Liquid Metal Interconnect Material Consistency in IoT Devices

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Interconnect Technology Background and Objectives

Liquid metal interconnect technology has emerged as a revolutionary approach in the field of electronics, particularly for Internet of Things (IoT) devices. The evolution of this technology can be traced back to the early 2000s when researchers began exploring alternatives to traditional rigid copper interconnects. Liquid metals, particularly gallium-based alloys such as Galinstan (gallium-indium-tin) and EGaIn (eutectic gallium-indium), have gained significant attention due to their unique combination of high electrical conductivity and fluidic properties at room temperature.

The development trajectory of liquid metal interconnects has been characterized by progressive improvements in material formulation, deposition techniques, and integration methods. Initially confined to laboratory demonstrations, these materials have gradually transitioned toward practical applications in flexible and stretchable electronics. The inherent fluidity of these materials enables self-healing capabilities and adaptability to mechanical deformation, addressing key limitations of conventional solid metal interconnects in dynamic environments.

Current technical objectives in liquid metal interconnect research focus on achieving consistent material properties across diverse operating conditions. This includes maintaining stable electrical performance during mechanical deformation, temperature fluctuations, and extended operational lifetimes. For IoT applications specifically, the miniaturization of liquid metal interconnects while preserving their electrical and mechanical integrity represents a critical technical goal.

Material consistency challenges have become increasingly prominent as the technology moves toward mass production. Variations in composition, oxidation behavior, and wetting characteristics can significantly impact device performance and reliability. The research aims to establish standardized formulations and processing methods that ensure predictable behavior across different manufacturing batches and environmental conditions.

Another key objective is to develop integration techniques compatible with existing semiconductor manufacturing processes. This includes addressing challenges related to encapsulation, patterning precision, and interface stability between liquid metals and other device components. The seamless integration with conventional electronics manufacturing workflows is essential for commercial viability.

Looking forward, the technology roadmap for liquid metal interconnects in IoT devices emphasizes achieving higher integration density, enhanced environmental stability, and reduced manufacturing costs. The ultimate goal is to enable a new generation of IoT devices with unprecedented mechanical flexibility, durability, and form factor advantages while maintaining reliable electrical performance throughout their operational lifetime.

The development trajectory of liquid metal interconnects has been characterized by progressive improvements in material formulation, deposition techniques, and integration methods. Initially confined to laboratory demonstrations, these materials have gradually transitioned toward practical applications in flexible and stretchable electronics. The inherent fluidity of these materials enables self-healing capabilities and adaptability to mechanical deformation, addressing key limitations of conventional solid metal interconnects in dynamic environments.

Current technical objectives in liquid metal interconnect research focus on achieving consistent material properties across diverse operating conditions. This includes maintaining stable electrical performance during mechanical deformation, temperature fluctuations, and extended operational lifetimes. For IoT applications specifically, the miniaturization of liquid metal interconnects while preserving their electrical and mechanical integrity represents a critical technical goal.

Material consistency challenges have become increasingly prominent as the technology moves toward mass production. Variations in composition, oxidation behavior, and wetting characteristics can significantly impact device performance and reliability. The research aims to establish standardized formulations and processing methods that ensure predictable behavior across different manufacturing batches and environmental conditions.

Another key objective is to develop integration techniques compatible with existing semiconductor manufacturing processes. This includes addressing challenges related to encapsulation, patterning precision, and interface stability between liquid metals and other device components. The seamless integration with conventional electronics manufacturing workflows is essential for commercial viability.

Looking forward, the technology roadmap for liquid metal interconnects in IoT devices emphasizes achieving higher integration density, enhanced environmental stability, and reduced manufacturing costs. The ultimate goal is to enable a new generation of IoT devices with unprecedented mechanical flexibility, durability, and form factor advantages while maintaining reliable electrical performance throughout their operational lifetime.

IoT Market Demand for Advanced Interconnect Materials

The Internet of Things (IoT) market is experiencing unprecedented growth, with projections indicating the number of connected devices will exceed 30 billion by 2025. This explosive expansion is driving significant demand for advanced interconnect materials that can meet the unique requirements of modern IoT applications. Traditional rigid interconnect solutions are increasingly inadequate for the evolving needs of IoT devices, which often require flexibility, stretchability, and reliability under various environmental conditions.

Liquid metal interconnects represent a revolutionary solution to these challenges, offering superior electrical conductivity combined with mechanical flexibility. Market research indicates that industries including wearable technology, healthcare monitoring, smart textiles, and flexible electronics are particularly eager for these advanced materials. The wearable technology segment alone is growing at a compound annual growth rate of 15.9%, creating substantial demand for interconnect materials that can withstand repeated bending, stretching, and twisting while maintaining consistent electrical performance.

Healthcare applications present another significant market opportunity, with medical IoT devices requiring biocompatible interconnect materials that can function reliably in contact with human tissue. The medical wearables market is expected to reach $19.5 billion by 2026, with interconnect materials being a critical component enabling this growth. Consistency in these materials is paramount, as variations can lead to device failure in critical healthcare monitoring scenarios.

Smart home and industrial IoT applications are similarly driving demand for reliable interconnect solutions that can operate across temperature extremes and withstand environmental stressors. The industrial IoT market particularly values materials that maintain consistent performance despite exposure to vibration, chemicals, and temperature fluctuations. This segment is projected to grow at 16.7% annually through 2027, creating substantial opportunities for advanced interconnect materials.

Consumer electronics manufacturers are increasingly incorporating flexible displays and form factors into their products, requiring interconnect materials that can accommodate these designs while maintaining reliability. The flexible electronics market is expected to reach $42 billion by 2027, with interconnect materials being a key enabling technology.

Automotive IoT applications represent another high-growth area, with connected vehicles requiring interconnect materials that maintain consistency despite extreme temperature variations and constant vibration. The automotive electronics market is projected to grow at 8% annually, with particular emphasis on materials that enable miniaturization while enhancing reliability.

Across all these market segments, there is a clear and growing demand for liquid metal interconnect materials that offer consistent performance, reliability, and manufacturability at scale. The ability to ensure material consistency across production batches will be a key differentiator for suppliers in this competitive landscape.

Liquid metal interconnects represent a revolutionary solution to these challenges, offering superior electrical conductivity combined with mechanical flexibility. Market research indicates that industries including wearable technology, healthcare monitoring, smart textiles, and flexible electronics are particularly eager for these advanced materials. The wearable technology segment alone is growing at a compound annual growth rate of 15.9%, creating substantial demand for interconnect materials that can withstand repeated bending, stretching, and twisting while maintaining consistent electrical performance.

Healthcare applications present another significant market opportunity, with medical IoT devices requiring biocompatible interconnect materials that can function reliably in contact with human tissue. The medical wearables market is expected to reach $19.5 billion by 2026, with interconnect materials being a critical component enabling this growth. Consistency in these materials is paramount, as variations can lead to device failure in critical healthcare monitoring scenarios.

Smart home and industrial IoT applications are similarly driving demand for reliable interconnect solutions that can operate across temperature extremes and withstand environmental stressors. The industrial IoT market particularly values materials that maintain consistent performance despite exposure to vibration, chemicals, and temperature fluctuations. This segment is projected to grow at 16.7% annually through 2027, creating substantial opportunities for advanced interconnect materials.

Consumer electronics manufacturers are increasingly incorporating flexible displays and form factors into their products, requiring interconnect materials that can accommodate these designs while maintaining reliability. The flexible electronics market is expected to reach $42 billion by 2027, with interconnect materials being a key enabling technology.

Automotive IoT applications represent another high-growth area, with connected vehicles requiring interconnect materials that maintain consistency despite extreme temperature variations and constant vibration. The automotive electronics market is projected to grow at 8% annually, with particular emphasis on materials that enable miniaturization while enhancing reliability.

Across all these market segments, there is a clear and growing demand for liquid metal interconnect materials that offer consistent performance, reliability, and manufacturability at scale. The ability to ensure material consistency across production batches will be a key differentiator for suppliers in this competitive landscape.

Current Status and Challenges in Liquid Metal Consistency

Liquid metal interconnect materials have emerged as a promising solution for flexible and stretchable electronics in IoT devices, offering unique advantages in conductivity and adaptability. Currently, gallium-based alloys, particularly eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan), dominate the field due to their low toxicity and room temperature liquidity. These materials maintain electrical conductivity even under significant mechanical deformation, making them ideal for wearable sensors and flexible displays in IoT applications.

Despite their potential, significant challenges persist in achieving consistent material properties across manufacturing batches. The oxide skin formation on liquid metal surfaces, while beneficial for pattern stability, introduces variability in electrical performance and mechanical behavior. This oxide layer's thickness and composition can vary based on environmental conditions, complicating quality control processes. Research indicates that even minor variations in oxygen exposure during manufacturing can lead to conductivity differences of up to 15% between batches.

Temperature sensitivity presents another major consistency challenge. Studies show that the viscosity and surface tension of gallium-based liquid metals change non-linearly with temperature fluctuations, affecting their flow characteristics during device fabrication. This sensitivity necessitates precise environmental control during manufacturing, which remains difficult to achieve at scale.

Material purity issues further complicate consistency efforts. Trace contaminants from manufacturing equipment or environment can significantly alter the electrical and mechanical properties of liquid metal interconnects. Recent research has documented how silicon or aluminum contamination at parts-per-million levels can change conductivity by up to 8% and affect wetting behavior on substrate materials.

The interaction between liquid metals and substrate materials represents another critical challenge. Different substrate materials exhibit varying degrees of compatibility with liquid metals, affecting adhesion, pattern definition, and long-term stability. This substrate-dependent behavior makes it difficult to establish standardized manufacturing protocols across different IoT device types.

Current manufacturing techniques for liquid metal integration, including microfluidic injection, direct writing, and stencil printing, each introduce their own consistency variables. The lack of standardized fabrication methods across the industry has resulted in significant device-to-device variation, with reported electrical resistance variations exceeding 20% in some manufacturing approaches.

Metrology and quality control systems for liquid metal interconnects remain underdeveloped compared to traditional solid conductors. The dynamic nature of these materials challenges conventional testing methods, and real-time monitoring techniques for liquid metal properties during manufacturing are still in early development stages.

Despite their potential, significant challenges persist in achieving consistent material properties across manufacturing batches. The oxide skin formation on liquid metal surfaces, while beneficial for pattern stability, introduces variability in electrical performance and mechanical behavior. This oxide layer's thickness and composition can vary based on environmental conditions, complicating quality control processes. Research indicates that even minor variations in oxygen exposure during manufacturing can lead to conductivity differences of up to 15% between batches.

Temperature sensitivity presents another major consistency challenge. Studies show that the viscosity and surface tension of gallium-based liquid metals change non-linearly with temperature fluctuations, affecting their flow characteristics during device fabrication. This sensitivity necessitates precise environmental control during manufacturing, which remains difficult to achieve at scale.

Material purity issues further complicate consistency efforts. Trace contaminants from manufacturing equipment or environment can significantly alter the electrical and mechanical properties of liquid metal interconnects. Recent research has documented how silicon or aluminum contamination at parts-per-million levels can change conductivity by up to 8% and affect wetting behavior on substrate materials.

The interaction between liquid metals and substrate materials represents another critical challenge. Different substrate materials exhibit varying degrees of compatibility with liquid metals, affecting adhesion, pattern definition, and long-term stability. This substrate-dependent behavior makes it difficult to establish standardized manufacturing protocols across different IoT device types.

Current manufacturing techniques for liquid metal integration, including microfluidic injection, direct writing, and stencil printing, each introduce their own consistency variables. The lack of standardized fabrication methods across the industry has resulted in significant device-to-device variation, with reported electrical resistance variations exceeding 20% in some manufacturing approaches.

Metrology and quality control systems for liquid metal interconnects remain underdeveloped compared to traditional solid conductors. The dynamic nature of these materials challenges conventional testing methods, and real-time monitoring techniques for liquid metal properties during manufacturing are still in early development stages.

Current Technical Solutions for Material Consistency Control

01 Gallium-based liquid metal interconnects

Gallium-based liquid metals are used as interconnect materials due to their low melting points and high electrical conductivity. These materials maintain consistency through controlled alloying with metals like indium and tin to form eutectic alloys that remain liquid at room temperature. The formulations provide stable electrical connections while allowing flexibility in electronic devices. These interconnects are particularly valuable in flexible electronics where traditional solid metal connections would fail under repeated bending or stretching.- Composition of liquid metal interconnects: Liquid metal interconnects can be composed of various alloys that maintain a liquid state at operating temperatures. These materials typically include gallium-based alloys, indium-tin alloys, or mercury-based compositions that provide excellent electrical conductivity while remaining in a liquid state. The consistency of these materials is critical for maintaining reliable electrical connections in semiconductor devices and flexible electronics. The liquid nature allows for self-healing properties and adaptation to mechanical stress.

- Encapsulation techniques for liquid metal stability: To maintain consistent properties of liquid metal interconnects, various encapsulation methods are employed. These include polymer-based encapsulation, micro-channel confinement, and specialized coating technologies that prevent oxidation and leakage while maintaining the liquid state of the metal. Proper encapsulation ensures the liquid metal maintains its volume, position, and electrical properties over time and under various operating conditions, which is essential for long-term device reliability.

- Temperature control for consistency maintenance: Temperature management is crucial for maintaining the consistency of liquid metal interconnects. Specialized heating elements, thermal interface materials, and temperature monitoring systems are integrated into devices to ensure the liquid metal remains at optimal viscosity. These systems prevent solidification at low temperatures and excessive fluidity at high temperatures, maintaining consistent electrical and mechanical properties across varying environmental conditions.

- Surface treatment for improved wetting and adhesion: Surface treatments are applied to improve the wetting characteristics and adhesion properties of liquid metal interconnects. These treatments include plasma cleaning, chemical functionalization, and micro/nano-texturing of contact surfaces. By controlling the surface energy and chemistry of the substrate materials, the consistency of the liquid metal interface can be significantly improved, resulting in more reliable electrical connections and reduced contact resistance.

- Integration methods for semiconductor applications: Specialized integration methods are developed for incorporating liquid metal interconnects into semiconductor devices. These include precise deposition techniques, micro-dispensing systems, and compatibility layers that allow liquid metals to interface with traditional semiconductor materials. Advanced packaging technologies are employed to ensure the liquid metal maintains consistent properties while interfacing with solid-state components, enabling reliable operation in integrated circuits and advanced electronic systems.

02 Temperature-stable liquid metal compositions

Specialized liquid metal compositions are engineered to maintain consistent electrical and mechanical properties across a wide temperature range. These formulations incorporate stabilizing agents and precise metal ratios to prevent phase separation or property changes during thermal cycling. The compositions often include nanoparticles or surface modifiers to control oxidation and wetting behaviors, ensuring reliable interconnection performance in varying environmental conditions. This stability is crucial for applications in automotive, aerospace, and other demanding environments.Expand Specific Solutions03 Encapsulation techniques for liquid metal interconnects

Various encapsulation methods are employed to maintain the consistency of liquid metal interconnects by preventing leakage, oxidation, and contamination. These techniques include polymer encapsulation, microfluidic channels, and specialized packaging materials that are compatible with liquid metals. The encapsulation systems allow for controlled deformation while maintaining electrical continuity, and often incorporate self-healing mechanisms to address potential ruptures. These approaches enable reliable integration of liquid metal interconnects into complex electronic systems.Expand Specific Solutions04 Surface treatment for improved liquid metal wetting and adhesion

Surface treatment processes are developed to enhance the wetting and adhesion properties of liquid metal interconnects on various substrate materials. These treatments include plasma activation, chemical functionalization, and micro/nano-texturing of surfaces to control the interfacial interactions between the liquid metal and substrate. By improving wetting characteristics, these methods ensure consistent electrical contact and mechanical stability of the interconnections. The treatments also help prevent dewetting and beading of the liquid metal during thermal or mechanical stress.Expand Specific Solutions05 Integration methods for liquid metal in semiconductor packaging

Advanced integration techniques are developed for incorporating liquid metal interconnects into semiconductor packaging with consistent performance. These methods include precise dispensing systems, controlled alloying processes during assembly, and specialized bonding techniques compatible with both liquid metals and traditional packaging materials. The integration approaches address challenges such as thermal management, electrical isolation, and mechanical reliability to ensure consistent interconnect properties throughout the device lifetime. These techniques enable higher performance in advanced computing, power electronics, and high-frequency applications.Expand Specific Solutions

Key Industry Players in Liquid Metal Interconnect Development

The liquid metal interconnect material market for IoT devices is in an early growth phase, characterized by increasing research activity and emerging commercial applications. The market size is expanding as IoT device proliferation drives demand for flexible, reliable interconnect solutions. From a technical maturity perspective, the landscape shows varied development levels: academic institutions like Tsinghua University and Beijing Institute of Technology are advancing fundamental research, while companies including Intel, IBM, and TSMC focus on integration capabilities. Specialized players such as Beijing Dream Ink Technology are developing manufacturing processes for practical implementation. The competitive dynamics reveal a collaborative ecosystem where semiconductor giants partner with research institutions to overcome technical challenges in consistency, reliability, and mass production of liquid metal interconnects for next-generation IoT applications.

International Business Machines Corp.

Technical Solution: IBM has developed an advanced liquid metal interconnect technology specifically engineered for high-reliability IoT applications. Their approach utilizes a proprietary gallium-based alloy system with carefully controlled additives that enhance wettability while maintaining consistent electrical properties across temperature variations. IBM's solution incorporates a nanoscale surface treatment process that creates strong interfacial bonding between the liquid metal and various substrate materials, preventing delamination during thermal cycling. The company has implemented a specialized encapsulation technology that prevents oxidation and contamination while allowing controlled deformation for flexible applications. Their research demonstrates remarkable consistency in electrical performance, with resistance variations below 3% after 2,000 hours of environmental stress testing including temperature cycling (-40°C to 85°C), humidity exposure (85% RH), and mechanical vibration. IBM has also developed automated deposition techniques compatible with their existing semiconductor manufacturing infrastructure, enabling precise control of interconnect dimensions down to 20μm feature sizes.

Strengths: Exceptional reliability under environmental stress conditions and compatibility with existing semiconductor manufacturing processes make this solution particularly valuable for mission-critical IoT applications. Weaknesses: Higher material costs compared to conventional soldering techniques and specialized equipment requirements may limit adoption in cost-sensitive consumer IoT devices.

Beijing Institute of Technology

Technical Solution: Beijing Institute of Technology has developed a comprehensive liquid metal interconnect solution specifically addressing consistency challenges in IoT applications. Their approach utilizes a gallium-indium-tin alloy system with precisely controlled oxygen content to manage oxide layer formation. The research team has created a novel microencapsulation technique that isolates individual liquid metal droplets within an elastomeric matrix, allowing for consistent electrical performance even under significant mechanical deformation. Their technology incorporates specialized surface treatments that enhance adhesion to common IoT substrate materials while preventing undesired migration or leakage. Testing has demonstrated remarkable consistency in electrical resistance (<1.5% variation) across 5,000 thermal cycles (-20°C to 70°C) and mechanical bending tests (radius down to 2mm). The team has also developed automated deposition methods compatible with existing manufacturing processes, enabling precise control of interconnect geometry and thickness.

Strengths: Excellent thermal cycling reliability and compatibility with automated manufacturing processes make this technology particularly suitable for mass-produced IoT devices. Weaknesses: Current formulations show increased resistance at temperatures below 0°C, potentially limiting applications in extreme cold environments without additional engineering considerations.

Critical Patents and Research in Liquid Metal Interconnect Technology

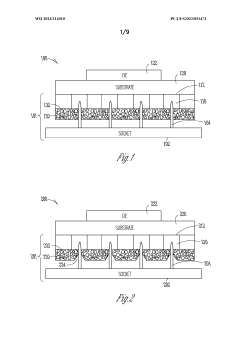

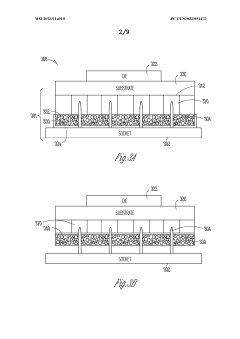

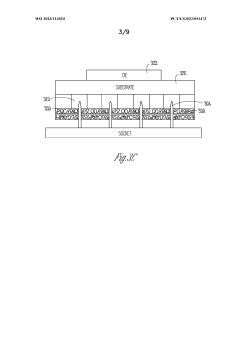

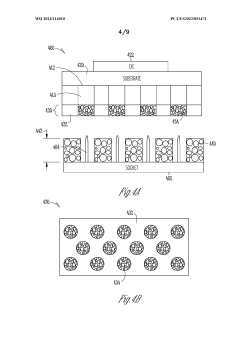

Self-diffusing liquid metal interconnect architectures enabling snap-on room temperature assembly

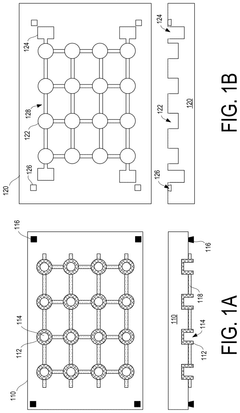

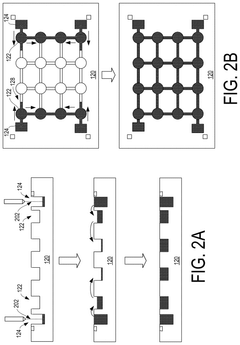

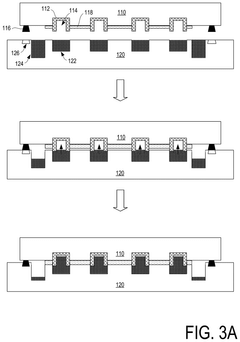

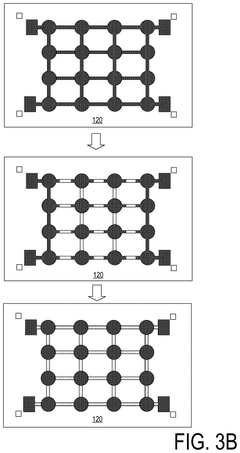

PatentPendingUS20250112190A1

Innovation

- A self-diffusion process using Gallium-based liquid metal interconnects facilitated by capillary action and a slip layer material to form connections at room temperature, allowing for minimal energy consumption and precise, scalable interconnect networks without complex processing.

Liquid metal connection device and method

PatentWO2023114010A1

Innovation

- The use of an electronic device with a socket that includes an array of liquid metal filled reservoirs, such as gallium or gallium alloys, and a cap layer with porous resilient material regions, which can be designed with specific pore sizes and strain relief features to facilitate easy insertion and sealing, while also incorporating moisture barrier layers to prevent moisture ingress.

Environmental Impact and Sustainability Considerations

The environmental implications of liquid metal interconnect materials in IoT devices represent a critical dimension of technological assessment that extends beyond mere performance metrics. Liquid metals, particularly gallium-based alloys such as Galinstan and EGaIn, offer significant advantages over conventional solid metal interconnects in terms of environmental sustainability. Their low toxicity profile compared to mercury-based alternatives presents a substantial ecological benefit, reducing potential contamination risks during manufacturing, device operation, and end-of-life disposal.

The recyclability potential of liquid metal interconnects stands as a notable sustainability advantage. Unlike traditional soldered connections that often require energy-intensive thermal processes for disassembly, liquid metal interconnects can be recovered through mechanical separation techniques that consume significantly less energy. This characteristic aligns with circular economy principles and could substantially reduce the electronic waste burden associated with the proliferation of IoT devices, which is projected to reach unprecedented levels as global IoT deployment accelerates.

Manufacturing processes for liquid metal interconnects generally require lower processing temperatures compared to conventional soldering methods, resulting in reduced energy consumption during production. This energy efficiency translates to a smaller carbon footprint across the manufacturing supply chain. Additionally, the room-temperature processing capability eliminates the need for certain flux chemicals and cleaning agents that contribute to environmental pollution in traditional electronics manufacturing.

However, challenges remain regarding the long-term environmental impact of gallium extraction. As demand for liquid metal interconnects increases, sustainable sourcing of gallium becomes a pressing concern. Currently, gallium is primarily obtained as a byproduct of aluminum and zinc production, which limits direct mining impacts but ties availability to other metal production cycles. Future research must address the development of more sustainable gallium recovery methods from both primary sources and electronic waste streams.

The potential for liquid metal interconnects to enable more durable and repairable IoT devices represents another significant environmental benefit. By facilitating non-destructive disassembly and component replacement, these materials could extend device lifespans considerably, reducing the resource intensity associated with frequent device replacement cycles. This characteristic is particularly valuable in environmental monitoring applications where IoT devices may be deployed in sensitive ecosystems.

Regulatory frameworks governing the use and disposal of liquid metal materials in electronics remain underdeveloped in many jurisdictions. Establishing comprehensive environmental standards specific to these materials will be essential to ensure their sustainable integration into the IoT ecosystem and prevent unintended ecological consequences as adoption scales globally.

The recyclability potential of liquid metal interconnects stands as a notable sustainability advantage. Unlike traditional soldered connections that often require energy-intensive thermal processes for disassembly, liquid metal interconnects can be recovered through mechanical separation techniques that consume significantly less energy. This characteristic aligns with circular economy principles and could substantially reduce the electronic waste burden associated with the proliferation of IoT devices, which is projected to reach unprecedented levels as global IoT deployment accelerates.

Manufacturing processes for liquid metal interconnects generally require lower processing temperatures compared to conventional soldering methods, resulting in reduced energy consumption during production. This energy efficiency translates to a smaller carbon footprint across the manufacturing supply chain. Additionally, the room-temperature processing capability eliminates the need for certain flux chemicals and cleaning agents that contribute to environmental pollution in traditional electronics manufacturing.

However, challenges remain regarding the long-term environmental impact of gallium extraction. As demand for liquid metal interconnects increases, sustainable sourcing of gallium becomes a pressing concern. Currently, gallium is primarily obtained as a byproduct of aluminum and zinc production, which limits direct mining impacts but ties availability to other metal production cycles. Future research must address the development of more sustainable gallium recovery methods from both primary sources and electronic waste streams.

The potential for liquid metal interconnects to enable more durable and repairable IoT devices represents another significant environmental benefit. By facilitating non-destructive disassembly and component replacement, these materials could extend device lifespans considerably, reducing the resource intensity associated with frequent device replacement cycles. This characteristic is particularly valuable in environmental monitoring applications where IoT devices may be deployed in sensitive ecosystems.

Regulatory frameworks governing the use and disposal of liquid metal materials in electronics remain underdeveloped in many jurisdictions. Establishing comprehensive environmental standards specific to these materials will be essential to ensure their sustainable integration into the IoT ecosystem and prevent unintended ecological consequences as adoption scales globally.

Manufacturing Scalability and Cost Analysis

The scalability of liquid metal interconnect manufacturing presents significant challenges for widespread IoT implementation. Current production methods primarily rely on laboratory-scale techniques such as microfluidic injection, direct printing, and selective wetting, which face substantial hurdles when transitioning to mass production environments. These methods typically achieve throughput rates of only 10-100 units per hour, far below the millions of units required for commercial IoT deployment.

Cost analysis reveals that liquid metal materials, particularly gallium-based alloys like EGaIn and Galinstan, remain prohibitively expensive at $200-600 per kilogram compared to conventional copper at $8-10 per kilogram. While each IoT device requires minimal amounts (typically 10-50mg), the cumulative material costs become significant at scale. Additionally, specialized equipment for handling and processing liquid metals adds $500,000-2,000,000 in capital expenditure for production lines.

Manufacturing yield rates present another critical challenge, with current processes achieving only 70-85% consistency in electrical performance across batches. This variability stems from oxidation control difficulties, precise dispensing challenges, and substrate adhesion inconsistencies. Industry standards typically demand 95%+ yield rates for viable commercial production, highlighting a significant gap requiring technological advancement.

Recent innovations show promise for improving scalability, including automated dispensing systems that increase throughput to 500-1000 units per hour and reduce material waste by 30-40%. Roll-to-roll processing techniques being developed by companies like Liquid X Printed Metals and Pragmatic Semiconductor could potentially achieve throughput rates of 5,000+ units per hour, though these remain in early development stages.

Economic modeling indicates that achieving price parity with traditional interconnect solutions requires production volumes exceeding 10 million units annually. Current cost projections suggest a 3-5 year timeline before liquid metal interconnects become economically viable for mainstream IoT applications, with initial adoption limited to premium devices where performance advantages justify higher costs.

Environmental considerations also impact manufacturing scalability, as gallium mining and processing carry significant ecological footprints. Recycling infrastructure for liquid metal recovery from disposed devices remains underdeveloped, potentially creating regulatory hurdles for mass production. Developing closed-loop manufacturing systems could address these concerns while potentially reducing long-term material costs by 15-25%.

Cost analysis reveals that liquid metal materials, particularly gallium-based alloys like EGaIn and Galinstan, remain prohibitively expensive at $200-600 per kilogram compared to conventional copper at $8-10 per kilogram. While each IoT device requires minimal amounts (typically 10-50mg), the cumulative material costs become significant at scale. Additionally, specialized equipment for handling and processing liquid metals adds $500,000-2,000,000 in capital expenditure for production lines.

Manufacturing yield rates present another critical challenge, with current processes achieving only 70-85% consistency in electrical performance across batches. This variability stems from oxidation control difficulties, precise dispensing challenges, and substrate adhesion inconsistencies. Industry standards typically demand 95%+ yield rates for viable commercial production, highlighting a significant gap requiring technological advancement.

Recent innovations show promise for improving scalability, including automated dispensing systems that increase throughput to 500-1000 units per hour and reduce material waste by 30-40%. Roll-to-roll processing techniques being developed by companies like Liquid X Printed Metals and Pragmatic Semiconductor could potentially achieve throughput rates of 5,000+ units per hour, though these remain in early development stages.

Economic modeling indicates that achieving price parity with traditional interconnect solutions requires production volumes exceeding 10 million units annually. Current cost projections suggest a 3-5 year timeline before liquid metal interconnects become economically viable for mainstream IoT applications, with initial adoption limited to premium devices where performance advantages justify higher costs.

Environmental considerations also impact manufacturing scalability, as gallium mining and processing carry significant ecological footprints. Recycling infrastructure for liquid metal recovery from disposed devices remains underdeveloped, potentially creating regulatory hurdles for mass production. Developing closed-loop manufacturing systems could address these concerns while potentially reducing long-term material costs by 15-25%.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!