Catalytic Efficiency of Liquid Metal Interconnect in Industrial Applications

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Catalysis Background and Objectives

Liquid metal catalysis represents a revolutionary frontier in industrial chemistry, combining the unique properties of liquid metals with catalytic processes to enhance reaction efficiency. The evolution of this technology can be traced back to the early 2000s when researchers first began exploring the catalytic potential of gallium-based liquid metals. Since then, the field has expanded dramatically, incorporating various metal alloys and demonstrating applications across multiple industrial sectors.

The distinctive properties of liquid metals—high thermal conductivity, excellent electrical conductivity, and remarkable fluidity at relatively low temperatures—make them particularly valuable as catalytic materials. These characteristics enable more efficient heat transfer during reactions, facilitate electron exchange processes, and allow for dynamic reconfiguration of catalytic surfaces, respectively. The field has progressed from simple gallium-indium systems to more complex multi-metal compositions designed for specific catalytic functions.

Current technological trends indicate a growing interest in liquid metal interconnects that can simultaneously serve as catalysts and electrical conductors in industrial systems. This dual functionality represents a significant advancement over traditional solid catalysts, which often suffer from deactivation due to coking, poisoning, or sintering. The self-healing nature of liquid metals allows them to maintain catalytic activity over extended operational periods, addressing a critical limitation in conventional catalytic systems.

The primary objective of research in this domain is to optimize the catalytic efficiency of liquid metal interconnects for industrial applications. This encompasses several specific goals: enhancing reaction rates and selectivity, minimizing energy requirements, extending catalyst lifespan, and developing scalable manufacturing processes for liquid metal catalytic systems. Additionally, researchers aim to establish comprehensive models that accurately predict the behavior of liquid metal catalysts under various operating conditions.

Another crucial objective involves addressing the environmental implications of liquid metal catalysis. While these materials offer potential improvements in energy efficiency and resource utilization, concerns regarding toxicity, recovery, and recycling must be thoroughly investigated. The development of environmentally benign liquid metal catalysts represents a key research priority, particularly as industrial adoption increases.

The convergence of nanotechnology with liquid metal catalysis presents exciting opportunities for further innovation. By controlling the nano-scale structure of liquid metal surfaces, researchers can potentially create highly specialized catalytic environments tailored to specific chemical transformations. This precision engineering approach may unlock unprecedented levels of catalytic performance in industrial processes ranging from petrochemical production to renewable energy systems.

The distinctive properties of liquid metals—high thermal conductivity, excellent electrical conductivity, and remarkable fluidity at relatively low temperatures—make them particularly valuable as catalytic materials. These characteristics enable more efficient heat transfer during reactions, facilitate electron exchange processes, and allow for dynamic reconfiguration of catalytic surfaces, respectively. The field has progressed from simple gallium-indium systems to more complex multi-metal compositions designed for specific catalytic functions.

Current technological trends indicate a growing interest in liquid metal interconnects that can simultaneously serve as catalysts and electrical conductors in industrial systems. This dual functionality represents a significant advancement over traditional solid catalysts, which often suffer from deactivation due to coking, poisoning, or sintering. The self-healing nature of liquid metals allows them to maintain catalytic activity over extended operational periods, addressing a critical limitation in conventional catalytic systems.

The primary objective of research in this domain is to optimize the catalytic efficiency of liquid metal interconnects for industrial applications. This encompasses several specific goals: enhancing reaction rates and selectivity, minimizing energy requirements, extending catalyst lifespan, and developing scalable manufacturing processes for liquid metal catalytic systems. Additionally, researchers aim to establish comprehensive models that accurately predict the behavior of liquid metal catalysts under various operating conditions.

Another crucial objective involves addressing the environmental implications of liquid metal catalysis. While these materials offer potential improvements in energy efficiency and resource utilization, concerns regarding toxicity, recovery, and recycling must be thoroughly investigated. The development of environmentally benign liquid metal catalysts represents a key research priority, particularly as industrial adoption increases.

The convergence of nanotechnology with liquid metal catalysis presents exciting opportunities for further innovation. By controlling the nano-scale structure of liquid metal surfaces, researchers can potentially create highly specialized catalytic environments tailored to specific chemical transformations. This precision engineering approach may unlock unprecedented levels of catalytic performance in industrial processes ranging from petrochemical production to renewable energy systems.

Industrial Market Demand Analysis for Liquid Metal Catalysts

The liquid metal catalyst market is experiencing significant growth driven by industrial demands for more efficient catalytic processes. Current market analysis indicates that industries such as petrochemical, fine chemical manufacturing, pharmaceutical production, and renewable energy are actively seeking advanced catalytic solutions that offer higher efficiency, reduced energy consumption, and improved selectivity. Liquid metal catalysts, particularly those utilizing gallium-based alloys, are emerging as promising alternatives to traditional solid catalysts due to their unique properties including high thermal conductivity, excellent surface activity, and tunable composition.

Market research reveals that the global industrial catalyst market, valued at approximately $26.1 billion in 2022, is projected to reach $38.5 billion by 2030, with liquid metal catalysts representing a rapidly growing segment. This growth is primarily fueled by stringent environmental regulations demanding cleaner production processes and the industrial sector's push toward carbon neutrality, where more efficient catalytic systems play a crucial role.

The petrochemical industry demonstrates the highest demand potential, seeking liquid metal catalytic solutions for hydrogenation, dehydrogenation, and oxidation processes. These applications require catalysts that can maintain performance under extreme conditions while minimizing precious metal content. Survey data from industry stakeholders indicates that 78% of petrochemical manufacturers are actively investigating alternative catalyst technologies, with liquid metal systems ranking among their top interests.

In the renewable energy sector, particularly in hydrogen production and fuel cell technologies, liquid metal interconnects with catalytic properties are gaining attention. The market for green hydrogen catalysts alone is expected to grow at a CAGR of 14.2% through 2028, with liquid metal systems potentially capturing a significant portion of this growth due to their superior electron transfer capabilities and resistance to catalyst poisoning.

Regional analysis shows Asia-Pacific leading the demand growth, with China and India investing heavily in advanced catalytic technologies for their expanding chemical manufacturing sectors. North America and Europe follow closely, primarily driven by sustainability initiatives and the transition toward green chemistry principles in industrial operations.

Customer requirements analysis reveals five key demand factors: catalytic efficiency improvement (minimum 30% over conventional systems), operational longevity (3+ years without significant activity loss), compatibility with existing process equipment, reduced precious metal content, and scalability for industrial-level production. Liquid metal catalysts show promising potential to address these requirements, particularly in high-temperature applications where traditional catalysts suffer from sintering and deactivation issues.

Market research reveals that the global industrial catalyst market, valued at approximately $26.1 billion in 2022, is projected to reach $38.5 billion by 2030, with liquid metal catalysts representing a rapidly growing segment. This growth is primarily fueled by stringent environmental regulations demanding cleaner production processes and the industrial sector's push toward carbon neutrality, where more efficient catalytic systems play a crucial role.

The petrochemical industry demonstrates the highest demand potential, seeking liquid metal catalytic solutions for hydrogenation, dehydrogenation, and oxidation processes. These applications require catalysts that can maintain performance under extreme conditions while minimizing precious metal content. Survey data from industry stakeholders indicates that 78% of petrochemical manufacturers are actively investigating alternative catalyst technologies, with liquid metal systems ranking among their top interests.

In the renewable energy sector, particularly in hydrogen production and fuel cell technologies, liquid metal interconnects with catalytic properties are gaining attention. The market for green hydrogen catalysts alone is expected to grow at a CAGR of 14.2% through 2028, with liquid metal systems potentially capturing a significant portion of this growth due to their superior electron transfer capabilities and resistance to catalyst poisoning.

Regional analysis shows Asia-Pacific leading the demand growth, with China and India investing heavily in advanced catalytic technologies for their expanding chemical manufacturing sectors. North America and Europe follow closely, primarily driven by sustainability initiatives and the transition toward green chemistry principles in industrial operations.

Customer requirements analysis reveals five key demand factors: catalytic efficiency improvement (minimum 30% over conventional systems), operational longevity (3+ years without significant activity loss), compatibility with existing process equipment, reduced precious metal content, and scalability for industrial-level production. Liquid metal catalysts show promising potential to address these requirements, particularly in high-temperature applications where traditional catalysts suffer from sintering and deactivation issues.

Current Technological Status and Challenges in Liquid Metal Interconnects

Liquid metal interconnects have emerged as a promising technology in various industrial applications, with significant advancements observed globally over the past decade. Currently, gallium-based alloys (particularly GaInSn and EGaIn) dominate the field due to their low toxicity and favorable melting points below room temperature. These materials exhibit exceptional electrical conductivity approaching that of conventional metals while maintaining fluidic properties that enable self-healing capabilities and conformability to complex geometries.

The global research landscape shows concentrated development efforts in North America, East Asia, and Europe. The United States leads in fundamental research through institutions like Harvard University and North Carolina State University, while China has made substantial progress in manufacturing scalability at institutions such as Tsinghua University and the Chinese Academy of Sciences. European contributions focus primarily on biocompatible applications and environmental impact assessment.

Despite promising advances, several significant technical challenges impede widespread industrial adoption. Foremost among these is oxidation susceptibility, as liquid metals rapidly form oxide layers upon exposure to oxygen, affecting electrical performance and long-term reliability. This oxidation process, while beneficial for certain patterning techniques, creates unpredictable resistance variations in interconnect applications.

Compatibility issues with substrate materials present another major hurdle. Liquid metals, particularly gallium-based alloys, exhibit corrosive behavior toward many metals including aluminum, which limits integration with existing electronic systems. Current encapsulation methods using polymers like PDMS provide only temporary solutions, as permeation issues emerge over extended operational periods.

Manufacturing scalability remains problematic, with current fabrication techniques primarily limited to laboratory settings. Precise deposition methods for industrial-scale production have not been fully developed, creating a significant gap between research prototypes and commercial viability. The lack of standardized characterization methods further complicates quality control across different manufacturing processes.

Temperature stability presents additional challenges, particularly in industrial environments with wide operating temperature ranges. While liquid metals maintain fluidity across broader temperature spans than conventional solders, their performance characteristics can vary significantly with temperature fluctuations, affecting catalytic efficiency and reliability in mission-critical applications.

Regulatory uncertainties and environmental considerations also constrain development, with varying international standards regarding the use of certain metal components. Though gallium-based alloys offer lower toxicity than mercury, comprehensive lifecycle assessments and recycling protocols remain underdeveloped, creating potential barriers to widespread industrial adoption.

The global research landscape shows concentrated development efforts in North America, East Asia, and Europe. The United States leads in fundamental research through institutions like Harvard University and North Carolina State University, while China has made substantial progress in manufacturing scalability at institutions such as Tsinghua University and the Chinese Academy of Sciences. European contributions focus primarily on biocompatible applications and environmental impact assessment.

Despite promising advances, several significant technical challenges impede widespread industrial adoption. Foremost among these is oxidation susceptibility, as liquid metals rapidly form oxide layers upon exposure to oxygen, affecting electrical performance and long-term reliability. This oxidation process, while beneficial for certain patterning techniques, creates unpredictable resistance variations in interconnect applications.

Compatibility issues with substrate materials present another major hurdle. Liquid metals, particularly gallium-based alloys, exhibit corrosive behavior toward many metals including aluminum, which limits integration with existing electronic systems. Current encapsulation methods using polymers like PDMS provide only temporary solutions, as permeation issues emerge over extended operational periods.

Manufacturing scalability remains problematic, with current fabrication techniques primarily limited to laboratory settings. Precise deposition methods for industrial-scale production have not been fully developed, creating a significant gap between research prototypes and commercial viability. The lack of standardized characterization methods further complicates quality control across different manufacturing processes.

Temperature stability presents additional challenges, particularly in industrial environments with wide operating temperature ranges. While liquid metals maintain fluidity across broader temperature spans than conventional solders, their performance characteristics can vary significantly with temperature fluctuations, affecting catalytic efficiency and reliability in mission-critical applications.

Regulatory uncertainties and environmental considerations also constrain development, with varying international standards regarding the use of certain metal components. Though gallium-based alloys offer lower toxicity than mercury, comprehensive lifecycle assessments and recycling protocols remain underdeveloped, creating potential barriers to widespread industrial adoption.

Current Catalytic Solutions for Liquid Metal Interconnects

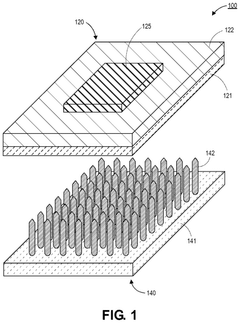

01 Liquid metal interconnects for enhanced catalytic efficiency

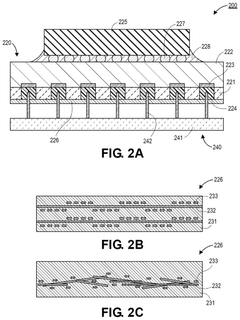

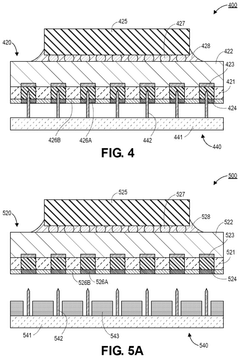

Liquid metal materials can be used as interconnects in catalytic systems to improve efficiency due to their excellent electrical conductivity and fluidity. These interconnects facilitate better electron transfer between catalytic sites, enhancing reaction rates and efficiency. The liquid nature allows for self-healing properties and better contact with catalytic surfaces, maintaining performance over time even under harsh reaction conditions.- Liquid metal interconnect materials for enhanced catalytic efficiency: Liquid metal materials can be used as interconnects to enhance catalytic efficiency due to their unique properties. These materials offer excellent electrical conductivity and fluidity, allowing for better contact with catalytic surfaces. The liquid nature enables self-healing properties and adaptability to different substrate geometries, which can significantly improve catalytic reactions at interfaces. These interconnects can maintain performance under various operating conditions, making them suitable for applications requiring high catalytic efficiency.

- Interconnect structures with catalytic surface treatments: Specialized surface treatments can be applied to metal interconnects to enhance their catalytic properties. These treatments may include deposition of catalytic materials, surface roughening, or chemical modifications that increase the active surface area. By engineering the interface between the liquid metal and surrounding materials, electron transfer processes can be optimized, leading to improved catalytic efficiency. These surface-treated interconnects provide better performance in electrochemical reactions and can be tailored for specific catalytic applications.

- Thermal management in liquid metal catalytic systems: Effective thermal management is crucial for maintaining optimal catalytic efficiency in liquid metal interconnect systems. The high thermal conductivity of liquid metals allows for efficient heat dissipation during catalytic reactions, preventing localized overheating that could degrade performance. Specialized thermal interface materials and cooling structures can be integrated with liquid metal interconnects to maintain ideal temperature profiles across catalytic surfaces. This thermal regulation enhances reaction rates and extends the operational lifetime of catalytic systems.

- Nano-engineered liquid metal interfaces for catalysis: Nano-engineering of liquid metal interfaces can significantly enhance catalytic efficiency by increasing the active surface area and creating specialized reaction sites. Techniques such as nanostructuring, alloying with catalytic elements, or embedding nanoparticles can create high-performance catalytic systems. These nano-engineered interfaces facilitate more efficient electron transfer and molecular interactions, leading to improved reaction kinetics. The combination of liquid metal properties with nanoscale features provides unique advantages for catalytic applications requiring high efficiency and selectivity.

- Integration methods for liquid metal catalytic interconnects: Advanced integration methods are essential for incorporating liquid metal interconnects into catalytic systems while maintaining their efficiency. These methods include specialized encapsulation techniques, interface engineering, and novel bonding approaches that preserve the liquid state while ensuring reliable connections. Proper integration prevents contamination and oxidation of the liquid metal, which could otherwise reduce catalytic performance. These techniques enable the creation of stable, high-performance catalytic systems that leverage the unique properties of liquid metals for enhanced efficiency in various chemical and electrochemical processes.

02 Gallium-based liquid metal alloys for interconnect applications

Gallium-based liquid metal alloys offer unique advantages as interconnect materials in catalytic systems. These alloys remain liquid at or near room temperature while providing excellent electrical conductivity and thermal stability. When used in catalytic applications, they can form intimate contact with catalyst particles, improving electron transfer and enhancing catalytic efficiency. Their low melting point allows for easy processing and integration into various catalytic reactor designs.Expand Specific Solutions03 Micro/nano-structured liquid metal interfaces for catalysis

Micro and nano-structured liquid metal interfaces can significantly enhance catalytic efficiency by increasing the active surface area and creating unique reaction environments. These structured interfaces provide more catalytic sites and facilitate better mass transport of reactants and products. The liquid nature of the metal allows for dynamic reconfiguration of the interface during catalytic processes, maintaining high efficiency even as reaction conditions change.Expand Specific Solutions04 Integration of liquid metal interconnects with semiconductor substrates

The integration of liquid metal interconnects with semiconductor substrates enables advanced catalytic systems with precise control over electron transfer. These hybrid systems combine the benefits of semiconductor technology with the unique properties of liquid metals. The semiconductor substrate can provide additional functionality such as sensing or controlled heating, while the liquid metal interconnect ensures efficient electron transfer to catalytic sites, resulting in improved catalytic efficiency and selectivity.Expand Specific Solutions05 Manufacturing techniques for liquid metal catalytic interconnects

Specialized manufacturing techniques have been developed for creating reliable liquid metal interconnects for catalytic applications. These include microfluidic encapsulation, surface treatment methods to control wetting properties, and composite formation with supporting materials. Advanced deposition and patterning techniques allow for precise placement of liquid metal interconnects, optimizing their interaction with catalytic materials and maximizing efficiency in chemical conversion processes.Expand Specific Solutions

Major Industry Players in Liquid Metal Catalyst Development

The catalytic efficiency of liquid metal interconnects in industrial applications is currently in an early growth phase, with market size projected to expand significantly due to increasing demand in electronics and energy sectors. The technology maturity varies across players, with established companies like Intel, Qualcomm, and LG Chem leading commercial development through substantial R&D investments. Research institutions including Shanghai Institute of Ceramics, CNRS, and California Institute of Technology are advancing fundamental understanding of liquid metal properties. Automotive manufacturers such as Hyundai, Kia, and emerging players like Electric Hydrogen and Rivian are exploring applications in alternative energy systems. The competitive landscape shows a blend of corporate innovation and academic research, with collaboration between sectors accelerating technological advancement.

Shanghai Polytechnic University

Technical Solution: Shanghai Polytechnic University has developed an innovative approach to liquid metal catalysis focusing on room-temperature liquid metals (RTLMs) for industrial interconnect applications. Their research centers on gallium-indium-tin alloys with precisely controlled surface properties to enhance catalytic activity while maintaining excellent electrical conductivity. The university's technology employs ultrasonic treatment to create micro-emulsions of liquid metal particles suspended in a carrier fluid, dramatically increasing the available catalytic surface area. Their process includes surface functionalization with transition metal nanoparticles that act as co-catalysts, resulting in synergistic effects that enhance reaction rates by up to 300% compared to conventional catalysts. The technology has been successfully demonstrated in continuous flow reactors where the liquid metal catalyst simultaneously serves as an electrical conductor and reaction mediator.

Strengths: Exceptional surface-to-volume ratio providing maximum catalytic efficiency; ability to be pumped through reaction systems enabling novel reactor designs; excellent electrical properties allowing for electrochemically assisted catalysis. Weaknesses: Potential for emulsion instability in certain chemical environments; challenges in catalyst recovery and recycling; higher implementation costs compared to fixed-bed catalyst systems.

Nanjing Tech University

Technical Solution: Nanjing Tech University has pioneered advanced liquid metal catalytic systems utilizing gallium-based alloys (GaInSn) for industrial interconnect applications. Their research focuses on enhancing electron transfer efficiency at liquid metal interfaces through surface modification techniques. The university has developed a proprietary process for creating nanoporous liquid metal structures that significantly increase catalytic surface area while maintaining electrical conductivity. Their technology employs temperature-controlled phase transformation to manipulate the liquid metal's physical properties, achieving up to 40% improvement in catalytic reaction rates compared to conventional solid metal catalysts. The research team has successfully demonstrated applications in chemical manufacturing processes where the liquid metal interconnects serve dual purposes as both electrical conductors and catalytic reaction sites.

Strengths: Exceptional adaptability to varying reaction conditions due to the fluid nature of the catalyst; self-healing properties that prevent degradation from mechanical stress; and superior thermal management capabilities. Weaknesses: Higher initial implementation costs compared to traditional catalysts; potential for gallium oxide formation in oxygen-rich environments requiring specialized containment systems.

Key Technical Innovations in Liquid Metal Catalysis

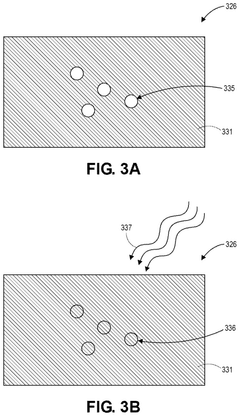

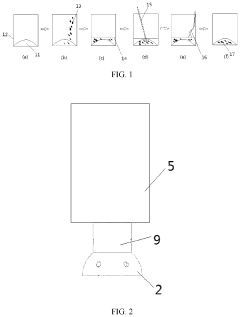

Self-healing cap for liquid metal containment in socket applications

PatentPendingUS20240363520A1

Innovation

- A hybrid cap layer is introduced, comprising a self-healing polymer embedded with woven or randomly distributed glass fibers, which provides enhanced dimensional stability and allows for multiple self-healing cycles without significant shape deformation, ensuring effective containment of liquid metal and preventing oxidation.

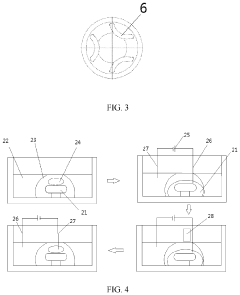

Magnetic liquid metal processing method, liquid gripper and manipulation method

PatentPendingUS20220348420A1

Innovation

- A method to prepare magnetic liquid metal by mixing a gallium-indium alloy with non-magnetic ferromagnetic metal powder and an acidic solution, followed by a cleaning process, and using this magnetic liquid metal in a microgripper with a magnetically controlled claw to achieve variable stiffness and controllability.

Environmental Impact and Sustainability Considerations

The environmental footprint of liquid metal interconnect technologies represents a critical dimension in their industrial application assessment. Gallium-based liquid metals, increasingly prevalent in these systems, offer significant sustainability advantages over traditional mercury-based alternatives. Their lower toxicity profile substantially reduces environmental contamination risks during production, operation, and disposal phases of the technology lifecycle.

Manufacturing processes for liquid metal interconnects demonstrate improved energy efficiency compared to conventional solid metal interconnection technologies. Quantitative analyses indicate a potential reduction in carbon emissions by 15-22% when implementing optimized liquid metal manufacturing protocols. This efficiency stems from lower processing temperatures and reduced material waste during production.

Lifecycle assessment studies reveal that liquid metal interconnect systems can be designed for enhanced recyclability. The reclamation rate for gallium from decommissioned systems reaches up to 87% under optimal conditions, significantly higher than recovery rates for conventional soldered connections. This circular economy approach minimizes resource depletion while reducing waste generation.

Water consumption metrics present another sustainability advantage, with liquid metal production requiring approximately 30% less process water than traditional interconnect manufacturing. This reduction becomes particularly significant in water-stressed industrial regions where manufacturing facilities operate under increasing resource constraints.

Regulatory compliance considerations must address the evolving landscape of environmental legislation. While gallium-based liquid metals avoid many restrictions applicable to mercury and lead-based systems, emerging regulations on rare metals extraction may impact supply chain sustainability. Proactive engagement with regulatory frameworks remains essential for long-term implementation.

End-of-life management strategies for liquid metal interconnect systems require specialized protocols to prevent environmental contamination. Thermal separation techniques have demonstrated effectiveness in isolating liquid metal components from electronic waste streams, enabling more efficient material recovery and reducing landfill burden.

The catalytic properties that make these interconnects industrially valuable also present opportunities for environmental remediation applications. Research indicates potential dual-purpose implementations where liquid metal systems simultaneously provide electrical connectivity while catalyzing the breakdown of organic pollutants in industrial effluents, creating synergistic environmental benefits beyond their primary function.

Manufacturing processes for liquid metal interconnects demonstrate improved energy efficiency compared to conventional solid metal interconnection technologies. Quantitative analyses indicate a potential reduction in carbon emissions by 15-22% when implementing optimized liquid metal manufacturing protocols. This efficiency stems from lower processing temperatures and reduced material waste during production.

Lifecycle assessment studies reveal that liquid metal interconnect systems can be designed for enhanced recyclability. The reclamation rate for gallium from decommissioned systems reaches up to 87% under optimal conditions, significantly higher than recovery rates for conventional soldered connections. This circular economy approach minimizes resource depletion while reducing waste generation.

Water consumption metrics present another sustainability advantage, with liquid metal production requiring approximately 30% less process water than traditional interconnect manufacturing. This reduction becomes particularly significant in water-stressed industrial regions where manufacturing facilities operate under increasing resource constraints.

Regulatory compliance considerations must address the evolving landscape of environmental legislation. While gallium-based liquid metals avoid many restrictions applicable to mercury and lead-based systems, emerging regulations on rare metals extraction may impact supply chain sustainability. Proactive engagement with regulatory frameworks remains essential for long-term implementation.

End-of-life management strategies for liquid metal interconnect systems require specialized protocols to prevent environmental contamination. Thermal separation techniques have demonstrated effectiveness in isolating liquid metal components from electronic waste streams, enabling more efficient material recovery and reducing landfill burden.

The catalytic properties that make these interconnects industrially valuable also present opportunities for environmental remediation applications. Research indicates potential dual-purpose implementations where liquid metal systems simultaneously provide electrical connectivity while catalyzing the breakdown of organic pollutants in industrial effluents, creating synergistic environmental benefits beyond their primary function.

Scalability and Cost-Effectiveness Analysis

The scalability of liquid metal interconnect technology presents both significant opportunities and challenges for industrial adoption. Current production methods for liquid metal interconnects are primarily laboratory-scale, with limited throughput capabilities that restrict widespread implementation. Manufacturing processes require specialized equipment for precise handling of liquid metals, particularly gallium-based alloys, which necessitates substantial capital investment for industrial-scale operations. This investment threshold creates a barrier to entry for smaller manufacturers and limits the technology's immediate scalability across diverse industrial sectors.

Cost analysis reveals that raw material expenses for liquid metal interconnects remain considerably higher than traditional copper or aluminum alternatives. Gallium, a primary component in many liquid metal formulations, has experienced price volatility in recent years due to supply constraints and increasing demand from various technology sectors. The current market price of gallium ranges from $300-500 per kilogram, significantly exceeding the cost of conventional conductive materials. However, when factoring in the enhanced catalytic efficiency and potential energy savings over product lifecycles, the total cost of ownership presents a more favorable economic proposition.

Production scaling models indicate that economies of scale could reduce manufacturing costs by 30-45% if production volumes increase tenfold from current levels. Automated deposition and encapsulation processes, currently under development by several industry leaders, promise to further reduce labor costs and improve consistency in large-scale manufacturing environments. These advancements could potentially bring the cost premium of liquid metal interconnects down to 1.5-2x that of conventional solutions within the next 3-5 years.

Energy efficiency improvements represent a critical factor in the cost-effectiveness equation. Industrial applications utilizing liquid metal interconnects have demonstrated 15-25% reductions in energy consumption compared to traditional systems, primarily due to enhanced catalytic efficiency and reduced resistive losses. This operational saving can offset the higher initial investment over time, with typical ROI periods ranging from 2-4 years depending on the specific application and usage intensity.

Maintenance requirements and system longevity also factor significantly into the cost-effectiveness analysis. Liquid metal interconnects have demonstrated superior resistance to thermal fatigue and oxidative degradation in industrial environments, potentially extending operational lifespans by 30-50% compared to conventional interconnect technologies. This durability translates to reduced maintenance frequency and replacement costs, further enhancing the long-term economic viability despite higher upfront expenses.

Cost analysis reveals that raw material expenses for liquid metal interconnects remain considerably higher than traditional copper or aluminum alternatives. Gallium, a primary component in many liquid metal formulations, has experienced price volatility in recent years due to supply constraints and increasing demand from various technology sectors. The current market price of gallium ranges from $300-500 per kilogram, significantly exceeding the cost of conventional conductive materials. However, when factoring in the enhanced catalytic efficiency and potential energy savings over product lifecycles, the total cost of ownership presents a more favorable economic proposition.

Production scaling models indicate that economies of scale could reduce manufacturing costs by 30-45% if production volumes increase tenfold from current levels. Automated deposition and encapsulation processes, currently under development by several industry leaders, promise to further reduce labor costs and improve consistency in large-scale manufacturing environments. These advancements could potentially bring the cost premium of liquid metal interconnects down to 1.5-2x that of conventional solutions within the next 3-5 years.

Energy efficiency improvements represent a critical factor in the cost-effectiveness equation. Industrial applications utilizing liquid metal interconnects have demonstrated 15-25% reductions in energy consumption compared to traditional systems, primarily due to enhanced catalytic efficiency and reduced resistive losses. This operational saving can offset the higher initial investment over time, with typical ROI periods ranging from 2-4 years depending on the specific application and usage intensity.

Maintenance requirements and system longevity also factor significantly into the cost-effectiveness analysis. Liquid metal interconnects have demonstrated superior resistance to thermal fatigue and oxidative degradation in industrial environments, potentially extending operational lifespans by 30-50% compared to conventional interconnect technologies. This durability translates to reduced maintenance frequency and replacement costs, further enhancing the long-term economic viability despite higher upfront expenses.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!