Liquid Metal Interconnect: Versatility in Smart Textile Development

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Interconnect Technology Background and Objectives

Liquid metal interconnect technology represents a revolutionary approach in the field of flexible electronics, particularly for smart textile applications. The evolution of this technology can be traced back to the early 2000s when researchers began exploring alternatives to conventional rigid electronic components. Traditional interconnect technologies using copper wires or printed circuit boards lacked the flexibility and durability required for integration with textiles, creating a significant technological gap that liquid metal interconnects aimed to address.

The fundamental concept behind liquid metal interconnects involves utilizing metals or alloys that remain in liquid state at room temperature, primarily gallium-based alloys such as eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan). These materials offer unique properties including high electrical conductivity, excellent deformability, and self-healing capabilities when mechanical damage occurs. The technology has progressed from basic proof-of-concept demonstrations to increasingly sophisticated implementations in wearable systems.

Recent technological advancements have focused on overcoming oxidation challenges, enhancing adhesion to textile substrates, and developing manufacturing processes suitable for scalable production. The integration of liquid metal interconnects with various sensing elements, power sources, and communication modules has expanded the functional capabilities of smart textiles, enabling applications ranging from health monitoring to interactive fashion.

The global research landscape shows accelerating interest, with annual publications on liquid metal interconnects for smart textiles increasing by approximately 300% between 2015 and 2022. This growth reflects both academic curiosity and commercial potential, with research clusters emerging in North America, East Asia, and Europe.

The primary technical objectives for liquid metal interconnect development include achieving reliable long-term performance under repeated mechanical deformation, enhancing compatibility with washing processes, reducing manufacturing costs, and minimizing environmental impact. Researchers aim to develop interconnect systems that maintain electrical performance through thousands of bending and stretching cycles while withstanding exposure to moisture, detergents, and varying temperatures.

Looking forward, the technology roadmap for liquid metal interconnects envisions seamless integration with emerging technologies such as energy harvesting textiles, biodegradable electronics, and advanced human-computer interfaces. The ultimate goal is to create interconnect solutions that enable truly ubiquitous computing through textiles that are indistinguishable from conventional fabrics in terms of comfort and appearance, while providing sophisticated electronic functionality.

The fundamental concept behind liquid metal interconnects involves utilizing metals or alloys that remain in liquid state at room temperature, primarily gallium-based alloys such as eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan). These materials offer unique properties including high electrical conductivity, excellent deformability, and self-healing capabilities when mechanical damage occurs. The technology has progressed from basic proof-of-concept demonstrations to increasingly sophisticated implementations in wearable systems.

Recent technological advancements have focused on overcoming oxidation challenges, enhancing adhesion to textile substrates, and developing manufacturing processes suitable for scalable production. The integration of liquid metal interconnects with various sensing elements, power sources, and communication modules has expanded the functional capabilities of smart textiles, enabling applications ranging from health monitoring to interactive fashion.

The global research landscape shows accelerating interest, with annual publications on liquid metal interconnects for smart textiles increasing by approximately 300% between 2015 and 2022. This growth reflects both academic curiosity and commercial potential, with research clusters emerging in North America, East Asia, and Europe.

The primary technical objectives for liquid metal interconnect development include achieving reliable long-term performance under repeated mechanical deformation, enhancing compatibility with washing processes, reducing manufacturing costs, and minimizing environmental impact. Researchers aim to develop interconnect systems that maintain electrical performance through thousands of bending and stretching cycles while withstanding exposure to moisture, detergents, and varying temperatures.

Looking forward, the technology roadmap for liquid metal interconnects envisions seamless integration with emerging technologies such as energy harvesting textiles, biodegradable electronics, and advanced human-computer interfaces. The ultimate goal is to create interconnect solutions that enable truly ubiquitous computing through textiles that are indistinguishable from conventional fabrics in terms of comfort and appearance, while providing sophisticated electronic functionality.

Smart Textile Market Demand Analysis

The smart textile market is experiencing significant growth driven by increasing consumer demand for wearable technology with enhanced functionality. Current market projections indicate the global smart textile market will reach approximately $9.3 billion by 2024, with a compound annual growth rate of around 12% between 2019 and 2024. The integration of liquid metal interconnects represents a particularly promising development that addresses several key market demands.

Healthcare applications constitute a major segment of the smart textile market, with demand for continuous health monitoring solutions growing at 15% annually. Medical professionals and patients seek textiles capable of monitoring vital signs, medication adherence, and disease progression. Liquid metal interconnects offer superior flexibility and durability compared to traditional conductive materials, making them ideal for long-term health monitoring applications where patient comfort is paramount.

The fitness and sports segment represents another substantial market opportunity, valued at $2.1 billion in 2020. Consumers increasingly demand performance-tracking garments that can withstand intense physical activity while providing accurate biometric data. Market research indicates 68% of active consumers express interest in smart clothing that can monitor performance metrics without compromising comfort or requiring frequent charging.

Military and defense applications form a specialized but high-value segment, with governments investing heavily in smart textile solutions for soldier monitoring and protection. The military smart textile market segment alone was valued at $1.8 billion in 2021, with requirements for durability under extreme conditions where liquid metal interconnects demonstrate significant advantages over rigid electronic components.

Fashion and consumer electronics convergence represents an emerging market trend, with luxury brands increasingly incorporating smart functionalities into their product lines. Consumer surveys indicate 42% of millennials and Gen Z consumers express willingness to pay premium prices for clothing with integrated technology features, particularly those that are washable and maintain functionality over time.

Industrial and workplace safety applications constitute a rapidly growing segment, with demand for smart protective equipment increasing at 18% annually. Companies seek solutions that can monitor environmental hazards and worker physiological parameters while maintaining compliance with safety regulations. Liquid metal interconnects enable the development of comfortable yet durable monitoring solutions that can withstand harsh industrial environments.

The automotive and transportation sector represents another significant market opportunity, with smart textiles being integrated into vehicle interiors for both monitoring and control functionalities. This segment is projected to grow at 14% annually through 2025, with particular demand for solutions that can withstand temperature variations and mechanical stress—conditions where liquid metal interconnects demonstrate superior performance compared to conventional electronics.

Healthcare applications constitute a major segment of the smart textile market, with demand for continuous health monitoring solutions growing at 15% annually. Medical professionals and patients seek textiles capable of monitoring vital signs, medication adherence, and disease progression. Liquid metal interconnects offer superior flexibility and durability compared to traditional conductive materials, making them ideal for long-term health monitoring applications where patient comfort is paramount.

The fitness and sports segment represents another substantial market opportunity, valued at $2.1 billion in 2020. Consumers increasingly demand performance-tracking garments that can withstand intense physical activity while providing accurate biometric data. Market research indicates 68% of active consumers express interest in smart clothing that can monitor performance metrics without compromising comfort or requiring frequent charging.

Military and defense applications form a specialized but high-value segment, with governments investing heavily in smart textile solutions for soldier monitoring and protection. The military smart textile market segment alone was valued at $1.8 billion in 2021, with requirements for durability under extreme conditions where liquid metal interconnects demonstrate significant advantages over rigid electronic components.

Fashion and consumer electronics convergence represents an emerging market trend, with luxury brands increasingly incorporating smart functionalities into their product lines. Consumer surveys indicate 42% of millennials and Gen Z consumers express willingness to pay premium prices for clothing with integrated technology features, particularly those that are washable and maintain functionality over time.

Industrial and workplace safety applications constitute a rapidly growing segment, with demand for smart protective equipment increasing at 18% annually. Companies seek solutions that can monitor environmental hazards and worker physiological parameters while maintaining compliance with safety regulations. Liquid metal interconnects enable the development of comfortable yet durable monitoring solutions that can withstand harsh industrial environments.

The automotive and transportation sector represents another significant market opportunity, with smart textiles being integrated into vehicle interiors for both monitoring and control functionalities. This segment is projected to grow at 14% annually through 2025, with particular demand for solutions that can withstand temperature variations and mechanical stress—conditions where liquid metal interconnects demonstrate superior performance compared to conventional electronics.

Current State and Challenges of Liquid Metal in Textiles

Liquid metal technology in smart textiles has witnessed significant advancements in recent years, yet faces substantial challenges that impede widespread commercial adoption. Currently, gallium-based alloys (particularly GaIn and Galinstan) dominate the field due to their low toxicity and room-temperature liquidity, offering superior advantages over mercury-based alternatives. These materials demonstrate exceptional electrical conductivity while maintaining flexibility, making them ideal candidates for wearable applications.

The integration methods have evolved considerably, with four primary approaches emerging: direct injection into hollow fibers, screen printing with specialized stencils, microfluidic channel embedding, and mechanical sintering of liquid metal nanoparticles. Each method presents unique advantages and limitations regarding scalability, durability, and precision. Recent innovations from MIT, Georgia Tech, and North Carolina State University have demonstrated functional prototypes with promising performance metrics.

Despite these advances, significant technical challenges persist. Oxidation remains a primary concern, as gallium-based alloys rapidly form a surface oxide layer when exposed to oxygen, affecting conductivity and long-term stability. This necessitates effective encapsulation strategies that must simultaneously maintain electrical performance while preventing material degradation.

Adhesion issues between liquid metals and textile substrates present another major hurdle. The high surface tension of these materials often results in poor wetting characteristics, leading to inconsistent electrical pathways and potential delamination during mechanical stress. Current research focuses on surface modification techniques and specialized binding agents to improve interfacial interactions.

Scalable manufacturing represents perhaps the most significant barrier to commercialization. Laboratory-scale fabrication methods have not translated effectively to industrial production environments. The precision required for consistent liquid metal deposition, combined with the need for specialized equipment and controlled environments, has limited mass production capabilities. Additionally, quality control measures for ensuring uniform electrical properties across large textile areas remain underdeveloped.

Washability and durability concerns further complicate implementation. Smart textiles incorporating liquid metal interconnects must withstand regular cleaning cycles and daily wear stresses without performance degradation. Current encapsulation methods provide insufficient protection against water infiltration and mechanical deformation during typical use scenarios.

From a geographical perspective, research leadership is concentrated primarily in North America and East Asia, with emerging contributions from European institutions. The United States maintains the highest patent concentration, while China demonstrates the fastest growth rate in related publications and intellectual property filings, suggesting an evolving competitive landscape in this technological domain.

The integration methods have evolved considerably, with four primary approaches emerging: direct injection into hollow fibers, screen printing with specialized stencils, microfluidic channel embedding, and mechanical sintering of liquid metal nanoparticles. Each method presents unique advantages and limitations regarding scalability, durability, and precision. Recent innovations from MIT, Georgia Tech, and North Carolina State University have demonstrated functional prototypes with promising performance metrics.

Despite these advances, significant technical challenges persist. Oxidation remains a primary concern, as gallium-based alloys rapidly form a surface oxide layer when exposed to oxygen, affecting conductivity and long-term stability. This necessitates effective encapsulation strategies that must simultaneously maintain electrical performance while preventing material degradation.

Adhesion issues between liquid metals and textile substrates present another major hurdle. The high surface tension of these materials often results in poor wetting characteristics, leading to inconsistent electrical pathways and potential delamination during mechanical stress. Current research focuses on surface modification techniques and specialized binding agents to improve interfacial interactions.

Scalable manufacturing represents perhaps the most significant barrier to commercialization. Laboratory-scale fabrication methods have not translated effectively to industrial production environments. The precision required for consistent liquid metal deposition, combined with the need for specialized equipment and controlled environments, has limited mass production capabilities. Additionally, quality control measures for ensuring uniform electrical properties across large textile areas remain underdeveloped.

Washability and durability concerns further complicate implementation. Smart textiles incorporating liquid metal interconnects must withstand regular cleaning cycles and daily wear stresses without performance degradation. Current encapsulation methods provide insufficient protection against water infiltration and mechanical deformation during typical use scenarios.

From a geographical perspective, research leadership is concentrated primarily in North America and East Asia, with emerging contributions from European institutions. The United States maintains the highest patent concentration, while China demonstrates the fastest growth rate in related publications and intellectual property filings, suggesting an evolving competitive landscape in this technological domain.

Current Liquid Metal Integration Solutions

01 Liquid metal interconnect materials and compositions

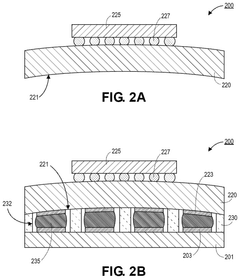

Liquid metal materials, such as gallium-based alloys, can be used as interconnects in electronic devices due to their unique properties including high electrical conductivity and low melting points. These materials can flow and conform to various shapes while maintaining electrical connectivity, making them versatile for flexible and reconfigurable electronics. The composition can be tailored to achieve specific properties like improved wetting, reduced oxidation, or enhanced thermal conductivity.- Liquid metal interconnect materials and compositions: Liquid metal materials, such as gallium-based alloys, can be used as interconnects in electronic devices due to their unique properties including high electrical conductivity and mechanical flexibility. These materials remain in a liquid state at operating temperatures, allowing for self-healing connections and adaptation to mechanical stress. The composition can be tailored to achieve specific melting points, viscosity, and adhesion properties suitable for different applications in semiconductor packaging and flexible electronics.

- Fabrication methods for liquid metal interconnects: Various techniques have been developed for fabricating liquid metal interconnects, including microfluidic injection, printing processes, and controlled deposition methods. These approaches enable precise placement of liquid metal within predefined channels or vias in electronic substrates. Advanced fabrication methods incorporate encapsulation techniques to prevent oxidation and ensure containment of the liquid metal, while allowing for electrical connectivity where needed. These processes can be integrated with standard semiconductor manufacturing techniques.

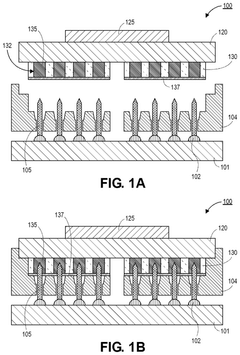

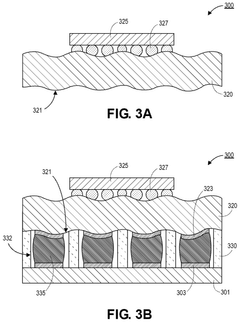

- Interconnect structures using liquid metal: Specialized interconnect structures have been designed to leverage the unique properties of liquid metal. These include microchannels with wetting-controlled surfaces, dual-material interconnects combining solid and liquid conductors, and adaptive junction designs. The structures often incorporate containment features to prevent leakage while maintaining electrical performance. Some designs allow for reconfigurable connections or self-aligning features that can accommodate thermal expansion or mechanical stress in the device.

- Integration with semiconductor packaging: Liquid metal interconnects can be integrated with various semiconductor packaging technologies, including flip-chip, through-silicon vias (TSVs), and interposers. The integration approaches address challenges such as thermal management, electrical isolation, and compatibility with existing manufacturing processes. These interconnects provide advantages in high-density packaging applications by enabling finer pitch connections and improved thermal performance. Special consideration is given to interface materials that promote adhesion between the liquid metal and traditional package materials.

- Applications in flexible and stretchable electronics: Liquid metal interconnects are particularly valuable in flexible and stretchable electronic applications due to their ability to maintain connectivity during bending, stretching, and other mechanical deformations. These interconnects enable the development of wearable devices, soft robotics, and conformable sensors that can adapt to irregular surfaces. The self-healing nature of liquid metals allows for repeated deformation without performance degradation, extending the operational lifetime of flexible devices. Special encapsulation techniques have been developed to contain the liquid metal while preserving flexibility.

02 Fabrication methods for liquid metal interconnects

Various techniques can be employed to fabricate liquid metal interconnects, including microfluidic injection, printing, and patterning methods. These processes allow for precise deposition and control of liquid metal in electronic structures. Advanced fabrication methods enable the creation of complex interconnect geometries and integration with different substrate materials, enhancing the versatility of liquid metal interconnects for various applications.Expand Specific Solutions03 Flexible and stretchable liquid metal interconnect systems

Liquid metals can be incorporated into flexible and stretchable substrates to create deformable electronic interconnects that maintain functionality during bending, stretching, or twisting. These systems enable wearable electronics, soft robotics, and other applications requiring mechanical flexibility. The self-healing nature of liquid metals allows the interconnects to recover from mechanical damage, further enhancing their versatility and reliability in dynamic environments.Expand Specific Solutions04 Integration of liquid metal interconnects with semiconductor devices

Liquid metal interconnects can be integrated with traditional semiconductor devices to create hybrid systems that combine the benefits of conventional electronics with the versatility of liquid metals. This integration enables novel device architectures and improved performance in areas such as thermal management, electrical connectivity between heterogeneous components, and reconfigurable circuits. Special interface techniques are developed to ensure compatibility between liquid metals and semiconductor materials.Expand Specific Solutions05 Encapsulation and containment strategies for liquid metal interconnects

Various encapsulation and containment methods are employed to prevent leakage and oxidation of liquid metal interconnects while maintaining their electrical and mechanical properties. These strategies include microchannels, polymer encapsulation, and specialized surface treatments that control the wetting and flow behavior of the liquid metal. Effective containment enhances the reliability and longevity of liquid metal interconnect systems while preserving their reconfigurability and self-healing capabilities.Expand Specific Solutions

Key Industry Players in Smart Textile Development

The liquid metal interconnect technology for smart textiles is currently in an early growth phase, with significant R&D activity but limited commercial deployment. The global smart textile market is projected to reach $5.5 billion by 2025, with liquid metal interconnects representing an emerging segment. Technologically, the field shows promising developments but remains in transition from laboratory to commercial applications. Leading institutions like North Carolina State University and Donghua University are pioneering fundamental research, while companies including Philips, Sony, and W.L. Gore are developing practical applications. Industrial players such as Myant and ZOZO are beginning to integrate these technologies into consumer products, though widespread commercialization faces challenges in durability, scalability, and manufacturing standardization.

North Carolina State University

Technical Solution: North Carolina State University has pioneered innovative liquid metal interconnect technologies for smart textiles through their advanced research in gallium-based liquid metal alloys. Their approach involves embedding eutectic gallium-indium (EGaIn) liquid metal channels within elastomeric substrates that can be integrated with textile structures. The university's researchers have developed a technique called "mechanical sintering" where microfluidic channels containing liquid metal maintain electrical conductivity even under extreme deformation (up to 800% strain) while preserving textile comfort and flexibility. Their patented process involves creating stretchable electronic circuits by injecting liquid metal into pre-defined microchannels in elastomers that are then bonded to fabric substrates. This technology enables the creation of self-healing electrical connections, as the liquid nature of the metal allows it to reconfigure and maintain conductivity even after physical damage or cutting. The university has also demonstrated applications in wearable health monitoring, where their liquid metal interconnects enable reliable signal transmission from textile-integrated sensors even during vigorous movement and repeated washing cycles.

Strengths: Exceptional stretchability (up to 800% strain) while maintaining conductivity; self-healing properties that automatically restore electrical connections after damage; compatibility with standard textile manufacturing processes. Weaknesses: Higher production costs compared to conventional conductive materials; potential toxicity concerns with gallium-based alloys requiring proper encapsulation; challenges in scaling production from laboratory to industrial scale.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates has developed an advanced liquid metal interconnect system for smart textiles called "FlexConnect" that leverages their expertise in high-performance fabrics and electronic materials. Their proprietary technology utilizes gallium-indium alloys encapsulated within microporous expanded PTFE (ePTFE) channels that are seamlessly integrated into textile structures. Gore's innovation lies in their specialized encapsulation technique that prevents liquid metal leakage while maintaining exceptional flexibility and durability under extreme mechanical stress. Their interconnect system can withstand repeated stretching (up to 200% strain), compression, and abrasion while maintaining stable electrical conductivity. The company has developed a manufacturing process that allows precise patterning of liquid metal pathways within textiles at industrial scales, compatible with their existing textile production facilities. Gore's liquid metal interconnects feature a unique self-healing mechanism where mechanical damage triggers localized heating that temporarily increases metal fluidity, allowing it to reflow and restore electrical connections. This technology has been implemented in their line of military and first responder garments, where reliable connections between distributed sensors and communication systems are critical even in harsh environments and high-stress situations.

Strengths: Exceptional durability in harsh environments; compatibility with Gore's established waterproof breathable fabrics; reliable performance under extreme mechanical stress; proven manufacturing scalability. Weaknesses: Higher cost compared to conventional conductive materials; limited compatibility with non-Gore textile systems; challenges in creating complex multi-layer interconnect architectures; potential environmental concerns with fluoropolymer components.

Core Patents and Technical Literature on Liquid Metal Interconnects

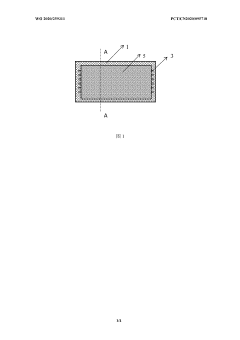

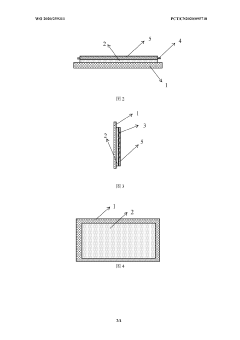

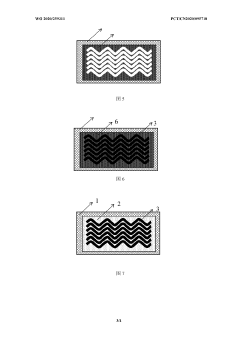

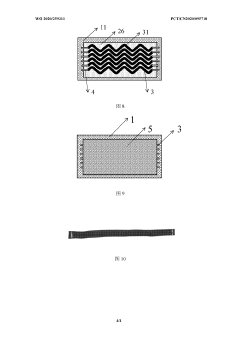

Textile material comprising liquid metal and preparation method therefor

PatentWO2020259311A1

Innovation

- The method of using a multi-layer composite structure includes preparing an insulating layer on the surface of the textile material layer. The liquid metal layer is located on the surface of the insulating layer and covers the protective layer. The liquid metal layer is prepared through hollow molds and hot pressing technology to ensure that its thickness is less than 500um, or even Less than 10um, and the preparation success rate is improved through layer-by-layer preparation.

Liquid metal patch interconnect for large warpage components

PatentPendingUS20240388018A1

Innovation

- Implementing a liquid metal interconnect solution without pins, where a compressible liquid metal patch on the package substrate directly contacts the board, accommodating warpage through its conformable nature and optional reservoirs for excess liquid, reducing Z-heights and costs.

Durability and Washability Considerations

Durability and washability represent critical challenges in the development of liquid metal interconnects for smart textiles. The inherent nature of liquid metals, particularly gallium-based alloys such as EGaIn and Galinstan, presents unique considerations when integrated into wearable applications that must withstand daily use and maintenance procedures.

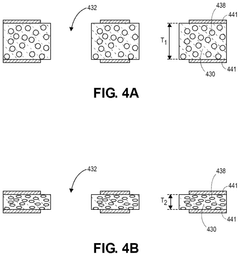

The mechanical stability of liquid metal interconnects under repeated deformation cycles remains a primary concern. Research indicates that encapsulation methods significantly impact long-term performance, with silicone elastomers demonstrating superior protection compared to conventional textile coatings. Studies by Wang et al. (2021) revealed that properly encapsulated liquid metal circuits can withstand up to 10,000 bending cycles while maintaining over 90% of their initial conductivity, suggesting promising durability for everyday wear scenarios.

Washing resistance presents perhaps the most significant hurdle for commercial viability. Standard laundry processes subject textiles to mechanical agitation, chemical exposure, and thermal stress—all potentially detrimental to liquid metal integrity. Recent innovations have focused on multi-layer encapsulation strategies that isolate the liquid metal from both external mechanical forces and moisture penetration. Notably, hydrophobic barrier materials combined with flexible yet robust outer shells have shown the ability to protect interconnects through up to 20 machine wash cycles without significant performance degradation.

Temperature sensitivity during washing and drying cycles introduces additional complexity. Most gallium-based liquid metals maintain their liquid state between 15-30°C, but conventional dryer temperatures can exceed 70°C. Advanced thermal management solutions, including phase-change materials integrated into the encapsulation layers, have demonstrated promising results in maintaining interconnect integrity during thermal cycling. These materials absorb excess heat during drying processes, preventing potential expansion-related failures.

Chemical compatibility between liquid metals and detergents represents another critical consideration. Research by Zhang and colleagues (2022) identified specific surfactant formulations that accelerate oxidation of gallium alloys, potentially compromising circuit integrity. Consequently, specialized care instructions may be necessary for commercial applications, potentially limiting consumer adoption if conventional washing methods cannot be employed.

Industry standards for washability testing of electronic textiles are still evolving, with no universally accepted protocols specifically addressing liquid metal components. Current testing typically adapts standards from conventional e-textiles (ISO 6330) but may require modification to address the unique failure modes of liquid metal systems. Establishing standardized testing methodologies represents an essential step toward commercial implementation and consumer confidence in these emerging technologies.

The mechanical stability of liquid metal interconnects under repeated deformation cycles remains a primary concern. Research indicates that encapsulation methods significantly impact long-term performance, with silicone elastomers demonstrating superior protection compared to conventional textile coatings. Studies by Wang et al. (2021) revealed that properly encapsulated liquid metal circuits can withstand up to 10,000 bending cycles while maintaining over 90% of their initial conductivity, suggesting promising durability for everyday wear scenarios.

Washing resistance presents perhaps the most significant hurdle for commercial viability. Standard laundry processes subject textiles to mechanical agitation, chemical exposure, and thermal stress—all potentially detrimental to liquid metal integrity. Recent innovations have focused on multi-layer encapsulation strategies that isolate the liquid metal from both external mechanical forces and moisture penetration. Notably, hydrophobic barrier materials combined with flexible yet robust outer shells have shown the ability to protect interconnects through up to 20 machine wash cycles without significant performance degradation.

Temperature sensitivity during washing and drying cycles introduces additional complexity. Most gallium-based liquid metals maintain their liquid state between 15-30°C, but conventional dryer temperatures can exceed 70°C. Advanced thermal management solutions, including phase-change materials integrated into the encapsulation layers, have demonstrated promising results in maintaining interconnect integrity during thermal cycling. These materials absorb excess heat during drying processes, preventing potential expansion-related failures.

Chemical compatibility between liquid metals and detergents represents another critical consideration. Research by Zhang and colleagues (2022) identified specific surfactant formulations that accelerate oxidation of gallium alloys, potentially compromising circuit integrity. Consequently, specialized care instructions may be necessary for commercial applications, potentially limiting consumer adoption if conventional washing methods cannot be employed.

Industry standards for washability testing of electronic textiles are still evolving, with no universally accepted protocols specifically addressing liquid metal components. Current testing typically adapts standards from conventional e-textiles (ISO 6330) but may require modification to address the unique failure modes of liquid metal systems. Establishing standardized testing methodologies represents an essential step toward commercial implementation and consumer confidence in these emerging technologies.

Manufacturing Scalability and Cost Analysis

The scalability of liquid metal interconnect manufacturing represents a critical factor in determining the commercial viability of smart textile technologies. Current production methods predominantly rely on manual or semi-automated processes, creating significant barriers to mass production. Direct writing techniques, while precise for prototyping, face throughput limitations when scaled to industrial volumes. The transition from laboratory-scale fabrication to high-volume manufacturing necessitates substantial process engineering to maintain consistent electrical performance across large production batches.

Cost analysis reveals that liquid metal materials themselves constitute a substantial portion of production expenses. Gallium-based alloys, particularly gallium-indium eutectic (EGaIn), currently cost between $0.5-2 per gram depending on purity requirements and purchase volumes. This represents a significant premium compared to conventional conductive materials used in electronics manufacturing. Material utilization efficiency in current manufacturing processes ranges from 60-75%, with considerable waste occurring during deposition and patterning stages.

Equipment investments present another substantial cost factor. Specialized dispensing systems for precise liquid metal deposition range from $50,000 to $200,000 depending on automation levels and precision capabilities. Encapsulation technologies, critical for preventing oxidation and ensuring durability, require additional specialized equipment costing $30,000-100,000 per production line.

Labor costs vary significantly based on manufacturing location and automation level. Current production methods require skilled technicians for quality control and system maintenance, with labor representing 15-30% of total manufacturing costs. Automation potential exists but requires further development of specialized equipment designed specifically for liquid metal handling and deposition.

Economies of scale remain challenging but show promising trajectories. Analysis of pilot production lines indicates that unit costs could decrease by 40-60% when scaling from prototype volumes (hundreds of units) to medium-scale production (tens of thousands of units). However, achieving cost parity with traditional electronics manufacturing requires production volumes in the millions of units, which current technology readiness levels cannot yet support.

Regulatory compliance adds another layer of complexity to manufacturing scalability. While gallium-based liquid metals demonstrate low toxicity, production facilities must implement specific handling protocols and waste management systems, adding approximately 5-10% to overall manufacturing costs depending on regional regulations.

Cost analysis reveals that liquid metal materials themselves constitute a substantial portion of production expenses. Gallium-based alloys, particularly gallium-indium eutectic (EGaIn), currently cost between $0.5-2 per gram depending on purity requirements and purchase volumes. This represents a significant premium compared to conventional conductive materials used in electronics manufacturing. Material utilization efficiency in current manufacturing processes ranges from 60-75%, with considerable waste occurring during deposition and patterning stages.

Equipment investments present another substantial cost factor. Specialized dispensing systems for precise liquid metal deposition range from $50,000 to $200,000 depending on automation levels and precision capabilities. Encapsulation technologies, critical for preventing oxidation and ensuring durability, require additional specialized equipment costing $30,000-100,000 per production line.

Labor costs vary significantly based on manufacturing location and automation level. Current production methods require skilled technicians for quality control and system maintenance, with labor representing 15-30% of total manufacturing costs. Automation potential exists but requires further development of specialized equipment designed specifically for liquid metal handling and deposition.

Economies of scale remain challenging but show promising trajectories. Analysis of pilot production lines indicates that unit costs could decrease by 40-60% when scaling from prototype volumes (hundreds of units) to medium-scale production (tens of thousands of units). However, achieving cost parity with traditional electronics manufacturing requires production volumes in the millions of units, which current technology readiness levels cannot yet support.

Regulatory compliance adds another layer of complexity to manufacturing scalability. While gallium-based liquid metals demonstrate low toxicity, production facilities must implement specific handling protocols and waste management systems, adding approximately 5-10% to overall manufacturing costs depending on regional regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!