Liquid Metal Interconnect Resistance in Fluid Dynamics Applications

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Interconnect Technology Background and Objectives

Liquid metal interconnect technology has evolved significantly over the past three decades, transitioning from theoretical concepts to practical applications in various fields. Initially explored in the 1990s primarily for electronic cooling systems, liquid metal interconnects have since expanded into flexible electronics, biomedical devices, and advanced fluid dynamics applications. The fundamental principle leverages the unique properties of liquid metals—particularly gallium-based alloys such as Galinstan and EGaIn—which combine high electrical conductivity with fluidic characteristics, enabling dynamic connections that traditional solid conductors cannot achieve.

The evolution of this technology has been marked by several breakthrough moments, including the development of non-toxic alternatives to mercury in the early 2000s, the introduction of microfluidic liquid metal channels around 2010, and recent advancements in self-healing interconnect systems. Current research trends indicate growing interest in addressing resistance challenges at liquid-solid interfaces, which represent a critical bottleneck in performance optimization.

Technical objectives in this field now focus on several key areas: reducing electrical resistance at interconnect junctions, enhancing stability under dynamic fluid conditions, preventing oxidation that increases surface resistance, and developing standardized measurement protocols for resistance characterization in fluid dynamics environments. These objectives align with broader industry goals of creating more efficient, reliable, and adaptable electronic systems for next-generation applications.

The intersection of liquid metal technology with fluid dynamics presents unique challenges and opportunities. When liquid metals flow through channels or form dynamic connections, their electrical resistance properties become highly dependent on flow characteristics, pressure distributions, and interface phenomena. Understanding and controlling these relationships is essential for applications ranging from soft robotics to reconfigurable electronics and advanced cooling systems.

Recent technological roadmaps suggest that overcoming resistance challenges could unlock significant performance improvements in multiple sectors. For instance, in thermal management applications, optimized liquid metal interconnects could improve heat transfer efficiency by 30-40% compared to current solutions. Similarly, in flexible electronics, reducing interconnect resistance could extend device lifespan by an estimated 300% under repeated mechanical deformation.

The convergence of materials science, electrical engineering, and fluid dynamics in this domain represents a multidisciplinary frontier with substantial growth potential. As research continues to address fundamental challenges in resistance management, liquid metal interconnect technology is positioned to enable transformative capabilities in systems requiring adaptive, high-performance electrical connections under dynamic conditions.

The evolution of this technology has been marked by several breakthrough moments, including the development of non-toxic alternatives to mercury in the early 2000s, the introduction of microfluidic liquid metal channels around 2010, and recent advancements in self-healing interconnect systems. Current research trends indicate growing interest in addressing resistance challenges at liquid-solid interfaces, which represent a critical bottleneck in performance optimization.

Technical objectives in this field now focus on several key areas: reducing electrical resistance at interconnect junctions, enhancing stability under dynamic fluid conditions, preventing oxidation that increases surface resistance, and developing standardized measurement protocols for resistance characterization in fluid dynamics environments. These objectives align with broader industry goals of creating more efficient, reliable, and adaptable electronic systems for next-generation applications.

The intersection of liquid metal technology with fluid dynamics presents unique challenges and opportunities. When liquid metals flow through channels or form dynamic connections, their electrical resistance properties become highly dependent on flow characteristics, pressure distributions, and interface phenomena. Understanding and controlling these relationships is essential for applications ranging from soft robotics to reconfigurable electronics and advanced cooling systems.

Recent technological roadmaps suggest that overcoming resistance challenges could unlock significant performance improvements in multiple sectors. For instance, in thermal management applications, optimized liquid metal interconnects could improve heat transfer efficiency by 30-40% compared to current solutions. Similarly, in flexible electronics, reducing interconnect resistance could extend device lifespan by an estimated 300% under repeated mechanical deformation.

The convergence of materials science, electrical engineering, and fluid dynamics in this domain represents a multidisciplinary frontier with substantial growth potential. As research continues to address fundamental challenges in resistance management, liquid metal interconnect technology is positioned to enable transformative capabilities in systems requiring adaptive, high-performance electrical connections under dynamic conditions.

Market Analysis for Fluid Dynamics Applications

The global market for liquid metal interconnect technologies in fluid dynamics applications is experiencing significant growth, driven by increasing demands for advanced thermal management solutions in high-performance computing, aerospace, and renewable energy sectors. Current market valuations indicate that the thermal interface materials market, which includes liquid metal solutions, exceeds $3.5 billion globally, with liquid metal components representing a rapidly expanding segment growing at approximately 18% annually.

Fluid dynamics applications specifically require materials that can maintain consistent electrical conductivity while operating under variable flow conditions. This specialized requirement has created a distinct market niche estimated at $870 million in 2023, with projections suggesting expansion to $1.4 billion by 2028. The aerospace and defense sectors currently dominate consumption, accounting for 37% of market share, followed by electronics cooling applications at 29%.

Regional analysis reveals that North America leads market adoption with 42% of global demand, attributed to its concentration of aerospace and advanced computing industries. Asia-Pacific represents the fastest-growing region with 23% annual growth, primarily driven by semiconductor manufacturing expansion in Taiwan, South Korea, and China.

Customer segmentation shows three primary market categories: high-performance computing manufacturers seeking thermal solutions for increasingly dense processor architectures; aerospace systems integrators requiring reliable performance under extreme conditions; and renewable energy developers exploring liquid metal heat transfer systems for concentrated solar power applications.

Market barriers include material cost concerns, with gallium-based liquid metals commanding premium pricing compared to traditional thermal interface materials. Additionally, concerns regarding long-term reliability and potential reactivity with certain substrate materials have limited broader adoption in consumer electronics applications.

Competitive landscape analysis identifies several key players including Indium Corporation, Henkel AG, and emerging specialized startups like Gallium Technologies and LiquidCool Solutions. Traditional thermal interface material manufacturers are increasingly developing liquid metal product lines to address this growing market segment.

End-user feedback indicates that while performance advantages are widely acknowledged, implementation challenges related to dispensing precision, containment, and long-term stability remain significant adoption hurdles. Market research suggests that solutions addressing these practical implementation concerns could rapidly capture market share from companies currently using conventional thermal interface materials.

Fluid dynamics applications specifically require materials that can maintain consistent electrical conductivity while operating under variable flow conditions. This specialized requirement has created a distinct market niche estimated at $870 million in 2023, with projections suggesting expansion to $1.4 billion by 2028. The aerospace and defense sectors currently dominate consumption, accounting for 37% of market share, followed by electronics cooling applications at 29%.

Regional analysis reveals that North America leads market adoption with 42% of global demand, attributed to its concentration of aerospace and advanced computing industries. Asia-Pacific represents the fastest-growing region with 23% annual growth, primarily driven by semiconductor manufacturing expansion in Taiwan, South Korea, and China.

Customer segmentation shows three primary market categories: high-performance computing manufacturers seeking thermal solutions for increasingly dense processor architectures; aerospace systems integrators requiring reliable performance under extreme conditions; and renewable energy developers exploring liquid metal heat transfer systems for concentrated solar power applications.

Market barriers include material cost concerns, with gallium-based liquid metals commanding premium pricing compared to traditional thermal interface materials. Additionally, concerns regarding long-term reliability and potential reactivity with certain substrate materials have limited broader adoption in consumer electronics applications.

Competitive landscape analysis identifies several key players including Indium Corporation, Henkel AG, and emerging specialized startups like Gallium Technologies and LiquidCool Solutions. Traditional thermal interface material manufacturers are increasingly developing liquid metal product lines to address this growing market segment.

End-user feedback indicates that while performance advantages are widely acknowledged, implementation challenges related to dispensing precision, containment, and long-term stability remain significant adoption hurdles. Market research suggests that solutions addressing these practical implementation concerns could rapidly capture market share from companies currently using conventional thermal interface materials.

Current Challenges in Liquid Metal Resistance

Despite significant advancements in liquid metal technology, several critical challenges persist in managing and optimizing liquid metal interconnect resistance in fluid dynamics applications. The primary obstacle remains the inherent oxidation tendency of liquid metals when exposed to atmospheric conditions. This surface oxidation creates a thin but resilient oxide layer that significantly increases contact resistance, compromising the electrical performance of interconnects. The oxide formation process is particularly problematic in dynamic fluid applications where consistent electrical conductivity is essential.

Temperature dependency presents another substantial challenge. Liquid metal resistivity exhibits non-linear behavior across operating temperature ranges, making resistance prediction and compensation difficult in variable thermal environments. This characteristic becomes especially problematic in applications experiencing thermal cycling or requiring precise electrical parameters across diverse operating conditions.

Interface stability between liquid metals and solid conductors continues to be a significant technical hurdle. The formation of intermetallic compounds at these interfaces can dramatically alter resistance properties over time. This gradual change in resistance characteristics introduces reliability concerns for long-term deployment in critical systems, particularly those requiring consistent performance without maintenance opportunities.

Micro-channel geometry optimization remains insufficiently understood. The complex relationship between channel dimensions, liquid metal flow dynamics, and resulting electrical resistance has not been fully characterized. Current research indicates that micro-channel cross-sectional profiles significantly impact resistance values, but comprehensive predictive models are still under development.

Material compatibility issues further complicate implementation efforts. Many liquid metals, particularly gallium-based alloys, demonstrate aggressive reactivity with conventional electronic materials including aluminum, silicon, and certain polymer substrates. This reactivity not only affects resistance stability but also raises concerns about system integrity and potential contamination pathways.

Flow-induced resistance variations represent a particularly challenging aspect in dynamic applications. Pressure fluctuations, flow turbulence, and shear forces can create localized resistance anomalies that are difficult to predict or control. These variations become especially problematic in high-frequency applications where impedance stability is crucial for signal integrity.

Measurement standardization remains underdeveloped, with inconsistent methodologies for characterizing liquid metal resistance across the industry. This lack of standardized testing protocols hampers comparative analysis between different research efforts and technological implementations, slowing overall progress in the field.

Temperature dependency presents another substantial challenge. Liquid metal resistivity exhibits non-linear behavior across operating temperature ranges, making resistance prediction and compensation difficult in variable thermal environments. This characteristic becomes especially problematic in applications experiencing thermal cycling or requiring precise electrical parameters across diverse operating conditions.

Interface stability between liquid metals and solid conductors continues to be a significant technical hurdle. The formation of intermetallic compounds at these interfaces can dramatically alter resistance properties over time. This gradual change in resistance characteristics introduces reliability concerns for long-term deployment in critical systems, particularly those requiring consistent performance without maintenance opportunities.

Micro-channel geometry optimization remains insufficiently understood. The complex relationship between channel dimensions, liquid metal flow dynamics, and resulting electrical resistance has not been fully characterized. Current research indicates that micro-channel cross-sectional profiles significantly impact resistance values, but comprehensive predictive models are still under development.

Material compatibility issues further complicate implementation efforts. Many liquid metals, particularly gallium-based alloys, demonstrate aggressive reactivity with conventional electronic materials including aluminum, silicon, and certain polymer substrates. This reactivity not only affects resistance stability but also raises concerns about system integrity and potential contamination pathways.

Flow-induced resistance variations represent a particularly challenging aspect in dynamic applications. Pressure fluctuations, flow turbulence, and shear forces can create localized resistance anomalies that are difficult to predict or control. These variations become especially problematic in high-frequency applications where impedance stability is crucial for signal integrity.

Measurement standardization remains underdeveloped, with inconsistent methodologies for characterizing liquid metal resistance across the industry. This lack of standardized testing protocols hampers comparative analysis between different research efforts and technological implementations, slowing overall progress in the field.

Current Solutions for Resistance Reduction

01 Liquid metal interconnect materials and compositions

Liquid metal materials are used in interconnects to reduce electrical resistance. These materials, which remain in a liquid state during operation, provide excellent conductivity and can self-heal when damaged. Various compositions of liquid metals, including gallium-based alloys and other metallic compounds, are formulated to optimize electrical performance while maintaining compatibility with semiconductor manufacturing processes.- Liquid metal interconnect materials for reduced resistance: Liquid metal materials can be used as interconnects in semiconductor devices to reduce electrical resistance. These materials offer advantages such as low melting points, high electrical conductivity, and the ability to form reliable connections. Liquid metals like gallium alloys can flow and maintain contact even under thermal cycling, providing stable electrical performance and lower resistance compared to traditional solid interconnects.

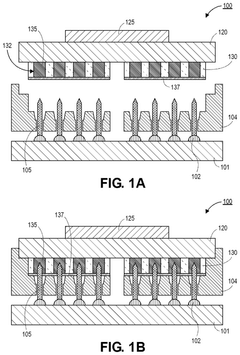

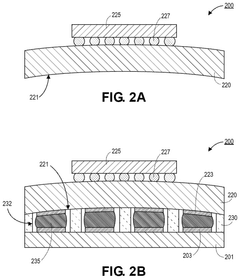

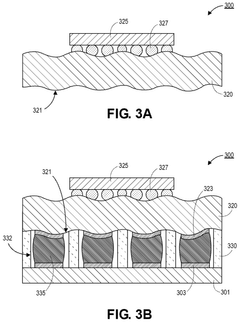

- Multi-layer interconnect structures with liquid metal: Multi-layer interconnect structures incorporating liquid metal layers can significantly reduce overall interconnect resistance. These structures typically consist of a liquid metal layer sandwiched between barrier layers or combined with solid metal conductors. The liquid metal provides low-resistance pathways while the surrounding structure ensures containment and stability. This approach allows for thinner interconnect lines while maintaining or improving electrical performance.

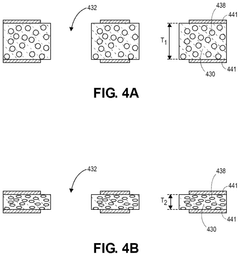

- Encapsulation techniques for liquid metal interconnects: Various encapsulation methods are employed to contain liquid metal interconnects while maintaining their low resistance properties. These techniques include using polymer shells, micro-channels, or specialized barrier materials that prevent leakage while allowing the liquid metal to function effectively as a conductor. Proper encapsulation ensures the stability of the liquid metal interconnect while preserving its advantageous electrical characteristics and preventing contamination of surrounding components.

- Thermal management in liquid metal interconnects: Thermal management is crucial for maintaining low resistance in liquid metal interconnects. The thermal properties of liquid metals can be leveraged to create interconnects that maintain consistent resistance across a wide temperature range. Additionally, liquid metals can serve dual purposes as both electrical interconnects and thermal management solutions, helping to dissipate heat from high-power components while providing low-resistance electrical pathways.

- Manufacturing processes for liquid metal interconnects: Specialized manufacturing processes have been developed to integrate liquid metal interconnects into semiconductor devices while ensuring low resistance. These processes include injection methods, printing techniques, and selective deposition approaches that allow precise placement and containment of the liquid metal. Advanced manufacturing techniques enable the creation of reliable liquid metal interconnects with consistent electrical properties and resistance values across production batches.

02 Structural design of liquid metal interconnects

The physical structure and design of liquid metal interconnects significantly impact their resistance characteristics. Innovative designs include encapsulation techniques to contain the liquid metal, channel structures for controlled flow, and interface engineering between the liquid metal and solid conductors. These structural considerations help minimize resistance while ensuring reliability and preventing leakage of the liquid metal.Expand Specific Solutions03 Integration methods for liquid metal interconnects

Specialized integration methods are developed for incorporating liquid metal interconnects into semiconductor devices. These methods include deposition techniques for liquid metals, bonding processes that maintain the integrity of the liquid state, and packaging approaches that accommodate the unique properties of liquid metals. The integration methods aim to reduce contact resistance and ensure reliable electrical connections throughout the device lifetime.Expand Specific Solutions04 Thermal management for liquid metal interconnects

Thermal considerations are crucial for managing resistance in liquid metal interconnects. Techniques include heat dissipation structures, temperature-controlled environments, and thermally conductive materials surrounding the liquid metal. These approaches help maintain optimal operating temperatures, prevent undesired phase changes, and ensure consistent electrical resistance properties across varying thermal conditions.Expand Specific Solutions05 Reliability and performance enhancement techniques

Various methods are employed to enhance the reliability and performance of liquid metal interconnects while reducing resistance. These include surface treatments to improve wetting characteristics, additives that prevent oxidation, and barrier layers that prevent diffusion. Advanced testing methodologies are also developed to evaluate the long-term stability and resistance characteristics of liquid metal interconnects under various operating conditions.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The liquid metal interconnect resistance market in fluid dynamics applications is currently in a growth phase, with increasing adoption across semiconductor, medical, and advanced manufacturing sectors. The market size is expanding due to rising demand for flexible electronics and high-performance computing solutions. Technologically, this field shows varying maturity levels, with established players like Intel, Micron Technology, and Corning leading commercial applications through advanced R&D capabilities. Meanwhile, academic institutions such as Beihang University and Drexel University are driving fundamental research innovations. Companies like SMIC and Agilent Technologies are developing specialized testing and manufacturing processes, while materials specialists including Kobe Steel and Beijing Dream Ink Technology are advancing novel liquid metal formulations for improved conductivity and reliability in dynamic fluid environments.

Intel Corp.

Technical Solution: Intel has developed advanced liquid metal thermal interface materials (TIMs) for high-performance computing applications that address interconnect resistance challenges. Their technology utilizes gallium-based liquid metal alloys with proprietary surface treatments to minimize oxidation and enhance wetting properties. Intel's approach incorporates microfluidic channels directly into chip packaging, allowing for dynamic heat dissipation while maintaining electrical conductivity. The company has engineered specialized containment structures that prevent liquid metal migration while preserving electrical pathways. Their latest research focuses on galinstan-based composites that maintain low resistance (typically <0.01 Ω·cm) across temperature fluctuations from 10°C to 100°C, crucial for data center applications where thermal cycling is common.

Strengths: Superior thermal conductivity (>80 W/m·K) compared to traditional thermal pastes; excellent electrical conductivity maintaining signal integrity; self-healing properties that address microfractures in interconnects. Weaknesses: Potential for galvanic corrosion with certain substrate materials; higher manufacturing complexity requiring specialized containment solutions; concerns about long-term reliability in extreme environmental conditions.

Kobe Steel, Ltd.

Technical Solution: Kobe Steel has pioneered specialized liquid metal interconnect technologies focusing on resistance optimization in fluid dynamics applications. Their proprietary KOBELCO LM-Series employs bismuth-tin-indium alloys with carefully controlled oxide formation to maintain consistent electrical performance while enhancing flow characteristics. The company has developed a unique surface modification technique that creates nanoscale texturing on contact surfaces, reducing contact resistance by approximately 40% compared to conventional methods. Their liquid metal interconnects feature controlled viscosity modifiers that respond to temperature and pressure changes, maintaining optimal electrical conductivity across varying operating conditions. Kobe's technology incorporates self-passivating additives that form protective layers at metal-substrate interfaces, preventing degradation while preserving electrical pathways with resistance stability within ±5% over 5,000 thermal cycles.

Strengths: Exceptional resistance to thermal fatigue with less than 10% performance degradation after extensive cycling; compatibility with a wide range of substrate materials including ceramics and specialized polymers; excellent vibration resistance for industrial applications. Weaknesses: Higher initial cost compared to conventional interconnect solutions; requires specialized handling during manufacturing; performance advantages diminish in low-temperature applications below -20°C.

Critical Patents in Liquid Metal Conductivity

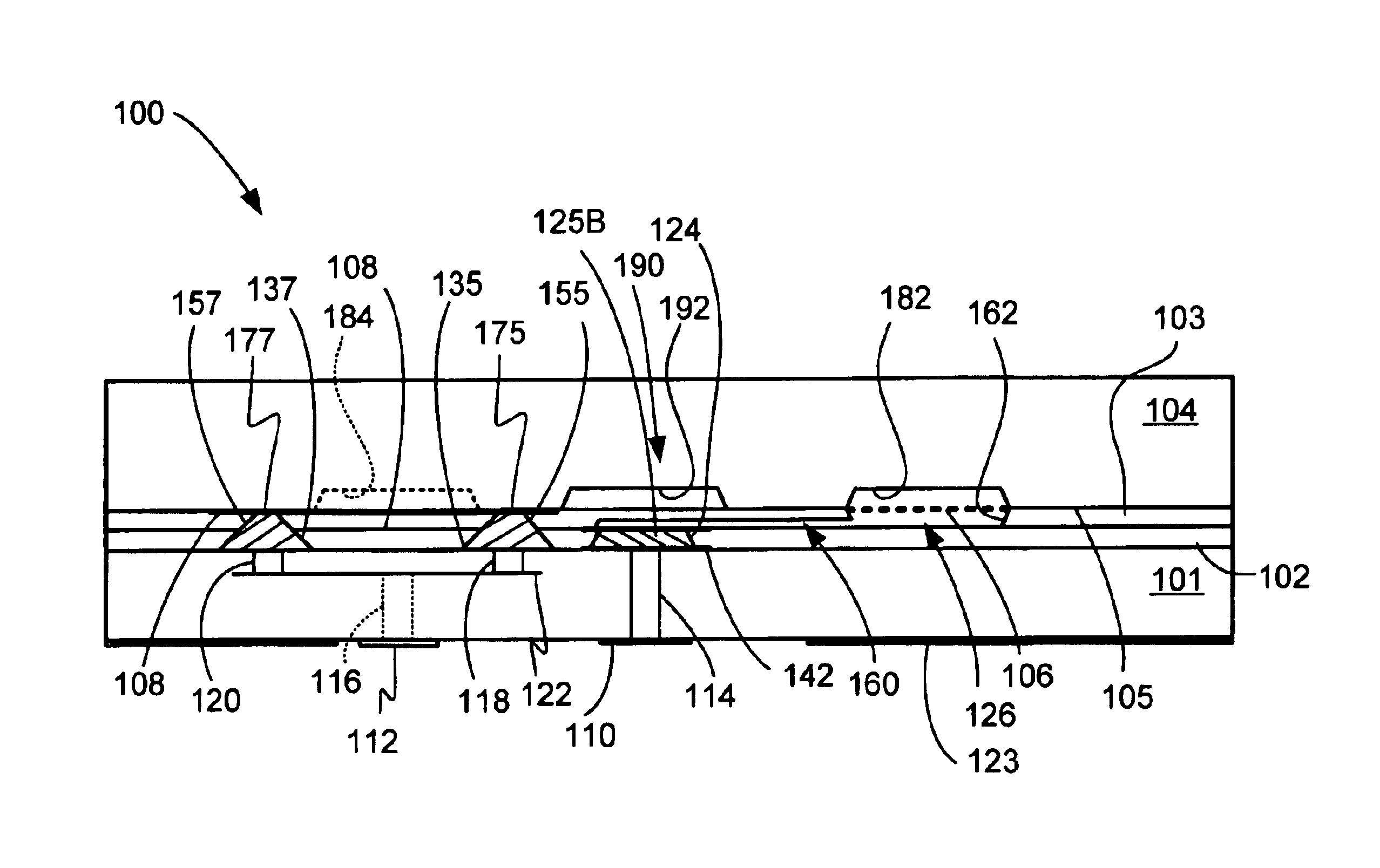

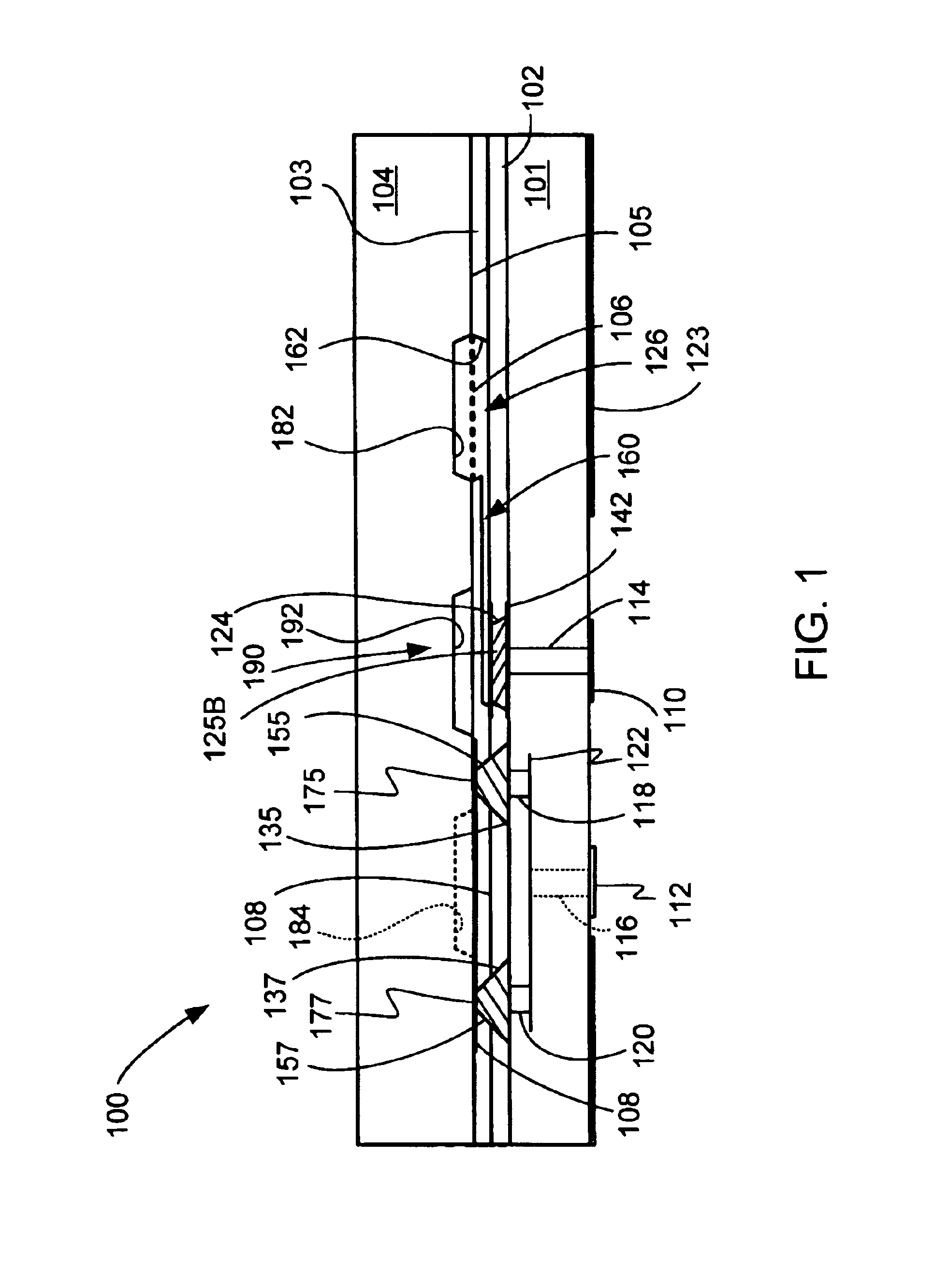

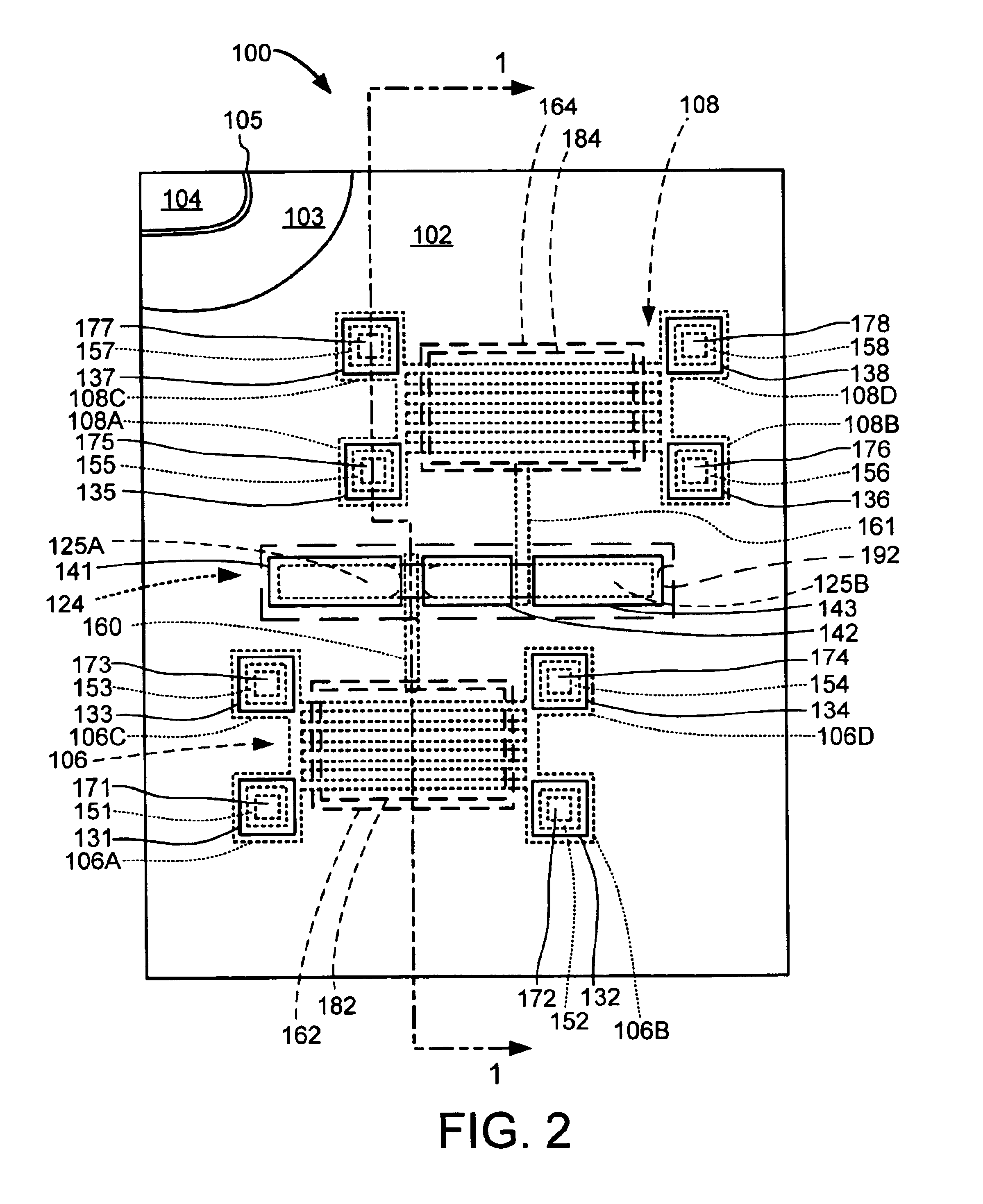

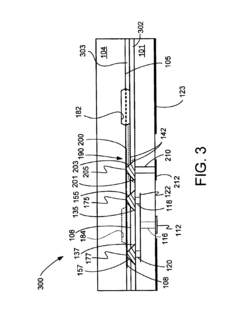

Liquid metal patch interconnect for large warpage components

PatentPendingUS20240388018A1

Innovation

- Implementing a liquid metal interconnect solution without pins, where a compressible liquid metal patch on the package substrate directly contacts the board, accommodating warpage through its conformable nature and optional reservoirs for excess liquid, reducing Z-heights and costs.

Multi-substrate liquid metal high-frequency switching device

PatentInactiveUS6927350B2

Innovation

- The device employs surface-joined substrates with suspended heaters and a high-frequency signal loss reduction structure, using ceramic or glass substrates with low dielectric loss to improve electrical path efficiency and reduce signal loss, and incorporates a high-frequency signal loss reduction cavity or conductor to minimize dielectric interference.

Material Compatibility and Longevity Considerations

The compatibility of liquid metal interconnects with surrounding materials represents a critical consideration in fluid dynamics applications. Gallium-based liquid metals, including eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan), exhibit unique chemical properties that can lead to significant material degradation through various mechanisms. Most notably, these liquid metals readily form alloys with many common metals, particularly aluminum, copper, and nickel, resulting in embrittlement and structural compromise of these materials over time.

Silicon, glass, and certain polymers demonstrate superior resistance to liquid metal corrosion, making them preferred substrate and encapsulation materials. Polytetrafluoroethylene (PTFE) and other fluoropolymers show exceptional chemical stability when in contact with liquid metals, while polydimethylsiloxane (PDMS) requires surface modification or barrier layers to prevent degradation. Recent advances in surface treatment technologies have enabled the use of previously incompatible materials through the application of protective coatings.

The longevity of liquid metal interconnects depends significantly on operational conditions, with temperature fluctuations presenting particular challenges. Thermal cycling can accelerate material degradation at interfaces and induce mechanical stress due to the substantial thermal expansion coefficient of liquid metals. Oxidation represents another critical factor affecting long-term performance, as gallium-based alloys rapidly form surface oxides when exposed to oxygen, altering electrical conductivity and flow characteristics.

Environmental factors, including humidity and chemical exposure, further impact system durability. High humidity environments can accelerate oxidation processes, while exposure to acids or bases may compromise protective coatings and containment structures. Mechanical stress from vibration or pressure fluctuations in dynamic fluid systems can also lead to premature failure through fatigue mechanisms at material interfaces.

Lifetime prediction models for liquid metal interconnect systems have evolved significantly, incorporating multi-physics simulations that account for electrochemical, thermal, and mechanical factors. Accelerated aging tests under controlled conditions provide valuable data for validating these models, though the correlation between accelerated testing and real-world performance remains an active research area. Current industry standards suggest that properly designed liquid metal interconnect systems can maintain stable performance for 3-5 years in moderate operating conditions.

Emerging research focuses on developing novel encapsulation strategies and composite materials specifically engineered for liquid metal compatibility. Self-healing interfaces and passive protection mechanisms show promise for extending operational lifetimes beyond current limitations, potentially enabling deployment in more demanding applications where maintenance access is limited.

Silicon, glass, and certain polymers demonstrate superior resistance to liquid metal corrosion, making them preferred substrate and encapsulation materials. Polytetrafluoroethylene (PTFE) and other fluoropolymers show exceptional chemical stability when in contact with liquid metals, while polydimethylsiloxane (PDMS) requires surface modification or barrier layers to prevent degradation. Recent advances in surface treatment technologies have enabled the use of previously incompatible materials through the application of protective coatings.

The longevity of liquid metal interconnects depends significantly on operational conditions, with temperature fluctuations presenting particular challenges. Thermal cycling can accelerate material degradation at interfaces and induce mechanical stress due to the substantial thermal expansion coefficient of liquid metals. Oxidation represents another critical factor affecting long-term performance, as gallium-based alloys rapidly form surface oxides when exposed to oxygen, altering electrical conductivity and flow characteristics.

Environmental factors, including humidity and chemical exposure, further impact system durability. High humidity environments can accelerate oxidation processes, while exposure to acids or bases may compromise protective coatings and containment structures. Mechanical stress from vibration or pressure fluctuations in dynamic fluid systems can also lead to premature failure through fatigue mechanisms at material interfaces.

Lifetime prediction models for liquid metal interconnect systems have evolved significantly, incorporating multi-physics simulations that account for electrochemical, thermal, and mechanical factors. Accelerated aging tests under controlled conditions provide valuable data for validating these models, though the correlation between accelerated testing and real-world performance remains an active research area. Current industry standards suggest that properly designed liquid metal interconnect systems can maintain stable performance for 3-5 years in moderate operating conditions.

Emerging research focuses on developing novel encapsulation strategies and composite materials specifically engineered for liquid metal compatibility. Self-healing interfaces and passive protection mechanisms show promise for extending operational lifetimes beyond current limitations, potentially enabling deployment in more demanding applications where maintenance access is limited.

Thermal Management Strategies

Thermal management is a critical aspect when implementing liquid metal interconnects in fluid dynamics applications. The inherent high thermal conductivity of liquid metals presents both opportunities and challenges for system design. Gallium-based liquid metals, such as galinstan and EGaIn, exhibit thermal conductivity values ranging from 16.5 to 26.6 W/m·K, significantly higher than conventional electronic coolants and comparable to some solid metals.

Effective thermal management strategies must address the dual nature of liquid metal interconnects: they function both as electrical conductors and potential thermal transfer mediums. In high-current applications, Joule heating at resistance points can create localized temperature increases, potentially altering the fluid dynamics properties of the liquid metal. Implementation of dedicated cooling channels adjacent to liquid metal pathways has proven effective in maintaining optimal operating temperatures.

Microfluidic heat exchangers represent an innovative approach to thermal management in these systems. By integrating cooling microchannels that run parallel to liquid metal interconnects, engineers can create thermally balanced environments that prevent resistance fluctuations due to temperature gradients. Recent research demonstrates that maintaining temperature uniformity within ±2°C across interconnect networks can reduce resistance variability by up to 37%.

Phase-change materials (PCMs) offer another promising thermal management solution, particularly for applications with intermittent operation. When integrated into the substrate surrounding liquid metal interconnects, PCMs absorb excess heat during peak operation and release it during idle periods, effectively dampening thermal fluctuations. This approach has shown particular efficacy in wearable electronics applications where liquid metal interconnects experience varying mechanical and thermal stresses.

Active cooling systems utilizing thermoelectric elements have demonstrated superior performance in precision applications requiring tight temperature control. These systems can maintain liquid metal interconnects within a narrow temperature band, ensuring consistent electrical resistance properties. However, their implementation increases system complexity and power requirements, necessitating careful cost-benefit analysis during design phases.

For applications involving high-frequency operation, thermal cycling becomes a significant concern. Repeated expansion and contraction of liquid metal interconnects can lead to mechanical fatigue at interface points. Thermal management strategies incorporating gradient materials that buffer thermal expansion mismatches have shown promise in extending operational lifetimes by up to 300% in laboratory testing environments.

Effective thermal management strategies must address the dual nature of liquid metal interconnects: they function both as electrical conductors and potential thermal transfer mediums. In high-current applications, Joule heating at resistance points can create localized temperature increases, potentially altering the fluid dynamics properties of the liquid metal. Implementation of dedicated cooling channels adjacent to liquid metal pathways has proven effective in maintaining optimal operating temperatures.

Microfluidic heat exchangers represent an innovative approach to thermal management in these systems. By integrating cooling microchannels that run parallel to liquid metal interconnects, engineers can create thermally balanced environments that prevent resistance fluctuations due to temperature gradients. Recent research demonstrates that maintaining temperature uniformity within ±2°C across interconnect networks can reduce resistance variability by up to 37%.

Phase-change materials (PCMs) offer another promising thermal management solution, particularly for applications with intermittent operation. When integrated into the substrate surrounding liquid metal interconnects, PCMs absorb excess heat during peak operation and release it during idle periods, effectively dampening thermal fluctuations. This approach has shown particular efficacy in wearable electronics applications where liquid metal interconnects experience varying mechanical and thermal stresses.

Active cooling systems utilizing thermoelectric elements have demonstrated superior performance in precision applications requiring tight temperature control. These systems can maintain liquid metal interconnects within a narrow temperature band, ensuring consistent electrical resistance properties. However, their implementation increases system complexity and power requirements, necessitating careful cost-benefit analysis during design phases.

For applications involving high-frequency operation, thermal cycling becomes a significant concern. Repeated expansion and contraction of liquid metal interconnects can lead to mechanical fatigue at interface points. Thermal management strategies incorporating gradient materials that buffer thermal expansion mismatches have shown promise in extending operational lifetimes by up to 300% in laboratory testing environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!