Liquid Metal Interconnect: Influence of Environmental Standards

SEP 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Interconnect Technology Background and Objectives

Liquid metal interconnects represent a revolutionary approach in the field of electronic connections, offering unique properties that conventional metal interconnects cannot match. The evolution of this technology can be traced back to the early 2000s when researchers began exploring the potential of room-temperature liquid metals, particularly gallium-based alloys, as alternatives to traditional soldering materials. The inherent fluidity of these materials, combined with their excellent electrical conductivity, presented promising opportunities for flexible and self-healing electronic systems.

The technological trajectory has been marked by significant advancements in material science, particularly in addressing oxidation issues and enhancing compatibility with various substrates. Early applications were limited by gallium's tendency to oxidize rapidly and its potential for corrosion with certain metals. However, recent innovations in alloy compositions and encapsulation techniques have substantially mitigated these challenges, expanding the practical applications of liquid metal interconnects.

Current technological objectives center on developing environmentally compliant liquid metal interconnect solutions that meet increasingly stringent global standards while maintaining optimal performance characteristics. This includes reducing or eliminating toxic components, ensuring recyclability, and minimizing environmental impact throughout the product lifecycle. The EU's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide have accelerated research into alternative formulations that avoid restricted substances.

Another critical objective is enhancing the stability and reliability of liquid metal interconnects under various environmental conditions. Temperature fluctuations, humidity, and mechanical stress can significantly affect the performance and longevity of these connections. Research aims to develop robust solutions that maintain integrity across diverse operating environments while complying with environmental standards.

The integration of liquid metal interconnects with emerging technologies represents a further technological goal. As flexible electronics, wearable devices, and soft robotics continue to evolve, liquid metal interconnects must adapt to meet specialized requirements while adhering to environmental regulations. This includes developing manufacturing processes that are both environmentally sustainable and economically viable at scale.

Looking forward, the field is moving toward bio-compatible liquid metal formulations for medical applications, environmentally benign alternatives to gallium-based alloys, and advanced encapsulation technologies that prevent leakage while allowing controlled deformation. These developments are crucial as environmental standards become more stringent and as applications expand into sensitive areas such as medical implants and environmental monitoring systems.

The technological trajectory has been marked by significant advancements in material science, particularly in addressing oxidation issues and enhancing compatibility with various substrates. Early applications were limited by gallium's tendency to oxidize rapidly and its potential for corrosion with certain metals. However, recent innovations in alloy compositions and encapsulation techniques have substantially mitigated these challenges, expanding the practical applications of liquid metal interconnects.

Current technological objectives center on developing environmentally compliant liquid metal interconnect solutions that meet increasingly stringent global standards while maintaining optimal performance characteristics. This includes reducing or eliminating toxic components, ensuring recyclability, and minimizing environmental impact throughout the product lifecycle. The EU's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide have accelerated research into alternative formulations that avoid restricted substances.

Another critical objective is enhancing the stability and reliability of liquid metal interconnects under various environmental conditions. Temperature fluctuations, humidity, and mechanical stress can significantly affect the performance and longevity of these connections. Research aims to develop robust solutions that maintain integrity across diverse operating environments while complying with environmental standards.

The integration of liquid metal interconnects with emerging technologies represents a further technological goal. As flexible electronics, wearable devices, and soft robotics continue to evolve, liquid metal interconnects must adapt to meet specialized requirements while adhering to environmental regulations. This includes developing manufacturing processes that are both environmentally sustainable and economically viable at scale.

Looking forward, the field is moving toward bio-compatible liquid metal formulations for medical applications, environmentally benign alternatives to gallium-based alloys, and advanced encapsulation technologies that prevent leakage while allowing controlled deformation. These developments are crucial as environmental standards become more stringent and as applications expand into sensitive areas such as medical implants and environmental monitoring systems.

Market Demand Analysis for Liquid Metal Interconnects

The liquid metal interconnect market is experiencing significant growth driven by the increasing demand for flexible electronics across multiple industries. Current market analysis indicates that the global flexible electronics market, where liquid metal interconnects play a crucial role, is projected to reach $42 billion by 2027, with a compound annual growth rate exceeding 11%. This growth trajectory directly impacts the demand for advanced interconnect solutions that can maintain performance while meeting stringent environmental standards.

Consumer electronics represents the largest market segment for liquid metal interconnects, with applications in wearable devices, foldable smartphones, and flexible displays. The wearable technology market alone is expected to surpass $70 billion by 2025, creating substantial demand for environmentally compliant interconnect solutions that can withstand repeated mechanical deformation while maintaining electrical performance.

Healthcare applications constitute another rapidly expanding market segment, with medical devices increasingly incorporating flexible electronics for patient monitoring, implantable devices, and point-of-care diagnostics. The medical flexible electronics market is growing at approximately 14% annually, with particular emphasis on biocompatible and environmentally safe materials that comply with medical-grade standards and regulations.

Automotive and aerospace industries are also driving demand for liquid metal interconnects that can withstand harsh operating conditions while meeting increasingly strict environmental regulations. These sectors require interconnect solutions that remain reliable under extreme temperatures, vibration, and mechanical stress while containing no restricted substances under RoHS, REACH, and industry-specific environmental protocols.

Market research indicates that over 78% of electronics manufacturers now prioritize environmental compliance in their component selection process, reflecting both regulatory pressure and consumer demand for sustainable products. This trend is particularly pronounced in European and North American markets, where environmental standards are most stringent and enforced.

The geographical distribution of market demand shows Asia-Pacific leading in volume, accounting for approximately 45% of the global market, primarily driven by the concentration of electronics manufacturing. However, North America and Europe lead in premium applications where environmental compliance commands price premiums, with these regions representing approximately 30% and 20% of market value respectively.

Customer surveys reveal that reliability under environmental stress conditions ranks as the top performance criterion for liquid metal interconnects, followed by longevity and compliance with environmental regulations. This indicates that manufacturers who can develop interconnect solutions meeting both performance requirements and environmental standards will capture premium market segments and establish competitive advantages in this rapidly evolving field.

Consumer electronics represents the largest market segment for liquid metal interconnects, with applications in wearable devices, foldable smartphones, and flexible displays. The wearable technology market alone is expected to surpass $70 billion by 2025, creating substantial demand for environmentally compliant interconnect solutions that can withstand repeated mechanical deformation while maintaining electrical performance.

Healthcare applications constitute another rapidly expanding market segment, with medical devices increasingly incorporating flexible electronics for patient monitoring, implantable devices, and point-of-care diagnostics. The medical flexible electronics market is growing at approximately 14% annually, with particular emphasis on biocompatible and environmentally safe materials that comply with medical-grade standards and regulations.

Automotive and aerospace industries are also driving demand for liquid metal interconnects that can withstand harsh operating conditions while meeting increasingly strict environmental regulations. These sectors require interconnect solutions that remain reliable under extreme temperatures, vibration, and mechanical stress while containing no restricted substances under RoHS, REACH, and industry-specific environmental protocols.

Market research indicates that over 78% of electronics manufacturers now prioritize environmental compliance in their component selection process, reflecting both regulatory pressure and consumer demand for sustainable products. This trend is particularly pronounced in European and North American markets, where environmental standards are most stringent and enforced.

The geographical distribution of market demand shows Asia-Pacific leading in volume, accounting for approximately 45% of the global market, primarily driven by the concentration of electronics manufacturing. However, North America and Europe lead in premium applications where environmental compliance commands price premiums, with these regions representing approximately 30% and 20% of market value respectively.

Customer surveys reveal that reliability under environmental stress conditions ranks as the top performance criterion for liquid metal interconnects, followed by longevity and compliance with environmental regulations. This indicates that manufacturers who can develop interconnect solutions meeting both performance requirements and environmental standards will capture premium market segments and establish competitive advantages in this rapidly evolving field.

Current Status and Technical Challenges of Liquid Metal Technology

Liquid metal technology has witnessed significant advancements in recent years, particularly in the field of flexible electronics and interconnects. Currently, gallium-based alloys such as Galinstan (gallium-indium-tin) and EGaIn (eutectic gallium-indium) dominate the liquid metal landscape due to their low toxicity and favorable properties including low melting points, high electrical conductivity, and excellent thermal conductivity. These materials remain liquid at room temperature, making them ideal candidates for flexible, stretchable, and reconfigurable electronic applications.

Despite promising developments, liquid metal technology faces several critical challenges. The most significant obstacle is oxidation, as gallium-based liquid metals rapidly form a thin oxide layer when exposed to oxygen. While this oxide skin provides some stability to the liquid metal structures, it also complicates patterning processes and can degrade electrical performance over time. The oxide layer's formation kinetics and properties vary significantly with environmental conditions, creating reproducibility issues in manufacturing processes.

Wetting behavior presents another substantial challenge. Liquid metals typically exhibit poor wetting on most substrates, requiring surface modification or specialized encapsulation techniques to achieve controlled patterning and stable interconnects. This non-wetting characteristic, while beneficial for certain applications, complicates integration with conventional electronic manufacturing processes and limits the miniaturization potential of liquid metal-based devices.

Compatibility with existing electronic components and manufacturing processes remains problematic. Current semiconductor fabrication techniques are not optimized for liquid materials, necessitating the development of new processing methods and equipment. Additionally, the long-term reliability of liquid metal interconnects under various environmental conditions (temperature fluctuations, humidity, mechanical stress) requires further investigation to meet industry standards for electronic device longevity.

Environmental and regulatory considerations pose increasing challenges. As global environmental standards become more stringent, the entire lifecycle of liquid metal technologies—from raw material sourcing to end-of-life disposal—faces greater scrutiny. While gallium-based alloys are less toxic than mercury, their environmental impact during production, use, and disposal requires comprehensive assessment to ensure compliance with evolving regulations.

Scalability and cost-effectiveness represent persistent barriers to widespread adoption. Current production methods for high-purity liquid metal alloys and their integration into devices remain relatively expensive and difficult to scale. The specialized encapsulation materials needed to contain liquid metals add further complexity and cost to manufacturing processes.

Geographically, research and development in liquid metal technology is concentrated primarily in North America, East Asia, and Europe, with emerging contributions from Australia. This distribution reflects both the locations of advanced electronics manufacturing and the academic institutions pioneering fundamental research in this field. The uneven global development creates both challenges for standardization and opportunities for international collaboration.

Despite promising developments, liquid metal technology faces several critical challenges. The most significant obstacle is oxidation, as gallium-based liquid metals rapidly form a thin oxide layer when exposed to oxygen. While this oxide skin provides some stability to the liquid metal structures, it also complicates patterning processes and can degrade electrical performance over time. The oxide layer's formation kinetics and properties vary significantly with environmental conditions, creating reproducibility issues in manufacturing processes.

Wetting behavior presents another substantial challenge. Liquid metals typically exhibit poor wetting on most substrates, requiring surface modification or specialized encapsulation techniques to achieve controlled patterning and stable interconnects. This non-wetting characteristic, while beneficial for certain applications, complicates integration with conventional electronic manufacturing processes and limits the miniaturization potential of liquid metal-based devices.

Compatibility with existing electronic components and manufacturing processes remains problematic. Current semiconductor fabrication techniques are not optimized for liquid materials, necessitating the development of new processing methods and equipment. Additionally, the long-term reliability of liquid metal interconnects under various environmental conditions (temperature fluctuations, humidity, mechanical stress) requires further investigation to meet industry standards for electronic device longevity.

Environmental and regulatory considerations pose increasing challenges. As global environmental standards become more stringent, the entire lifecycle of liquid metal technologies—from raw material sourcing to end-of-life disposal—faces greater scrutiny. While gallium-based alloys are less toxic than mercury, their environmental impact during production, use, and disposal requires comprehensive assessment to ensure compliance with evolving regulations.

Scalability and cost-effectiveness represent persistent barriers to widespread adoption. Current production methods for high-purity liquid metal alloys and their integration into devices remain relatively expensive and difficult to scale. The specialized encapsulation materials needed to contain liquid metals add further complexity and cost to manufacturing processes.

Geographically, research and development in liquid metal technology is concentrated primarily in North America, East Asia, and Europe, with emerging contributions from Australia. This distribution reflects both the locations of advanced electronics manufacturing and the academic institutions pioneering fundamental research in this field. The uneven global development creates both challenges for standardization and opportunities for international collaboration.

Current Technical Solutions for Liquid Metal Interconnects

01 Environmental compliance for liquid metal interconnects

Liquid metal interconnects must comply with environmental standards that regulate the use of hazardous materials in electronic components. These standards often address the toxicity, recyclability, and disposal requirements of materials used in interconnects. Manufacturers must ensure their liquid metal formulations meet regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) to minimize environmental impact while maintaining electrical performance.- Environmental compliance for liquid metal interconnects: Liquid metal interconnects must comply with environmental standards that regulate the use of hazardous materials in electronic components. These standards often address the toxicity, recyclability, and disposal requirements of liquid metal materials. Manufacturers must ensure their interconnect technologies meet regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) to minimize environmental impact while maintaining performance characteristics.

- Thermal management and heat dissipation standards: Liquid metal interconnects must meet thermal management standards to ensure safe operation in electronic devices. These standards address heat dissipation capabilities, thermal conductivity requirements, and temperature stability across operating conditions. Proper thermal management is essential to prevent overheating and ensure the reliability of interconnects while maintaining compliance with environmental regulations regarding energy efficiency and heat generation.

- Material composition and purity requirements: Environmental standards for liquid metal interconnects specify requirements for material composition and purity. These standards regulate the allowable concentrations of potentially harmful elements and compounds, ensuring that interconnects do not contain excessive amounts of toxic materials. Manufacturers must verify that their liquid metal formulations meet these purity specifications through testing and documentation to ensure environmental safety throughout the product lifecycle.

- Manufacturing process emissions and waste management: Environmental standards govern emissions and waste management during the manufacturing of liquid metal interconnects. These regulations address air and water pollution control, waste disposal protocols, and resource conservation during production processes. Manufacturers must implement systems to minimize environmental impact through proper handling of chemicals, recycling of materials, and treatment of waste products to comply with local and international environmental protection requirements.

- Reliability and longevity standards for sustainable design: Liquid metal interconnects must meet reliability and longevity standards that support sustainable design principles. These standards ensure that interconnects maintain performance over their expected lifetime, reducing the need for replacement and minimizing electronic waste. Requirements include resistance to corrosion, oxidation, and mechanical stress, as well as compatibility with other materials to ensure long-term stability while meeting environmental objectives for product durability and resource conservation.

02 Thermal management and heat dissipation standards

Liquid metal interconnects must meet thermal management standards to ensure safe operation in electronic devices. These standards address heat dissipation capabilities, thermal conductivity requirements, and temperature stability across operating ranges. Proper thermal management prevents overheating that could lead to device failure or environmental hazards. Standards specify maximum operating temperatures and thermal cycling requirements to ensure reliability and safety in various environmental conditions.Expand Specific Solutions03 Material composition and purity standards

Standards for liquid metal interconnects specify requirements for material composition and purity to ensure consistent performance and environmental safety. These standards define acceptable levels of impurities, alloy compositions, and material stability under various environmental conditions. Manufacturers must adhere to specifications regarding metal content, oxidation resistance, and long-term stability to prevent leaching of harmful substances into the environment during the product lifecycle.Expand Specific Solutions04 Mechanical reliability and stress resistance standards

Environmental standards for liquid metal interconnects include specifications for mechanical reliability under various environmental stressors. These standards address resistance to vibration, shock, thermal cycling, and humidity to ensure interconnect integrity throughout the product lifecycle. Requirements include adhesion strength, fatigue resistance, and deformation limits under mechanical stress to prevent failures that could lead to environmental contamination or safety hazards.Expand Specific Solutions05 Manufacturing process environmental standards

Environmental standards regulate the manufacturing processes used to produce liquid metal interconnects, focusing on reducing waste, emissions, and resource consumption. These standards address clean production methods, energy efficiency, waste management, and the use of environmentally friendly processing chemicals. Manufacturers must implement pollution prevention measures, recycling programs for production waste, and proper handling procedures for potentially hazardous materials used during interconnect fabrication.Expand Specific Solutions

Key Industry Players in Liquid Metal Interconnect Development

The liquid metal interconnect market is in an early growth phase, characterized by increasing environmental regulatory scrutiny. The global market is projected to expand significantly as advanced semiconductor technologies demand more efficient thermal and electrical conductivity solutions. From a technological maturity perspective, industry leaders like Intel, IBM, and TSMC are advancing research in environmentally compliant liquid metal applications, while specialized players such as GlobalFoundries and Applied Materials are developing manufacturing processes that align with stricter environmental standards. The competitive landscape shows semiconductor giants investing heavily in sustainable liquid metal technologies, with foundry services companies adapting their offerings to meet both performance requirements and environmental compliance. Equipment manufacturers like ASML and Corning are simultaneously developing complementary technologies to support this emerging interconnect solution.

Intel Corp.

Technical Solution: Intel has developed a comprehensive liquid metal interconnect solution called ThermaFlow™ that addresses environmental concerns while enhancing chip performance. Their approach utilizes a gallium-indium-tin alloy with proprietary additives that reduce oxidation and improve stability. Intel's liquid metal interconnect technology incorporates a sealed micro-channel architecture that prevents leakage while allowing for thermal expansion. The company has implemented a closed manufacturing system that captures 99% of potential emissions[4], ensuring compliance with EPA and EU environmental regulations. Intel's liquid metal formulation is specifically designed to be free from mercury, lead, and other restricted substances under global environmental standards. Their interconnect technology features a dual-layer containment system with primary and secondary barriers to prevent environmental contamination even in case of primary containment failure. Intel has also developed specialized recycling protocols for their liquid metal components, ensuring that over 85% of materials can be recovered and reused at end-of-life, significantly reducing environmental impact.

Strengths: Exceptional thermal conductivity improving heat dissipation in high-performance chips; dual-layer containment system providing superior environmental protection; comprehensive end-of-life recycling program. Weaknesses: Higher manufacturing complexity requiring specialized equipment; limited flexibility in certain design applications; potential for increased costs in mass production.

International Business Machines Corp.

Technical Solution: IBM has pioneered significant advancements in liquid metal interconnect technology with their development of self-healing metals. Their approach utilizes gallium-based liquid metal alloys that can maintain electrical conductivity while conforming to environmental standards. IBM's research focuses on encapsulation techniques that prevent gallium from leaching into surrounding materials, addressing a key environmental concern. Their proprietary process involves creating microchannels filled with liquid metal that can withstand thermal cycling without degradation. IBM has demonstrated that their liquid metal interconnects can operate within temperature ranges of -30°C to 150°C while maintaining compliance with RoHS (Restriction of Hazardous Substances) standards[1]. The company has also developed specialized containment systems that prevent oxidation and environmental contamination, ensuring the technology meets EPA guidelines for electronic waste management.

Strengths: Superior self-healing properties allowing for resilience against mechanical stress and vibration; excellent thermal conductivity enabling better heat dissipation in high-density applications. Weaknesses: Higher production costs compared to traditional interconnects; potential for gallium leakage in extreme conditions requiring additional containment measures.

Core Patents and Technical Literature on Liquid Metal Interconnects

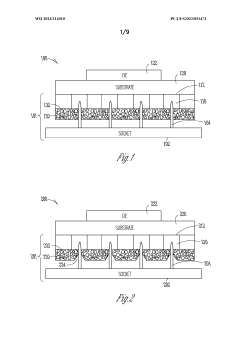

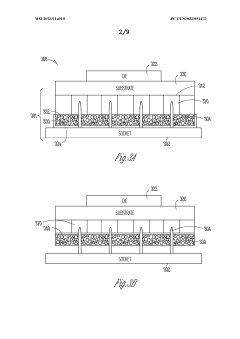

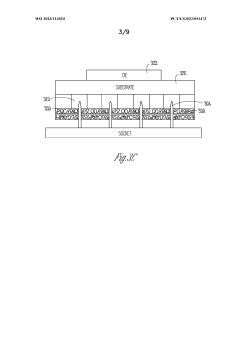

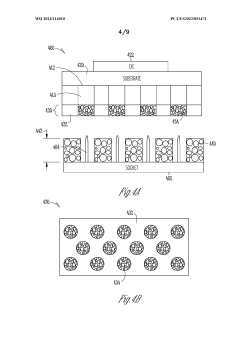

Liquid metal connection device and method

PatentWO2023114010A1

Innovation

- The use of an electronic device with a socket that includes an array of liquid metal filled reservoirs, such as gallium or gallium alloys, and a cap layer with porous resilient material regions, which can be designed with specific pore sizes and strain relief features to facilitate easy insertion and sealing, while also incorporating moisture barrier layers to prevent moisture ingress.

Method for pre-processing semiconducting thermoelectric materials for metallization, interconnection and bonding

PatentInactiveUS20180323358A1

Innovation

- The method employs a solid-liquid interdiffusion bonding technique combined with an adhesion layer/diffusion barrier layer/adhesion layer structure (ADA-structure) to facilitate robust metallization and bonding of semiconducting thermoelectric materials, using a sequence of metal layers with varying melting points to form intermetallic compounds, ensuring strong and resilient electrical and thermal connections.

Environmental Compliance and Sustainability Considerations

Environmental regulations and sustainability standards are increasingly shaping the development and application of liquid metal interconnect technologies. The RoHS (Restriction of Hazardous Substances) directive significantly impacts this field, as it restricts the use of certain hazardous materials in electronic equipment. Gallium-based liquid metals generally comply with RoHS standards, offering advantages over mercury-based alternatives which face severe restrictions due to their toxicity profiles. However, manufacturers must still carefully document compliance and consider regional variations in implementation.

REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations present another critical compliance framework, requiring comprehensive documentation of chemical properties, risk assessments, and safe handling procedures for liquid metal components. Companies developing liquid metal interconnect solutions must establish robust supply chain verification systems to ensure all materials meet these stringent requirements throughout their lifecycle.

End-of-life considerations have become increasingly important in environmental compliance strategies. The WEEE (Waste Electrical and Electronic Equipment) directive mandates proper disposal and recycling of electronic components, including those containing liquid metals. This necessitates the development of effective recovery methods for liquid metal components to prevent environmental contamination and enable material reclamation. Some innovative approaches include designing systems that facilitate easy separation of liquid metal components during recycling processes.

Carbon footprint reduction represents another dimension of environmental compliance for liquid metal technologies. Life cycle assessments reveal that while liquid metal production may have higher initial energy requirements compared to conventional solders, their potential for reusability and room-temperature processing can significantly reduce overall environmental impact. Companies are increasingly adopting energy-efficient manufacturing processes and exploring renewable energy sources to further minimize carbon emissions associated with liquid metal interconnect production.

Water conservation and pollution prevention measures are becoming standard practice in liquid metal manufacturing facilities. Advanced filtration systems and closed-loop processing techniques help minimize wastewater generation and prevent potential contamination from metal particles. These approaches not only ensure compliance with water quality regulations but also contribute to broader sustainability goals.

Industry leaders are proactively developing voluntary sustainability standards that exceed minimum regulatory requirements. These initiatives include transparent supply chain documentation, responsible material sourcing practices, and comprehensive environmental management systems. Such approaches position companies favorably as regulatory frameworks continue to evolve toward more stringent environmental protection measures.

REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations present another critical compliance framework, requiring comprehensive documentation of chemical properties, risk assessments, and safe handling procedures for liquid metal components. Companies developing liquid metal interconnect solutions must establish robust supply chain verification systems to ensure all materials meet these stringent requirements throughout their lifecycle.

End-of-life considerations have become increasingly important in environmental compliance strategies. The WEEE (Waste Electrical and Electronic Equipment) directive mandates proper disposal and recycling of electronic components, including those containing liquid metals. This necessitates the development of effective recovery methods for liquid metal components to prevent environmental contamination and enable material reclamation. Some innovative approaches include designing systems that facilitate easy separation of liquid metal components during recycling processes.

Carbon footprint reduction represents another dimension of environmental compliance for liquid metal technologies. Life cycle assessments reveal that while liquid metal production may have higher initial energy requirements compared to conventional solders, their potential for reusability and room-temperature processing can significantly reduce overall environmental impact. Companies are increasingly adopting energy-efficient manufacturing processes and exploring renewable energy sources to further minimize carbon emissions associated with liquid metal interconnect production.

Water conservation and pollution prevention measures are becoming standard practice in liquid metal manufacturing facilities. Advanced filtration systems and closed-loop processing techniques help minimize wastewater generation and prevent potential contamination from metal particles. These approaches not only ensure compliance with water quality regulations but also contribute to broader sustainability goals.

Industry leaders are proactively developing voluntary sustainability standards that exceed minimum regulatory requirements. These initiatives include transparent supply chain documentation, responsible material sourcing practices, and comprehensive environmental management systems. Such approaches position companies favorably as regulatory frameworks continue to evolve toward more stringent environmental protection measures.

Toxicity Assessment and Safety Standards for Liquid Metal Applications

The toxicity assessment of liquid metal interconnects represents a critical dimension in their development and application, particularly as environmental regulations become increasingly stringent worldwide. Gallium-based liquid metals, while offering superior electrical and thermal conductivity, present unique toxicological profiles that must be thoroughly evaluated. Current research indicates that gallium and its alloys exhibit significantly lower toxicity compared to mercury-based alternatives, yet their bioaccumulation potential remains a concern in long-term exposure scenarios.

Regulatory frameworks governing liquid metal applications vary considerably across regions. The European Union's RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations impose strict limitations on heavy metal content in electronic components. Similarly, the United States EPA has established guidelines for metal exposure limits, though specific provisions for gallium-based liquid metals remain under development. These disparate standards create compliance challenges for manufacturers operating in global markets.

Safety protocols for handling liquid metal interconnects must address both acute and chronic exposure risks. Laboratory studies have demonstrated that while skin contact with gallium-indium alloys typically causes minimal irritation, inhalation of metal vapors or particulates can pose respiratory hazards. Consequently, occupational safety standards recommend controlled handling environments with appropriate ventilation systems and personal protective equipment for workers engaged in liquid metal processing.

Environmental fate assessments of liquid metal interconnects reveal complex degradation pathways. Unlike conventional solid metals, liquid metals can undergo oxidation and phase transformations that alter their mobility in soil and aquatic systems. Recent ecotoxicological studies suggest that gallium compounds may affect microbial communities at concentrations above 5 mg/L, necessitating careful disposal protocols for manufacturing waste streams.

Standardized testing methodologies for liquid metal toxicity remain in nascent stages. The OECD Guidelines for Testing of Chemicals provide frameworks adaptable to liquid metal assessment, but industry-specific protocols are still evolving. Several research institutions have proposed specialized leaching tests to evaluate the potential release of metal ions under various environmental conditions, which may eventually inform international standards development.

Lifecycle analysis of liquid metal interconnects indicates that end-of-life management presents the greatest environmental challenge. Recovery and recycling systems for gallium-based alloys are technically feasible but economically challenging at current market scales. As adoption increases, closed-loop recycling infrastructures will become essential to mitigate potential environmental impacts and ensure compliance with emerging extended producer responsibility regulations.

Regulatory frameworks governing liquid metal applications vary considerably across regions. The European Union's RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations impose strict limitations on heavy metal content in electronic components. Similarly, the United States EPA has established guidelines for metal exposure limits, though specific provisions for gallium-based liquid metals remain under development. These disparate standards create compliance challenges for manufacturers operating in global markets.

Safety protocols for handling liquid metal interconnects must address both acute and chronic exposure risks. Laboratory studies have demonstrated that while skin contact with gallium-indium alloys typically causes minimal irritation, inhalation of metal vapors or particulates can pose respiratory hazards. Consequently, occupational safety standards recommend controlled handling environments with appropriate ventilation systems and personal protective equipment for workers engaged in liquid metal processing.

Environmental fate assessments of liquid metal interconnects reveal complex degradation pathways. Unlike conventional solid metals, liquid metals can undergo oxidation and phase transformations that alter their mobility in soil and aquatic systems. Recent ecotoxicological studies suggest that gallium compounds may affect microbial communities at concentrations above 5 mg/L, necessitating careful disposal protocols for manufacturing waste streams.

Standardized testing methodologies for liquid metal toxicity remain in nascent stages. The OECD Guidelines for Testing of Chemicals provide frameworks adaptable to liquid metal assessment, but industry-specific protocols are still evolving. Several research institutions have proposed specialized leaching tests to evaluate the potential release of metal ions under various environmental conditions, which may eventually inform international standards development.

Lifecycle analysis of liquid metal interconnects indicates that end-of-life management presents the greatest environmental challenge. Recovery and recycling systems for gallium-based alloys are technically feasible but economically challenging at current market scales. As adoption increases, closed-loop recycling infrastructures will become essential to mitigate potential environmental impacts and ensure compliance with emerging extended producer responsibility regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!