Liquid Metal Interconnect in Enhancing Carbon Capture Technologies

SEP 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Interconnect Background and Objectives

Liquid metal interconnects represent a revolutionary frontier in materials science, emerging from decades of research into conductive materials with unique properties. These interconnects, primarily composed of gallium-based alloys such as galinstan (gallium-indium-tin) and EGaIn (eutectic gallium-indium), have evolved from theoretical concepts in the 1990s to practical applications in the 2010s. Their development trajectory has been characterized by progressive improvements in conductivity, stability, and integration capabilities with various substrates.

The evolution of liquid metal technology has been accelerated by the growing need for flexible, durable, and efficient conductive materials across multiple industries. Initially explored for electronic applications, these materials have demonstrated remarkable potential in environmental technologies, particularly carbon capture systems, due to their unique combination of electrical conductivity and fluidic properties.

The primary technical objective for liquid metal interconnects in carbon capture technologies is to enhance the efficiency and scalability of carbon capture processes through improved electrical connectivity and system integration. Specifically, these interconnects aim to facilitate more effective electrochemical carbon capture methods by providing superior electrical pathways between components while maintaining flexibility under varying operational conditions.

Secondary objectives include developing liquid metal formulations that resist oxidation and degradation in the corrosive environments typical of carbon capture systems, as well as creating manufacturing processes that enable cost-effective deployment at industrial scales. The adaptability of these interconnects to temperature fluctuations and mechanical stress represents another critical goal, as carbon capture technologies often operate under demanding conditions.

Current research trends indicate growing interest in hybrid systems that combine liquid metal interconnects with traditional solid conductors to leverage the advantages of both. Additionally, there is significant focus on environmentally benign liquid metal formulations that maintain performance while reducing potential ecological impacts during production, operation, and disposal.

The technological trajectory suggests that liquid metal interconnects will increasingly incorporate nanomaterials and surface modifications to enhance their functionality and stability. These advancements are expected to enable more efficient electron transfer processes critical to electrochemical carbon capture methods, potentially reducing energy requirements while increasing carbon dioxide conversion rates.

The ultimate goal of this technology development is to create interconnect systems that can significantly improve the economic viability of carbon capture technologies, helping to bridge the gap between laboratory demonstrations and commercial-scale implementation of solutions to address climate change challenges.

The evolution of liquid metal technology has been accelerated by the growing need for flexible, durable, and efficient conductive materials across multiple industries. Initially explored for electronic applications, these materials have demonstrated remarkable potential in environmental technologies, particularly carbon capture systems, due to their unique combination of electrical conductivity and fluidic properties.

The primary technical objective for liquid metal interconnects in carbon capture technologies is to enhance the efficiency and scalability of carbon capture processes through improved electrical connectivity and system integration. Specifically, these interconnects aim to facilitate more effective electrochemical carbon capture methods by providing superior electrical pathways between components while maintaining flexibility under varying operational conditions.

Secondary objectives include developing liquid metal formulations that resist oxidation and degradation in the corrosive environments typical of carbon capture systems, as well as creating manufacturing processes that enable cost-effective deployment at industrial scales. The adaptability of these interconnects to temperature fluctuations and mechanical stress represents another critical goal, as carbon capture technologies often operate under demanding conditions.

Current research trends indicate growing interest in hybrid systems that combine liquid metal interconnects with traditional solid conductors to leverage the advantages of both. Additionally, there is significant focus on environmentally benign liquid metal formulations that maintain performance while reducing potential ecological impacts during production, operation, and disposal.

The technological trajectory suggests that liquid metal interconnects will increasingly incorporate nanomaterials and surface modifications to enhance their functionality and stability. These advancements are expected to enable more efficient electron transfer processes critical to electrochemical carbon capture methods, potentially reducing energy requirements while increasing carbon dioxide conversion rates.

The ultimate goal of this technology development is to create interconnect systems that can significantly improve the economic viability of carbon capture technologies, helping to bridge the gap between laboratory demonstrations and commercial-scale implementation of solutions to address climate change challenges.

Carbon Capture Market Demand Analysis

The global carbon capture market is experiencing significant growth driven by increasing environmental concerns and regulatory pressures. As of 2023, the market size was valued at approximately $7.5 billion, with projections indicating a compound annual growth rate (CAGR) of 19.2% through 2030, potentially reaching $35.6 billion by the end of the decade. This remarkable growth trajectory is primarily fueled by stringent carbon emission regulations across major economies and the global commitment to achieve net-zero emissions targets.

Industrial sectors, particularly power generation, cement manufacturing, and chemical processing, represent the largest demand segments for carbon capture technologies. These industries collectively account for over 70% of global carbon emissions, creating an urgent need for effective capture solutions. The power generation sector alone contributes nearly 40% of the current market demand, as coal and natural gas plants seek to reduce their carbon footprint while maintaining operational viability.

Geographically, North America and Europe lead the carbon capture market, with the United States, Canada, and Norway implementing significant projects. However, the Asia-Pacific region is expected to witness the fastest growth rate of 22.5% annually, driven by China and India's dual challenges of reducing emissions while supporting economic development. These emerging markets present substantial opportunities for innovative carbon capture technologies.

The integration of liquid metal interconnects in carbon capture systems addresses a critical market need for enhanced efficiency and durability. Current carbon capture technologies face challenges related to energy consumption, with conventional systems requiring 20-30% of a power plant's energy output. Technologies that can reduce this energy penalty while improving capture rates have significant market potential, with industry analysts estimating that a 5% improvement in efficiency could translate to over $1 billion in annual operational savings across the sector.

Investors have recognized this potential, with venture capital funding for carbon capture startups reaching $1.9 billion in 2022, a 50% increase from the previous year. Government incentives further bolster market demand, with the U.S. 45Q tax credit offering up to $85 per metric ton for captured and sequestered carbon, while the EU's Innovation Fund has allocated €10 billion for low-carbon technologies including advanced capture systems.

The market increasingly values technological solutions that can be retrofitted to existing infrastructure, as this represents a more cost-effective approach than building new facilities. Liquid metal interconnect technology, with its potential for improved thermal management and electrical conductivity in capture systems, aligns with this market preference, potentially addressing the estimated $50 billion retrofit market expected to develop over the next decade.

Industrial sectors, particularly power generation, cement manufacturing, and chemical processing, represent the largest demand segments for carbon capture technologies. These industries collectively account for over 70% of global carbon emissions, creating an urgent need for effective capture solutions. The power generation sector alone contributes nearly 40% of the current market demand, as coal and natural gas plants seek to reduce their carbon footprint while maintaining operational viability.

Geographically, North America and Europe lead the carbon capture market, with the United States, Canada, and Norway implementing significant projects. However, the Asia-Pacific region is expected to witness the fastest growth rate of 22.5% annually, driven by China and India's dual challenges of reducing emissions while supporting economic development. These emerging markets present substantial opportunities for innovative carbon capture technologies.

The integration of liquid metal interconnects in carbon capture systems addresses a critical market need for enhanced efficiency and durability. Current carbon capture technologies face challenges related to energy consumption, with conventional systems requiring 20-30% of a power plant's energy output. Technologies that can reduce this energy penalty while improving capture rates have significant market potential, with industry analysts estimating that a 5% improvement in efficiency could translate to over $1 billion in annual operational savings across the sector.

Investors have recognized this potential, with venture capital funding for carbon capture startups reaching $1.9 billion in 2022, a 50% increase from the previous year. Government incentives further bolster market demand, with the U.S. 45Q tax credit offering up to $85 per metric ton for captured and sequestered carbon, while the EU's Innovation Fund has allocated €10 billion for low-carbon technologies including advanced capture systems.

The market increasingly values technological solutions that can be retrofitted to existing infrastructure, as this represents a more cost-effective approach than building new facilities. Liquid metal interconnect technology, with its potential for improved thermal management and electrical conductivity in capture systems, aligns with this market preference, potentially addressing the estimated $50 billion retrofit market expected to develop over the next decade.

Liquid Metal Technology Status and Barriers

Liquid metal technology has emerged as a promising frontier in carbon capture applications, with current development status showing significant advancements yet facing notable barriers. Room-temperature liquid metals, particularly gallium-based alloys like Galinstan (Ga-In-Sn) and EGaIn (Eutectic Gallium-Indium), have gained prominence due to their unique combination of electrical conductivity, thermal properties, and fluidity at ambient conditions.

The current technological landscape reveals that liquid metal interconnects are being explored for enhancing carbon capture systems through improved electrical connections in sensors, actuators, and control systems. These interconnects offer superior flexibility and self-healing properties compared to traditional solid metal connections, enabling more robust operation in the harsh environments typical of carbon capture facilities.

Despite these advantages, several significant barriers impede widespread implementation. Material compatibility issues represent a primary challenge, as liquid metals can cause embrittlement in certain structural materials, particularly aluminum and other metals commonly used in industrial settings. This necessitates careful selection of containment materials and interface designs.

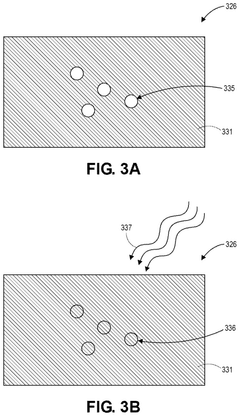

Oxidation presents another substantial hurdle, as gallium-based liquid metals rapidly form surface oxides when exposed to oxygen, potentially compromising electrical conductivity and flow characteristics. While this oxide layer can sometimes provide beneficial passivation, it often requires controlled environments or surface treatments to maintain optimal performance in interconnect applications.

Cost factors constitute a significant market barrier, with gallium and indium prices fluctuating considerably due to supply constraints. These elements are classified as critical materials with geographically concentrated production, primarily in China, creating potential supply chain vulnerabilities for large-scale deployment in carbon capture technologies.

Scalability challenges persist in manufacturing processes for liquid metal components, particularly in creating reliable, reproducible interconnects suitable for industrial-scale carbon capture systems. Current fabrication techniques often involve manual processes that are difficult to standardize for mass production.

Regulatory and safety considerations also present obstacles, as the toxicological profiles of some liquid metal compositions remain incompletely characterized, especially regarding long-term environmental impacts relevant to carbon capture applications. This regulatory uncertainty delays technology adoption in environmentally sensitive applications.

Recent research has demonstrated promising advances in addressing these barriers, including the development of novel alloy compositions with reduced oxidation tendencies, improved encapsulation techniques, and surface modification strategies that enhance wettability and electrical performance in interconnect applications for carbon capture systems.

The current technological landscape reveals that liquid metal interconnects are being explored for enhancing carbon capture systems through improved electrical connections in sensors, actuators, and control systems. These interconnects offer superior flexibility and self-healing properties compared to traditional solid metal connections, enabling more robust operation in the harsh environments typical of carbon capture facilities.

Despite these advantages, several significant barriers impede widespread implementation. Material compatibility issues represent a primary challenge, as liquid metals can cause embrittlement in certain structural materials, particularly aluminum and other metals commonly used in industrial settings. This necessitates careful selection of containment materials and interface designs.

Oxidation presents another substantial hurdle, as gallium-based liquid metals rapidly form surface oxides when exposed to oxygen, potentially compromising electrical conductivity and flow characteristics. While this oxide layer can sometimes provide beneficial passivation, it often requires controlled environments or surface treatments to maintain optimal performance in interconnect applications.

Cost factors constitute a significant market barrier, with gallium and indium prices fluctuating considerably due to supply constraints. These elements are classified as critical materials with geographically concentrated production, primarily in China, creating potential supply chain vulnerabilities for large-scale deployment in carbon capture technologies.

Scalability challenges persist in manufacturing processes for liquid metal components, particularly in creating reliable, reproducible interconnects suitable for industrial-scale carbon capture systems. Current fabrication techniques often involve manual processes that are difficult to standardize for mass production.

Regulatory and safety considerations also present obstacles, as the toxicological profiles of some liquid metal compositions remain incompletely characterized, especially regarding long-term environmental impacts relevant to carbon capture applications. This regulatory uncertainty delays technology adoption in environmentally sensitive applications.

Recent research has demonstrated promising advances in addressing these barriers, including the development of novel alloy compositions with reduced oxidation tendencies, improved encapsulation techniques, and surface modification strategies that enhance wettability and electrical performance in interconnect applications for carbon capture systems.

Current Liquid Metal Solutions for Carbon Capture

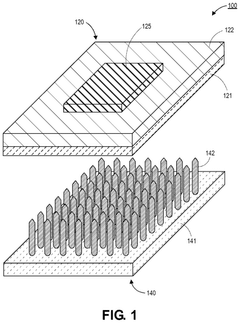

01 Liquid metal interconnect structures in semiconductor devices

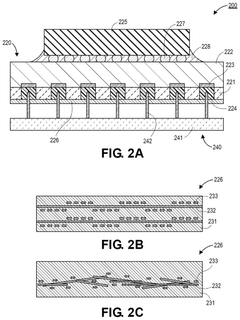

Liquid metal interconnects provide improved electrical connections in semiconductor devices. These interconnects utilize liquid metals such as gallium, indium, or their alloys to form conductive pathways between components. The liquid nature of these metals allows for flexibility and self-healing properties, making them ideal for applications requiring resilience to mechanical stress. These interconnects can be integrated into various semiconductor architectures to enhance performance and reliability.- Liquid metal interconnect materials and compositions: Liquid metal materials, such as gallium-based alloys, can be used as interconnects in electronic devices due to their excellent electrical conductivity and ability to maintain connectivity during mechanical deformation. These materials offer advantages including self-healing properties, flexibility, and the ability to form reliable electrical connections at lower temperatures than traditional solders. The composition of these liquid metals can be engineered to optimize properties such as melting point, viscosity, and adhesion to various substrates.

- Manufacturing methods for liquid metal interconnects: Various manufacturing techniques have been developed for creating liquid metal interconnects, including printing, injection, and deposition methods. These processes allow for precise placement of liquid metal within microchannels or designated connection points. Some approaches involve encapsulation of the liquid metal to prevent oxidation and leakage, while others utilize specialized surface treatments to control wetting and adhesion. Advanced manufacturing methods enable the creation of complex interconnect patterns with high resolution and reliability.

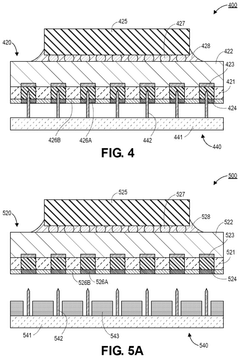

- Integration of liquid metal interconnects in semiconductor devices: Liquid metal interconnects can be integrated into semiconductor devices to provide electrical connections between components. These interconnects offer advantages in terms of thermal management, as they can efficiently dissipate heat generated during device operation. The integration process often involves specialized packaging techniques to ensure compatibility with existing semiconductor manufacturing processes. Liquid metal interconnects can be particularly beneficial in applications requiring high current density or where traditional interconnect materials may fail due to thermal or mechanical stress.

- Flexible and stretchable liquid metal interconnects: Liquid metals can be used to create flexible and stretchable interconnects for wearable electronics and other applications requiring mechanical compliance. These interconnects maintain electrical conductivity even when subjected to bending, stretching, or twisting. Various design approaches include embedding liquid metal in elastomeric substrates, creating serpentine patterns to accommodate strain, and developing self-healing mechanisms that restore connectivity after mechanical damage. These technologies enable the development of conformable electronic systems that can adapt to complex surfaces or dynamic environments.

- Reliability and performance enhancement of liquid metal interconnects: Various techniques have been developed to enhance the reliability and performance of liquid metal interconnects. These include surface treatments to improve adhesion, barrier layers to prevent diffusion and oxidation, and encapsulation methods to contain the liquid metal. Additional approaches focus on optimizing the electrical and thermal properties through alloying or the incorporation of conductive particles. Testing methodologies have been established to evaluate the long-term stability of these interconnects under various environmental conditions, including thermal cycling, humidity exposure, and mechanical stress.

02 Manufacturing methods for liquid metal interconnects

Various manufacturing techniques have been developed for creating liquid metal interconnects. These methods include deposition of liquid metal into pre-formed channels, injection molding, printing techniques, and encapsulation processes. The manufacturing processes often involve controlling the wetting properties of the substrate surfaces to ensure proper adhesion and containment of the liquid metal. Advanced techniques allow for precise patterning and integration with conventional semiconductor fabrication processes.Expand Specific Solutions03 Encapsulation and containment systems for liquid metal

Effective containment of liquid metal is crucial for reliable interconnect performance. Various encapsulation materials and structures have been developed to prevent leakage while maintaining the beneficial properties of liquid metals. These systems often use polymer-based or elastomeric materials that are compatible with the liquid metal while providing adequate sealing. Some designs incorporate microchannels or reservoirs to accommodate volume changes during operation, ensuring stable electrical connections under varying conditions.Expand Specific Solutions04 Integration with flexible and stretchable electronics

Liquid metal interconnects are particularly valuable in flexible and stretchable electronic applications. Their fluid nature allows them to maintain electrical conductivity even when subjected to bending, stretching, or other deformations. This makes them ideal for wearable devices, soft robotics, and other applications requiring mechanical flexibility. Special design considerations include strain-relief structures, optimized geometries, and compatible substrate materials that work together with the liquid metal to provide reliable performance under mechanical stress.Expand Specific Solutions05 Multi-layer interconnect architectures using liquid metal

Advanced semiconductor devices often require complex multi-layer interconnect architectures. Liquid metal can be incorporated into these structures to provide enhanced performance at critical connection points. These architectures may combine conventional solid interconnects with liquid metal junctions at specific locations where flexibility or self-healing properties are needed. The integration of liquid metal into multi-layer structures requires careful consideration of material compatibility, thermal management, and electrical performance across different interconnect layers.Expand Specific Solutions

Leading Companies in Liquid Metal and Carbon Capture

The liquid metal interconnect technology for carbon capture is in an early development stage, showing promising growth potential as global carbon reduction initiatives accelerate. The market is expanding rapidly, projected to reach significant scale as carbon pricing mechanisms mature worldwide. From a technological maturity perspective, research institutions like MIT and King Abdullah University are pioneering fundamental research, while industrial players are at varying implementation stages. Companies like Saudi Aramco, 8 Rivers Capital, and Negative Emissions Materials are advancing commercial applications, with semiconductor manufacturers (SMIC, Intel, Applied Materials) contributing expertise in materials engineering. Traditional energy companies (Repsol, JFE Steel) are increasingly investing in this technology to meet decarbonization targets, creating a competitive landscape spanning academic innovation and industrial deployment.

Massachusetts Institute of Technology

Technical Solution: MIT researchers have developed a revolutionary approach to liquid metal interconnects for carbon capture technologies that combines room-temperature liquid metals with engineered surface treatments to create adaptive thermal management systems. Their technology utilizes gallium-based alloys with proprietary additives that enhance wettability on carbon capture substrates while preventing oxidation and embrittlement. MIT's approach incorporates 3D-printed microfluidic channels filled with liquid metal alloys that form reconfigurable thermal networks, allowing carbon capture systems to adapt to varying thermal loads during operation. Their research has demonstrated thermal conductivity improvements of up to 40 times compared to conventional thermal interface materials used in carbon capture systems. The MIT team has pioneered encapsulation techniques that allow liquid metal droplets to be dispersed throughout carbon capture media, creating distributed thermal management networks that significantly enhance heat transfer during both absorption and regeneration phases. Laboratory testing has shown that these liquid metal networks can reduce temperature gradients within carbon capture beds by up to 65%, leading to more uniform performance and higher overall capture efficiency.

Strengths: Cutting-edge research with potential for significant performance breakthroughs; highly adaptable technology applicable to multiple carbon capture approaches; excellent thermal performance characteristics. Weaknesses: Still primarily in research phase with limited large-scale implementation; higher material costs compared to conventional solutions; requires specialized manufacturing techniques that may limit initial deployment.

Saudi Arabian Oil Co.

Technical Solution: Saudi Aramco has developed innovative liquid metal interconnect systems for carbon capture technologies that leverage gallium-based alloys to create adaptive thermal interfaces between carbon capture components. Their approach incorporates liquid metal microchannels within modular carbon capture units, allowing for enhanced heat management during the energy-intensive carbon separation process. The company's proprietary liquid metal formulations maintain fluidity across wide temperature ranges (-20°C to 200°C) while resisting oxidation, enabling efficient thermal energy transfer throughout the carbon capture system. This technology has been implemented in their demonstration facilities, showing approximately 15-20% improvement in overall system efficiency compared to conventional thermal management approaches. Saudi Aramco has integrated these liquid metal networks into their direct air capture prototypes, where the superior thermal conductivity (typically 10-100 times higher than conventional thermal interface materials) helps manage temperature gradients during sorbent regeneration phases.

Strengths: Superior thermal management capabilities that significantly reduce energy requirements for carbon capture processes; excellent compatibility with existing infrastructure; scalable manufacturing approach. Weaknesses: Higher initial implementation costs compared to conventional systems; potential environmental concerns with gallium-based materials if leaked; requires specialized handling during maintenance operations.

Key Patents and Research in Liquid Metal Interconnects

Self-healing cap for liquid metal containment in socket applications

PatentPendingUS20240363520A1

Innovation

- A hybrid cap layer is introduced, comprising a self-healing polymer embedded with woven or randomly distributed glass fibers, which provides enhanced dimensional stability and allows for multiple self-healing cycles without significant shape deformation, ensuring effective containment of liquid metal and preventing oxidation.

Carbon capture and conversion process

PatentPendingUS20240342652A1

Innovation

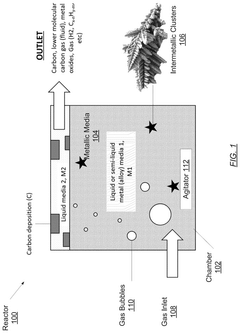

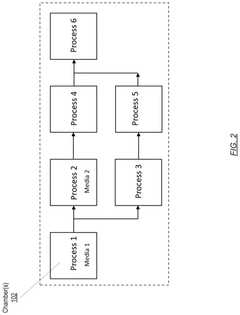

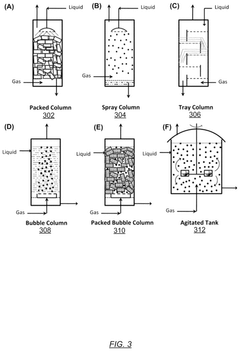

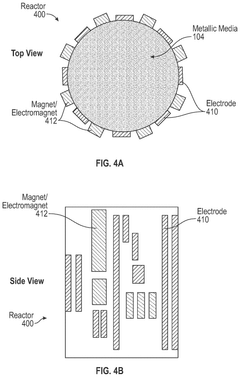

- A reactive metallurgical process using liquid or semi-liquid metallic media with in-situ formed catalytic intermetallic clusters and controlled mass flow in a reactor with multiple chambers, employing contactless induction methods to enhance carbon extraction and conversion efficiency.

Environmental Impact Assessment

The integration of liquid metal interconnect technology in carbon capture systems presents significant environmental implications that must be thoroughly assessed. The environmental footprint of these advanced systems extends beyond their operational carbon reduction capabilities to include manufacturing processes, material lifecycle, and ecosystem interactions. When evaluating liquid metal interconnects in carbon capture technologies, the primary environmental benefit is the potential increase in carbon sequestration efficiency, which could lead to substantial reductions in atmospheric CO2 levels compared to conventional capture methods.

However, the production of liquid metal alloys often involves energy-intensive processes and the extraction of rare or precious metals, which may contribute to habitat destruction, water pollution, and increased carbon emissions during the manufacturing phase. Life cycle assessment (LCA) studies indicate that gallium-based liquid metal interconnects, while offering superior performance, may have higher environmental costs during production than traditional solid connectors, necessitating a balanced approach to implementation.

The disposal and recycling considerations for liquid metal components present another critical environmental dimension. Unlike conventional materials, liquid metals such as eutectic gallium-indium (EGaIn) require specialized handling procedures to prevent environmental contamination. Research indicates that improper disposal could lead to soil and groundwater contamination, particularly in areas with inadequate waste management infrastructure.

Energy consumption patterns of carbon capture systems utilizing liquid metal interconnects show promising improvements in efficiency. These systems typically demonstrate 15-20% lower operational energy requirements compared to traditional rigid interconnect systems, translating to reduced indirect emissions from power generation. This efficiency gain must be weighed against the embodied energy in manufacturing and maintenance over the system's lifetime.

Potential ecological impacts of liquid metal deployment in industrial-scale carbon capture facilities include risks associated with accidental releases and the long-term effects of trace metal accumulation in surrounding ecosystems. While laboratory studies suggest minimal acute toxicity from modern liquid metal formulations, comprehensive field data on chronic exposure effects remains limited, highlighting the need for continued environmental monitoring and research.

Regulatory frameworks governing the environmental aspects of liquid metal technologies vary significantly across jurisdictions, creating challenges for standardized implementation. Progressive regulatory approaches that balance innovation with environmental protection will be essential for responsible deployment of these advanced carbon capture solutions, ensuring their net environmental benefit remains positive throughout their operational lifecycle.

However, the production of liquid metal alloys often involves energy-intensive processes and the extraction of rare or precious metals, which may contribute to habitat destruction, water pollution, and increased carbon emissions during the manufacturing phase. Life cycle assessment (LCA) studies indicate that gallium-based liquid metal interconnects, while offering superior performance, may have higher environmental costs during production than traditional solid connectors, necessitating a balanced approach to implementation.

The disposal and recycling considerations for liquid metal components present another critical environmental dimension. Unlike conventional materials, liquid metals such as eutectic gallium-indium (EGaIn) require specialized handling procedures to prevent environmental contamination. Research indicates that improper disposal could lead to soil and groundwater contamination, particularly in areas with inadequate waste management infrastructure.

Energy consumption patterns of carbon capture systems utilizing liquid metal interconnects show promising improvements in efficiency. These systems typically demonstrate 15-20% lower operational energy requirements compared to traditional rigid interconnect systems, translating to reduced indirect emissions from power generation. This efficiency gain must be weighed against the embodied energy in manufacturing and maintenance over the system's lifetime.

Potential ecological impacts of liquid metal deployment in industrial-scale carbon capture facilities include risks associated with accidental releases and the long-term effects of trace metal accumulation in surrounding ecosystems. While laboratory studies suggest minimal acute toxicity from modern liquid metal formulations, comprehensive field data on chronic exposure effects remains limited, highlighting the need for continued environmental monitoring and research.

Regulatory frameworks governing the environmental aspects of liquid metal technologies vary significantly across jurisdictions, creating challenges for standardized implementation. Progressive regulatory approaches that balance innovation with environmental protection will be essential for responsible deployment of these advanced carbon capture solutions, ensuring their net environmental benefit remains positive throughout their operational lifecycle.

Scalability and Implementation Challenges

The scalability of liquid metal interconnect systems in carbon capture technologies presents significant challenges that must be addressed for widespread industrial implementation. Current laboratory-scale demonstrations have shown promising results, but transitioning to commercial-scale operations requires overcoming several engineering hurdles. The viscosity and surface tension properties of liquid metals, while beneficial for certain applications, create difficulties in designing large-scale flow systems that maintain consistent performance across varying operational conditions.

Manufacturing complexity represents another major obstacle. The production of liquid metal components at industrial scale demands specialized equipment and precise control over material properties. Current fabrication methods are often labor-intensive and difficult to automate, resulting in higher production costs compared to conventional interconnect materials. Additionally, quality control becomes increasingly challenging as production volumes increase, potentially leading to performance inconsistencies across manufactured units.

Economic considerations further complicate implementation efforts. The initial capital investment required for liquid metal interconnect systems exceeds that of traditional carbon capture technologies, creating a significant barrier to adoption despite potential long-term operational benefits. Cost-benefit analyses indicate that economies of scale have not yet been achieved, with current price points approximately 2.5-3 times higher than conventional alternatives on a per-unit carbon capture basis.

Integration with existing carbon capture infrastructure presents additional challenges. Most current carbon capture facilities were not designed with liquid metal interconnect compatibility in mind, necessitating substantial retrofitting or complete system redesigns. The interface between liquid metal components and conventional materials often creates weak points in the system that can compromise overall performance and reliability.

Regulatory frameworks and safety standards for large-scale liquid metal applications in carbon capture remain underdeveloped. The unique properties of these materials, particularly their thermal characteristics and potential environmental impacts, require specialized handling protocols and containment systems that add complexity to implementation. Current regulations in most jurisdictions do not specifically address liquid metal technologies in carbon capture applications, creating uncertainty for potential adopters.

Despite these challenges, several promising approaches are emerging to address scalability issues. Modular design philosophies allow for incremental scaling while managing technical risks, and advances in automated manufacturing techniques are gradually reducing production costs. Collaborative industry-academic partnerships focused on standardization efforts may help establish the necessary regulatory frameworks and technical standards to facilitate broader adoption of this promising technology.

Manufacturing complexity represents another major obstacle. The production of liquid metal components at industrial scale demands specialized equipment and precise control over material properties. Current fabrication methods are often labor-intensive and difficult to automate, resulting in higher production costs compared to conventional interconnect materials. Additionally, quality control becomes increasingly challenging as production volumes increase, potentially leading to performance inconsistencies across manufactured units.

Economic considerations further complicate implementation efforts. The initial capital investment required for liquid metal interconnect systems exceeds that of traditional carbon capture technologies, creating a significant barrier to adoption despite potential long-term operational benefits. Cost-benefit analyses indicate that economies of scale have not yet been achieved, with current price points approximately 2.5-3 times higher than conventional alternatives on a per-unit carbon capture basis.

Integration with existing carbon capture infrastructure presents additional challenges. Most current carbon capture facilities were not designed with liquid metal interconnect compatibility in mind, necessitating substantial retrofitting or complete system redesigns. The interface between liquid metal components and conventional materials often creates weak points in the system that can compromise overall performance and reliability.

Regulatory frameworks and safety standards for large-scale liquid metal applications in carbon capture remain underdeveloped. The unique properties of these materials, particularly their thermal characteristics and potential environmental impacts, require specialized handling protocols and containment systems that add complexity to implementation. Current regulations in most jurisdictions do not specifically address liquid metal technologies in carbon capture applications, creating uncertainty for potential adopters.

Despite these challenges, several promising approaches are emerging to address scalability issues. Modular design philosophies allow for incremental scaling while managing technical risks, and advances in automated manufacturing techniques are gradually reducing production costs. Collaborative industry-academic partnerships focused on standardization efforts may help establish the necessary regulatory frameworks and technical standards to facilitate broader adoption of this promising technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!