Mechanical Properties of Liquid Metal Interconnect in Flexible Devices

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Interconnect Background and Objectives

Liquid metal interconnects have emerged as a revolutionary technology in the field of flexible electronics over the past decade. These materials, primarily gallium-based alloys such as eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan), possess unique properties that combine metallic conductivity with fluidic characteristics at room temperature. The evolution of this technology can be traced back to early experiments with mercury, which despite its excellent electrical properties, was limited by toxicity concerns. The development of non-toxic gallium alloys in the early 2000s marked a significant turning point, enabling safer applications in wearable and biocompatible devices.

The technological trajectory of liquid metal interconnects has been characterized by progressive improvements in integration methods, from simple microchannels to advanced printing techniques. Recent advancements have focused on addressing oxidation issues, enhancing adhesion to substrates, and developing novel patterning approaches to achieve higher resolution and reliability in complex circuits. These developments have been driven by the growing demand for electronics that can withstand mechanical deformation while maintaining electrical performance.

The primary objective of research into the mechanical properties of liquid metal interconnects is to develop robust, reliable connections that can endure repeated deformation cycles without performance degradation. This includes understanding the fundamental mechanics of liquid metals under strain, their interaction with encapsulating materials, and the development of predictive models for failure mechanisms. Additionally, researchers aim to establish standardized testing protocols and performance metrics specific to liquid metal interconnects in flexible devices.

Another critical goal is to bridge the gap between laboratory demonstrations and commercial viability. This requires addressing challenges related to scalable manufacturing, long-term stability, and integration with existing electronic components and systems. The development of cost-effective production methods that maintain the unique properties of liquid metals while enabling mass production represents a significant technical hurdle.

Furthermore, research objectives extend to exploring novel applications that leverage the unique mechanical properties of liquid metal interconnects. These include self-healing circuits, reconfigurable electronics, soft robotics, and advanced biomedical devices. The ability of liquid metals to maintain conductivity under extreme deformation opens possibilities for applications previously unattainable with conventional solid conductors.

The field also aims to develop comprehensive design guidelines that enable engineers to incorporate liquid metal interconnects into new product designs with predictable performance characteristics. This includes creating simulation tools that accurately model the behavior of liquid metals under various mechanical and environmental conditions, facilitating the optimization of device architectures before physical prototyping.

The technological trajectory of liquid metal interconnects has been characterized by progressive improvements in integration methods, from simple microchannels to advanced printing techniques. Recent advancements have focused on addressing oxidation issues, enhancing adhesion to substrates, and developing novel patterning approaches to achieve higher resolution and reliability in complex circuits. These developments have been driven by the growing demand for electronics that can withstand mechanical deformation while maintaining electrical performance.

The primary objective of research into the mechanical properties of liquid metal interconnects is to develop robust, reliable connections that can endure repeated deformation cycles without performance degradation. This includes understanding the fundamental mechanics of liquid metals under strain, their interaction with encapsulating materials, and the development of predictive models for failure mechanisms. Additionally, researchers aim to establish standardized testing protocols and performance metrics specific to liquid metal interconnects in flexible devices.

Another critical goal is to bridge the gap between laboratory demonstrations and commercial viability. This requires addressing challenges related to scalable manufacturing, long-term stability, and integration with existing electronic components and systems. The development of cost-effective production methods that maintain the unique properties of liquid metals while enabling mass production represents a significant technical hurdle.

Furthermore, research objectives extend to exploring novel applications that leverage the unique mechanical properties of liquid metal interconnects. These include self-healing circuits, reconfigurable electronics, soft robotics, and advanced biomedical devices. The ability of liquid metals to maintain conductivity under extreme deformation opens possibilities for applications previously unattainable with conventional solid conductors.

The field also aims to develop comprehensive design guidelines that enable engineers to incorporate liquid metal interconnects into new product designs with predictable performance characteristics. This includes creating simulation tools that accurately model the behavior of liquid metals under various mechanical and environmental conditions, facilitating the optimization of device architectures before physical prototyping.

Market Analysis for Flexible Electronics

The flexible electronics market has been experiencing robust growth, with a global market value reaching $31.6 billion in 2022 and projected to expand at a CAGR of 15.8% through 2030. This growth is primarily driven by increasing demand for wearable devices, foldable displays, and soft robotics applications across consumer electronics, healthcare, and industrial sectors.

Liquid metal interconnects represent a critical component within this market, addressing the fundamental challenge of maintaining electrical conductivity while undergoing mechanical deformation. The market segment specifically for stretchable and flexible interconnect technologies is estimated at $4.2 billion, with liquid metal solutions capturing approximately 18% of this segment due to their superior mechanical properties.

Consumer electronics currently dominates the application landscape, accounting for 42% of flexible electronics market share, followed by healthcare applications at 28%. Within these sectors, devices requiring high mechanical resilience in interconnects - such as skin-mounted health monitors and foldable smartphones - are showing the strongest growth trajectories at 22% and 19% annually, respectively.

Regional analysis reveals Asia-Pacific as the dominant manufacturing hub, controlling 58% of production capacity, with South Korea, Japan, and China leading innovation in liquid metal interconnect technologies. North America follows with 24% market share, primarily focused on advanced research and premium applications in medical devices and aerospace.

Key market drivers include miniaturization trends in electronics, growing consumer preference for wearable technology, and increasing healthcare applications requiring biocompatible flexible interfaces. The mechanical properties of liquid metal interconnects - particularly their self-healing capabilities, negligible mechanical hysteresis, and fatigue resistance - directly address these market requirements, positioning them as premium solutions in high-value applications.

Market challenges include scaling production processes, reducing manufacturing costs (currently 2.8-4.5 times higher than conventional rigid interconnects), and addressing environmental concerns related to gallium-based liquid metal alloys. Despite these challenges, the specialized nature of liquid metal interconnects creates significant value-added opportunities, with profit margins averaging 32-38% for manufacturers who can overcome technical barriers.

Industry forecasts suggest that as mechanical reliability becomes increasingly critical in next-generation flexible devices, liquid metal interconnect technologies will expand beyond current niche applications to capture broader market segments, potentially reaching $2.7 billion in direct market value by 2028.

Liquid metal interconnects represent a critical component within this market, addressing the fundamental challenge of maintaining electrical conductivity while undergoing mechanical deformation. The market segment specifically for stretchable and flexible interconnect technologies is estimated at $4.2 billion, with liquid metal solutions capturing approximately 18% of this segment due to their superior mechanical properties.

Consumer electronics currently dominates the application landscape, accounting for 42% of flexible electronics market share, followed by healthcare applications at 28%. Within these sectors, devices requiring high mechanical resilience in interconnects - such as skin-mounted health monitors and foldable smartphones - are showing the strongest growth trajectories at 22% and 19% annually, respectively.

Regional analysis reveals Asia-Pacific as the dominant manufacturing hub, controlling 58% of production capacity, with South Korea, Japan, and China leading innovation in liquid metal interconnect technologies. North America follows with 24% market share, primarily focused on advanced research and premium applications in medical devices and aerospace.

Key market drivers include miniaturization trends in electronics, growing consumer preference for wearable technology, and increasing healthcare applications requiring biocompatible flexible interfaces. The mechanical properties of liquid metal interconnects - particularly their self-healing capabilities, negligible mechanical hysteresis, and fatigue resistance - directly address these market requirements, positioning them as premium solutions in high-value applications.

Market challenges include scaling production processes, reducing manufacturing costs (currently 2.8-4.5 times higher than conventional rigid interconnects), and addressing environmental concerns related to gallium-based liquid metal alloys. Despite these challenges, the specialized nature of liquid metal interconnects creates significant value-added opportunities, with profit margins averaging 32-38% for manufacturers who can overcome technical barriers.

Industry forecasts suggest that as mechanical reliability becomes increasingly critical in next-generation flexible devices, liquid metal interconnect technologies will expand beyond current niche applications to capture broader market segments, potentially reaching $2.7 billion in direct market value by 2028.

Current Mechanical Challenges in Liquid Metal Applications

Despite the promising potential of liquid metal interconnects in flexible electronics, several significant mechanical challenges currently limit their widespread application. The inherent fluidity of liquid metals, while advantageous for flexibility, creates substantial difficulties in maintaining stable electrical connections under mechanical deformation. When flexible devices undergo bending, stretching, or twisting, liquid metal interconnects often experience issues with shape retention and positional stability, leading to performance degradation.

One primary challenge is the containment of liquid metals within designated channels. Traditional encapsulation methods using polymers like PDMS (polydimethylsiloxane) frequently suffer from delamination at the liquid metal-polymer interface during repeated mechanical cycling. This interface failure results in leakage and electrical discontinuity, particularly at strain levels exceeding 30%. Recent studies have documented that after approximately 1000 bending cycles, up to 15% of liquid metal interconnects may exhibit some form of mechanical failure.

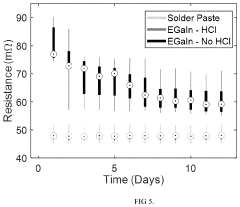

The oxidation behavior of gallium-based liquid metals presents another significant mechanical challenge. While the oxide skin formation helps maintain shape, it simultaneously introduces mechanical stiffness that can compromise the overall flexibility of the interconnect system. This oxide layer, typically 1-3 nm thick, can crack under strain, creating unpredictable electrical resistance variations that range from 5% to 20% depending on deformation magnitude.

Thermal cycling further exacerbates mechanical stability issues. The coefficient of thermal expansion mismatch between liquid metals and surrounding materials generates internal stresses that can reach up to 5 MPa at temperature differentials of 100°C. These stresses often lead to microcracks in encapsulation layers and subsequent device failure, particularly in applications requiring operation across wide temperature ranges.

The viscosity characteristics of liquid metals also present engineering challenges. Under high-frequency vibrations or impact forces, liquid metals can exhibit non-Newtonian behavior, resulting in temporary resistance spikes of up to 200% during mechanical shock events. This phenomenon significantly impacts reliability in wearable applications where sudden movements are common.

Adhesion between liquid metals and contact electrodes remains problematic, with contact resistance variations of 10-30% observed during mechanical deformation. The dynamic nature of these interfaces under strain creates unpredictable electrical performance that complicates circuit design and reliability engineering.

Current manufacturing processes further compound these challenges, as precise deposition and patterning of liquid metals at microscale dimensions remains difficult to achieve with high repeatability. Dimensional variations of ±5-10% are common in production environments, creating inconsistent mechanical properties across devices.

One primary challenge is the containment of liquid metals within designated channels. Traditional encapsulation methods using polymers like PDMS (polydimethylsiloxane) frequently suffer from delamination at the liquid metal-polymer interface during repeated mechanical cycling. This interface failure results in leakage and electrical discontinuity, particularly at strain levels exceeding 30%. Recent studies have documented that after approximately 1000 bending cycles, up to 15% of liquid metal interconnects may exhibit some form of mechanical failure.

The oxidation behavior of gallium-based liquid metals presents another significant mechanical challenge. While the oxide skin formation helps maintain shape, it simultaneously introduces mechanical stiffness that can compromise the overall flexibility of the interconnect system. This oxide layer, typically 1-3 nm thick, can crack under strain, creating unpredictable electrical resistance variations that range from 5% to 20% depending on deformation magnitude.

Thermal cycling further exacerbates mechanical stability issues. The coefficient of thermal expansion mismatch between liquid metals and surrounding materials generates internal stresses that can reach up to 5 MPa at temperature differentials of 100°C. These stresses often lead to microcracks in encapsulation layers and subsequent device failure, particularly in applications requiring operation across wide temperature ranges.

The viscosity characteristics of liquid metals also present engineering challenges. Under high-frequency vibrations or impact forces, liquid metals can exhibit non-Newtonian behavior, resulting in temporary resistance spikes of up to 200% during mechanical shock events. This phenomenon significantly impacts reliability in wearable applications where sudden movements are common.

Adhesion between liquid metals and contact electrodes remains problematic, with contact resistance variations of 10-30% observed during mechanical deformation. The dynamic nature of these interfaces under strain creates unpredictable electrical performance that complicates circuit design and reliability engineering.

Current manufacturing processes further compound these challenges, as precise deposition and patterning of liquid metals at microscale dimensions remains difficult to achieve with high repeatability. Dimensional variations of ±5-10% are common in production environments, creating inconsistent mechanical properties across devices.

Current Solutions for Liquid Metal Mechanical Stability

01 Mechanical properties of liquid metal interconnects

Liquid metal interconnects offer unique mechanical properties including flexibility, stretchability, and self-healing capabilities. These properties make them suitable for applications requiring resistance to mechanical stress, vibration, and thermal cycling. The liquid state allows for maintaining electrical connectivity even during deformation, which is particularly valuable in flexible electronics and semiconductor packaging where traditional solid interconnects might fail under mechanical strain.- Mechanical properties of liquid metal interconnects: Liquid metal interconnects offer unique mechanical properties including flexibility, stretchability, and self-healing capabilities. These properties make them ideal for applications requiring resistance to mechanical stress, vibration, and thermal cycling. The liquid state allows for movement and redistribution under stress, preventing typical failure modes seen in solid interconnects such as cracking and fatigue. These interconnects maintain electrical conductivity even when subjected to bending, stretching, or other mechanical deformations.

- Composition and material selection for liquid metal interconnects: The composition of liquid metal interconnects significantly affects their mechanical properties. Gallium-based alloys (such as gallium-indium-tin or galinstan) are commonly used due to their low melting points and good electrical conductivity. Other compositions include mercury-based alloys and low-melting-point solders. The selection of specific metal compositions can be tailored to achieve desired mechanical characteristics such as viscosity, surface tension, and adhesion properties. Additives and surfactants can be incorporated to modify wetting behavior and prevent oxidation.

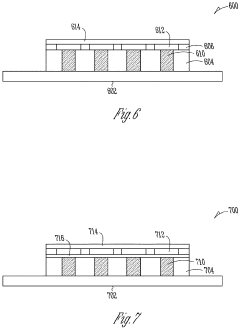

- Encapsulation techniques for liquid metal interconnects: Encapsulation methods significantly impact the mechanical performance of liquid metal interconnects. Various elastomeric materials such as PDMS, silicone, and specialized polymers are used to contain the liquid metal while allowing for flexibility and stretchability. The encapsulation design must balance mechanical protection with maintaining the beneficial properties of the liquid metal. Channel structures, microcavities, and patterned substrates can be engineered to control the movement and deformation of the liquid metal under stress, enhancing reliability and performance in dynamic applications.

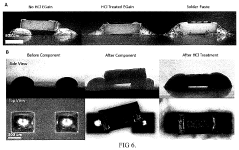

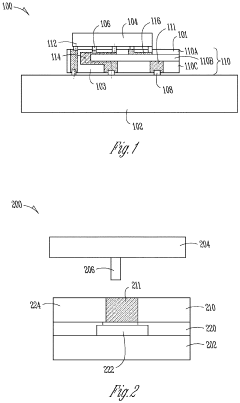

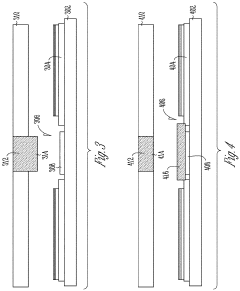

- Integration of liquid metal interconnects with semiconductor devices: Integrating liquid metal interconnects with traditional semiconductor devices presents unique challenges and opportunities for improving mechanical reliability. Special interface layers and bonding techniques are developed to ensure good electrical contact between liquid metals and solid conductors. These integration methods must accommodate the different thermal expansion coefficients and mechanical behaviors of liquid metals compared to conventional materials. Advanced packaging techniques allow liquid metal interconnects to serve as stress-relieving elements in complex electronic assemblies, potentially extending device lifetimes in harsh environments or applications with significant mechanical stress.

- Testing and characterization methods for liquid metal interconnect properties: Specialized testing methodologies have been developed to evaluate the mechanical properties of liquid metal interconnects. These include cyclic bend testing, stretch-and-release cycles, thermal cycling, and vibration testing to assess reliability and performance limits. Advanced imaging techniques such as X-ray microscopy and in-situ mechanical testing allow for real-time observation of liquid metal behavior under stress. Electrical performance monitoring during mechanical testing provides insights into the relationship between physical deformation and functional reliability. These characterization methods are essential for designing robust liquid metal interconnect systems for specific application requirements.

02 Composition and material selection for liquid metal interconnects

The composition of liquid metal interconnects significantly affects their mechanical properties. Gallium-based alloys (such as gallium-indium-tin) are commonly used due to their low melting points and favorable mechanical characteristics. Adding specific elements or nanoparticles to the liquid metal matrix can enhance properties like tensile strength, adhesion, and resistance to oxidation. Material selection must balance electrical conductivity requirements with desired mechanical performance for specific applications.Expand Specific Solutions03 Encapsulation techniques for liquid metal interconnects

Encapsulation methods significantly impact the mechanical stability of liquid metal interconnects. Various elastomeric materials and polymers can be used to contain the liquid metal while allowing for flexibility and stretchability. The encapsulation design must accommodate thermal expansion, prevent leakage, and maintain the desired mechanical properties of the interconnect system. Advanced encapsulation techniques include microchannels, patterned structures, and multi-layer containment systems that enhance mechanical reliability.Expand Specific Solutions04 Interface and bonding mechanisms in liquid metal interconnects

The mechanical properties of liquid metal interconnects are heavily influenced by their interfaces with solid substrates and components. Surface treatments, adhesion layers, and bonding techniques can enhance mechanical stability and reliability. Understanding the wetting behavior, intermetallic compound formation, and interfacial reactions is crucial for optimizing mechanical performance. Various methods including plasma treatment, chemical modification, and specialized coatings can improve adhesion strength and mechanical integrity at these critical interfaces.Expand Specific Solutions05 Reliability and failure mechanisms of liquid metal interconnects

The long-term mechanical reliability of liquid metal interconnects depends on understanding and mitigating various failure mechanisms. These include metal migration, oxidation, phase separation, and mechanical fatigue. Testing protocols involving thermal cycling, mechanical stress, and environmental exposure help characterize the durability of these interconnects. Design considerations to enhance reliability include strain-relief structures, optimized geometries, and protective barriers that maintain mechanical integrity under operational conditions.Expand Specific Solutions

Leading Companies in Flexible Electronics Materials

The liquid metal interconnect technology for flexible devices is currently in an early growth phase, with market expansion driven by increasing demand for wearable electronics and flexible displays. The global market is projected to reach significant scale as applications diversify across consumer electronics, healthcare, and automotive sectors. From a technical maturity perspective, research institutions like Tsinghua University, Technical Institute of Physics & Chemistry CAS, and Karlsruher Institut für Technologie are pioneering fundamental research, while companies including Intel, Beijing Dream Ink Technology, and Microsoft Technology Licensing are developing commercial applications. The technology faces challenges in reliability and mass production, with industry players focusing on improving mechanical stability, stretchability, and integration methods to enhance performance in real-world flexible device applications.

Beijing Dream Ink Technology Co., Ltd.

Technical Solution: Beijing Dream Ink Technology has commercialized proprietary liquid metal-based flexible interconnect solutions using gallium-indium alloys with customized additives to enhance mechanical performance. Their technology platform, "FlexMetal," incorporates microstructured liquid metal particles dispersed in a polymer matrix that forms conductive pathways under minimal pressure. This approach enables interconnects that maintain conductivity even when stretched to 500% of their original length[4]. Their manufacturing process involves precision dispensing systems that can create interconnect patterns with resolution down to 20 μm. Dream Ink has developed specialized encapsulation materials that prevent liquid metal oxidation while maintaining flexibility, addressing one of the key challenges in liquid metal electronics. Their products demonstrate remarkable fatigue resistance, withstanding over 10,000 bending cycles with less than 10% change in electrical resistance. The company has also pioneered techniques for integrating their liquid metal interconnects with conventional rigid electronics, creating hybrid systems that combine flexibility with high-performance computing capabilities.

Strengths: Industry-leading stretchability (up to 500%); excellent fatigue resistance over thousands of cycles; proprietary encapsulation technology preventing oxidation; seamless integration with conventional electronics. Weaknesses: Higher cost compared to traditional conductive materials; challenges with mass production scaling; potential for metal migration under certain electrical conditions.

Tsinghua University

Technical Solution: Tsinghua University has developed advanced liquid metal interconnect technologies focusing on room-temperature liquid metals (primarily gallium-indium alloys) for next-generation flexible electronics. Their proprietary approach involves precise control of the oxide skin formation on liquid metal surfaces to enable stable patterning and enhanced mechanical reliability. They've engineered composite systems where liquid metals are strategically embedded in polymer matrices with tailored interfaces that allow controlled deformation under mechanical stress. Their research demonstrates interconnects capable of withstanding strains up to 400% while maintaining electrical functionality, with resistance changes less than 5% under repeated deformation cycles[2]. Tsinghua's innovations include novel printing techniques for direct-writing of liquid metal circuits on various substrates and self-healing mechanisms where broken circuits can autonomously restore connectivity when damaged. They've also developed methods to control the viscosity and surface tension of liquid metal alloys to optimize their mechanical behavior in dynamic applications.

Strengths: Exceptional strain tolerance with minimal resistance change; innovative self-healing capabilities for enhanced durability; advanced printing techniques enabling complex circuit geometries. Weaknesses: Challenges with long-term encapsulation stability; potential for galvanic corrosion with certain substrate materials; higher production costs compared to conventional interconnect technologies.

Key Innovations in Liquid Metal Mechanical Properties

Liquid metal circuits and methods of making the same

PatentPendingUS20240032189A1

Innovation

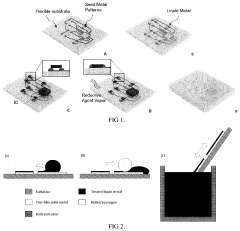

- The development of liquid metal circuits with self-healing properties, achieved through coating metallic traces with eutectic gallium-indium (EGaIn) or gallium-indium-tin (Galinstan) alloys on elastic substrates, enabling high-throughput manufacturing and integration with traditional electronics for enhanced conductivity and flexibility.

Flexible liquid metal connection device and method

PatentPendingEP4199045A1

Innovation

- The use of compliant dielectric layers with liquid metal interconnects, where the liquid metal, such as gallium or its alloys, forms conduction pathways through dielectric layers, providing flexibility and ease of electrical connection without the need for heating, allowing for pitch scaling between different devices or circuit boards.

Manufacturing Processes for Liquid Metal Integration

The integration of liquid metals into flexible devices requires sophisticated manufacturing processes that balance precision, scalability, and compatibility with various substrate materials. Current manufacturing approaches can be categorized into several distinct methodologies, each with specific advantages for different application scenarios.

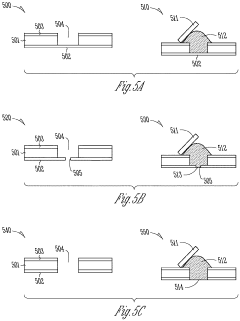

Direct printing techniques represent the most straightforward approach, utilizing modified inkjet or extrusion printing systems to deposit liquid metal patterns onto substrates. These methods typically employ specially formulated liquid metal inks with controlled viscosity and surface tension properties. The printing resolution has improved significantly, with recent systems achieving feature sizes below 10 μm under optimized conditions.

Microfluidic channel filling has emerged as another prominent technique, particularly for creating complex circuit patterns. This process involves fabricating microchannels in elastomeric substrates using soft lithography, followed by injection or vacuum-assisted filling with liquid metal alloys. The channel dimensions can be precisely controlled, enabling consistent electrical performance across different device geometries.

Selective wetting methods exploit the unique surface chemistry of liquid metals to create patterned structures. By treating substrate surfaces with oxygen plasma or chemical modifiers, researchers can control where liquid metals adhere, facilitating selective deposition. This approach is particularly valuable for creating intricate patterns without mechanical constraints.

Mask-based deposition techniques adapt traditional microfabrication processes for liquid metal patterning. Photolithography or stencil masks define regions where liquid metal is subsequently deposited, often through spray coating or dip coating. These methods offer excellent reproducibility and alignment precision for multi-layer device fabrication.

Encapsulation processes represent a critical final manufacturing step, protecting liquid metal interconnects from environmental exposure while maintaining flexibility. Advanced encapsulation materials include ultralow-modulus elastomers, parylene films, and multilayer barrier structures that minimize oxygen and moisture permeation while accommodating mechanical deformation.

Recent innovations have focused on addressing manufacturing challenges related to oxide skin formation during processing. Techniques such as continuous gallium oxide removal through acidic environments, controlled atmosphere processing, and the development of alloy compositions with reduced oxidation rates have significantly improved manufacturing reliability and electrical performance consistency.

Scale-up considerations remain a significant challenge, with current laboratory techniques requiring adaptation for industrial production volumes. Roll-to-roll compatible processes are under development, with promising results for high-throughput manufacturing of liquid metal-based flexible electronics.

Direct printing techniques represent the most straightforward approach, utilizing modified inkjet or extrusion printing systems to deposit liquid metal patterns onto substrates. These methods typically employ specially formulated liquid metal inks with controlled viscosity and surface tension properties. The printing resolution has improved significantly, with recent systems achieving feature sizes below 10 μm under optimized conditions.

Microfluidic channel filling has emerged as another prominent technique, particularly for creating complex circuit patterns. This process involves fabricating microchannels in elastomeric substrates using soft lithography, followed by injection or vacuum-assisted filling with liquid metal alloys. The channel dimensions can be precisely controlled, enabling consistent electrical performance across different device geometries.

Selective wetting methods exploit the unique surface chemistry of liquid metals to create patterned structures. By treating substrate surfaces with oxygen plasma or chemical modifiers, researchers can control where liquid metals adhere, facilitating selective deposition. This approach is particularly valuable for creating intricate patterns without mechanical constraints.

Mask-based deposition techniques adapt traditional microfabrication processes for liquid metal patterning. Photolithography or stencil masks define regions where liquid metal is subsequently deposited, often through spray coating or dip coating. These methods offer excellent reproducibility and alignment precision for multi-layer device fabrication.

Encapsulation processes represent a critical final manufacturing step, protecting liquid metal interconnects from environmental exposure while maintaining flexibility. Advanced encapsulation materials include ultralow-modulus elastomers, parylene films, and multilayer barrier structures that minimize oxygen and moisture permeation while accommodating mechanical deformation.

Recent innovations have focused on addressing manufacturing challenges related to oxide skin formation during processing. Techniques such as continuous gallium oxide removal through acidic environments, controlled atmosphere processing, and the development of alloy compositions with reduced oxidation rates have significantly improved manufacturing reliability and electrical performance consistency.

Scale-up considerations remain a significant challenge, with current laboratory techniques requiring adaptation for industrial production volumes. Roll-to-roll compatible processes are under development, with promising results for high-throughput manufacturing of liquid metal-based flexible electronics.

Reliability Testing Standards for Flexible Interconnects

Reliability testing standards for flexible interconnects using liquid metal technology have evolved significantly in response to the unique mechanical properties these materials exhibit. The International Electrotechnical Commission (IEC) and ASTM International have developed specialized testing protocols that address the distinctive behavior of liquid metal interconnects under mechanical stress. Standard IEC 62715-6-2 specifically addresses the mechanical durability requirements for flexible display devices, which can be applied to liquid metal interconnect evaluation with appropriate modifications.

The bend testing methodology for liquid metal interconnects typically requires more nuanced approaches than traditional solid conductors. ASTM D7249 provides guidelines for flexural testing that have been adapted for liquid metal applications, with testing parameters including minimum bend radius (typically 1-5mm), cycling frequency (0.5-2 Hz), and total cycle count (10,000-100,000 cycles). These parameters must be carefully calibrated to simulate real-world usage scenarios while accounting for the self-healing properties of liquid metals.

Tensile testing standards for flexible interconnects have been modified to accommodate the unique flow characteristics of liquid metals. The IEEE P1247 standard outlines procedures for evaluating electrical continuity under strain, with liquid metal interconnects typically expected to maintain functionality at strains exceeding 100%, significantly outperforming conventional metal traces which fail at 2-5% strain. Testing equipment must be specially configured to simultaneously measure electrical resistance changes while applying controlled mechanical deformation.

Environmental reliability standards have also been established to evaluate liquid metal performance under various conditions. JEDEC JESD22-A104 thermal cycling tests have been adapted to assess the stability of liquid metal interconnects across temperature ranges from -40°C to 85°C, with particular attention to phase transition behaviors and potential separation from substrate materials. Humidity testing following IEC 60068-2-78 guidelines evaluates potential oxidation and degradation of the liquid metal-substrate interface.

Accelerated aging protocols combining mechanical stress with environmental factors have emerged as critical evaluation tools. These tests typically involve simultaneous application of cyclic bending, temperature fluctuations, and humidity exposure to simulate years of device usage within weeks of testing. The failure criteria for liquid metal interconnects differ significantly from conventional interconnects, with emphasis on resistance change thresholds rather than catastrophic failure points, acknowledging the gradual performance degradation pattern typical of these materials.

The bend testing methodology for liquid metal interconnects typically requires more nuanced approaches than traditional solid conductors. ASTM D7249 provides guidelines for flexural testing that have been adapted for liquid metal applications, with testing parameters including minimum bend radius (typically 1-5mm), cycling frequency (0.5-2 Hz), and total cycle count (10,000-100,000 cycles). These parameters must be carefully calibrated to simulate real-world usage scenarios while accounting for the self-healing properties of liquid metals.

Tensile testing standards for flexible interconnects have been modified to accommodate the unique flow characteristics of liquid metals. The IEEE P1247 standard outlines procedures for evaluating electrical continuity under strain, with liquid metal interconnects typically expected to maintain functionality at strains exceeding 100%, significantly outperforming conventional metal traces which fail at 2-5% strain. Testing equipment must be specially configured to simultaneously measure electrical resistance changes while applying controlled mechanical deformation.

Environmental reliability standards have also been established to evaluate liquid metal performance under various conditions. JEDEC JESD22-A104 thermal cycling tests have been adapted to assess the stability of liquid metal interconnects across temperature ranges from -40°C to 85°C, with particular attention to phase transition behaviors and potential separation from substrate materials. Humidity testing following IEC 60068-2-78 guidelines evaluates potential oxidation and degradation of the liquid metal-substrate interface.

Accelerated aging protocols combining mechanical stress with environmental factors have emerged as critical evaluation tools. These tests typically involve simultaneous application of cyclic bending, temperature fluctuations, and humidity exposure to simulate years of device usage within weeks of testing. The failure criteria for liquid metal interconnects differ significantly from conventional interconnects, with emphasis on resistance change thresholds rather than catastrophic failure points, acknowledging the gradual performance degradation pattern typical of these materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!