What Challenges Exist for Liquid Metal Interconnect in Computing?

SEP 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Interconnect Evolution and Objectives

Liquid metal interconnects represent a revolutionary approach to computing architecture, evolving from traditional copper and aluminum wiring solutions that have dominated the semiconductor industry for decades. The concept of using liquid metals for electrical connections emerged in the early 2000s as researchers sought alternatives to overcome the physical limitations of solid metal interconnects in increasingly miniaturized computing environments. This technological trajectory has been driven by the relentless pursuit of Moore's Law and the growing demands for higher performance, lower power consumption, and greater reliability in computing systems.

The evolution of liquid metal interconnect technology can be traced through several key developmental phases. Initially, gallium-based alloys gained attention for their unique properties of maintaining liquid state at room temperature while offering excellent electrical conductivity. Early research focused primarily on eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan) alloys, which demonstrated promising electrical properties but presented significant integration challenges with conventional semiconductor manufacturing processes.

By the mid-2010s, research expanded to address fundamental material science questions regarding the behavior of liquid metals in micro and nanoscale environments. This period saw significant advancements in understanding oxide layer formation, wetting behaviors, and containment strategies that would become crucial for practical implementation. The development of novel encapsulation techniques and surface treatment methods marked important milestones in making liquid metal interconnects more compatible with existing fabrication technologies.

The primary objective of liquid metal interconnect technology is to overcome the fundamental limitations of solid metal interconnects, particularly as computing architectures approach atomic scales. These objectives include achieving significantly lower electrical resistance to minimize power consumption and heat generation, enabling self-healing capabilities to address electromigration and physical stress failures, and facilitating reconfigurable computing architectures through dynamically adjustable connections.

Another critical objective is to develop interconnect solutions that can function effectively in three-dimensional integrated circuits, where traditional solid interconnects face severe thermal and spatial constraints. Liquid metal's inherent fluidity offers promising pathways for creating truly volumetric computing architectures rather than the predominantly planar designs that have dominated computing for generations.

Looking forward, the technology aims to enable new paradigms in computing by supporting heterogeneous integration of diverse materials and components that currently face compatibility challenges with traditional interconnect solutions. The ultimate goal is to create interconnect systems that can adapt to changing computational demands in real-time, potentially revolutionizing how computing systems are designed and operated.

The evolution of liquid metal interconnect technology can be traced through several key developmental phases. Initially, gallium-based alloys gained attention for their unique properties of maintaining liquid state at room temperature while offering excellent electrical conductivity. Early research focused primarily on eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan) alloys, which demonstrated promising electrical properties but presented significant integration challenges with conventional semiconductor manufacturing processes.

By the mid-2010s, research expanded to address fundamental material science questions regarding the behavior of liquid metals in micro and nanoscale environments. This period saw significant advancements in understanding oxide layer formation, wetting behaviors, and containment strategies that would become crucial for practical implementation. The development of novel encapsulation techniques and surface treatment methods marked important milestones in making liquid metal interconnects more compatible with existing fabrication technologies.

The primary objective of liquid metal interconnect technology is to overcome the fundamental limitations of solid metal interconnects, particularly as computing architectures approach atomic scales. These objectives include achieving significantly lower electrical resistance to minimize power consumption and heat generation, enabling self-healing capabilities to address electromigration and physical stress failures, and facilitating reconfigurable computing architectures through dynamically adjustable connections.

Another critical objective is to develop interconnect solutions that can function effectively in three-dimensional integrated circuits, where traditional solid interconnects face severe thermal and spatial constraints. Liquid metal's inherent fluidity offers promising pathways for creating truly volumetric computing architectures rather than the predominantly planar designs that have dominated computing for generations.

Looking forward, the technology aims to enable new paradigms in computing by supporting heterogeneous integration of diverse materials and components that currently face compatibility challenges with traditional interconnect solutions. The ultimate goal is to create interconnect systems that can adapt to changing computational demands in real-time, potentially revolutionizing how computing systems are designed and operated.

Market Demand Analysis for Advanced Computing Interconnects

The demand for advanced computing interconnects is experiencing unprecedented growth, driven primarily by the rapid evolution of high-performance computing systems, artificial intelligence applications, and data-intensive workloads. Traditional copper-based interconnects are increasingly becoming bottlenecks in system performance, creating market opportunities for innovative solutions like liquid metal interconnects.

Market research indicates that the global high-performance computing market is projected to grow at a compound annual growth rate of 6.5% through 2028, with interconnect technologies representing a significant segment of this expansion. This growth is fueled by escalating requirements for faster data transfer rates, lower latency, and improved power efficiency across computing platforms.

Data centers represent the largest market segment demanding advanced interconnect solutions. With the exponential increase in cloud computing services and the proliferation of edge computing, data centers are under pressure to optimize their infrastructure for maximum throughput and minimal energy consumption. Liquid metal interconnects offer promising advantages in thermal management and electrical conductivity that directly address these pain points.

The semiconductor industry's continuous push toward smaller node sizes and three-dimensional integration creates another substantial market opportunity. As traditional interconnect technologies approach their physical limitations, manufacturers are actively seeking alternatives that can maintain signal integrity at higher frequencies while accommodating increasingly complex chip architectures.

Consumer electronics manufacturers constitute another significant market segment, particularly as devices become more powerful and compact. The demand for seamless connectivity in smartphones, tablets, and wearable technology drives the need for interconnect solutions that can deliver high performance within strict space and power constraints.

Automotive and aerospace industries are emerging markets for advanced interconnects, with the rise of autonomous vehicles and sophisticated avionics systems requiring robust, high-bandwidth communication between numerous sensors and processing units. These applications demand interconnect technologies that can withstand harsh environmental conditions while maintaining reliable performance.

Geographically, North America and Asia-Pacific regions dominate the market demand, with major technology hubs in the United States, China, Taiwan, and South Korea leading research and implementation efforts. European markets show growing interest, particularly in automotive applications and scientific computing installations.

The market is further characterized by increasing emphasis on sustainability and environmental considerations, creating demand for interconnect solutions with reduced reliance on rare or toxic materials. Liquid metal technologies using gallium-based alloys align well with this trend, offering potential advantages over traditional materials containing lead or other hazardous elements.

Market research indicates that the global high-performance computing market is projected to grow at a compound annual growth rate of 6.5% through 2028, with interconnect technologies representing a significant segment of this expansion. This growth is fueled by escalating requirements for faster data transfer rates, lower latency, and improved power efficiency across computing platforms.

Data centers represent the largest market segment demanding advanced interconnect solutions. With the exponential increase in cloud computing services and the proliferation of edge computing, data centers are under pressure to optimize their infrastructure for maximum throughput and minimal energy consumption. Liquid metal interconnects offer promising advantages in thermal management and electrical conductivity that directly address these pain points.

The semiconductor industry's continuous push toward smaller node sizes and three-dimensional integration creates another substantial market opportunity. As traditional interconnect technologies approach their physical limitations, manufacturers are actively seeking alternatives that can maintain signal integrity at higher frequencies while accommodating increasingly complex chip architectures.

Consumer electronics manufacturers constitute another significant market segment, particularly as devices become more powerful and compact. The demand for seamless connectivity in smartphones, tablets, and wearable technology drives the need for interconnect solutions that can deliver high performance within strict space and power constraints.

Automotive and aerospace industries are emerging markets for advanced interconnects, with the rise of autonomous vehicles and sophisticated avionics systems requiring robust, high-bandwidth communication between numerous sensors and processing units. These applications demand interconnect technologies that can withstand harsh environmental conditions while maintaining reliable performance.

Geographically, North America and Asia-Pacific regions dominate the market demand, with major technology hubs in the United States, China, Taiwan, and South Korea leading research and implementation efforts. European markets show growing interest, particularly in automotive applications and scientific computing installations.

The market is further characterized by increasing emphasis on sustainability and environmental considerations, creating demand for interconnect solutions with reduced reliance on rare or toxic materials. Liquid metal technologies using gallium-based alloys align well with this trend, offering potential advantages over traditional materials containing lead or other hazardous elements.

Current Limitations and Technical Barriers in Liquid Metal Implementation

Despite the promising potential of liquid metal interconnects in computing systems, several significant technical barriers currently impede their widespread implementation. The high surface tension of liquid metals, particularly gallium-based alloys like Galinstan and EGaIn, presents a fundamental challenge. This property causes these materials to form spherical droplets rather than maintaining desired interconnect geometries, limiting their application in complex circuit designs that require precise patterning and stable configurations.

Oxidation represents another critical limitation. When exposed to oxygen, gallium-based liquid metals rapidly form a thin oxide layer on their surface. While this oxide skin can be beneficial for pattern stability in some applications, it also increases electrical resistance at interfaces and complicates the formation of reliable electrical connections. The oxide layer's properties change over time, introducing unpredictability in long-term performance characteristics.

Compatibility issues with traditional semiconductor manufacturing processes pose significant integration challenges. Liquid metals can be corrosive to certain metals commonly used in electronics, particularly aluminum, which is ubiquitous in computing hardware. This corrosivity necessitates protective barrier layers or alternative metallization schemes, adding complexity to fabrication processes and potentially compromising performance.

The mechanical stability of liquid metal interconnects under operational conditions remains problematic. Computing environments involve thermal cycling, mechanical vibration, and other stresses that can disrupt liquid metal connections. Without proper encapsulation or stabilization mechanisms, these interconnects may suffer from migration, leakage, or complete disconnection during normal operation.

Temperature sensitivity further complicates implementation. While liquid metals maintain their fluid state across a wide temperature range, their electrical and mechanical properties can vary significantly with temperature fluctuations. This variability introduces reliability concerns in computing applications where consistent performance across different thermal conditions is essential.

Scalability to nanoscale dimensions represents perhaps the most significant barrier to adoption in advanced computing architectures. Current liquid metal patterning techniques struggle to achieve the sub-micron feature sizes required for modern integrated circuits. Conventional methods like microfluidic injection, direct writing, and template-based approaches typically yield features in the tens to hundreds of micrometers range, far larger than the nanometer-scale interconnects in contemporary processors.

Finally, the lack of standardized characterization methods and reliability testing protocols specifically designed for liquid metal interconnects hinders comparative assessment and quality control. Without established benchmarks and testing procedures, it remains difficult to evaluate different liquid metal formulations and implementation strategies against current solid-state interconnect technologies.

Oxidation represents another critical limitation. When exposed to oxygen, gallium-based liquid metals rapidly form a thin oxide layer on their surface. While this oxide skin can be beneficial for pattern stability in some applications, it also increases electrical resistance at interfaces and complicates the formation of reliable electrical connections. The oxide layer's properties change over time, introducing unpredictability in long-term performance characteristics.

Compatibility issues with traditional semiconductor manufacturing processes pose significant integration challenges. Liquid metals can be corrosive to certain metals commonly used in electronics, particularly aluminum, which is ubiquitous in computing hardware. This corrosivity necessitates protective barrier layers or alternative metallization schemes, adding complexity to fabrication processes and potentially compromising performance.

The mechanical stability of liquid metal interconnects under operational conditions remains problematic. Computing environments involve thermal cycling, mechanical vibration, and other stresses that can disrupt liquid metal connections. Without proper encapsulation or stabilization mechanisms, these interconnects may suffer from migration, leakage, or complete disconnection during normal operation.

Temperature sensitivity further complicates implementation. While liquid metals maintain their fluid state across a wide temperature range, their electrical and mechanical properties can vary significantly with temperature fluctuations. This variability introduces reliability concerns in computing applications where consistent performance across different thermal conditions is essential.

Scalability to nanoscale dimensions represents perhaps the most significant barrier to adoption in advanced computing architectures. Current liquid metal patterning techniques struggle to achieve the sub-micron feature sizes required for modern integrated circuits. Conventional methods like microfluidic injection, direct writing, and template-based approaches typically yield features in the tens to hundreds of micrometers range, far larger than the nanometer-scale interconnects in contemporary processors.

Finally, the lack of standardized characterization methods and reliability testing protocols specifically designed for liquid metal interconnects hinders comparative assessment and quality control. Without established benchmarks and testing procedures, it remains difficult to evaluate different liquid metal formulations and implementation strategies against current solid-state interconnect technologies.

Contemporary Approaches to Liquid Metal Interconnect Challenges

01 Liquid metal interconnect materials and compositions

Liquid metal materials, such as gallium-based alloys, can be used as interconnects in electronic devices due to their excellent electrical conductivity and ability to maintain connectivity during mechanical deformation. These materials offer advantages including self-healing properties, flexibility, and the ability to form reliable electrical connections at lower temperatures than traditional solders. The composition can be tailored to achieve specific melting points, viscosity, and adhesion properties suitable for various applications.- Liquid metal interconnect materials and compositions: Liquid metal materials, such as gallium-based alloys, can be used as interconnects in electronic devices due to their excellent electrical conductivity and ability to maintain connectivity during mechanical deformation. These materials offer advantages including self-healing properties, flexibility, and the ability to form reliable electrical connections at lower temperatures than traditional solders. Various compositions and additives can be incorporated to optimize properties such as melting point, adhesion, and oxidation resistance.

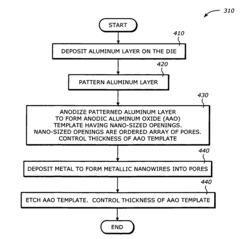

- Fabrication methods for liquid metal interconnects: Various techniques can be employed to fabricate liquid metal interconnects, including printing, injection, microfluidic channels, and patterning methods. These processes allow for precise deposition and confinement of liquid metals to create stable electrical pathways. Advanced fabrication approaches include encapsulation techniques to prevent oxidation, methods to control wetting behavior, and integration with conventional semiconductor processing techniques to enable compatibility with existing manufacturing processes.

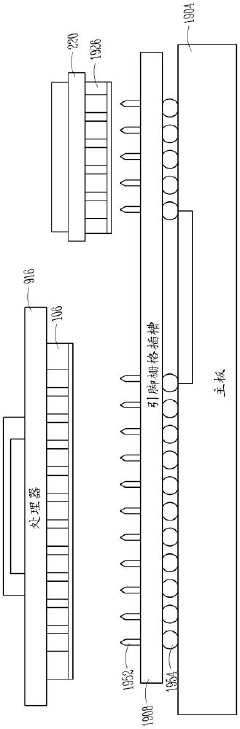

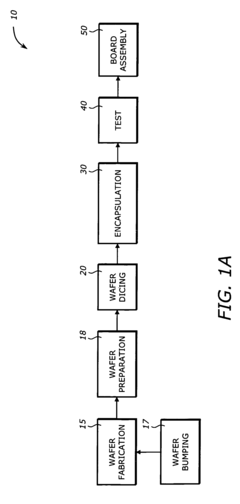

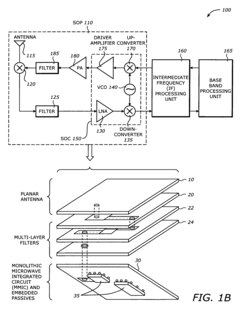

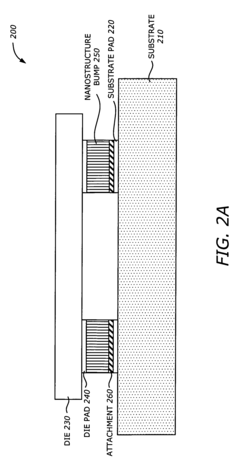

- Integration of liquid metal interconnects in semiconductor devices: Liquid metal interconnects can be integrated into semiconductor devices to provide electrical connections between components. This integration involves specialized techniques for creating vias, trenches, and contact points that accommodate the unique properties of liquid metals. Design considerations include preventing metal migration, ensuring compatibility with surrounding materials, and maintaining electrical performance across temperature variations. These interconnects can be particularly valuable in 3D integrated circuits and advanced packaging applications.

- Flexible and stretchable liquid metal interconnects: Liquid metals enable the creation of flexible and stretchable interconnects that maintain electrical conductivity during bending, stretching, and other mechanical deformations. These interconnects can be embedded in elastomeric substrates or confined within microchannels to create robust connections for wearable electronics, soft robotics, and other applications requiring mechanical flexibility. The self-healing nature of liquid metals allows these interconnects to recover from mechanical damage and maintain functionality under repeated strain.

- Thermal management and reliability of liquid metal interconnects: Liquid metal interconnects offer excellent thermal conductivity, making them valuable for heat dissipation in electronic devices. Design considerations include preventing corrosion of adjacent materials, managing oxidation at interfaces, and ensuring long-term stability under operational conditions. Various encapsulation strategies and surface treatments can be employed to enhance reliability and prevent undesired chemical reactions. The high thermal conductivity of liquid metals can be leveraged to create interconnects that simultaneously serve as electrical pathways and thermal management structures.

02 Fabrication methods for liquid metal interconnects

Various techniques can be employed to fabricate liquid metal interconnects, including printing, injection, microfluidic channels, and encapsulation methods. These processes allow for precise deposition and patterning of liquid metal to form reliable electrical pathways. Advanced fabrication methods include selective wetting, template-assisted deposition, and surface modification to control the flow and adhesion of liquid metals. These techniques enable the creation of complex interconnect structures with high resolution and reliability.Expand Specific Solutions03 Encapsulation and containment strategies

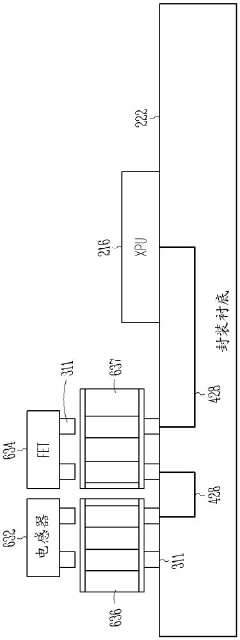

Effective encapsulation is crucial for liquid metal interconnects to prevent leakage and oxidation while maintaining electrical performance. Materials such as elastomers, polymers, and specialized coatings can be used to contain the liquid metal while allowing for flexibility and stretchability. Microchannels and reservoirs can be designed to accommodate volume changes during thermal cycling. Advanced encapsulation techniques include self-healing barriers and multi-layer structures that maintain integrity under mechanical stress.Expand Specific Solutions04 Integration with semiconductor devices

Liquid metal interconnects can be integrated with semiconductor devices to create reliable electrical connections between components. This integration requires specialized interface designs to ensure compatibility between the liquid metal and semiconductor materials. Techniques such as surface treatment, barrier layers, and specialized bonding methods are employed to create stable connections. The integration allows for novel device architectures that can benefit from the unique properties of liquid metals, including thermal management and stress relief during thermal cycling.Expand Specific Solutions05 Reliability and performance enhancement

Enhancing the reliability and performance of liquid metal interconnects involves addressing challenges such as oxidation, metal migration, and mechanical stability. Additives and surface treatments can improve wetting properties and reduce oxidation. Specialized designs incorporating strain relief structures and redundant pathways can enhance mechanical reliability. Testing methodologies have been developed to evaluate performance under thermal cycling, mechanical stress, and environmental conditions, ensuring long-term functionality in various applications.Expand Specific Solutions

Critical Patents and Breakthroughs in Liquid Metal Conductivity

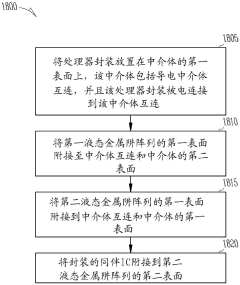

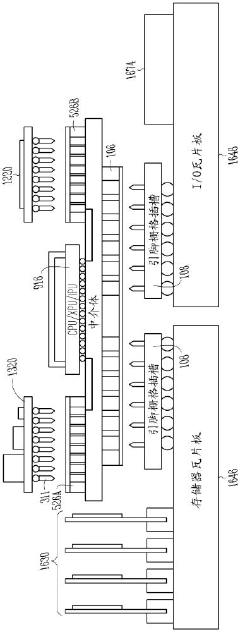

Liquid metal interconnect for modular encapsulated server architecture

PatentPendingCN116344503A

Innovation

- A non-permanent zero-force interconnect using a liquid metal structure, through contact between the liquid metal well array and the pin grid array slot, provides direct soldering isoelectric properties and a compact packaging structure, reducing the physical size and mechanical dimensions of the processor package Loading requirements.

Nanostructure-based package interconnect

PatentInactiveUS7371674B2

Innovation

- The use of nanostructure bumps with templates defining nano-sized openings, such as anodized aluminum oxide or polycarbonate membranes, to grow metallic nano-wires like gold, silver, or copper, which provide high current-carrying capability and reduce electro-migration risks, enabling fine pitches for high-density interconnects.

Thermal Management Strategies for Liquid Metal Interconnects

Thermal management represents a critical challenge for liquid metal interconnects in computing systems. As these interconnects operate, they generate significant heat due to electrical resistance and current flow, which must be efficiently dissipated to maintain system stability and performance. Traditional cooling methods such as air cooling prove inadequate for the high thermal loads generated by liquid metal interconnects, necessitating more advanced thermal management strategies.

Heat spreaders and heat sinks specifically designed for liquid metal applications have emerged as primary thermal management solutions. These components typically incorporate high thermal conductivity materials like copper, aluminum, or advanced ceramic composites that efficiently transfer heat away from the interconnect regions. The design of these heat dissipation systems must account for the unique thermal properties of liquid metals, including their high thermal conductivity and potential for phase changes under extreme conditions.

Active cooling technologies have shown promising results when integrated with liquid metal interconnect systems. These include microfluidic cooling channels that run adjacent to interconnect pathways, allowing for direct heat extraction through circulating coolants. Advanced implementations utilize two-phase cooling systems where the coolant undergoes phase transition, significantly enhancing heat absorption capacity through latent heat of vaporization.

Thermal interface materials (TIMs) play a crucial role in maximizing heat transfer efficiency between liquid metal interconnects and cooling systems. Specialized TIMs have been developed that remain stable when in proximity to liquid metals while providing excellent thermal conductivity. These materials often incorporate nanoparticles or phase-change compounds that adapt to thermal expansion differences between interconnect materials and cooling components.

Computational fluid dynamics (CFD) modeling has become essential for optimizing thermal management strategies. These simulations predict heat distribution patterns within liquid metal interconnect systems, allowing engineers to identify potential hotspots before physical implementation. Advanced thermal modeling also enables the development of dynamic cooling solutions that adjust cooling intensity based on real-time temperature monitoring, ensuring optimal thermal conditions while minimizing energy consumption.

Emerging research focuses on integrating thermal management directly into the liquid metal formulation. This includes developing liquid metal composites with enhanced thermal properties or incorporating thermally responsive additives that improve heat dissipation characteristics without compromising electrical conductivity. Such innovations represent a paradigm shift from treating thermal management as a separate system to embedding it within the interconnect material itself.

Heat spreaders and heat sinks specifically designed for liquid metal applications have emerged as primary thermal management solutions. These components typically incorporate high thermal conductivity materials like copper, aluminum, or advanced ceramic composites that efficiently transfer heat away from the interconnect regions. The design of these heat dissipation systems must account for the unique thermal properties of liquid metals, including their high thermal conductivity and potential for phase changes under extreme conditions.

Active cooling technologies have shown promising results when integrated with liquid metal interconnect systems. These include microfluidic cooling channels that run adjacent to interconnect pathways, allowing for direct heat extraction through circulating coolants. Advanced implementations utilize two-phase cooling systems where the coolant undergoes phase transition, significantly enhancing heat absorption capacity through latent heat of vaporization.

Thermal interface materials (TIMs) play a crucial role in maximizing heat transfer efficiency between liquid metal interconnects and cooling systems. Specialized TIMs have been developed that remain stable when in proximity to liquid metals while providing excellent thermal conductivity. These materials often incorporate nanoparticles or phase-change compounds that adapt to thermal expansion differences between interconnect materials and cooling components.

Computational fluid dynamics (CFD) modeling has become essential for optimizing thermal management strategies. These simulations predict heat distribution patterns within liquid metal interconnect systems, allowing engineers to identify potential hotspots before physical implementation. Advanced thermal modeling also enables the development of dynamic cooling solutions that adjust cooling intensity based on real-time temperature monitoring, ensuring optimal thermal conditions while minimizing energy consumption.

Emerging research focuses on integrating thermal management directly into the liquid metal formulation. This includes developing liquid metal composites with enhanced thermal properties or incorporating thermally responsive additives that improve heat dissipation characteristics without compromising electrical conductivity. Such innovations represent a paradigm shift from treating thermal management as a separate system to embedding it within the interconnect material itself.

Environmental and Safety Considerations in Liquid Metal Computing

The environmental and safety implications of liquid metal technologies in computing systems present significant challenges that must be addressed before widespread adoption. Many liquid metal alloys contain elements such as gallium, indium, and mercury, which raise toxicity concerns. While gallium-based alloys are generally considered less hazardous than mercury, their long-term environmental impact remains inadequately studied. The potential leaching of these metals into soil and water systems could create environmental contamination issues if liquid metal computing devices are improperly disposed of or experience containment failures.

Manufacturing processes for liquid metal interconnects may involve chemical treatments and surface modifications that utilize potentially harmful substances. These processes require stringent safety protocols and waste management systems to prevent worker exposure and environmental release. Additionally, the energy consumption associated with specialized manufacturing techniques for liquid metal integration presents sustainability challenges that must be factored into environmental impact assessments.

The recyclability of liquid metal components presents another critical consideration. While theoretically recoverable, the intimate integration of liquid metals with other computing components may complicate end-of-life separation and recycling efforts. Current electronic waste management systems are not optimized for handling devices containing liquid metal elements, potentially leading to resource loss and environmental contamination if not properly addressed through specialized recycling protocols.

Temperature sensitivity of certain liquid metal alloys raises safety concerns in computing applications. Some gallium-based alloys expand upon solidification, potentially causing mechanical stress or ruptures in containment structures. This expansion characteristic necessitates robust containment solutions to prevent leakage events that could expose users to direct contact with these materials or damage surrounding electronic components.

Regulatory frameworks governing the use of liquid metals in consumer electronics remain underdeveloped in many jurisdictions. The novel nature of these materials in computing applications means that existing electronic safety standards may not adequately address their unique properties and risks. International harmonization of safety standards and disposal regulations will be essential to ensure consistent environmental protection as liquid metal computing technologies advance toward commercialization.

Ongoing research into biocompatible and environmentally benign liquid metal formulations represents a promising direction for addressing these challenges. Development of non-toxic alternatives and improved containment technologies will be crucial for balancing the performance benefits of liquid metal interconnects with environmental responsibility and user safety.

Manufacturing processes for liquid metal interconnects may involve chemical treatments and surface modifications that utilize potentially harmful substances. These processes require stringent safety protocols and waste management systems to prevent worker exposure and environmental release. Additionally, the energy consumption associated with specialized manufacturing techniques for liquid metal integration presents sustainability challenges that must be factored into environmental impact assessments.

The recyclability of liquid metal components presents another critical consideration. While theoretically recoverable, the intimate integration of liquid metals with other computing components may complicate end-of-life separation and recycling efforts. Current electronic waste management systems are not optimized for handling devices containing liquid metal elements, potentially leading to resource loss and environmental contamination if not properly addressed through specialized recycling protocols.

Temperature sensitivity of certain liquid metal alloys raises safety concerns in computing applications. Some gallium-based alloys expand upon solidification, potentially causing mechanical stress or ruptures in containment structures. This expansion characteristic necessitates robust containment solutions to prevent leakage events that could expose users to direct contact with these materials or damage surrounding electronic components.

Regulatory frameworks governing the use of liquid metals in consumer electronics remain underdeveloped in many jurisdictions. The novel nature of these materials in computing applications means that existing electronic safety standards may not adequately address their unique properties and risks. International harmonization of safety standards and disposal regulations will be essential to ensure consistent environmental protection as liquid metal computing technologies advance toward commercialization.

Ongoing research into biocompatible and environmentally benign liquid metal formulations represents a promising direction for addressing these challenges. Development of non-toxic alternatives and improved containment technologies will be crucial for balancing the performance benefits of liquid metal interconnects with environmental responsibility and user safety.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!