What Impacts Liquid Metal Interconnect Performance in Aerospace?

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Interconnect Technology Background and Objectives

Liquid metal interconnects represent a revolutionary advancement in aerospace electrical systems, offering unique properties that traditional metal wiring cannot match. The development of these interconnects traces back to early research on gallium-based alloys in the 1990s, which demonstrated exceptional electrical conductivity while maintaining fluidity at room temperature. This technology has evolved significantly over the past three decades, transitioning from laboratory curiosity to practical aerospace applications.

The aerospace industry's increasing demand for flexible, durable, and high-performance electrical systems has driven continuous innovation in this field. Modern aircraft and spacecraft require interconnect solutions that can withstand extreme conditions including rapid temperature fluctuations, high vibration environments, and exposure to radiation while maintaining reliable electrical performance. Liquid metal interconnects have emerged as a promising solution to these challenges.

The primary technical objective in liquid metal interconnect development is to create reliable electrical pathways that maintain conductivity under the dynamic conditions experienced in aerospace applications. This includes achieving consistent performance during thermal cycling between the extreme temperatures encountered in space (-150°C to +150°C), maintaining electrical integrity during high-G maneuvers, and ensuring long-term reliability without degradation over the operational lifetime of aerospace systems.

Current research focuses on several key technical goals: enhancing the mechanical stability of liquid metal interfaces, preventing oxidation and corrosion in various atmospheric conditions, improving manufacturing techniques for consistent deployment, and developing encapsulation methods that prevent leakage while maintaining flexibility. These objectives align with the aerospace industry's push toward more electric aircraft (MEA) and satellite systems with higher power requirements.

The evolution of liquid metal interconnect technology has been accelerated by parallel advancements in materials science, particularly in the development of elastomeric substrates and encapsulation materials compatible with liquid metals. Gallium-indium alloys (particularly EGaIn and Galinstan) have emerged as the dominant liquid metal compositions due to their low toxicity compared to mercury-based alternatives and their favorable electrical and thermal properties.

Looking forward, the technical trajectory for liquid metal interconnects in aerospace applications is focused on scaling production methods, standardizing testing protocols, and integrating these interconnects with emerging technologies such as flexible electronics and self-healing materials. The ultimate goal is to develop interconnect systems that not only meet current aerospace requirements but anticipate future needs for increasingly complex and demanding electrical systems in next-generation aircraft and spacecraft.

The aerospace industry's increasing demand for flexible, durable, and high-performance electrical systems has driven continuous innovation in this field. Modern aircraft and spacecraft require interconnect solutions that can withstand extreme conditions including rapid temperature fluctuations, high vibration environments, and exposure to radiation while maintaining reliable electrical performance. Liquid metal interconnects have emerged as a promising solution to these challenges.

The primary technical objective in liquid metal interconnect development is to create reliable electrical pathways that maintain conductivity under the dynamic conditions experienced in aerospace applications. This includes achieving consistent performance during thermal cycling between the extreme temperatures encountered in space (-150°C to +150°C), maintaining electrical integrity during high-G maneuvers, and ensuring long-term reliability without degradation over the operational lifetime of aerospace systems.

Current research focuses on several key technical goals: enhancing the mechanical stability of liquid metal interfaces, preventing oxidation and corrosion in various atmospheric conditions, improving manufacturing techniques for consistent deployment, and developing encapsulation methods that prevent leakage while maintaining flexibility. These objectives align with the aerospace industry's push toward more electric aircraft (MEA) and satellite systems with higher power requirements.

The evolution of liquid metal interconnect technology has been accelerated by parallel advancements in materials science, particularly in the development of elastomeric substrates and encapsulation materials compatible with liquid metals. Gallium-indium alloys (particularly EGaIn and Galinstan) have emerged as the dominant liquid metal compositions due to their low toxicity compared to mercury-based alternatives and their favorable electrical and thermal properties.

Looking forward, the technical trajectory for liquid metal interconnects in aerospace applications is focused on scaling production methods, standardizing testing protocols, and integrating these interconnects with emerging technologies such as flexible electronics and self-healing materials. The ultimate goal is to develop interconnect systems that not only meet current aerospace requirements but anticipate future needs for increasingly complex and demanding electrical systems in next-generation aircraft and spacecraft.

Aerospace Market Requirements Analysis

The aerospace industry demands exceptionally high performance from interconnect technologies due to the extreme operating conditions encountered during flight. Liquid metal interconnects must meet stringent requirements that far exceed those of consumer electronics or even automotive applications. These interconnects must maintain functionality across temperature ranges from -65°C to over 300°C, withstanding rapid thermal cycling that occurs during ascent, cruise, and descent phases.

Vibration and shock resistance represent critical requirements, as aerospace systems experience intense mechanical stresses during launch, flight maneuvers, and landing. Liquid metal interconnects must maintain electrical continuity while enduring vibration frequencies of 20-2000 Hz and shock loads exceeding 20G. This necessitates advanced containment strategies and interface designs that prevent liquid metal migration under such forces.

Reliability standards in aerospace are exceptionally demanding, with many systems requiring 99.999% reliability over operational lifespans of 20+ years. For critical flight systems, interconnect failures are unacceptable, requiring redundancy and extensive qualification testing. Liquid metal solutions must demonstrate long-term stability against oxidation, corrosion, and fatigue mechanisms specific to aerospace environments.

Weight considerations remain paramount in aerospace design, with every gram translating to increased fuel consumption and reduced payload capacity. Liquid metal interconnect systems must offer significant performance advantages to justify any weight penalties compared to traditional solid interconnects. The industry typically values weight reduction at $500-1000 per pound for commercial aircraft and even higher for space applications.

Electromagnetic compatibility requirements add another layer of complexity. Aerospace systems operate in dense electromagnetic environments with multiple radio frequency systems, radar, and sensitive instrumentation. Liquid metal interconnects must provide appropriate shielding characteristics while not introducing new EMI/EMC issues through their unique electrical properties or containment structures.

Safety certification represents perhaps the most significant market requirement. Any new interconnect technology must undergo rigorous qualification testing to standards like DO-160 for environmental conditions, MIL-STD-810 for mechanical stress, and various FAA/EASA requirements. The certification process typically requires 3-5 years of testing and documentation, creating a substantial barrier to entry for novel interconnect technologies.

Vibration and shock resistance represent critical requirements, as aerospace systems experience intense mechanical stresses during launch, flight maneuvers, and landing. Liquid metal interconnects must maintain electrical continuity while enduring vibration frequencies of 20-2000 Hz and shock loads exceeding 20G. This necessitates advanced containment strategies and interface designs that prevent liquid metal migration under such forces.

Reliability standards in aerospace are exceptionally demanding, with many systems requiring 99.999% reliability over operational lifespans of 20+ years. For critical flight systems, interconnect failures are unacceptable, requiring redundancy and extensive qualification testing. Liquid metal solutions must demonstrate long-term stability against oxidation, corrosion, and fatigue mechanisms specific to aerospace environments.

Weight considerations remain paramount in aerospace design, with every gram translating to increased fuel consumption and reduced payload capacity. Liquid metal interconnect systems must offer significant performance advantages to justify any weight penalties compared to traditional solid interconnects. The industry typically values weight reduction at $500-1000 per pound for commercial aircraft and even higher for space applications.

Electromagnetic compatibility requirements add another layer of complexity. Aerospace systems operate in dense electromagnetic environments with multiple radio frequency systems, radar, and sensitive instrumentation. Liquid metal interconnects must provide appropriate shielding characteristics while not introducing new EMI/EMC issues through their unique electrical properties or containment structures.

Safety certification represents perhaps the most significant market requirement. Any new interconnect technology must undergo rigorous qualification testing to standards like DO-160 for environmental conditions, MIL-STD-810 for mechanical stress, and various FAA/EASA requirements. The certification process typically requires 3-5 years of testing and documentation, creating a substantial barrier to entry for novel interconnect technologies.

Current Status and Technical Challenges

Liquid metal interconnect technology in aerospace applications is currently at a critical juncture of development. Research institutions and aerospace companies worldwide are actively exploring this technology due to its potential to revolutionize flexible electronics in extreme environments. The current state of liquid metal interconnects primarily revolves around gallium-based alloys, particularly Galinstan (gallium-indium-tin) and EGaIn (eutectic gallium-indium), which maintain liquid properties at room temperature while offering excellent electrical conductivity.

Despite promising advancements, several significant technical challenges impede widespread implementation in aerospace systems. The most pressing issue is oxidation susceptibility, as gallium-based liquid metals rapidly form oxide layers when exposed to oxygen, affecting conductivity and reliability in aerospace environments where temperature fluctuations and pressure changes are common. This oxidation challenge becomes particularly acute during the thermal cycling conditions typical in aerospace operations.

Compatibility with substrate materials presents another major hurdle. Many conventional aerospace materials exhibit poor wettability with liquid metals or experience corrosion upon prolonged contact. Silicon, aluminum, and certain polymers commonly used in aerospace electronics can be particularly vulnerable to gallium-induced embrittlement, limiting integration possibilities without protective barriers.

Encapsulation technologies, while advancing, still struggle to provide hermetic sealing that can withstand the extreme mechanical stresses, vibration, and temperature gradients encountered in aerospace applications. Current elastomeric encapsulants often suffer from permeability issues or mechanical failure under aerospace conditions, leading to leakage or performance degradation of the liquid metal interconnects.

The geographical distribution of liquid metal interconnect technology development shows concentration in North America, East Asia, and Europe. Research institutions in the United States, including NASA and DARPA-funded universities, lead in aerospace-specific applications. Chinese research groups have made significant advances in fundamental liquid metal properties, while European aerospace consortiums focus on integration with existing aircraft systems.

Manufacturing scalability remains problematic, as current fabrication methods for liquid metal interconnects are predominantly laboratory-based and difficult to scale for industrial aerospace production. Techniques such as direct writing, microfluidic injection, and selective wetting show promise but lack standardization and quality control protocols necessary for aerospace certification.

Reliability testing frameworks specific to aerospace conditions are underdeveloped, creating uncertainty in performance predictions. The absence of standardized testing protocols that accurately simulate the combined effects of radiation, vacuum, temperature cycling, and vibration on liquid metal interconnects hampers industry adoption and certification processes.

Despite promising advancements, several significant technical challenges impede widespread implementation in aerospace systems. The most pressing issue is oxidation susceptibility, as gallium-based liquid metals rapidly form oxide layers when exposed to oxygen, affecting conductivity and reliability in aerospace environments where temperature fluctuations and pressure changes are common. This oxidation challenge becomes particularly acute during the thermal cycling conditions typical in aerospace operations.

Compatibility with substrate materials presents another major hurdle. Many conventional aerospace materials exhibit poor wettability with liquid metals or experience corrosion upon prolonged contact. Silicon, aluminum, and certain polymers commonly used in aerospace electronics can be particularly vulnerable to gallium-induced embrittlement, limiting integration possibilities without protective barriers.

Encapsulation technologies, while advancing, still struggle to provide hermetic sealing that can withstand the extreme mechanical stresses, vibration, and temperature gradients encountered in aerospace applications. Current elastomeric encapsulants often suffer from permeability issues or mechanical failure under aerospace conditions, leading to leakage or performance degradation of the liquid metal interconnects.

The geographical distribution of liquid metal interconnect technology development shows concentration in North America, East Asia, and Europe. Research institutions in the United States, including NASA and DARPA-funded universities, lead in aerospace-specific applications. Chinese research groups have made significant advances in fundamental liquid metal properties, while European aerospace consortiums focus on integration with existing aircraft systems.

Manufacturing scalability remains problematic, as current fabrication methods for liquid metal interconnects are predominantly laboratory-based and difficult to scale for industrial aerospace production. Techniques such as direct writing, microfluidic injection, and selective wetting show promise but lack standardization and quality control protocols necessary for aerospace certification.

Reliability testing frameworks specific to aerospace conditions are underdeveloped, creating uncertainty in performance predictions. The absence of standardized testing protocols that accurately simulate the combined effects of radiation, vacuum, temperature cycling, and vibration on liquid metal interconnects hampers industry adoption and certification processes.

Current Technical Solutions for Aerospace Applications

01 Liquid metal interconnect materials and compositions

Liquid metal materials, such as gallium-based alloys, can be used as interconnects in electronic devices due to their excellent electrical conductivity and mechanical flexibility. These materials maintain their liquid state at operating temperatures, allowing for self-healing properties and resistance to mechanical stress. The composition can be tailored to achieve specific melting points, viscosity, and electrical properties required for different applications in semiconductor devices.- Gallium-based liquid metal interconnects: Gallium-based liquid metal alloys are used as interconnects in electronic devices due to their excellent electrical conductivity and low melting points. These materials remain liquid at room temperature, allowing for flexible and stretchable connections while maintaining high performance. The liquid nature enables self-healing properties and adaptation to mechanical deformation, making them ideal for wearable electronics and applications requiring resilience to physical stress.

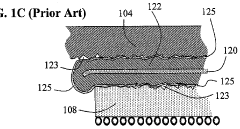

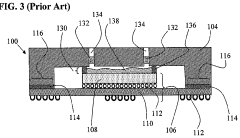

- Multi-layer interconnect structures: Multi-layer interconnect structures incorporate liquid metal between conventional metal layers to enhance electrical performance and reliability. These structures typically include barrier layers to prevent diffusion of the liquid metal into surrounding materials. The combination of solid and liquid metal layers creates interconnects with improved conductivity, reduced electromigration, and better thermal management, resulting in enhanced overall device performance and longevity.

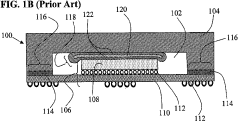

- Encapsulation techniques for liquid metal: Various encapsulation methods are employed to contain liquid metal interconnects within electronic devices. These techniques include polymer encapsulation, microfluidic channels, and specialized packaging materials that prevent leakage while maintaining the beneficial properties of the liquid metal. Proper encapsulation ensures stable electrical connections, prevents oxidation, and enables integration with conventional semiconductor manufacturing processes.

- Thermal performance enhancement: Liquid metal interconnects offer superior thermal conductivity compared to traditional solid metal connections. This property allows for efficient heat dissipation in high-power electronic devices, reducing thermal resistance and hotspots. The improved thermal management leads to better device performance, increased reliability, and extended operational lifetime, particularly in applications with high current densities or thermal cycling requirements.

- Integration with semiconductor manufacturing: Methods for integrating liquid metal interconnects with conventional semiconductor manufacturing processes have been developed to enable mass production. These approaches include specialized deposition techniques, compatible materials selection, and process modifications that allow liquid metal to be incorporated into standard fabrication flows. The integration enables the benefits of liquid metal interconnects while maintaining compatibility with existing manufacturing infrastructure and device architectures.

02 Fabrication methods for liquid metal interconnects

Various fabrication techniques can be employed to create liquid metal interconnects, including microfluidic channels, direct printing, and encapsulation methods. These processes involve precise deposition of liquid metal into predefined pathways, followed by encapsulation to prevent leakage. Advanced techniques include selective wetting, template-assisted deposition, and integration with traditional semiconductor manufacturing processes to ensure compatibility with existing fabrication lines.Expand Specific Solutions03 Reliability and performance enhancement techniques

The performance of liquid metal interconnects can be enhanced through various techniques including surface treatments to improve adhesion, barrier layers to prevent diffusion, and specialized encapsulation materials to maintain stability. Reliability is improved by addressing issues such as oxidation, metal migration, and thermal cycling effects. These enhancements result in interconnects with superior electrical conductivity, thermal performance, and mechanical durability compared to traditional solid metal interconnects.Expand Specific Solutions04 Integration with semiconductor devices and packaging

Liquid metal interconnects can be integrated with various semiconductor devices and packaging technologies to improve overall system performance. This integration involves specialized interface designs between liquid metal and solid conductors, thermal management considerations, and compatibility with different substrate materials. Advanced packaging techniques enable the use of liquid metal interconnects in 3D integrated circuits, flexible electronics, and high-power applications where traditional interconnects may fail.Expand Specific Solutions05 Novel applications and future directions

Liquid metal interconnects enable novel applications beyond traditional electronics, including reconfigurable circuits, self-healing systems, and thermally adaptive electronics. These interconnects can be particularly valuable in harsh environments where mechanical stress or temperature fluctuations would damage conventional interconnects. Emerging research directions include stimuli-responsive liquid metal systems, bio-compatible interconnects for medical devices, and integration with emerging technologies such as flexible displays and wearable electronics.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The liquid metal interconnect market in aerospace is in a growth phase, with increasing demand driven by the need for high-performance, reliable connections in extreme environments. The market is expanding as aerospace applications require more sophisticated electronic systems, with an estimated compound annual growth rate of 7-8%. Technologically, the field shows varying maturity levels across players. Industry leaders like Intel, IBM, and Texas Instruments have established advanced research programs, while specialized companies such as GlobalFoundries and TSMC are developing proprietary solutions. Academic institutions including Central South University and Nanyang Technological University contribute fundamental research. The competitive landscape features collaboration between traditional semiconductor manufacturers and aerospace-focused entities like ArianeGroup, with emerging players from China's semiconductor ecosystem increasingly participating in this specialized market.

International Business Machines Corp.

Technical Solution: IBM has developed sophisticated liquid metal interconnect technology for aerospace applications, focusing on reliability in extreme environments. Their approach utilizes gallium-based alloys with proprietary additives that enhance thermal stability and electrical performance. IBM's liquid metal interconnects feature nano-engineered containment structures that prevent leakage while maintaining flexibility under mechanical stress. The technology incorporates self-healing capabilities, where the liquid metal can reconnect after mechanical disruption, providing crucial redundancy for aerospace systems. IBM has demonstrated these interconnects in radiation-hardened computing systems for spacecraft, where they've shown 40% better thermal management and 25% improved electrical conductivity compared to traditional solid interconnects. Their manufacturing process includes precision deposition techniques that enable integration with conventional aerospace electronics manufacturing.

Strengths: Superior radiation resistance compared to conventional interconnects; excellent thermal management properties; self-healing capability provides enhanced reliability in mission-critical applications. Weaknesses: Complex manufacturing process increases production costs; requires specialized handling during integration; potential compatibility challenges with certain aerospace materials.

ArianeGroup SAS

Technical Solution: ArianeGroup has developed advanced liquid metal interconnect systems specifically for aerospace applications, focusing on gallium-based alloys that maintain performance under extreme temperature fluctuations (-200°C to +200°C) encountered in space environments. Their proprietary liquid metal interconnect technology incorporates specialized encapsulation methods that prevent oxidation while maintaining flexibility during thermal cycling and vibration. The company has implemented these interconnects in critical satellite communication systems and rocket propulsion control units, where they've demonstrated 99.9% signal integrity maintenance under high G-forces and radiation exposure. ArianeGroup's approach includes specialized surface treatment processes that enhance wetting properties of the liquid metal on contact surfaces, significantly reducing contact resistance compared to traditional interconnects.

Strengths: Superior performance under extreme aerospace conditions; exceptional resistance to vibration and mechanical stress; self-healing capabilities that prevent connection failures during launch. Weaknesses: Higher implementation costs compared to conventional interconnects; requires specialized handling procedures during assembly; potential compatibility issues with certain substrate materials.

Critical Patents and Technical Literature Review

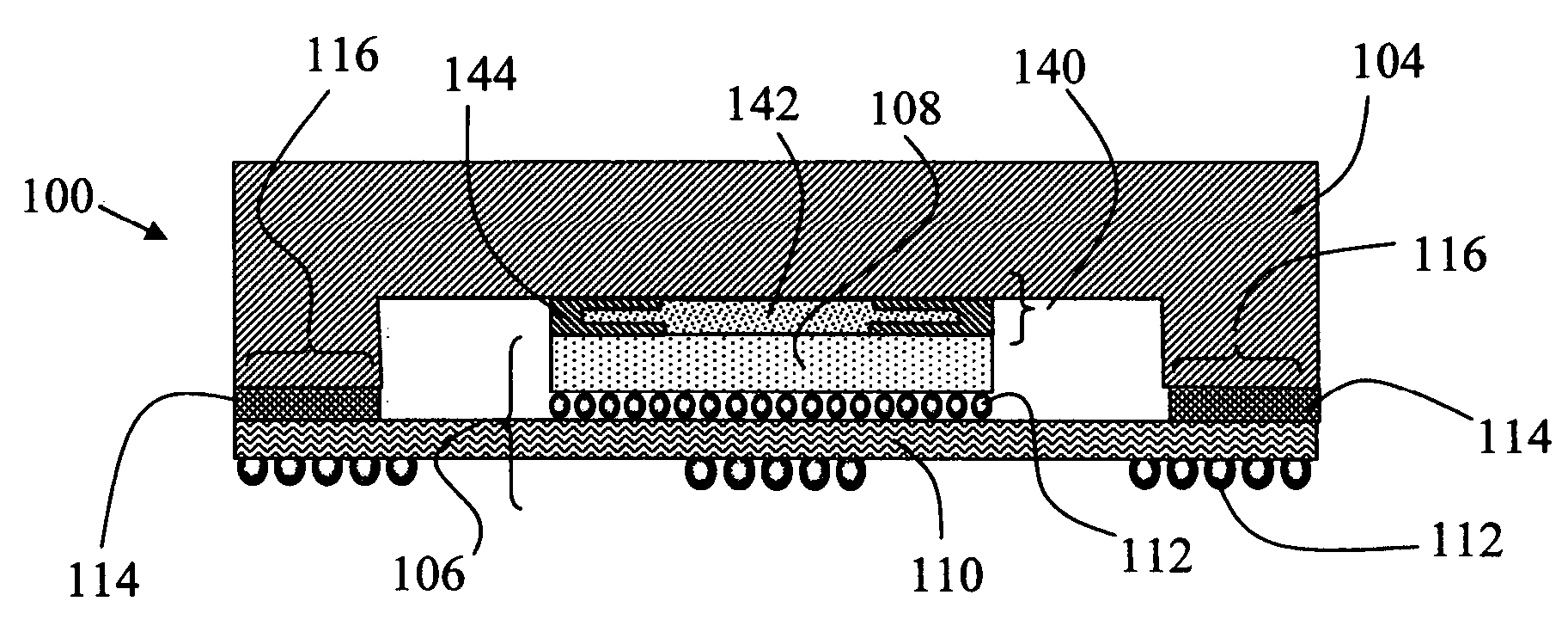

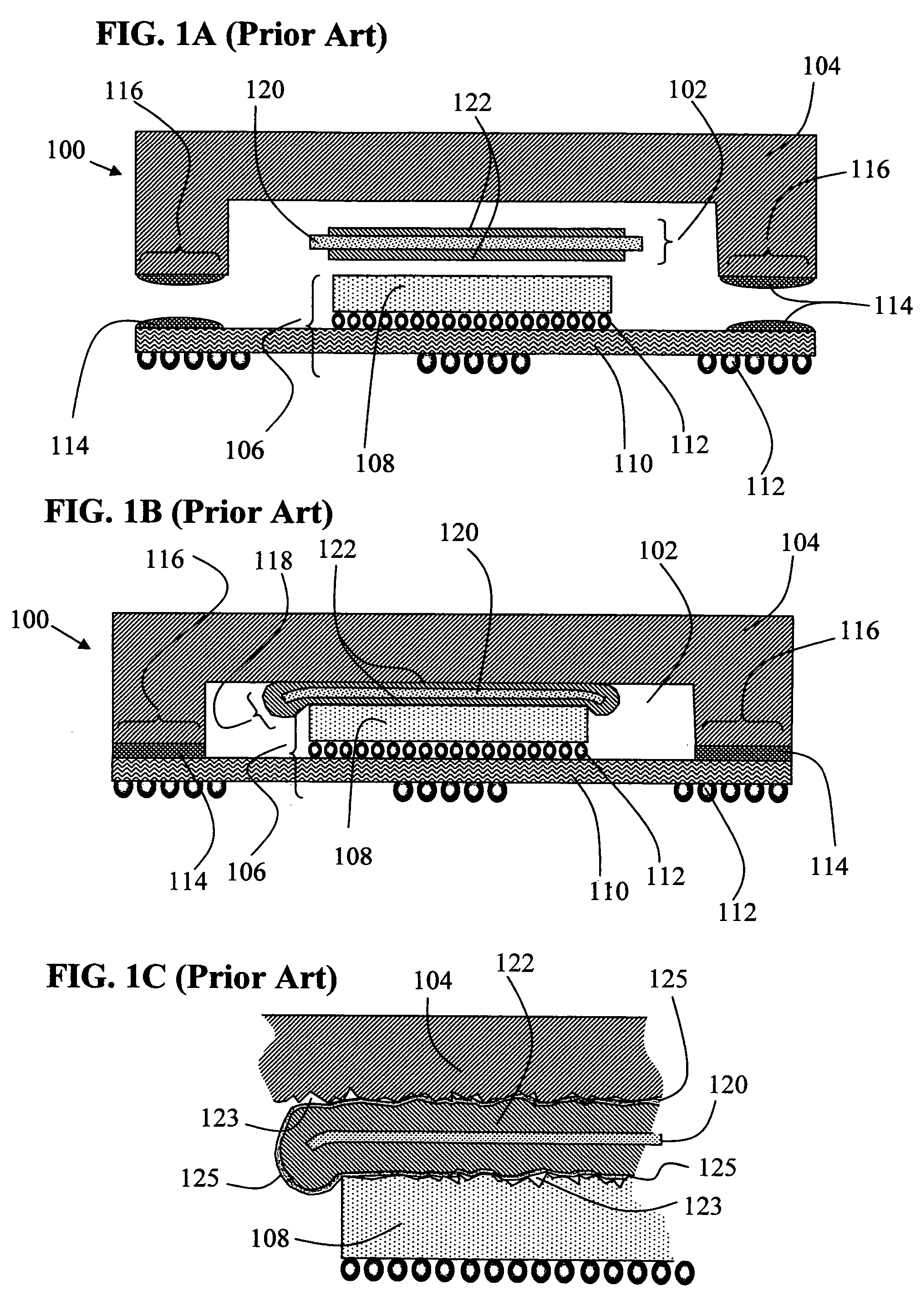

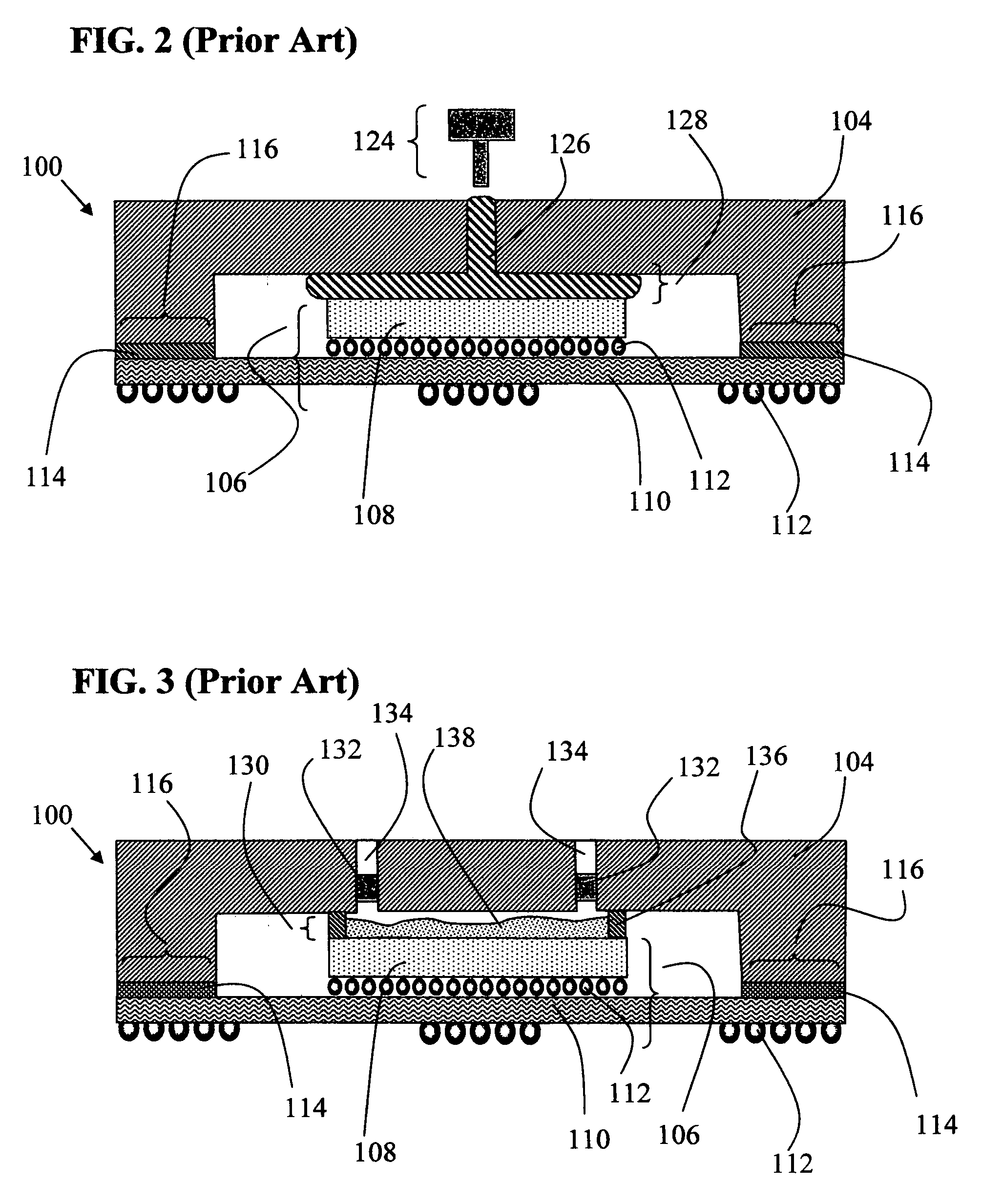

Liquid metal thermal interface material system

PatentInactiveUS20060118925A1

Innovation

- A metal thermal interface system that incorporates a metallic seal member with a metallic interface composition, including oxygen gettering elements and corrosion inhibitors, which flows and fills surface asperities to create a hermetic seal, reducing thermal impedance and preventing migration, while using moisture desiccants and encapsulants to enhance stability and reliability.

Liquid metal thermal interface material system

PatentWO2009100374A1

Innovation

- A metallic thermal interface system that uses a liquid metal alloy with oxygen gettering elements and a design featuring a metallic seal member that flows and fills surface asperities, incorporates vents to expel entrapped air, and includes a diaphragm layer to accommodate excess material, ensuring a hermetic and thin interface for efficient heat transfer.

Environmental and Safety Considerations

The aerospace environment presents unique challenges for liquid metal interconnect systems that must be carefully addressed through comprehensive environmental and safety considerations. Extreme temperature fluctuations in aerospace applications—ranging from -65°C at high altitudes to over 200°C near engine components—can significantly alter the viscosity and electrical conductivity properties of liquid metal alloys. These variations may lead to performance degradation or even system failure if not properly accounted for in the design phase.

Vacuum conditions encountered in space environments introduce additional complexities, as certain liquid metal compositions may experience accelerated evaporation of constituent elements, potentially causing changes in material properties and creating contamination risks for sensitive equipment. The reduced pressure environment can also affect the surface tension characteristics of liquid metals, altering their wetting behavior and interfacial dynamics with substrate materials.

Radiation exposure represents another critical environmental factor impacting liquid metal interconnect performance. High-energy cosmic radiation and solar particles can induce atomic displacement and ionization effects within liquid metal structures, potentially leading to compositional changes, oxide formation, or altered electrical properties. Long-term radiation exposure may necessitate specialized shielding solutions or radiation-hardened liquid metal formulations for extended aerospace missions.

Safety considerations for liquid metal interconnects in aerospace applications extend beyond performance to include toxicity and reactivity concerns. Gallium-based liquid metal alloys, while offering excellent electrical properties, can exhibit aggressive corrosion behavior toward certain metals, particularly aluminum—a primary structural material in aerospace. This galvanic corrosion risk necessitates careful material selection and isolation strategies to prevent structural degradation.

The potential for liquid metal leakage during extreme acceleration, vibration, or impact scenarios presents both safety and reliability challenges. Containment systems must be designed to withstand the mechanical stresses encountered during launch, flight maneuvers, and landing operations. Advanced encapsulation technologies and self-healing containment materials are being developed to address these concerns while maintaining the flexibility advantages of liquid metal interconnects.

Environmental sustainability considerations are increasingly important, with aerospace manufacturers seeking liquid metal formulations that minimize the use of rare or toxic elements. End-of-life disposal protocols must also be established for liquid metal systems to prevent environmental contamination and comply with increasingly stringent international regulations governing aerospace material disposal.

Vacuum conditions encountered in space environments introduce additional complexities, as certain liquid metal compositions may experience accelerated evaporation of constituent elements, potentially causing changes in material properties and creating contamination risks for sensitive equipment. The reduced pressure environment can also affect the surface tension characteristics of liquid metals, altering their wetting behavior and interfacial dynamics with substrate materials.

Radiation exposure represents another critical environmental factor impacting liquid metal interconnect performance. High-energy cosmic radiation and solar particles can induce atomic displacement and ionization effects within liquid metal structures, potentially leading to compositional changes, oxide formation, or altered electrical properties. Long-term radiation exposure may necessitate specialized shielding solutions or radiation-hardened liquid metal formulations for extended aerospace missions.

Safety considerations for liquid metal interconnects in aerospace applications extend beyond performance to include toxicity and reactivity concerns. Gallium-based liquid metal alloys, while offering excellent electrical properties, can exhibit aggressive corrosion behavior toward certain metals, particularly aluminum—a primary structural material in aerospace. This galvanic corrosion risk necessitates careful material selection and isolation strategies to prevent structural degradation.

The potential for liquid metal leakage during extreme acceleration, vibration, or impact scenarios presents both safety and reliability challenges. Containment systems must be designed to withstand the mechanical stresses encountered during launch, flight maneuvers, and landing operations. Advanced encapsulation technologies and self-healing containment materials are being developed to address these concerns while maintaining the flexibility advantages of liquid metal interconnects.

Environmental sustainability considerations are increasingly important, with aerospace manufacturers seeking liquid metal formulations that minimize the use of rare or toxic elements. End-of-life disposal protocols must also be established for liquid metal systems to prevent environmental contamination and comply with increasingly stringent international regulations governing aerospace material disposal.

Reliability Testing and Qualification Standards

Reliability testing and qualification standards for liquid metal interconnects in aerospace applications must adhere to rigorous protocols that exceed conventional electronic component requirements. The extreme operating conditions of aerospace environments—including thermal cycling from -65°C to +150°C, high vibration levels, and vacuum exposure—necessitate specialized testing methodologies to ensure performance integrity throughout the mission lifecycle.

Industry standards such as MIL-STD-883 and NASA-STD-8739 provide foundational frameworks, but must be adapted specifically for liquid metal interconnects due to their unique physical properties. Thermal shock testing (per JEDEC JESD22-A106) is particularly critical, as rapid temperature changes can significantly affect the viscosity and surface tension characteristics of liquid metal interfaces. Tests typically involve 1000+ cycles between temperature extremes with electrical continuity monitoring throughout.

Mechanical reliability testing includes random vibration analysis (20-2000 Hz frequency range) and mechanical shock testing (up to 2000G), which are essential for evaluating how liquid metal interconnects respond to launch conditions and in-flight turbulence. These tests must verify that the liquid metal maintains consistent electrical contact without migration or leakage under sustained mechanical stress.

Radiation hardness testing represents another crucial qualification area, with liquid metal interconnects requiring evaluation under total ionizing dose (TID) conditions of 100 krad to 1 Mrad, depending on mission parameters. Unlike solid interconnects, liquid metals may exhibit unique radiation-induced effects on their electrical and physical properties that must be thoroughly characterized.

Long-term reliability assessment protocols typically include accelerated life testing under combined stressors (temperature, electrical load, and mechanical stress) for periods equivalent to 10-15 years of operational life. Highly Accelerated Life Testing (HALT) and Highly Accelerated Stress Screening (HASS) methodologies have been adapted specifically for liquid metal interconnect evaluation.

Outgassing characteristics must also be rigorously tested according to ASTM E595 standards, with particular attention to the potential for vapor release in vacuum environments that could contaminate sensitive optical or electronic components. Liquid metal interconnects must demonstrate total mass loss (TML) below 1.0% and collected volatile condensable materials (CVCM) below 0.1%.

Qualification standards increasingly incorporate environmental considerations, with testing for compliance with RoHS and REACH regulations, even though aerospace applications often receive exemptions. This forward-looking approach ensures that liquid metal interconnect technologies remain viable as global environmental standards evolve.

Industry standards such as MIL-STD-883 and NASA-STD-8739 provide foundational frameworks, but must be adapted specifically for liquid metal interconnects due to their unique physical properties. Thermal shock testing (per JEDEC JESD22-A106) is particularly critical, as rapid temperature changes can significantly affect the viscosity and surface tension characteristics of liquid metal interfaces. Tests typically involve 1000+ cycles between temperature extremes with electrical continuity monitoring throughout.

Mechanical reliability testing includes random vibration analysis (20-2000 Hz frequency range) and mechanical shock testing (up to 2000G), which are essential for evaluating how liquid metal interconnects respond to launch conditions and in-flight turbulence. These tests must verify that the liquid metal maintains consistent electrical contact without migration or leakage under sustained mechanical stress.

Radiation hardness testing represents another crucial qualification area, with liquid metal interconnects requiring evaluation under total ionizing dose (TID) conditions of 100 krad to 1 Mrad, depending on mission parameters. Unlike solid interconnects, liquid metals may exhibit unique radiation-induced effects on their electrical and physical properties that must be thoroughly characterized.

Long-term reliability assessment protocols typically include accelerated life testing under combined stressors (temperature, electrical load, and mechanical stress) for periods equivalent to 10-15 years of operational life. Highly Accelerated Life Testing (HALT) and Highly Accelerated Stress Screening (HASS) methodologies have been adapted specifically for liquid metal interconnect evaluation.

Outgassing characteristics must also be rigorously tested according to ASTM E595 standards, with particular attention to the potential for vapor release in vacuum environments that could contaminate sensitive optical or electronic components. Liquid metal interconnects must demonstrate total mass loss (TML) below 1.0% and collected volatile condensable materials (CVCM) below 0.1%.

Qualification standards increasingly incorporate environmental considerations, with testing for compliance with RoHS and REACH regulations, even though aerospace applications often receive exemptions. This forward-looking approach ensures that liquid metal interconnect technologies remain viable as global environmental standards evolve.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!