Liquid Metal Interconnect Impact on Sensor Calibration Standards

SEP 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Interconnect Technology Evolution and Objectives

Liquid metal interconnect technology has evolved significantly over the past decades, transitioning from theoretical concepts to practical applications in flexible electronics. The journey began in the early 2000s with pioneering research on room-temperature liquid metals, primarily gallium-based alloys such as eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan). These materials offered unique properties of maintaining liquid state at room temperature while providing excellent electrical conductivity comparable to many solid metals.

The evolution accelerated around 2010-2015 when researchers demonstrated the first functional prototypes of stretchable circuits using liquid metal interconnects. This period marked a crucial shift from laboratory curiosities to engineered solutions addressing real-world challenges in wearable technology and soft robotics. The development of novel encapsulation techniques and patterning methods enabled more complex circuit designs and improved reliability.

By 2018, the technology had matured sufficiently to allow integration with various sensing platforms, creating a new paradigm for sensor design where the interconnect itself could adapt to mechanical deformation without compromising electrical performance. This adaptability proved particularly valuable for applications requiring calibration stability under varying physical conditions.

Recent advancements have focused on addressing oxidation challenges, enhancing adhesion to substrates, and developing manufacturing techniques suitable for mass production. The introduction of surface modification methods and composite formulations has expanded the application scope while improving long-term stability and performance predictability critical for sensor calibration standards.

The primary objective of liquid metal interconnect technology development is to establish reliable, reproducible electrical connections that maintain consistent performance under mechanical stress, thereby enabling accurate and stable sensor calibration across diverse operating environments. This includes developing standardized characterization methods to quantify electrical, mechanical, and thermal properties under various deformation scenarios.

Secondary objectives include miniaturization of liquid metal channels for higher-density integration, reduction of manufacturing costs through automated deposition techniques, and enhancement of long-term stability through improved encapsulation strategies. These advancements aim to address current limitations in sensor calibration drift that occur with traditional rigid interconnects when subjected to mechanical strain.

Looking forward, the technology roadmap targets seamless integration with emerging sensing platforms, particularly in healthcare monitoring, environmental sensing, and industrial automation. The ultimate goal is to establish liquid metal interconnects as a standardized solution for next-generation flexible sensing systems where calibration stability under mechanical deformation is paramount, enabling reliable data collection in dynamic environments.

The evolution accelerated around 2010-2015 when researchers demonstrated the first functional prototypes of stretchable circuits using liquid metal interconnects. This period marked a crucial shift from laboratory curiosities to engineered solutions addressing real-world challenges in wearable technology and soft robotics. The development of novel encapsulation techniques and patterning methods enabled more complex circuit designs and improved reliability.

By 2018, the technology had matured sufficiently to allow integration with various sensing platforms, creating a new paradigm for sensor design where the interconnect itself could adapt to mechanical deformation without compromising electrical performance. This adaptability proved particularly valuable for applications requiring calibration stability under varying physical conditions.

Recent advancements have focused on addressing oxidation challenges, enhancing adhesion to substrates, and developing manufacturing techniques suitable for mass production. The introduction of surface modification methods and composite formulations has expanded the application scope while improving long-term stability and performance predictability critical for sensor calibration standards.

The primary objective of liquid metal interconnect technology development is to establish reliable, reproducible electrical connections that maintain consistent performance under mechanical stress, thereby enabling accurate and stable sensor calibration across diverse operating environments. This includes developing standardized characterization methods to quantify electrical, mechanical, and thermal properties under various deformation scenarios.

Secondary objectives include miniaturization of liquid metal channels for higher-density integration, reduction of manufacturing costs through automated deposition techniques, and enhancement of long-term stability through improved encapsulation strategies. These advancements aim to address current limitations in sensor calibration drift that occur with traditional rigid interconnects when subjected to mechanical strain.

Looking forward, the technology roadmap targets seamless integration with emerging sensing platforms, particularly in healthcare monitoring, environmental sensing, and industrial automation. The ultimate goal is to establish liquid metal interconnects as a standardized solution for next-generation flexible sensing systems where calibration stability under mechanical deformation is paramount, enabling reliable data collection in dynamic environments.

Market Analysis for Advanced Sensor Calibration Solutions

The global market for advanced sensor calibration solutions is experiencing significant growth, driven by the increasing adoption of IoT devices, autonomous systems, and precision manufacturing processes. Current market valuations indicate that the sensor calibration market reached approximately $5.2 billion in 2022 and is projected to grow at a CAGR of 6.8% through 2028. Within this broader market, solutions addressing liquid metal interconnect challenges represent an emerging segment with substantial growth potential.

Demand for high-precision calibration standards is particularly strong in industries requiring extreme reliability, including aerospace, medical devices, automotive safety systems, and industrial automation. The introduction of liquid metal interconnect technology has created a specialized market need for calibration solutions that can account for the unique electrical and thermal properties of these materials. This segment is expected to grow faster than the overall market at approximately 9.3% annually.

Regional analysis reveals that North America currently holds the largest market share at 38%, followed by Europe (27%) and Asia-Pacific (24%). However, the Asia-Pacific region is demonstrating the fastest growth rate, particularly in countries with expanding electronics manufacturing sectors such as China, South Korea, and Taiwan. These regions are investing heavily in advanced manufacturing capabilities that require sophisticated sensor calibration technologies.

Customer segmentation shows distinct market requirements across different sectors. Medical device manufacturers prioritize calibration solutions with regulatory compliance features, while automotive and aerospace customers emphasize long-term stability and performance under extreme conditions. Industrial automation clients typically seek cost-effective solutions that can be deployed at scale while maintaining precision.

Competitive analysis reveals a fragmented market landscape with several specialized players focusing on liquid metal interconnect calibration solutions. Market leaders include established instrumentation companies that have expanded their offerings, alongside innovative startups developing proprietary calibration methodologies specifically for liquid metal applications. The market is characterized by moderate barriers to entry due to the specialized knowledge required, but low customer switching costs create competitive pressure on pricing and service offerings.

Market drivers include the increasing miniaturization of sensors, growing demand for flexible electronics, and stricter regulatory requirements for sensor accuracy in critical applications. The adoption of liquid metal interconnects in next-generation wearable health monitors and implantable medical devices is creating particularly strong demand for specialized calibration solutions that can ensure consistent performance throughout product lifecycles.

Demand for high-precision calibration standards is particularly strong in industries requiring extreme reliability, including aerospace, medical devices, automotive safety systems, and industrial automation. The introduction of liquid metal interconnect technology has created a specialized market need for calibration solutions that can account for the unique electrical and thermal properties of these materials. This segment is expected to grow faster than the overall market at approximately 9.3% annually.

Regional analysis reveals that North America currently holds the largest market share at 38%, followed by Europe (27%) and Asia-Pacific (24%). However, the Asia-Pacific region is demonstrating the fastest growth rate, particularly in countries with expanding electronics manufacturing sectors such as China, South Korea, and Taiwan. These regions are investing heavily in advanced manufacturing capabilities that require sophisticated sensor calibration technologies.

Customer segmentation shows distinct market requirements across different sectors. Medical device manufacturers prioritize calibration solutions with regulatory compliance features, while automotive and aerospace customers emphasize long-term stability and performance under extreme conditions. Industrial automation clients typically seek cost-effective solutions that can be deployed at scale while maintaining precision.

Competitive analysis reveals a fragmented market landscape with several specialized players focusing on liquid metal interconnect calibration solutions. Market leaders include established instrumentation companies that have expanded their offerings, alongside innovative startups developing proprietary calibration methodologies specifically for liquid metal applications. The market is characterized by moderate barriers to entry due to the specialized knowledge required, but low customer switching costs create competitive pressure on pricing and service offerings.

Market drivers include the increasing miniaturization of sensors, growing demand for flexible electronics, and stricter regulatory requirements for sensor accuracy in critical applications. The adoption of liquid metal interconnects in next-generation wearable health monitors and implantable medical devices is creating particularly strong demand for specialized calibration solutions that can ensure consistent performance throughout product lifecycles.

Technical Challenges in Liquid Metal Interconnect Implementation

Despite the promising potential of liquid metal interconnects in flexible electronics, several significant technical challenges impede their widespread implementation. The inherent fluidity of liquid metals, while advantageous for flexibility, creates substantial difficulties in maintaining stable electrical connections. Surface oxidation occurs rapidly when gallium-based liquid metals are exposed to oxygen, forming a thin oxide layer that affects conductivity and interface properties. This oxidation process, though providing some structural stability, introduces unpredictable electrical resistance variations that complicate sensor calibration procedures.

Mechanical stability presents another critical challenge, as liquid metal interconnects are susceptible to deformation under external forces. The tendency of these materials to migrate or redistribute under stress conditions leads to inconsistent electrical pathways, directly impacting sensor performance reliability. Current encapsulation techniques struggle to balance the need for containing the liquid metal while maintaining the flexibility that makes these interconnects desirable in the first place.

Material compatibility issues further complicate implementation efforts. Gallium-based liquid metals exhibit corrosive properties toward certain metals, particularly aluminum, which limits substrate and electrode material options. This corrosion mechanism involves gallium penetrating the grain boundaries of metals, causing embrittlement and eventual structural failure. The resulting intermetallic compounds formed at interfaces create additional electrical resistance that changes over time, introducing drift in sensor calibration parameters.

Temperature sensitivity represents another significant hurdle, as liquid metals demonstrate substantial viscosity and electrical conductivity changes across operational temperature ranges. These variations create non-linear response characteristics that require complex compensation algorithms for accurate sensor readings. The phase transition behaviors near temperature extremes can cause catastrophic connection failures in demanding environments.

Manufacturing scalability remains problematic due to the precise deposition requirements for liquid metal interconnects. Current techniques like microfluidic injection, direct writing, and stencil printing lack the precision and reproducibility necessary for mass production. The absence of standardized fabrication protocols results in significant device-to-device variations that undermine calibration consistency across production batches.

Addressing these challenges requires interdisciplinary approaches combining materials science, electrical engineering, and manufacturing innovation. Recent research has explored composite materials that maintain liquid properties while enhancing stability, advanced encapsulation techniques using stretchable polymers with selective permeability, and novel surface treatments to control oxidation behavior. These developments show promise but require further refinement before liquid metal interconnects can reliably meet the stringent calibration standards demanded by precision sensing applications.

Mechanical stability presents another critical challenge, as liquid metal interconnects are susceptible to deformation under external forces. The tendency of these materials to migrate or redistribute under stress conditions leads to inconsistent electrical pathways, directly impacting sensor performance reliability. Current encapsulation techniques struggle to balance the need for containing the liquid metal while maintaining the flexibility that makes these interconnects desirable in the first place.

Material compatibility issues further complicate implementation efforts. Gallium-based liquid metals exhibit corrosive properties toward certain metals, particularly aluminum, which limits substrate and electrode material options. This corrosion mechanism involves gallium penetrating the grain boundaries of metals, causing embrittlement and eventual structural failure. The resulting intermetallic compounds formed at interfaces create additional electrical resistance that changes over time, introducing drift in sensor calibration parameters.

Temperature sensitivity represents another significant hurdle, as liquid metals demonstrate substantial viscosity and electrical conductivity changes across operational temperature ranges. These variations create non-linear response characteristics that require complex compensation algorithms for accurate sensor readings. The phase transition behaviors near temperature extremes can cause catastrophic connection failures in demanding environments.

Manufacturing scalability remains problematic due to the precise deposition requirements for liquid metal interconnects. Current techniques like microfluidic injection, direct writing, and stencil printing lack the precision and reproducibility necessary for mass production. The absence of standardized fabrication protocols results in significant device-to-device variations that undermine calibration consistency across production batches.

Addressing these challenges requires interdisciplinary approaches combining materials science, electrical engineering, and manufacturing innovation. Recent research has explored composite materials that maintain liquid properties while enhancing stability, advanced encapsulation techniques using stretchable polymers with selective permeability, and novel surface treatments to control oxidation behavior. These developments show promise but require further refinement before liquid metal interconnects can reliably meet the stringent calibration standards demanded by precision sensing applications.

Current Liquid Metal Interconnect Solutions for Sensors

01 Liquid metal interconnect materials and compositions

Various compositions of liquid metal materials are used for interconnect calibration standards. These include gallium-based alloys, indium-tin alloys, and other metallic compositions that remain liquid at operating temperatures. These materials provide reliable electrical conductivity while allowing for flexibility in connections. The liquid state enables self-healing properties and adaptation to thermal expansion, making them ideal for calibration standards where consistent electrical properties are required.- Liquid metal interconnect materials and compositions: Various compositions of liquid metal materials are used for interconnect applications, including gallium-based alloys and other metallic compounds. These materials offer advantages such as high electrical conductivity, thermal stability, and flexibility. The formulations can be optimized for specific calibration standard applications by adjusting the metal composition ratios and incorporating additives that enhance performance characteristics.

- Calibration methods for liquid metal interconnects: Specialized calibration techniques are employed to ensure accurate measurements of liquid metal interconnect properties. These methods include temperature compensation algorithms, reference standard comparisons, and precision measurement protocols. Calibration standards are designed to account for the unique physical properties of liquid metals, such as their thermal expansion characteristics and electrical resistance variations under different conditions.

- Fabrication techniques for liquid metal interconnect standards: Advanced manufacturing processes are used to create precise liquid metal interconnect calibration standards. These techniques include microfluidic channel formation, encapsulation methods to contain the liquid metal, and surface treatment processes to control wetting behaviors. Specialized deposition and patterning methods ensure consistent geometry and electrical properties across multiple calibration standards.

- Testing and validation systems for liquid metal interconnects: Comprehensive testing systems are developed to validate the performance of liquid metal interconnect calibration standards. These systems incorporate precision measurement equipment, environmental control chambers, and automated testing protocols. The validation process typically includes electrical conductivity measurements, thermal cycling tests, and mechanical stress evaluations to ensure the standards maintain accuracy under various operating conditions.

- Integration of liquid metal interconnects in semiconductor devices: Liquid metal interconnect calibration standards are integrated into semiconductor testing and manufacturing processes. This integration involves specialized packaging techniques, interface designs for connecting to test equipment, and compatibility considerations with existing semiconductor fabrication processes. The standards serve as reference points for validating the performance of interconnects in advanced semiconductor devices, ensuring reliable electrical connections and signal integrity.

02 Calibration methods for liquid metal interconnects

Specific calibration methodologies have been developed for liquid metal interconnects to ensure accurate measurements. These methods include temperature compensation techniques, impedance matching procedures, and reference standard comparisons. Calibration systems may incorporate automated testing equipment that can verify the electrical characteristics of liquid metal interconnects against known standards, ensuring measurement accuracy across different operating conditions.Expand Specific Solutions03 Packaging and containment systems for liquid metal standards

Specialized packaging solutions are designed to contain liquid metal interconnects while maintaining their calibration properties. These include hermetically sealed enclosures, micro-channels with non-reactive coatings, and temperature-controlled housings. The containment systems prevent oxidation and contamination of the liquid metal while allowing for reliable electrical connections to measurement equipment. Some designs incorporate flexible membranes that accommodate the fluid nature of the interconnect material.Expand Specific Solutions04 Temperature control and stability for liquid metal calibration standards

Temperature management systems are critical for maintaining the accuracy of liquid metal interconnect calibration standards. These systems include precision heating elements, thermal isolation structures, and temperature monitoring sensors. Maintaining stable temperatures ensures consistent electrical properties of the liquid metal, which is essential for reliable calibration. Some advanced systems incorporate active feedback control to compensate for environmental temperature variations.Expand Specific Solutions05 Integration of liquid metal interconnects in semiconductor testing

Liquid metal interconnects are integrated into semiconductor testing platforms to provide reliable calibration standards. These implementations include probe card systems, wafer-level test fixtures, and chip-scale calibration references. The liquid metal provides consistent electrical characteristics while accommodating the mechanical stresses of testing environments. Advanced designs incorporate microfluidic delivery systems that can precisely position the liquid metal at test points, enabling accurate calibration of high-frequency measurement equipment.Expand Specific Solutions

Industry Leaders in Liquid Metal and Sensor Calibration

The liquid metal interconnect technology for sensor calibration is currently in a growth phase, with increasing market adoption driven by demands for higher precision and reliability in sensor applications. The market is expanding rapidly, estimated to reach significant scale by 2025 as industries embrace advanced calibration methods. From a technical maturity perspective, the landscape shows varied development stages: Intel and Samsung lead with comprehensive commercial solutions, while Infineon, Microchip, and Robert Bosch have established strong positions with specialized implementations. Companies like DENSO, Kyocera, and TE Connectivity are advancing application-specific adaptations, particularly in automotive and industrial sectors. Academic institutions including Hangzhou Dianzi University and Xidian University are contributing fundamental research to address remaining technical challenges in thermal stability and long-term reliability.

DENSO Corp.

Technical Solution: DENSO has pioneered a liquid metal interconnect system specifically designed for high-precision automotive sensor calibration. Their technology utilizes eutectic gallium-indium (EGaIn) alloys encapsulated in elastomeric microchannels to create stretchable, reliable connections between sensor components. DENSO's approach incorporates a proprietary surface treatment process that prevents liquid metal embrittlement while maintaining excellent electrical conductivity across temperature extremes. The company has developed standardized calibration protocols that account for the unique electrical resistance characteristics of liquid metal interconnects, ensuring measurement consistency across production batches[2]. Their system includes integrated temperature compensation algorithms that dynamically adjust calibration parameters based on the liquid metal's known thermal response curve, maintaining accuracy within ±0.5% across the automotive operating temperature range[4]. DENSO has successfully implemented this technology in mass-produced MEMS-based pressure sensors for engine management systems.

Strengths: Exceptional flexibility allowing integration into complex 3D sensor geometries while maintaining calibration integrity. Demonstrated long-term stability with minimal drift over 8+ years of simulated vehicle lifetime testing. Weaknesses: Higher initial production costs compared to traditional wire bonding. Requires specialized handling procedures during manufacturing to prevent contamination of the liquid metal interface.

Robert Bosch GmbH

Technical Solution: Robert Bosch has developed advanced liquid metal interconnect technology for automotive sensor calibration that utilizes gallium-based alloys with precise thermal and electrical conductivity properties. Their solution implements microfluidic channels within sensor packages that allow liquid metal to form dynamic interconnections between sensing elements and processing circuits. This approach enables real-time calibration adjustment as environmental conditions change, particularly important for pressure and temperature sensors in engine management systems. Bosch's technology incorporates self-healing capabilities where the liquid metal can reconnect if mechanical stress causes temporary disconnection[1]. Their calibration standards include automated compensation algorithms that continuously monitor the liquid metal's electrical properties to maintain measurement accuracy across wide temperature ranges (-40°C to 150°C), addressing a key challenge in automotive sensor applications[3].

Strengths: Superior thermal cycling resilience compared to solid interconnects, with demonstrated reliability over 10,000+ thermal cycles. Self-healing capability provides enhanced durability in high-vibration environments. Weaknesses: Higher manufacturing complexity requiring specialized equipment for liquid metal handling and encapsulation. Potential for oxidation at interface points requiring additional protective measures.

Key Patents and Research in Liquid Metal Interconnect Technology

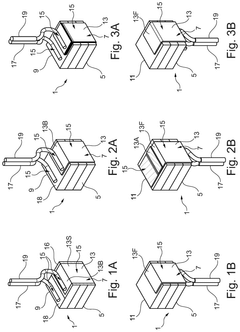

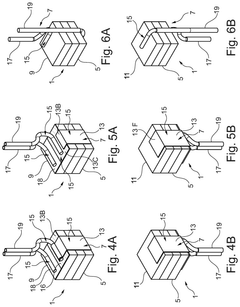

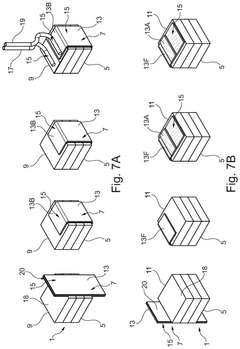

Sensor comprising an interconnect having a carrier film

PatentActiveUS12120961B2

Innovation

- A sensor with a metallic layer interconnect, comprising a carrier film or wire with a metallic coating, provides an electrical connection without compromising acoustic properties, by reducing the space needed for the interconnect and minimizing attenuation, using materials like gold or platinum for corrosion prevention.

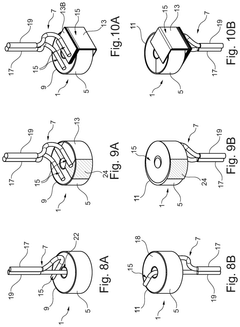

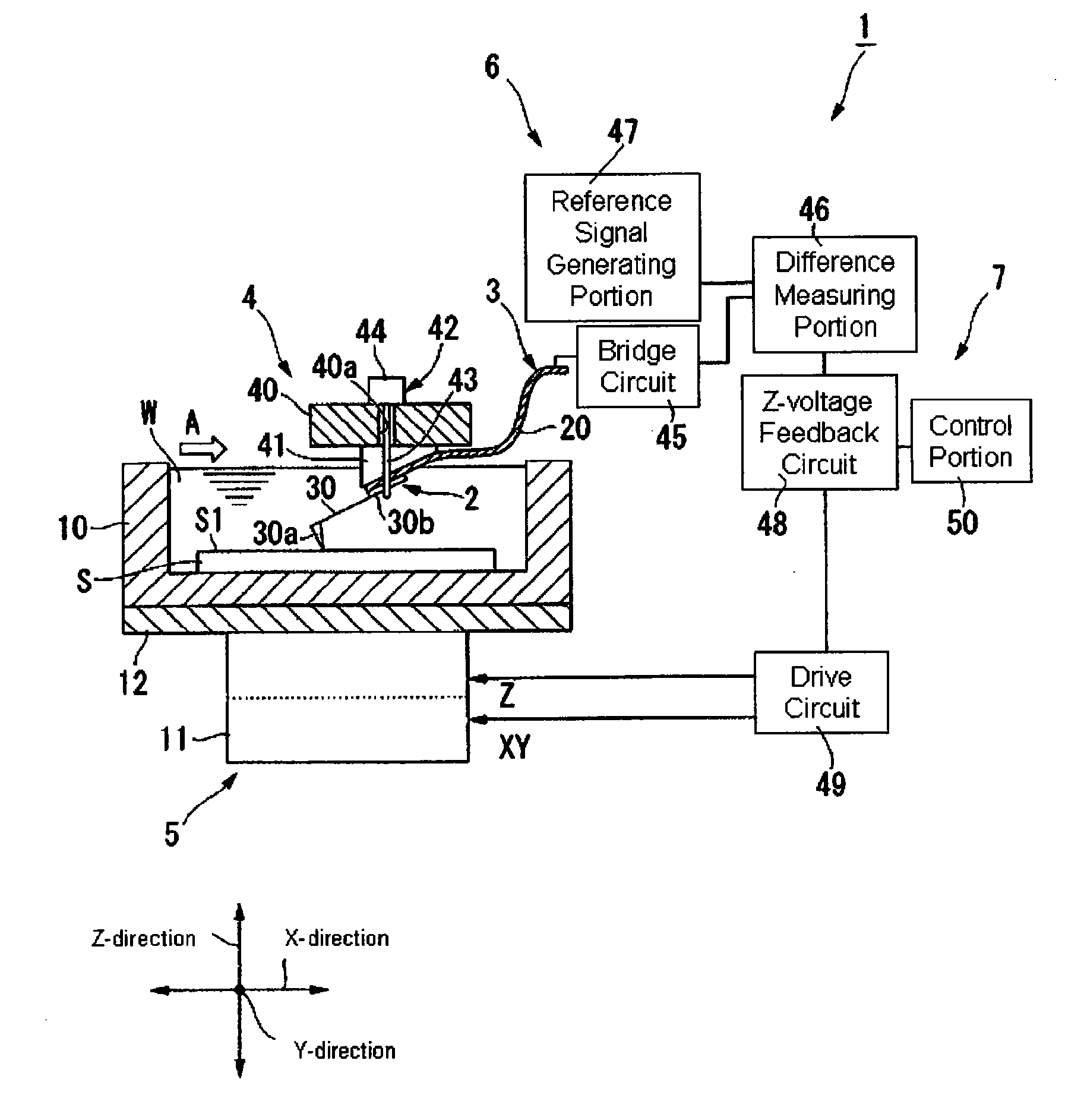

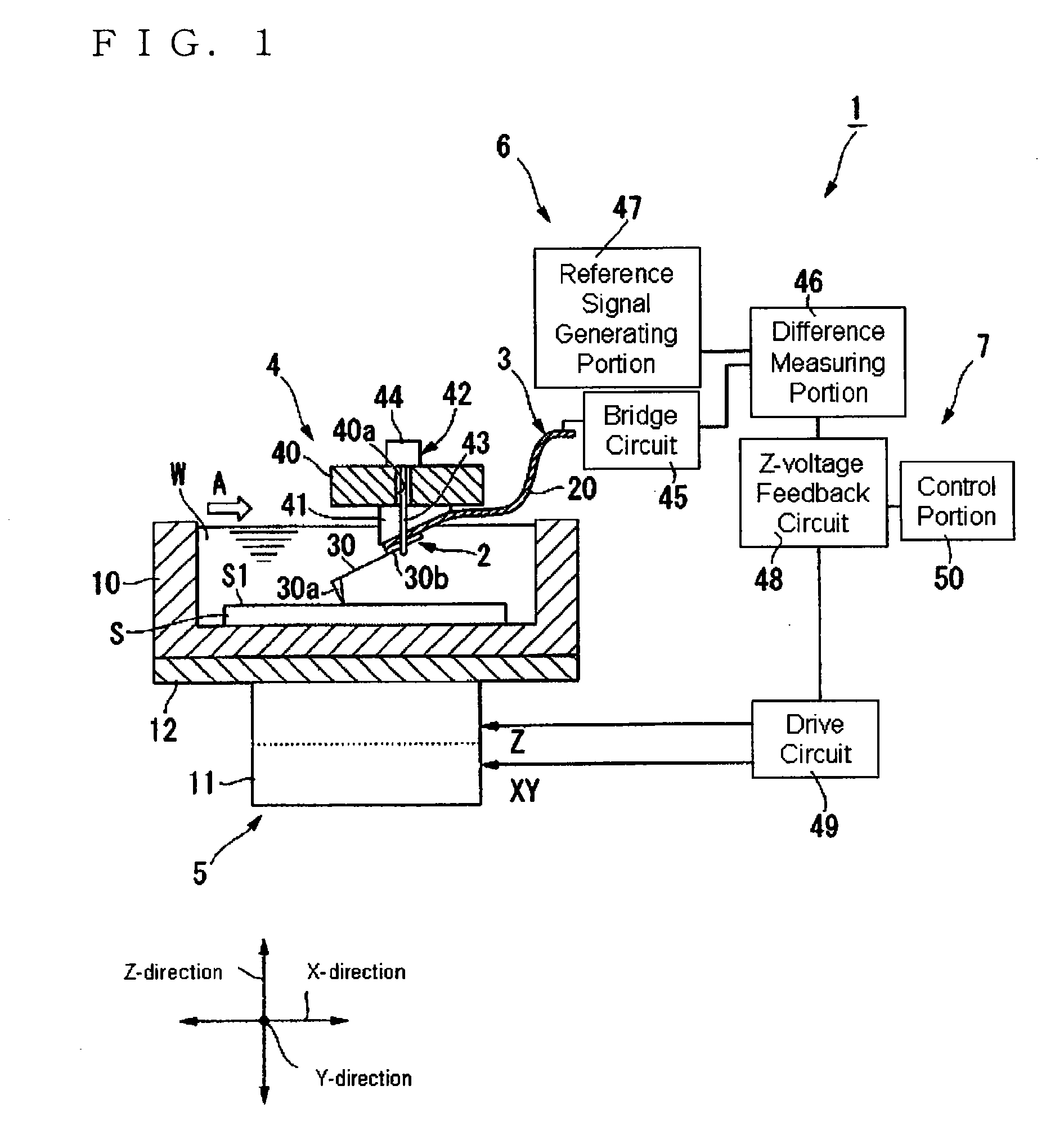

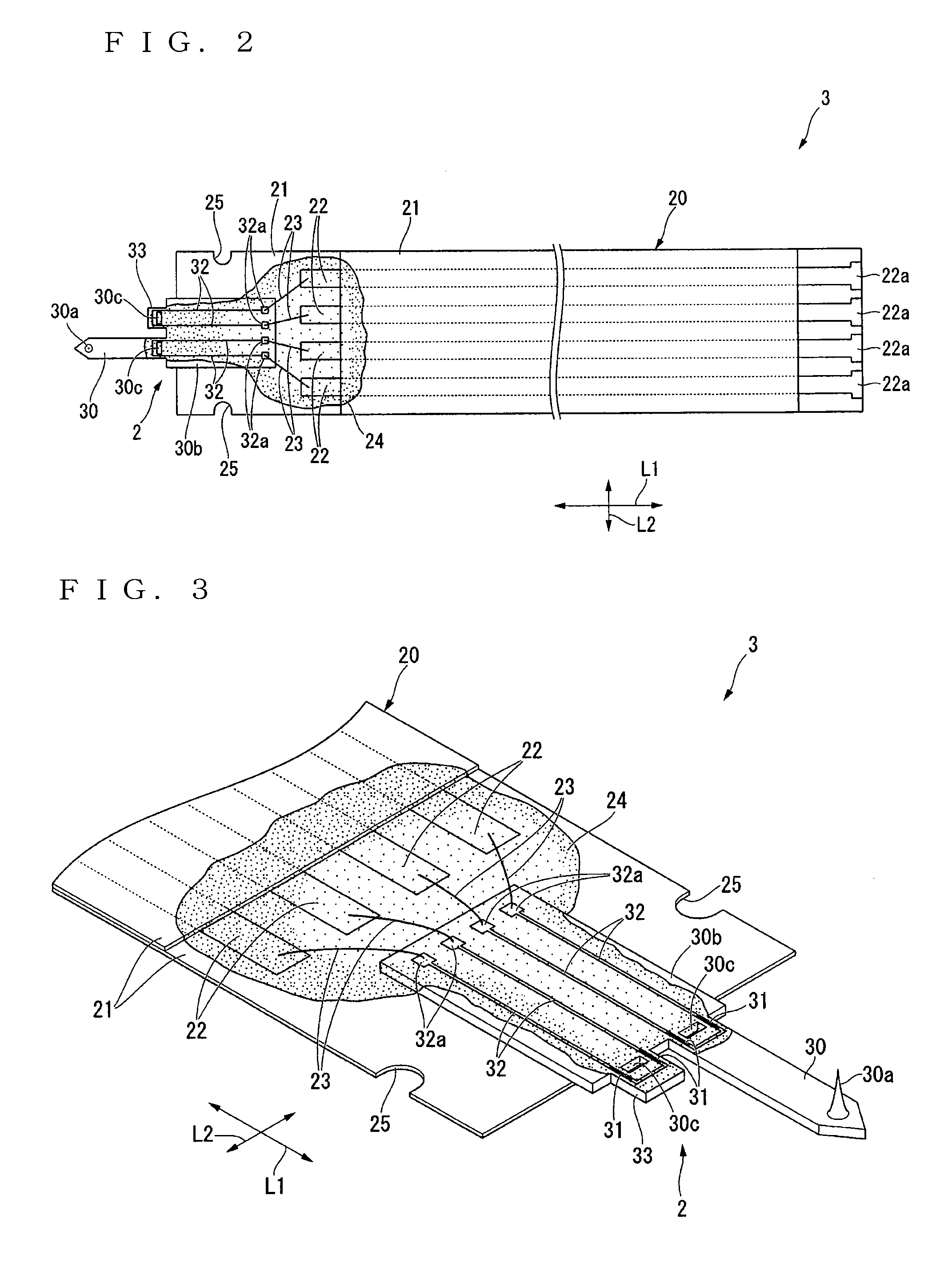

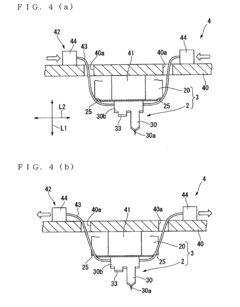

Sensor for observations in liquid environments and observation apparatus for use in liquid environments

PatentInactiveUS20090265819A1

Innovation

- A sensor design featuring a self-detecting probe with a flexible substrate and insulating resin coating, where the strain resistive element is protected from liquid contact, and external contacts are kept out of the liquid environment, ensuring waterproofing and preventing electrical shorting and corrosion.

Material Compatibility and Reliability Assessment

The compatibility of liquid metal interconnects with various sensor materials presents significant challenges for maintaining calibration standards. Gallium-based liquid metals, particularly eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan), exhibit corrosive interactions with numerous metallic substrates including aluminum, copper, and nickel. This corrosivity stems from gallium's tendency to form intermetallic compounds, leading to embrittlement and structural degradation of contact surfaces over time. Such material interactions directly impact sensor stability and measurement accuracy, necessitating comprehensive compatibility assessments before implementation.

Environmental factors substantially influence the reliability of liquid metal interconnects in sensor applications. Temperature fluctuations affect the viscosity and surface tension properties of liquid metals, potentially altering electrical conductivity and contact resistance at critical junctions. Humidity and oxidation represent additional concerns, as gallium-based alloys develop thin oxide layers upon exposure to oxygen, which can modify their electrical and mechanical characteristics. These environmental sensitivities must be quantified to establish appropriate calibration compensation algorithms.

Long-term stability testing reveals that liquid metal interconnects experience gradual performance degradation through multiple mechanisms. Contact resistance may increase over time due to progressive oxidation or intermetallic compound formation at interfaces. Mechanical stress cycling can induce migration of the liquid metal, potentially creating intermittent connections or complete circuit failures. Accelerated aging tests indicate that these effects become particularly pronounced under thermal cycling conditions, with reliability metrics declining significantly after 1000+ hours of operation in variable environments.

Encapsulation strategies have emerged as critical for enhancing compatibility and reliability. Polymeric barriers including polydimethylsiloxane (PDMS), parylene, and specialized fluoropolymer coatings can effectively isolate liquid metals from reactive substrates while maintaining flexibility. Recent research demonstrates that multilayer encapsulation approaches combining hydrophobic and elastomeric materials can extend operational lifetimes by 300-500% compared to unprotected interconnects, though these solutions add complexity to manufacturing processes.

Standardization efforts for material compatibility testing remain in nascent stages. Current protocols typically involve resistance monitoring under controlled environmental conditions, but lack industry-wide acceptance. The development of standardized testing methodologies specifically addressing liquid metal interconnect reliability represents an urgent need for sensor calibration applications. Such standards would ideally incorporate accelerated aging protocols, thermal cycling parameters, and mechanical stress testing to predict long-term performance in field conditions.

Environmental factors substantially influence the reliability of liquid metal interconnects in sensor applications. Temperature fluctuations affect the viscosity and surface tension properties of liquid metals, potentially altering electrical conductivity and contact resistance at critical junctions. Humidity and oxidation represent additional concerns, as gallium-based alloys develop thin oxide layers upon exposure to oxygen, which can modify their electrical and mechanical characteristics. These environmental sensitivities must be quantified to establish appropriate calibration compensation algorithms.

Long-term stability testing reveals that liquid metal interconnects experience gradual performance degradation through multiple mechanisms. Contact resistance may increase over time due to progressive oxidation or intermetallic compound formation at interfaces. Mechanical stress cycling can induce migration of the liquid metal, potentially creating intermittent connections or complete circuit failures. Accelerated aging tests indicate that these effects become particularly pronounced under thermal cycling conditions, with reliability metrics declining significantly after 1000+ hours of operation in variable environments.

Encapsulation strategies have emerged as critical for enhancing compatibility and reliability. Polymeric barriers including polydimethylsiloxane (PDMS), parylene, and specialized fluoropolymer coatings can effectively isolate liquid metals from reactive substrates while maintaining flexibility. Recent research demonstrates that multilayer encapsulation approaches combining hydrophobic and elastomeric materials can extend operational lifetimes by 300-500% compared to unprotected interconnects, though these solutions add complexity to manufacturing processes.

Standardization efforts for material compatibility testing remain in nascent stages. Current protocols typically involve resistance monitoring under controlled environmental conditions, but lack industry-wide acceptance. The development of standardized testing methodologies specifically addressing liquid metal interconnect reliability represents an urgent need for sensor calibration applications. Such standards would ideally incorporate accelerated aging protocols, thermal cycling parameters, and mechanical stress testing to predict long-term performance in field conditions.

Environmental and Safety Considerations for Liquid Metal Implementation

The implementation of liquid metal interconnects in sensor systems introduces significant environmental and safety considerations that must be thoroughly addressed. Gallium-based liquid metals, while offering exceptional electrical and thermal conductivity, present unique challenges due to their chemical properties. These materials can react with certain metals, particularly aluminum, causing embrittlement and structural degradation over time. This reactivity necessitates careful material selection for containment and interface components to prevent system failures and potential environmental contamination.

Toxicological profiles of liquid metal components require careful evaluation. While gallium itself has relatively low toxicity compared to mercury, alloys like Galinstan contain indium and tin, which may present different risk profiles. Long-term exposure studies remain limited, creating uncertainty regarding chronic health effects for workers regularly handling these materials during sensor manufacturing and calibration processes. Established handling protocols and appropriate personal protective equipment are essential to minimize exposure risks.

Environmental considerations extend to the entire lifecycle of liquid metal-enabled sensors. The production phase involves energy-intensive refining processes for constituent metals, contributing to carbon footprint concerns. More critically, end-of-life management presents challenges as improper disposal could lead to metal leaching into soil and water systems. Recycling infrastructure for these specialized materials remains underdeveloped, highlighting the need for closed-loop systems that can recover and repurpose liquid metals from decommissioned sensors.

Regulatory compliance frameworks for liquid metal implementation vary significantly across jurisdictions, creating complexity for global sensor deployment. The European Union's RoHS and REACH regulations impose strict documentation requirements for novel materials, while other regions may have less developed oversight. This regulatory landscape directly impacts calibration standards, as certification bodies must establish protocols that account for both performance characteristics and safety considerations of liquid metal interconnects.

Temperature sensitivity presents another safety consideration, as some liquid metal alloys expand upon solidification, potentially damaging sensor housings during extreme temperature events. This physical property necessitates robust containment designs and appropriate operational temperature range specifications to maintain calibration integrity and prevent mechanical failures that could lead to material release.

Electromagnetic compatibility represents an additional safety dimension, as liquid metal interconnects may interact differently with electromagnetic fields compared to conventional solid conductors. This characteristic could potentially affect sensor readings in high-EMI environments, requiring specialized calibration procedures and shielding considerations to maintain measurement accuracy and system safety in industrial applications.

Toxicological profiles of liquid metal components require careful evaluation. While gallium itself has relatively low toxicity compared to mercury, alloys like Galinstan contain indium and tin, which may present different risk profiles. Long-term exposure studies remain limited, creating uncertainty regarding chronic health effects for workers regularly handling these materials during sensor manufacturing and calibration processes. Established handling protocols and appropriate personal protective equipment are essential to minimize exposure risks.

Environmental considerations extend to the entire lifecycle of liquid metal-enabled sensors. The production phase involves energy-intensive refining processes for constituent metals, contributing to carbon footprint concerns. More critically, end-of-life management presents challenges as improper disposal could lead to metal leaching into soil and water systems. Recycling infrastructure for these specialized materials remains underdeveloped, highlighting the need for closed-loop systems that can recover and repurpose liquid metals from decommissioned sensors.

Regulatory compliance frameworks for liquid metal implementation vary significantly across jurisdictions, creating complexity for global sensor deployment. The European Union's RoHS and REACH regulations impose strict documentation requirements for novel materials, while other regions may have less developed oversight. This regulatory landscape directly impacts calibration standards, as certification bodies must establish protocols that account for both performance characteristics and safety considerations of liquid metal interconnects.

Temperature sensitivity presents another safety consideration, as some liquid metal alloys expand upon solidification, potentially damaging sensor housings during extreme temperature events. This physical property necessitates robust containment designs and appropriate operational temperature range specifications to maintain calibration integrity and prevent mechanical failures that could lead to material release.

Electromagnetic compatibility represents an additional safety dimension, as liquid metal interconnects may interact differently with electromagnetic fields compared to conventional solid conductors. This characteristic could potentially affect sensor readings in high-EMI environments, requiring specialized calibration procedures and shielding considerations to maintain measurement accuracy and system safety in industrial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!