where conventional interconnects fail due to thermal expansion, oxidation, and mechanical fatigue. Early implementations primarily utilized mercury, which presented significant toxicity concerns. Modern liquid metal interconnects predominantly employ gallium-based alloys such as Galinstan (gallium-indium-tin) and EGaIn (eutectic gallium-indium), offering superior thermal conductivity while maintaining electrical performance at temperatures exceeding 400°C.

The primary objective of liquid metal interconnect technology in high-temperature systems is to maintain reliable electrical connections under extreme thermal conditions while addressing the limitations of conventional solid interconnects. Specifically, these technologies aim to achieve stable electrical resistance across wide temperature ranges (-40°C to 800°C), minimize thermal expansion-induced mechanical stress, and provide self-healing capabilities for enhanced durability in harsh operating environments.

Current research focuses on overcoming key challenges including metal oxidation, containment strategies, and integration with existing electronic packaging technologies. The field is progressing toward developing encapsulation methods that prevent gallium diffusion into adjacent materials while maintaining the liquid state necessary for thermal compliance. Additionally, researchers are exploring novel alloy compositions to optimize electrical conductivity, wettability, and thermal stability.

The technology roadmap for liquid metal interconnects envisions progression from current laboratory demonstrations to commercial deployment in critical high-temperature applications within the next five years. This transition requires addressing manufacturing scalability, long-term reliability verification, and standardization of implementation methodologies across different electronic packaging platforms.

Emerging trends in this field include the integration of liquid metal interconnects with flexible electronics for wearable high-temperature sensors, development of self-healing interconnect systems utilizing controlled oxidation mechanisms, and exploration of hybrid solid-liquid interconnect architectures that combine the advantages of both approaches for optimal performance across varying thermal conditions.

Market Analysis for High-Temperature Interconnect Solutions

The high-temperature interconnect solutions market is experiencing significant growth driven by increasing demands across multiple industries including aerospace, automotive, industrial manufacturing, and energy production. Current market valuations indicate the global high-temperature interconnect market reached approximately 3.2 billion USD in 2022, with projections suggesting a compound annual growth rate of 6.8% through 2028. This growth trajectory is primarily fueled by the expanding need for reliable electronic systems capable of functioning in extreme temperature environments.

Aerospace and defense sectors represent the largest market segment, accounting for roughly 35% of the total market share. These industries require interconnect solutions that can withstand temperatures exceeding 200°C while maintaining signal integrity in mission-critical applications. The automotive industry follows closely behind with a 28% market share, particularly with the rise of electric vehicles and advanced driver assistance systems requiring robust high-temperature connections near engine components and power systems.

Industrial manufacturing constitutes approximately 20% of the market, with applications in furnace controls, metal processing, and industrial automation systems. The energy sector, including oil and gas exploration and renewable energy systems, represents about 15% of the market with growing demands for downhole electronics and geothermal applications.

Regionally, North America leads the market with approximately 38% share due to its strong aerospace and defense industries. Asia-Pacific follows at 32% with rapid growth driven by automotive manufacturing and industrial expansion in China, Japan, and South Korea. Europe accounts for 25% of the market, with particular strength in automotive and industrial applications.

Customer requirements are increasingly focused on interconnect solutions that can operate reliably at temperatures ranging from 150°C to over 300°C while maintaining electrical performance, mechanical stability, and long-term reliability. Traditional interconnect technologies using copper and conventional solders typically fail above 125-150°C, creating significant market opportunities for innovative solutions like liquid metal interconnects.

The market shows a clear trend toward miniaturization, with customers seeking smaller form factors without compromising thermal performance. Additionally, there is growing demand for environmentally friendly solutions that comply with RoHS and REACH regulations, particularly as industries move away from lead-based solders and other hazardous materials.

Price sensitivity varies significantly by application, with aerospace and defense customers willing to pay premium prices for proven reliability, while automotive and consumer electronics manufacturers seek more cost-effective solutions for mass production. This market segmentation creates diverse opportunities for liquid metal interconnect technologies across different price points and performance requirements.

Aerospace and defense sectors represent the largest market segment, accounting for roughly 35% of the total market share. These industries require interconnect solutions that can withstand temperatures exceeding 200°C while maintaining signal integrity in mission-critical applications. The automotive industry follows closely behind with a 28% market share, particularly with the rise of electric vehicles and advanced driver assistance systems requiring robust high-temperature connections near engine components and power systems.

Industrial manufacturing constitutes approximately 20% of the market, with applications in furnace controls, metal processing, and industrial automation systems. The energy sector, including oil and gas exploration and renewable energy systems, represents about 15% of the market with growing demands for downhole electronics and geothermal applications.

Regionally, North America leads the market with approximately 38% share due to its strong aerospace and defense industries. Asia-Pacific follows at 32% with rapid growth driven by automotive manufacturing and industrial expansion in China, Japan, and South Korea. Europe accounts for 25% of the market, with particular strength in automotive and industrial applications.

Customer requirements are increasingly focused on interconnect solutions that can operate reliably at temperatures ranging from 150°C to over 300°C while maintaining electrical performance, mechanical stability, and long-term reliability. Traditional interconnect technologies using copper and conventional solders typically fail above 125-150°C, creating significant market opportunities for innovative solutions like liquid metal interconnects.

The market shows a clear trend toward miniaturization, with customers seeking smaller form factors without compromising thermal performance. Additionally, there is growing demand for environmentally friendly solutions that comply with RoHS and REACH regulations, particularly as industries move away from lead-based solders and other hazardous materials.

Price sensitivity varies significantly by application, with aerospace and defense customers willing to pay premium prices for proven reliability, while automotive and consumer electronics manufacturers seek more cost-effective solutions for mass production. This market segmentation creates diverse opportunities for liquid metal interconnect technologies across different price points and performance requirements.

Current Challenges in Liquid Metal Technology for Extreme Environments

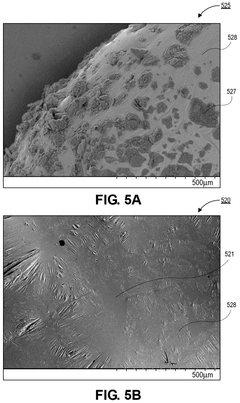

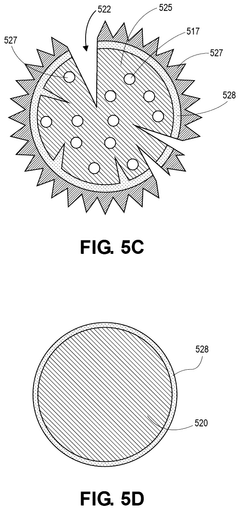

Despite significant advancements in liquid metal technology for high-temperature systems, several critical challenges continue to impede widespread implementation. The primary obstacle remains oxidation behavior, as liquid metals like gallium and its alloys rapidly form oxide layers when exposed to oxygen, particularly at elevated temperatures. This oxidation not only alters electrical conductivity but also affects wetting properties and mechanical stability of interconnects, creating reliability concerns in extreme environments where temperatures can exceed 400°C.

Material compatibility presents another significant challenge, as liquid metals exhibit aggressive chemical reactivity with many common substrate materials. Gallium, for instance, readily forms intermetallic compounds with metals like aluminum, copper, and nickel, leading to embrittlement and structural degradation. This limits packaging options and necessitates specialized containment strategies that can withstand both high temperatures and chemical interactions over extended operational periods.

Thermal expansion mismatch between liquid metals and surrounding materials introduces substantial mechanical stress during thermal cycling. With coefficient of thermal expansion (CTE) values significantly higher than most semiconductor materials and ceramics, liquid metals can exert destructive forces on interconnect structures during heating and cooling cycles, leading to delamination, cracking, or complete failure of electrical connections.

Containment and encapsulation technologies remain underdeveloped for extreme temperature applications. Current polymer-based encapsulants degrade rapidly above 250°C, while ceramic and glass encapsulation methods often lack the hermeticity required to prevent liquid metal leakage or evaporation at high temperatures. This containment challenge is particularly acute in applications experiencing vibration or mechanical shock.

The viscosity and surface tension properties of liquid metals change dramatically with temperature, affecting flow characteristics and wetting behavior. At extreme temperatures, these changes can lead to unpredictable migration, void formation, or dewetting phenomena that compromise electrical continuity. Additionally, the long-term stability of liquid metal interconnects under combined thermal, electrical, and mechanical stresses remains largely uncharacterized beyond a few thousand hours of operation.

Manufacturing scalability presents further complications, as current deposition and patterning techniques for liquid metals are primarily laboratory-scale processes not readily adaptable to high-volume production. The lack of standardized testing protocols specifically designed for liquid metal interconnects in extreme environments also hinders comparative assessment and qualification for mission-critical applications.

Material compatibility presents another significant challenge, as liquid metals exhibit aggressive chemical reactivity with many common substrate materials. Gallium, for instance, readily forms intermetallic compounds with metals like aluminum, copper, and nickel, leading to embrittlement and structural degradation. This limits packaging options and necessitates specialized containment strategies that can withstand both high temperatures and chemical interactions over extended operational periods.

Thermal expansion mismatch between liquid metals and surrounding materials introduces substantial mechanical stress during thermal cycling. With coefficient of thermal expansion (CTE) values significantly higher than most semiconductor materials and ceramics, liquid metals can exert destructive forces on interconnect structures during heating and cooling cycles, leading to delamination, cracking, or complete failure of electrical connections.

Containment and encapsulation technologies remain underdeveloped for extreme temperature applications. Current polymer-based encapsulants degrade rapidly above 250°C, while ceramic and glass encapsulation methods often lack the hermeticity required to prevent liquid metal leakage or evaporation at high temperatures. This containment challenge is particularly acute in applications experiencing vibration or mechanical shock.

The viscosity and surface tension properties of liquid metals change dramatically with temperature, affecting flow characteristics and wetting behavior. At extreme temperatures, these changes can lead to unpredictable migration, void formation, or dewetting phenomena that compromise electrical continuity. Additionally, the long-term stability of liquid metal interconnects under combined thermal, electrical, and mechanical stresses remains largely uncharacterized beyond a few thousand hours of operation.

Manufacturing scalability presents further complications, as current deposition and patterning techniques for liquid metals are primarily laboratory-scale processes not readily adaptable to high-volume production. The lack of standardized testing protocols specifically designed for liquid metal interconnects in extreme environments also hinders comparative assessment and qualification for mission-critical applications.

Current Implementation Methods for Liquid Metal Interconnects

01 Liquid metal interconnect materials and compositions

Liquid metal materials, such as gallium-based alloys, can be used as interconnects in electronic devices due to their excellent electrical conductivity and ability to maintain connectivity during mechanical deformation. These materials offer advantages including self-healing properties, flexibility, and the ability to form reliable electrical connections at low temperatures. The composition can be tailored to achieve specific melting points, viscosity, and adhesion properties suitable for various applications in flexible and stretchable electronics.- Liquid metal interconnect materials and compositions: Liquid metal materials, such as gallium-based alloys, can be used as interconnect materials in electronic devices. These materials offer advantages including high electrical conductivity, thermal stability, and the ability to form reliable connections at lower temperatures than traditional solders. The liquid nature of these metals allows them to maintain connectivity even during mechanical stress or thermal cycling, making them particularly useful for flexible or stretchable electronics applications.

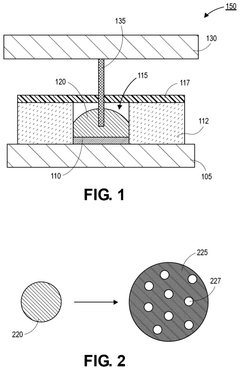

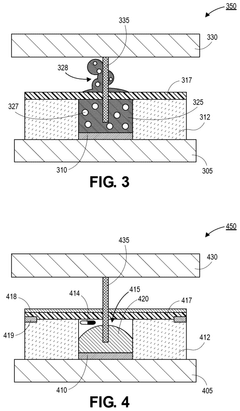

- Fabrication methods for liquid metal interconnects: Various fabrication techniques can be employed to create liquid metal interconnects, including printing, injection, microfluidic channels, and selective deposition. These methods enable precise placement and patterning of liquid metal to form electrical pathways between components. Advanced techniques may involve encapsulation of the liquid metal to prevent oxidation or leakage while maintaining its beneficial properties. Some approaches incorporate specialized surface treatments to control wetting and adhesion of the liquid metal to substrates.

- Integration of liquid metal interconnects in semiconductor devices: Liquid metal interconnects can be integrated into semiconductor devices to provide electrical connections between different components or layers. This integration may involve specialized vias, channels, or reservoirs to contain the liquid metal while allowing it to form reliable electrical connections. The self-healing properties of liquid metals can help maintain connectivity even as the device undergoes thermal or mechanical stress. These interconnects can be particularly valuable in advanced packaging technologies where traditional solid interconnects may fail.

- Liquid metal interconnects for flexible and stretchable electronics: Liquid metal interconnects are particularly advantageous for flexible and stretchable electronic applications due to their ability to maintain electrical connectivity during bending, stretching, or other deformations. These interconnects can be embedded in elastomeric substrates or encapsulated in flexible materials to create devices that can conform to non-planar surfaces or withstand repeated mechanical deformation. Applications include wearable electronics, soft robotics, and biomedical devices where traditional rigid interconnects would fail under mechanical stress.

- Reliability and performance enhancement of liquid metal interconnects: Various techniques can be employed to enhance the reliability and performance of liquid metal interconnects, including surface treatments, alloying with other metals, and specialized encapsulation methods. These approaches can address challenges such as oxidation, metal migration, and mechanical stability. Some methods involve creating composite structures that combine liquid metals with solid supports or specialized coatings to improve adhesion and prevent leakage while maintaining the beneficial electrical and thermal properties of the liquid metal.

02 Fabrication methods for liquid metal interconnects

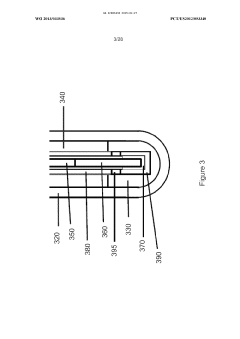

Various fabrication techniques can be employed to create liquid metal interconnects, including microfluidic injection, printing, and patterning methods. These processes involve precise deposition of liquid metal into channels or vias, often requiring surface treatments to control wetting behavior. Advanced manufacturing approaches include selective masking, vacuum-assisted filling, and encapsulation techniques to ensure stable containment of the liquid metal while maintaining electrical functionality. These methods enable the creation of complex interconnect structures with high reliability.Expand Specific Solutions03 Interconnect structures and architectures using liquid metal

Liquid metal interconnect structures can be designed in various configurations including vertical interconnects, horizontal traces, and three-dimensional networks. These structures often incorporate channels, reservoirs, or encapsulation layers to contain the liquid metal while allowing for electrical connectivity. Advanced architectures may include hierarchical designs with both solid and liquid metal components, redundant pathways for enhanced reliability, and specialized geometries that accommodate mechanical strain while maintaining electrical performance.Expand Specific Solutions04 Integration of liquid metal interconnects with semiconductor devices

Liquid metal interconnects can be integrated with semiconductor devices through specialized bonding and packaging techniques. This integration requires careful consideration of material compatibility, thermal management, and electrical performance. Methods include direct bonding to semiconductor surfaces, creation of hybrid interconnect systems combining traditional and liquid metal approaches, and specialized packaging solutions that maintain the liquid state while providing robust electrical connections. These integration approaches enable novel device architectures with enhanced flexibility and reliability.Expand Specific Solutions05 Applications and performance characteristics of liquid metal interconnects

Liquid metal interconnects find applications in flexible electronics, wearable devices, high-performance computing, and harsh environment electronics. Their performance characteristics include excellent electrical conductivity, thermal management capabilities, and mechanical compliance. These interconnects can withstand repeated mechanical deformation, thermal cycling, and vibration while maintaining reliable electrical connections. They offer advantages in applications requiring self-healing capabilities, reconfigurability, or operation under extreme conditions where traditional solid interconnects would fail.Expand Specific Solutions

Industry Leaders in Liquid Metal and High-Temperature Applications

The liquid metal interconnect market for high-temperature systems is in a growth phase, driven by increasing demand in aerospace, automotive, and electronics sectors. The market is projected to reach significant value as industries seek reliable solutions for extreme operating conditions. Technologically, the field shows varying maturity levels across applications. Leading players include Intel and Infineon Technologies focusing on semiconductor integration; Indium Corporation specializing in materials development; and academic institutions like Beijing Institute of Technology and University of Maryland advancing fundamental research. Taiwan Semiconductor and Corning are leveraging their materials expertise to develop specialized interconnect solutions, while research organizations such as Commissariat à l'énergie atomique are exploring next-generation applications for critical infrastructure.

The Indium Corporation of America

Technical Solution: The Indium Corporation has developed advanced liquid metal interconnect solutions specifically designed for high-temperature applications. Their technology utilizes indium-based alloys with carefully controlled compositions to achieve melting points tailored to specific application requirements. These liquid metal interconnects maintain electrical conductivity at temperatures exceeding 200°C while providing excellent thermal management capabilities. The company's proprietary manufacturing process ensures consistent quality and reliability through precise control of metal purity and oxide formation. Their liquid metal thermal interface materials (TIMs) provide thermal conductivity values of 20-86 W/mK, significantly outperforming traditional thermal greases (3-8 W/mK). The technology incorporates specialized encapsulation methods to prevent leakage and oxidation in harsh environments, extending operational lifetimes in high-temperature systems.

Strengths: Superior thermal conductivity compared to conventional solutions; excellent electrical properties maintained at high temperatures; customizable melting points for specific applications; proven reliability in harsh environments. Weaknesses: Higher cost compared to traditional interconnect materials; requires specialized handling during manufacturing and assembly; potential for material migration under certain conditions.

Infineon Technologies AG

Technical Solution: Infineon has pioneered liquid metal interconnect technology for power electronics operating in extreme temperature environments. Their solution incorporates gallium-based liquid metal alloys with specialized surface treatments to enhance wettability and adhesion to semiconductor surfaces. The company's approach focuses on creating reliable interconnects for silicon carbide (SiC) and gallium nitride (GaN) power devices operating at temperatures up to 250°C. Infineon's liquid metal interconnects feature self-healing properties that compensate for thermal expansion mismatches, reducing mechanical stress on semiconductor dies. Their technology includes proprietary barrier layers that prevent diffusion and intermetallic formation between the liquid metal and semiconductor materials. This solution achieves thermal resistance values below 0.1 K/W for high-power applications, enabling more efficient heat dissipation in compact power modules for automotive and industrial applications.

Strengths: Excellent compatibility with wide-bandgap semiconductor materials; self-healing properties that enhance reliability during thermal cycling; superior thermal performance enabling higher power density designs. Weaknesses: Complex integration process requiring precise control of surface chemistry; higher initial implementation costs compared to traditional soldering techniques; limited field deployment history in some application areas.

Critical Patents and Research in Liquid Metal Thermal Interfaces

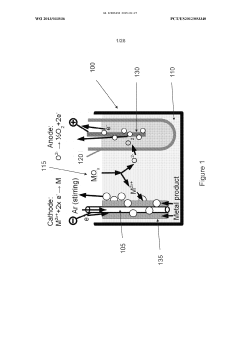

Integrated antioxidant and sealant solution to address temperature humidity reliability issue of liquid metal interconnect

PatentPendingUS20240304506A1

Innovation

- Applying an antioxidant protective layer over the liquid metal to prevent oxidation, maintaining its liquid phase and electrical conductivity even in high temperature and humidity environments, using materials like sodium ascorbate, thiol, or other suitable antioxidants that form a thin, non-continuous oxide layer.

Conductor of high electrical current at high temperature in oxygen and liquid metal environment

PatentInactiveCA2883430C

Innovation

- A tube-based apparatus with a stable electronic conductor system, including a first conductor and a second conductor partially disposed within the tube, which forms a gas-tight sheath to protect the core components from oxidation, and a contact with a melting point below the operating temperature, ensuring high electrical conductivity and stability in extreme conditions.

Material Safety and Environmental Impact Assessment

The safety profile of liquid metal interconnects in high-temperature systems presents significant considerations that must be thoroughly evaluated before widespread implementation. Gallium-based liquid metals, while offering excellent thermal and electrical conductivity, pose potential health risks due to their corrosive nature and toxicity when improperly handled. Direct skin contact with gallium alloys can cause irritation and dermatitis, while inhalation of metal vapors at elevated temperatures may lead to respiratory issues. Proper containment systems and handling protocols are therefore essential to minimize exposure risks to personnel working with these materials.

Environmental impact assessment of liquid metal interconnects reveals both advantages and concerns. On the positive side, many liquid metal alloys used in interconnects have lower environmental footprints compared to traditional solders containing lead. Gallium, indium, and tin—common components in liquid metal alloys—generally exhibit lower ecotoxicity than lead-based alternatives. However, the mining and processing of these metals, particularly indium and gallium which are often byproducts of zinc and aluminum production respectively, can contribute to habitat disruption and energy-intensive extraction processes.

Lifecycle analysis indicates that liquid metal interconnects may offer sustainability benefits through their potential for recovery and reuse. Unlike conventional solders that degrade after thermal cycling, liquid metals maintain their properties even after multiple heating and cooling cycles, potentially extending system lifespan and reducing electronic waste. Nevertheless, proper end-of-life management protocols must be established to prevent environmental contamination, as uncontrolled release of these metals into ecosystems could impact aquatic organisms and soil quality.

Regulatory frameworks governing liquid metal usage in high-temperature applications vary globally, creating compliance challenges for manufacturers. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions impose specific requirements on electronic materials. While most gallium-based alloys comply with these standards, comprehensive documentation of safety data and environmental impact assessments remains crucial for regulatory approval in sensitive applications such as aerospace, medical devices, and consumer electronics.

Risk mitigation strategies should include engineered containment solutions to prevent leakage, especially under thermal expansion conditions common in high-temperature systems. Encapsulation technologies using chemically resistant polymers or ceramic materials can effectively isolate liquid metals from both human contact and environmental release. Additionally, development of standardized disposal and recycling protocols specific to liquid metal interconnects will be essential as these technologies gain wider adoption in industrial and consumer applications.

Environmental impact assessment of liquid metal interconnects reveals both advantages and concerns. On the positive side, many liquid metal alloys used in interconnects have lower environmental footprints compared to traditional solders containing lead. Gallium, indium, and tin—common components in liquid metal alloys—generally exhibit lower ecotoxicity than lead-based alternatives. However, the mining and processing of these metals, particularly indium and gallium which are often byproducts of zinc and aluminum production respectively, can contribute to habitat disruption and energy-intensive extraction processes.

Lifecycle analysis indicates that liquid metal interconnects may offer sustainability benefits through their potential for recovery and reuse. Unlike conventional solders that degrade after thermal cycling, liquid metals maintain their properties even after multiple heating and cooling cycles, potentially extending system lifespan and reducing electronic waste. Nevertheless, proper end-of-life management protocols must be established to prevent environmental contamination, as uncontrolled release of these metals into ecosystems could impact aquatic organisms and soil quality.

Regulatory frameworks governing liquid metal usage in high-temperature applications vary globally, creating compliance challenges for manufacturers. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions impose specific requirements on electronic materials. While most gallium-based alloys comply with these standards, comprehensive documentation of safety data and environmental impact assessments remains crucial for regulatory approval in sensitive applications such as aerospace, medical devices, and consumer electronics.

Risk mitigation strategies should include engineered containment solutions to prevent leakage, especially under thermal expansion conditions common in high-temperature systems. Encapsulation technologies using chemically resistant polymers or ceramic materials can effectively isolate liquid metals from both human contact and environmental release. Additionally, development of standardized disposal and recycling protocols specific to liquid metal interconnects will be essential as these technologies gain wider adoption in industrial and consumer applications.

Reliability Testing Frameworks for Liquid Metal Systems

Reliability testing frameworks for liquid metal systems must be comprehensive and rigorous to ensure the long-term performance of these interconnects in high-temperature environments. Traditional testing methodologies often prove inadequate due to the unique properties of liquid metals, necessitating specialized approaches that account for their fluid nature and thermal behavior.

The cornerstone of an effective reliability testing framework begins with accelerated aging tests specifically designed for liquid metal interconnects. These tests typically subject the materials to temperatures exceeding operational parameters—often ranging from 200°C to 600°C—for extended periods to simulate years of service in compressed timeframes. Thermal cycling between extreme temperatures is particularly critical, as it reveals potential failure modes related to expansion, contraction, and phase changes that may occur in real-world applications.

Mechanical stress testing constitutes another essential component, evaluating how liquid metal interconnects respond to vibration, shock, and continuous mechanical loading. This is particularly relevant for applications in aerospace, automotive, and industrial settings where equipment experiences significant physical stresses alongside high temperatures. Testing protocols typically include vibration testing at various frequencies and amplitudes, drop testing, and constant force application to assess interconnect integrity.

Chemical compatibility assessment forms the third pillar of comprehensive reliability testing. Liquid metals must maintain their electrical and thermal properties while resisting oxidation and corrosion when exposed to various environmental conditions. Standardized tests involving exposure to humidity, salt spray, and industrial atmospheres help quantify the degradation rates and identify potential chemical interactions that could compromise system performance.

Electrical performance monitoring throughout these environmental stresses provides critical data on how the interconnect's fundamental properties evolve over time. Parameters such as resistance stability, current-carrying capacity, and signal integrity under thermal and mechanical stress offer insights into potential failure mechanisms and service life expectations.

Statistical analysis methodologies must be integrated into these frameworks to establish meaningful reliability metrics. Weibull analysis, mean time between failures (MTBF) calculations, and failure mode effects analysis (FMEA) help translate raw test data into actionable reliability predictions. These statistical approaches enable engineers to establish confidence intervals for expected service life and identify the most probable failure modes requiring mitigation.

Industry standards such as JEDEC, IPC, and MIL-STD provide baseline testing protocols that can be adapted for liquid metal applications, though significant modifications are typically necessary to address the unique characteristics of these materials in high-temperature systems.

The cornerstone of an effective reliability testing framework begins with accelerated aging tests specifically designed for liquid metal interconnects. These tests typically subject the materials to temperatures exceeding operational parameters—often ranging from 200°C to 600°C—for extended periods to simulate years of service in compressed timeframes. Thermal cycling between extreme temperatures is particularly critical, as it reveals potential failure modes related to expansion, contraction, and phase changes that may occur in real-world applications.

Mechanical stress testing constitutes another essential component, evaluating how liquid metal interconnects respond to vibration, shock, and continuous mechanical loading. This is particularly relevant for applications in aerospace, automotive, and industrial settings where equipment experiences significant physical stresses alongside high temperatures. Testing protocols typically include vibration testing at various frequencies and amplitudes, drop testing, and constant force application to assess interconnect integrity.

Chemical compatibility assessment forms the third pillar of comprehensive reliability testing. Liquid metals must maintain their electrical and thermal properties while resisting oxidation and corrosion when exposed to various environmental conditions. Standardized tests involving exposure to humidity, salt spray, and industrial atmospheres help quantify the degradation rates and identify potential chemical interactions that could compromise system performance.

Electrical performance monitoring throughout these environmental stresses provides critical data on how the interconnect's fundamental properties evolve over time. Parameters such as resistance stability, current-carrying capacity, and signal integrity under thermal and mechanical stress offer insights into potential failure mechanisms and service life expectations.

Statistical analysis methodologies must be integrated into these frameworks to establish meaningful reliability metrics. Weibull analysis, mean time between failures (MTBF) calculations, and failure mode effects analysis (FMEA) help translate raw test data into actionable reliability predictions. These statistical approaches enable engineers to establish confidence intervals for expected service life and identify the most probable failure modes requiring mitigation.

Industry standards such as JEDEC, IPC, and MIL-STD provide baseline testing protocols that can be adapted for liquid metal applications, though significant modifications are typically necessary to address the unique characteristics of these materials in high-temperature systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!