Liquid Metal Interconnect: Impact on Electromagnetic Shielding

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Interconnect Technology Background and Objectives

Liquid metal interconnects represent a revolutionary advancement in the field of flexible electronics, emerging from decades of research into conductive materials that can maintain electrical performance under mechanical deformation. The evolution of this technology can be traced back to early experiments with gallium-based alloys in the 1990s, which demonstrated unique properties of maintaining liquid state at room temperature while exhibiting excellent electrical conductivity. The subsequent development trajectory has seen significant acceleration in the past decade, with researchers focusing on enhancing the stability, reliability, and manufacturing scalability of these interconnects.

The fundamental appeal of liquid metal interconnects lies in their ability to combine the electrical conductivity of traditional metals with unprecedented mechanical flexibility. Unlike conventional copper or gold interconnects that fracture under strain, liquid metals can flow and reconfigure while maintaining electrical pathways. This characteristic has positioned them as a critical enabling technology for next-generation flexible, stretchable, and wearable electronic systems where traditional rigid interconnects fail to meet performance requirements.

Current technological objectives in this field center on addressing several key challenges. Primary among these is the development of effective encapsulation methods to prevent oxidation and ensure long-term stability of the liquid metal. Researchers are also focused on improving adhesion between liquid metals and various substrate materials, as poor interfacial bonding remains a significant limitation for widespread implementation.

A particularly promising and underexplored application domain is electromagnetic shielding, where liquid metal interconnects offer unique advantages. The inherent conductivity of materials like eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan) alloys, combined with their ability to conform to complex geometries, presents an opportunity to create adaptive shielding solutions that can respond dynamically to electromagnetic interference.

The technological roadmap for liquid metal interconnects is increasingly focused on integration with advanced manufacturing techniques such as 3D printing, microfluidic patterning, and selective wetting approaches. These fabrication methods aim to overcome precision limitations and enable mass production of complex liquid metal networks with controlled geometries and properties.

Industry objectives now extend beyond proof-of-concept demonstrations toward practical implementation in commercial products. This transition requires standardization of material compositions, processing techniques, and reliability testing protocols. Additionally, there is growing interest in exploring synergies between liquid metal interconnects and other emerging technologies such as self-healing materials and wireless power transfer systems to create multifunctional electronic platforms.

The fundamental appeal of liquid metal interconnects lies in their ability to combine the electrical conductivity of traditional metals with unprecedented mechanical flexibility. Unlike conventional copper or gold interconnects that fracture under strain, liquid metals can flow and reconfigure while maintaining electrical pathways. This characteristic has positioned them as a critical enabling technology for next-generation flexible, stretchable, and wearable electronic systems where traditional rigid interconnects fail to meet performance requirements.

Current technological objectives in this field center on addressing several key challenges. Primary among these is the development of effective encapsulation methods to prevent oxidation and ensure long-term stability of the liquid metal. Researchers are also focused on improving adhesion between liquid metals and various substrate materials, as poor interfacial bonding remains a significant limitation for widespread implementation.

A particularly promising and underexplored application domain is electromagnetic shielding, where liquid metal interconnects offer unique advantages. The inherent conductivity of materials like eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan) alloys, combined with their ability to conform to complex geometries, presents an opportunity to create adaptive shielding solutions that can respond dynamically to electromagnetic interference.

The technological roadmap for liquid metal interconnects is increasingly focused on integration with advanced manufacturing techniques such as 3D printing, microfluidic patterning, and selective wetting approaches. These fabrication methods aim to overcome precision limitations and enable mass production of complex liquid metal networks with controlled geometries and properties.

Industry objectives now extend beyond proof-of-concept demonstrations toward practical implementation in commercial products. This transition requires standardization of material compositions, processing techniques, and reliability testing protocols. Additionally, there is growing interest in exploring synergies between liquid metal interconnects and other emerging technologies such as self-healing materials and wireless power transfer systems to create multifunctional electronic platforms.

Market Demand Analysis for EMI Shielding Solutions

The electromagnetic interference (EMI) shielding solutions market is experiencing robust growth driven by the rapid proliferation of electronic devices across multiple industries. Current market valuations place the global EMI shielding market at approximately 6.8 billion USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 5.7% through 2030, potentially reaching 10 billion USD.

The demand for advanced EMI shielding solutions is primarily fueled by the telecommunications sector, particularly with the ongoing global deployment of 5G infrastructure. The higher frequencies utilized in 5G networks necessitate more sophisticated shielding solutions to maintain signal integrity and prevent interference. This trend is expected to continue as 6G research advances, creating sustained demand for next-generation shielding technologies.

Consumer electronics represents another significant market driver, with smartphones, tablets, and wearable devices requiring increasingly compact yet effective EMI shielding solutions. The miniaturization trend in consumer electronics has created specific challenges for traditional shielding methods, opening opportunities for innovative approaches like liquid metal interconnects.

The automotive industry has emerged as a rapidly growing segment for EMI shielding solutions, particularly with the accelerating adoption of electric vehicles (EVs) and advanced driver assistance systems (ADAS). Modern vehicles contain numerous electronic control units and sensors that must operate reliably in close proximity, creating complex EMI management challenges. The automotive EMI shielding segment is growing at a CAGR of 6.8%, outpacing the overall market.

Healthcare and medical devices represent a premium segment with stringent requirements for EMI shielding. The increasing integration of wireless connectivity in medical devices and the growth of telemedicine applications have heightened the importance of reliable EMI protection in these critical applications.

Regional analysis reveals Asia-Pacific as the dominant market for EMI shielding solutions, accounting for 42% of global demand. This is attributed to the concentration of electronics manufacturing in countries like China, South Korea, and Taiwan. North America follows with 28% market share, driven by aerospace, defense, and healthcare applications.

The market demonstrates a clear shift toward flexible, adaptable shielding solutions that can accommodate complex geometries and dynamic operating environments. This trend aligns favorably with liquid metal interconnect technology, which offers unique advantages in conformability and performance consistency across varying conditions.

The demand for advanced EMI shielding solutions is primarily fueled by the telecommunications sector, particularly with the ongoing global deployment of 5G infrastructure. The higher frequencies utilized in 5G networks necessitate more sophisticated shielding solutions to maintain signal integrity and prevent interference. This trend is expected to continue as 6G research advances, creating sustained demand for next-generation shielding technologies.

Consumer electronics represents another significant market driver, with smartphones, tablets, and wearable devices requiring increasingly compact yet effective EMI shielding solutions. The miniaturization trend in consumer electronics has created specific challenges for traditional shielding methods, opening opportunities for innovative approaches like liquid metal interconnects.

The automotive industry has emerged as a rapidly growing segment for EMI shielding solutions, particularly with the accelerating adoption of electric vehicles (EVs) and advanced driver assistance systems (ADAS). Modern vehicles contain numerous electronic control units and sensors that must operate reliably in close proximity, creating complex EMI management challenges. The automotive EMI shielding segment is growing at a CAGR of 6.8%, outpacing the overall market.

Healthcare and medical devices represent a premium segment with stringent requirements for EMI shielding. The increasing integration of wireless connectivity in medical devices and the growth of telemedicine applications have heightened the importance of reliable EMI protection in these critical applications.

Regional analysis reveals Asia-Pacific as the dominant market for EMI shielding solutions, accounting for 42% of global demand. This is attributed to the concentration of electronics manufacturing in countries like China, South Korea, and Taiwan. North America follows with 28% market share, driven by aerospace, defense, and healthcare applications.

The market demonstrates a clear shift toward flexible, adaptable shielding solutions that can accommodate complex geometries and dynamic operating environments. This trend aligns favorably with liquid metal interconnect technology, which offers unique advantages in conformability and performance consistency across varying conditions.

Current Status and Challenges in Liquid Metal EMI Shielding

The global landscape of liquid metal electromagnetic interference (EMI) shielding technology has witnessed significant advancements in recent years, with research institutions and industry players across North America, Europe, and Asia Pacific making substantial contributions. Currently, gallium-based liquid metal alloys, particularly eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan), dominate the field due to their low toxicity and favorable mechanical properties compared to mercury-based alternatives.

Despite promising developments, several technical challenges persist in liquid metal EMI shielding applications. The primary obstacle remains the high surface tension and oxidation tendency of liquid metals, which impedes their integration into complex electronic systems. When exposed to oxygen, gallium-based alloys rapidly form a thin oxide layer that, while providing some stability, complicates the manufacturing process and potentially compromises electromagnetic shielding effectiveness over time.

Connectivity issues between liquid metal components and conventional electronic systems present another significant challenge. The interface between liquid metals and solid conductors often suffers from inconsistent electrical contact, resulting in variable shielding performance. This variability becomes particularly problematic in applications requiring precise and stable EMI protection, such as medical devices and sensitive communication equipment.

Containment and encapsulation technologies represent a critical bottleneck in widespread adoption. Current materials used for containing liquid metals, including polydimethylsiloxane (PDMS) and other elastomers, exhibit limitations in terms of long-term stability and compatibility. These materials may degrade over time due to metal diffusion or chemical interactions, potentially leading to leakage and system failure.

From a manufacturing perspective, scalable production methods for liquid metal EMI shielding solutions remain underdeveloped. While laboratory demonstrations have shown promising results, translating these into mass-producible, cost-effective solutions has proven challenging. Current fabrication techniques, including microfluidic injection and direct writing, lack the throughput and consistency required for industrial-scale implementation.

Standardization represents another significant hurdle in the field. Unlike conventional EMI shielding materials, liquid metal solutions lack established testing protocols and performance metrics, making it difficult for manufacturers to validate and compare different solutions. This absence of standardization has slowed industry adoption despite the technology's theoretical advantages.

Recent research has begun addressing these challenges through innovative approaches, including surface modification techniques to control oxidation, development of specialized containment materials, and exploration of hybrid systems combining liquid metals with traditional shielding materials. However, these solutions remain primarily at the research stage, with significant work required before commercial viability can be achieved.

Despite promising developments, several technical challenges persist in liquid metal EMI shielding applications. The primary obstacle remains the high surface tension and oxidation tendency of liquid metals, which impedes their integration into complex electronic systems. When exposed to oxygen, gallium-based alloys rapidly form a thin oxide layer that, while providing some stability, complicates the manufacturing process and potentially compromises electromagnetic shielding effectiveness over time.

Connectivity issues between liquid metal components and conventional electronic systems present another significant challenge. The interface between liquid metals and solid conductors often suffers from inconsistent electrical contact, resulting in variable shielding performance. This variability becomes particularly problematic in applications requiring precise and stable EMI protection, such as medical devices and sensitive communication equipment.

Containment and encapsulation technologies represent a critical bottleneck in widespread adoption. Current materials used for containing liquid metals, including polydimethylsiloxane (PDMS) and other elastomers, exhibit limitations in terms of long-term stability and compatibility. These materials may degrade over time due to metal diffusion or chemical interactions, potentially leading to leakage and system failure.

From a manufacturing perspective, scalable production methods for liquid metal EMI shielding solutions remain underdeveloped. While laboratory demonstrations have shown promising results, translating these into mass-producible, cost-effective solutions has proven challenging. Current fabrication techniques, including microfluidic injection and direct writing, lack the throughput and consistency required for industrial-scale implementation.

Standardization represents another significant hurdle in the field. Unlike conventional EMI shielding materials, liquid metal solutions lack established testing protocols and performance metrics, making it difficult for manufacturers to validate and compare different solutions. This absence of standardization has slowed industry adoption despite the technology's theoretical advantages.

Recent research has begun addressing these challenges through innovative approaches, including surface modification techniques to control oxidation, development of specialized containment materials, and exploration of hybrid systems combining liquid metals with traditional shielding materials. However, these solutions remain primarily at the research stage, with significant work required before commercial viability can be achieved.

Current Technical Solutions for Liquid Metal EMI Applications

01 Liquid metal compositions for electromagnetic shielding

Liquid metal compositions can be formulated specifically for electromagnetic shielding applications. These compositions typically include gallium-based alloys that remain liquid at room temperature while providing excellent conductivity. The liquid nature allows for conformable shielding that can adapt to complex geometries and maintain continuous coverage even during mechanical deformation. These materials can be incorporated into flexible substrates to create adaptive electromagnetic shields that maintain effectiveness across a wide frequency range.- Liquid metal compositions for electromagnetic shielding: Liquid metal compositions can be formulated specifically for electromagnetic shielding applications. These compositions typically include gallium-based alloys such as galinstan (gallium-indium-tin) or eutectic gallium-indium (EGaIn) that remain liquid at room temperature. The liquid nature allows for conformable shielding that can adapt to complex geometries while maintaining continuous electrical conductivity. These materials can be encapsulated in flexible polymers to create stretchable shielding solutions that maintain effectiveness during deformation.

- Flexible and stretchable interconnect structures using liquid metals: Liquid metals can be incorporated into flexible and stretchable interconnect structures that provide electromagnetic shielding while accommodating mechanical deformation. These structures typically consist of microchannels or patterns filled with liquid metal within elastomeric substrates. When stretched or bent, the liquid metal maintains electrical continuity, preserving the shielding effectiveness. This approach enables wearable electronics and flexible devices with robust electromagnetic interference protection that can withstand repeated mechanical stress.

- Self-healing electromagnetic shielding using liquid metal networks: Liquid metal networks can create self-healing electromagnetic shielding systems that automatically restore electrical continuity after damage. When a shield containing encapsulated liquid metal is punctured or torn, the liquid metal flows to bridge the gap, restoring the conductive pathway and maintaining shielding effectiveness. This self-healing property significantly enhances the durability and reliability of electromagnetic shields in harsh environments or applications subject to mechanical damage, extending the operational lifetime of sensitive electronic components.

- Liquid metal-polymer composites for EMI shielding: Liquid metal-polymer composites combine the electromagnetic shielding properties of liquid metals with the mechanical advantages of polymers. These composites can be created by dispersing liquid metal droplets or particles within a polymer matrix, or by creating patterned liquid metal networks embedded in polymers. The resulting materials offer tunable shielding effectiveness based on the concentration and distribution of liquid metal, while maintaining flexibility, processability, and reduced weight compared to traditional metal shields. These composites can be molded, printed, or coated onto surfaces requiring electromagnetic protection.

- Thermal management integration with liquid metal electromagnetic shields: Liquid metal electromagnetic shields can simultaneously provide thermal management functionality due to the excellent thermal conductivity of liquid metals. These dual-function systems efficiently dissipate heat while blocking electromagnetic interference, addressing two critical challenges in electronic device design with a single solution. The liquid nature allows for intimate thermal contact with heat-generating components, while the metallic properties provide effective electromagnetic shielding. This integration is particularly valuable in high-power density applications where thermal management and EMI protection are both essential.

02 Interconnect structures using liquid metal for EMI shielding

Specialized interconnect structures can be designed using liquid metal to provide electromagnetic interference (EMI) shielding. These structures create conductive pathways that can be reconfigured or self-heal when damaged. The liquid metal interconnects can be embedded within flexible circuit boards or between components to provide continuous shielding while accommodating movement or vibration. This approach is particularly valuable in applications requiring both electrical connectivity and EMI protection in a single solution.Expand Specific Solutions03 Manufacturing techniques for liquid metal shielding components

Advanced manufacturing methods have been developed for creating liquid metal electromagnetic shielding components. These techniques include microfluidic channel fabrication, direct printing of liquid metal patterns, and encapsulation methods to prevent oxidation and leakage. Some approaches use template-based methods to create precise liquid metal structures, while others employ injection techniques to fill predefined cavities. These manufacturing processes enable mass production of reliable liquid metal shielding solutions for various electronic applications.Expand Specific Solutions04 Composite materials combining liquid metals with polymers for shielding

Composite materials that combine liquid metals with polymers offer enhanced electromagnetic shielding capabilities. These composites typically consist of liquid metal droplets or networks dispersed within a polymer matrix, creating a material that is both electrically conductive and mechanically flexible. The polymer component provides structural support and environmental protection, while the liquid metal provides the necessary conductivity for electromagnetic shielding. These composites can be formulated with varying concentrations of liquid metal to achieve specific shielding effectiveness at different frequencies.Expand Specific Solutions05 Self-healing electromagnetic shielding using liquid metals

Self-healing electromagnetic shielding systems utilize the unique properties of liquid metals to automatically repair damage. When the shielding layer is punctured or torn, the liquid metal can flow to fill gaps and restore electrical continuity, maintaining shielding effectiveness without external intervention. This capability is particularly valuable in applications subject to mechanical stress or impacts. The self-healing property can be enhanced through specific formulations that control surface tension, viscosity, and adhesion properties of the liquid metal to optimize the healing response.Expand Specific Solutions

Key Industry Players in Liquid Metal and EMI Shielding

The liquid metal interconnect market for electromagnetic shielding is in an early growth phase, with increasing adoption driven by demands for flexible, high-performance electronics. The market is projected to expand significantly as applications in automotive electronics, consumer devices, and telecommunications infrastructure grow. Intel, IBM, and Micron lead in advanced semiconductor applications, while automotive specialists like Sumitomo Wiring Systems, YAZAKI, and Magna International focus on vehicle-specific implementations. Asian manufacturers including SMIC and Beijing Dream Ink Technology are advancing manufacturing processes, while research institutions like Shenzhen Institutes of Advanced Technology contribute to material science innovations. The technology is approaching commercial maturity with major players investing in scalable production methods to address electromagnetic interference challenges in increasingly compact electronic systems.

Sumitomo Electric Industries Ltd.

Technical Solution: Sumitomo Electric has developed advanced liquid metal interconnect solutions that utilize gallium-based alloys for electromagnetic shielding applications. Their technology incorporates liquid metal into flexible polymer matrices to create conformable, self-healing electromagnetic shields. The company's approach involves microencapsulation of liquid metal particles within elastomeric substrates, allowing for stretchable interconnects that maintain electrical conductivity even under mechanical deformation. This technology enables effective EMI shielding across a wide frequency range (1-40 GHz) while providing flexibility that traditional rigid metal shields cannot offer. Sumitomo's liquid metal interconnects feature controlled viscosity and surface tension properties that allow them to form continuous conductive pathways when embedded in polymeric materials, creating effective Faraday cage structures for electromagnetic isolation. Their latest developments include temperature-stable liquid metal composites that maintain shielding effectiveness from -40°C to 150°C, making them suitable for automotive and industrial applications.

Strengths: Superior flexibility and conformability compared to solid metal shields, allowing application on complex geometries; self-healing properties that maintain shielding integrity after mechanical stress; excellent EMI attenuation across broad frequency ranges. Weaknesses: Higher production costs compared to traditional shielding methods; potential for galvanic corrosion when in contact with certain metals; requires specialized handling during manufacturing due to liquid metal properties.

International Business Machines Corp.

Technical Solution: IBM has pioneered liquid metal interconnect technology for electromagnetic shielding in high-performance computing environments. Their approach utilizes eutectic gallium-indium (EGaIn) alloys integrated into advanced packaging solutions for servers and data centers. IBM's proprietary process involves creating microscale channels within substrate materials that are subsequently filled with liquid metal to form adaptive electromagnetic shields. These liquid metal networks can dynamically reconfigure in response to thermal and mechanical stresses, maintaining continuous shielding effectiveness. IBM's research demonstrates shielding effectiveness of 60-85 dB across frequencies from 2-18 GHz, outperforming traditional copper shields in certain applications. The company has developed specialized surface treatments that prevent oxidation of the liquid metal interfaces, ensuring long-term reliability. Additionally, IBM has created hybrid solutions that combine liquid metal interconnects with conventional shielding materials to optimize performance in specific frequency bands while addressing thermal management challenges in densely packed electronic systems.

Strengths: Exceptional adaptability to thermal expansion and contraction cycles in high-performance computing environments; superior shielding effectiveness at high frequencies compared to conventional solutions; integration capability with existing manufacturing processes. Weaknesses: Higher implementation costs; concerns about long-term reliability in extreme operating conditions; potential migration of liquid metal under strong electromagnetic fields requires additional containment measures.

Core Patents and Research in Liquid Metal Shielding Technology

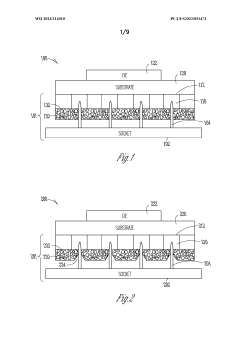

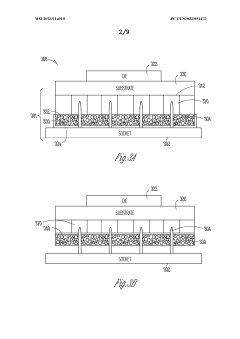

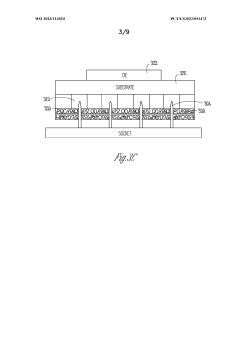

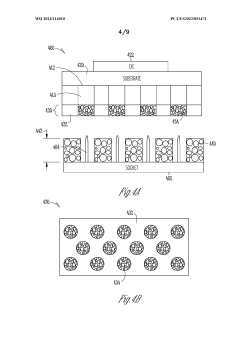

Liquid metal connection device and method

PatentWO2023114010A1

Innovation

- The use of an electronic device with a socket that includes an array of liquid metal filled reservoirs, such as gallium or gallium alloys, and a cap layer with porous resilient material regions, which can be designed with specific pore sizes and strain relief features to facilitate easy insertion and sealing, while also incorporating moisture barrier layers to prevent moisture ingress.

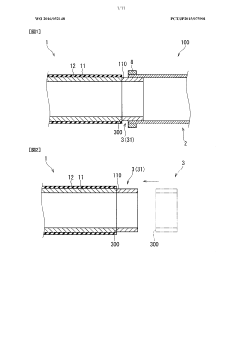

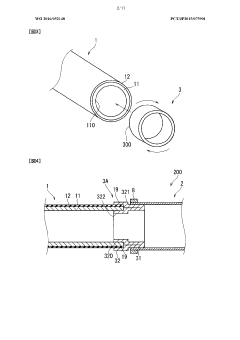

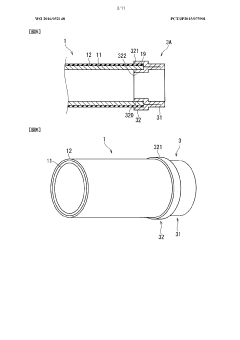

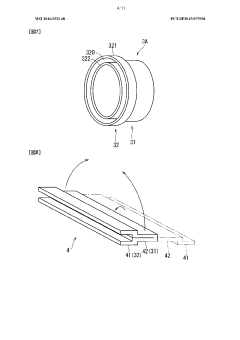

Electromagnetic shield member

PatentWO2016052148A1

Innovation

- The introduction of an intervening metal member that is electrically and mechanically connected to both the first and second shield members, providing a stable connection by methods such as solid phase bonding, press-fitting, or using deformable ring members to enhance the connection strength and ease of assembly.

Material Compatibility and Integration Considerations

The integration of liquid metal interconnects with electromagnetic shielding systems presents significant material compatibility challenges that must be addressed for successful implementation. Gallium-based liquid metals, particularly gallium-indium-tin alloys (Galinstan) and eutectic gallium-indium (EGaIn), exhibit strong chemical reactivity with various substrate materials. This reactivity manifests as corrosion or embrittlement when in contact with metals such as aluminum, copper, and nickel—materials commonly used in electromagnetic shielding applications.

Surface oxidation represents another critical consideration, as liquid metals rapidly form a thin oxide layer when exposed to oxygen. While this oxide skin provides mechanical stability in certain applications, it can significantly alter the electrical conductivity at interfaces, potentially compromising electromagnetic shielding performance. Engineering solutions such as pre-treatment with hydrochloric acid or continuous inert gas environments have been developed to mitigate these oxidation effects.

Temperature dependency further complicates integration efforts. Although liquid metals maintain their fluid state across a wide temperature range, their viscosity, surface tension, and electrical properties exhibit temperature-dependent variations that must be accounted for in design specifications. These variations can affect the stability of interconnects and their electromagnetic shielding capabilities, particularly in applications subject to thermal cycling or extreme operating conditions.

Substrate wettability presents another significant integration challenge. Most liquid metals exhibit poor wetting characteristics on non-metallic surfaces such as polymers and glass, which are often used as dielectric materials in electromagnetic shielding systems. Surface modification techniques including oxygen plasma treatment, chemical functionalization, and micro/nano-texturing have demonstrated improved wetting behavior, enabling more reliable integration with diverse substrate materials.

Encapsulation strategies must be carefully considered to prevent leakage while maintaining flexibility and durability. Traditional encapsulants like PDMS (polydimethylsiloxane) and parylene offer promising solutions but may introduce impedance mismatches or signal attenuation that could compromise electromagnetic shielding effectiveness. Recent advances in composite encapsulants incorporating conductive fillers show potential for preserving both mechanical integrity and electromagnetic performance.

Long-term stability remains a critical concern, as galvanic corrosion can occur at liquid metal-solid metal interfaces over extended periods. This electrochemical degradation may progressively undermine both mechanical and electrical properties, potentially leading to catastrophic failure of electromagnetic shielding systems. Barrier layers and corrosion inhibitors have shown promise in laboratory settings but require further validation for commercial implementation.

Surface oxidation represents another critical consideration, as liquid metals rapidly form a thin oxide layer when exposed to oxygen. While this oxide skin provides mechanical stability in certain applications, it can significantly alter the electrical conductivity at interfaces, potentially compromising electromagnetic shielding performance. Engineering solutions such as pre-treatment with hydrochloric acid or continuous inert gas environments have been developed to mitigate these oxidation effects.

Temperature dependency further complicates integration efforts. Although liquid metals maintain their fluid state across a wide temperature range, their viscosity, surface tension, and electrical properties exhibit temperature-dependent variations that must be accounted for in design specifications. These variations can affect the stability of interconnects and their electromagnetic shielding capabilities, particularly in applications subject to thermal cycling or extreme operating conditions.

Substrate wettability presents another significant integration challenge. Most liquid metals exhibit poor wetting characteristics on non-metallic surfaces such as polymers and glass, which are often used as dielectric materials in electromagnetic shielding systems. Surface modification techniques including oxygen plasma treatment, chemical functionalization, and micro/nano-texturing have demonstrated improved wetting behavior, enabling more reliable integration with diverse substrate materials.

Encapsulation strategies must be carefully considered to prevent leakage while maintaining flexibility and durability. Traditional encapsulants like PDMS (polydimethylsiloxane) and parylene offer promising solutions but may introduce impedance mismatches or signal attenuation that could compromise electromagnetic shielding effectiveness. Recent advances in composite encapsulants incorporating conductive fillers show potential for preserving both mechanical integrity and electromagnetic performance.

Long-term stability remains a critical concern, as galvanic corrosion can occur at liquid metal-solid metal interfaces over extended periods. This electrochemical degradation may progressively undermine both mechanical and electrical properties, potentially leading to catastrophic failure of electromagnetic shielding systems. Barrier layers and corrosion inhibitors have shown promise in laboratory settings but require further validation for commercial implementation.

Environmental and Safety Implications of Liquid Metal Technology

The environmental and safety implications of liquid metal technology in electromagnetic shielding applications require careful consideration as this emerging field continues to develop. Gallium-based liquid metals, particularly gallium-indium-tin alloys (Galinstan) and eutectic gallium-indium (EGaIn), present unique environmental challenges compared to traditional solid metal interconnects.

These liquid metals demonstrate significantly lower toxicity profiles than mercury, which was historically used in similar applications. However, their environmental impact remains a concern due to potential leaching into soil and water systems if improperly disposed of. The bioaccumulation potential of gallium compounds in aquatic ecosystems has been documented in limited studies, suggesting the need for proper containment and disposal protocols.

Manufacturing processes for liquid metal interconnects involve chemical treatments to control oxidation and ensure proper wetting behaviors. These processes often utilize strong acids or bases that present their own environmental and safety hazards. Proper industrial hygiene practices and waste treatment systems are essential to mitigate these risks during production phases.

The recyclability of liquid metal components presents both opportunities and challenges. While gallium can theoretically be recovered and reused, current recycling infrastructure is not optimized for these materials. The development of closed-loop recycling systems specifically designed for liquid metal recovery could significantly reduce the environmental footprint of these technologies.

Worker safety considerations include potential exposure to liquid metals through skin contact or inhalation of metal particles. Although gallium-based alloys are generally considered less hazardous than many industrial materials, proper personal protective equipment and handling protocols should be established to minimize exposure risks, particularly when working with heated liquid metals.

Long-term environmental persistence of these materials remains poorly understood. Unlike conventional electronic waste containing solid metals, liquid metal components may present unique end-of-life management challenges. Research into biodegradation pathways and environmental fate of gallium compounds is still in nascent stages.

Regulatory frameworks governing liquid metal handling, disposal, and recycling vary significantly across jurisdictions. As electromagnetic shielding applications utilizing liquid metal interconnects become more widespread, harmonized safety standards and environmental guidelines will be necessary to ensure responsible implementation of this technology across global markets.

These liquid metals demonstrate significantly lower toxicity profiles than mercury, which was historically used in similar applications. However, their environmental impact remains a concern due to potential leaching into soil and water systems if improperly disposed of. The bioaccumulation potential of gallium compounds in aquatic ecosystems has been documented in limited studies, suggesting the need for proper containment and disposal protocols.

Manufacturing processes for liquid metal interconnects involve chemical treatments to control oxidation and ensure proper wetting behaviors. These processes often utilize strong acids or bases that present their own environmental and safety hazards. Proper industrial hygiene practices and waste treatment systems are essential to mitigate these risks during production phases.

The recyclability of liquid metal components presents both opportunities and challenges. While gallium can theoretically be recovered and reused, current recycling infrastructure is not optimized for these materials. The development of closed-loop recycling systems specifically designed for liquid metal recovery could significantly reduce the environmental footprint of these technologies.

Worker safety considerations include potential exposure to liquid metals through skin contact or inhalation of metal particles. Although gallium-based alloys are generally considered less hazardous than many industrial materials, proper personal protective equipment and handling protocols should be established to minimize exposure risks, particularly when working with heated liquid metals.

Long-term environmental persistence of these materials remains poorly understood. Unlike conventional electronic waste containing solid metals, liquid metal components may present unique end-of-life management challenges. Research into biodegradation pathways and environmental fate of gallium compounds is still in nascent stages.

Regulatory frameworks governing liquid metal handling, disposal, and recycling vary significantly across jurisdictions. As electromagnetic shielding applications utilizing liquid metal interconnects become more widespread, harmonized safety standards and environmental guidelines will be necessary to ensure responsible implementation of this technology across global markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!