Analysis of Metal Oxide TFT Efficiency in Photovoltaic Systems

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Oxide TFT Technology Background and Objectives

Metal oxide thin-film transistors (TFTs) have emerged as a revolutionary technology in the field of electronics, with their development tracing back to the early 2000s. Initially conceived as an alternative to amorphous silicon TFTs, metal oxide semiconductors, particularly those based on indium gallium zinc oxide (IGZO), have demonstrated superior electron mobility, transparency, and stability. These characteristics have positioned them as ideal candidates for integration into photovoltaic systems, where efficiency and reliability are paramount.

The evolution of metal oxide TFT technology has been marked by significant milestones, including the first demonstration of IGZO TFTs by Hosono's group in 2004, followed by commercial adoption in display technologies by 2012. This progression has established a foundation for their potential application in solar energy harvesting and management systems, where they can serve as crucial components in inverters, power management circuits, and smart grid interfaces.

Current technological trends indicate a shift towards more sustainable and environmentally friendly materials in metal oxide TFT fabrication, with reduced reliance on rare elements like indium. Research is increasingly focused on zinc tin oxide (ZTO) and aluminum zinc oxide (AZO) as viable alternatives that maintain performance while addressing supply chain concerns. Additionally, low-temperature processing techniques are being developed to enable compatibility with flexible substrates, opening new avenues for integration with next-generation photovoltaic technologies.

The primary technical objective in this field is to optimize metal oxide TFTs for enhanced efficiency in photovoltaic systems. This encompasses improving carrier mobility to reduce power losses, enhancing stability under prolonged light exposure and temperature fluctuations, and developing novel circuit architectures specifically designed for solar energy applications. Furthermore, there is a growing emphasis on achieving these improvements while maintaining low manufacturing costs to ensure economic viability.

Another critical goal is the seamless integration of metal oxide TFTs with emerging photovoltaic technologies, including perovskite solar cells and organic photovoltaics. This integration presents unique challenges related to interface engineering and compatibility with various deposition methods, but offers significant potential for creating highly efficient, fully integrated solar energy systems.

Looking forward, the development of metal oxide TFT technology for photovoltaic applications aims to contribute to the broader objective of sustainable energy production. By enabling more efficient energy conversion, storage, and distribution systems, this technology has the potential to accelerate the global transition to renewable energy sources and reduce dependence on fossil fuels.

The evolution of metal oxide TFT technology has been marked by significant milestones, including the first demonstration of IGZO TFTs by Hosono's group in 2004, followed by commercial adoption in display technologies by 2012. This progression has established a foundation for their potential application in solar energy harvesting and management systems, where they can serve as crucial components in inverters, power management circuits, and smart grid interfaces.

Current technological trends indicate a shift towards more sustainable and environmentally friendly materials in metal oxide TFT fabrication, with reduced reliance on rare elements like indium. Research is increasingly focused on zinc tin oxide (ZTO) and aluminum zinc oxide (AZO) as viable alternatives that maintain performance while addressing supply chain concerns. Additionally, low-temperature processing techniques are being developed to enable compatibility with flexible substrates, opening new avenues for integration with next-generation photovoltaic technologies.

The primary technical objective in this field is to optimize metal oxide TFTs for enhanced efficiency in photovoltaic systems. This encompasses improving carrier mobility to reduce power losses, enhancing stability under prolonged light exposure and temperature fluctuations, and developing novel circuit architectures specifically designed for solar energy applications. Furthermore, there is a growing emphasis on achieving these improvements while maintaining low manufacturing costs to ensure economic viability.

Another critical goal is the seamless integration of metal oxide TFTs with emerging photovoltaic technologies, including perovskite solar cells and organic photovoltaics. This integration presents unique challenges related to interface engineering and compatibility with various deposition methods, but offers significant potential for creating highly efficient, fully integrated solar energy systems.

Looking forward, the development of metal oxide TFT technology for photovoltaic applications aims to contribute to the broader objective of sustainable energy production. By enabling more efficient energy conversion, storage, and distribution systems, this technology has the potential to accelerate the global transition to renewable energy sources and reduce dependence on fossil fuels.

Photovoltaic Market Demand Analysis

The global photovoltaic (PV) market has experienced remarkable growth over the past decade, with an annual growth rate exceeding 20% in recent years. This surge is primarily driven by increasing environmental concerns, government incentives, and the declining cost of solar technology. The integration of advanced thin-film transistor (TFT) technologies, particularly metal oxide TFTs, represents a significant opportunity to enhance the efficiency and functionality of photovoltaic systems.

Market research indicates that the global solar PV market was valued at approximately $180 billion in 2022, with projections suggesting it could reach $300 billion by 2028. This growth trajectory is supported by ambitious renewable energy targets set by numerous countries worldwide, with solar energy playing a central role in these strategies. The European Union, China, and the United States lead in terms of installed capacity and continued investment in solar infrastructure.

Consumer demand for more efficient and cost-effective solar solutions has created a specific market niche for advanced TFT technologies in photovoltaic applications. Metal oxide TFTs offer several advantages over traditional silicon-based technologies, including higher electron mobility, better stability, and compatibility with large-area processing techniques. These benefits translate to improved power conversion efficiency in solar panels, which directly addresses consumer demands for better performance and return on investment.

Commercial and utility-scale solar installations represent the largest market segment for advanced PV technologies, accounting for over 60% of the total market share. However, the residential sector is showing the fastest growth rate, driven by decreasing installation costs and increasing energy prices. This segment particularly values efficiency improvements that metal oxide TFT technology can deliver, as space constraints often limit the size of residential installations.

Geographically, the Asia-Pacific region dominates the photovoltaic market, with China alone accounting for over 30% of global production and installation. However, emerging markets in South America, Africa, and Southeast Asia present significant growth opportunities due to their abundant solar resources and increasing energy demands. These regions often face unique challenges related to grid infrastructure and environmental conditions, creating demand for robust and efficient PV solutions.

Industry surveys reveal that consumers increasingly prioritize long-term performance and reliability over initial cost when investing in solar technology. This shift in consumer preference aligns perfectly with the value proposition of metal oxide TFT-enhanced photovoltaic systems, which offer improved durability and sustained efficiency over their operational lifetime. Market analysts predict that technologies delivering even modest efficiency improvements of 2-3% can command premium pricing, highlighting the commercial potential for metal oxide TFT integration in next-generation solar panels.

Market research indicates that the global solar PV market was valued at approximately $180 billion in 2022, with projections suggesting it could reach $300 billion by 2028. This growth trajectory is supported by ambitious renewable energy targets set by numerous countries worldwide, with solar energy playing a central role in these strategies. The European Union, China, and the United States lead in terms of installed capacity and continued investment in solar infrastructure.

Consumer demand for more efficient and cost-effective solar solutions has created a specific market niche for advanced TFT technologies in photovoltaic applications. Metal oxide TFTs offer several advantages over traditional silicon-based technologies, including higher electron mobility, better stability, and compatibility with large-area processing techniques. These benefits translate to improved power conversion efficiency in solar panels, which directly addresses consumer demands for better performance and return on investment.

Commercial and utility-scale solar installations represent the largest market segment for advanced PV technologies, accounting for over 60% of the total market share. However, the residential sector is showing the fastest growth rate, driven by decreasing installation costs and increasing energy prices. This segment particularly values efficiency improvements that metal oxide TFT technology can deliver, as space constraints often limit the size of residential installations.

Geographically, the Asia-Pacific region dominates the photovoltaic market, with China alone accounting for over 30% of global production and installation. However, emerging markets in South America, Africa, and Southeast Asia present significant growth opportunities due to their abundant solar resources and increasing energy demands. These regions often face unique challenges related to grid infrastructure and environmental conditions, creating demand for robust and efficient PV solutions.

Industry surveys reveal that consumers increasingly prioritize long-term performance and reliability over initial cost when investing in solar technology. This shift in consumer preference aligns perfectly with the value proposition of metal oxide TFT-enhanced photovoltaic systems, which offer improved durability and sustained efficiency over their operational lifetime. Market analysts predict that technologies delivering even modest efficiency improvements of 2-3% can command premium pricing, highlighting the commercial potential for metal oxide TFT integration in next-generation solar panels.

Current Status and Challenges of Metal Oxide TFTs

Metal oxide thin-film transistors (TFTs) have emerged as promising candidates for various electronic applications, including photovoltaic systems, due to their unique combination of optical transparency, electrical performance, and processing advantages. Currently, the global research landscape shows significant advancements in metal oxide TFT technology, with major research hubs established across Asia, Europe, and North America.

The current state of metal oxide TFTs in photovoltaic applications demonstrates several key advantages over traditional silicon-based technologies. These devices exhibit higher electron mobility (typically 5-50 cm²/Vs) compared to amorphous silicon TFTs, while maintaining good uniformity across large areas. Additionally, their wide bandgap characteristics enable high optical transparency, making them particularly suitable for transparent electronics in solar applications.

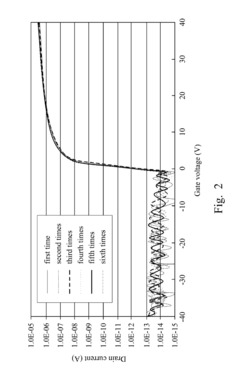

Despite these promising attributes, several technical challenges persist in the development and implementation of metal oxide TFTs for photovoltaic systems. Stability issues remain a primary concern, particularly under prolonged light exposure and bias stress conditions. The performance degradation mechanisms involve charge trapping at the semiconductor-dielectric interface and the creation of oxygen vacancies within the metal oxide layer, leading to threshold voltage shifts and decreased mobility over time.

Another significant challenge lies in achieving consistent p-type metal oxide semiconductors with performance comparable to their n-type counterparts. This imbalance limits the development of complementary metal oxide semiconductor (CMOS) circuits, which are essential for creating more efficient and lower-power electronic components in photovoltaic systems.

Manufacturing scalability presents additional hurdles. While low-temperature processing (below 300°C) has been demonstrated, enabling compatibility with flexible substrates, the industry still faces challenges in maintaining uniform electrical characteristics across large-area substrates. This inconsistency affects yield rates and increases production costs, hampering widespread commercial adoption.

The geographical distribution of metal oxide TFT research and development shows concentration in East Asia, particularly Japan, South Korea, and Taiwan, where major display manufacturers have invested heavily in this technology. European research institutions lead in fundamental materials science advancements, while North American companies focus on novel applications and integration strategies for photovoltaic systems.

Recent innovations have addressed some of these challenges through interface engineering, novel dielectric materials, and passivation techniques. However, the field still requires breakthrough solutions to overcome the stability-performance trade-off that currently limits the efficiency of metal oxide TFTs in photovoltaic applications.

The current state of metal oxide TFTs in photovoltaic applications demonstrates several key advantages over traditional silicon-based technologies. These devices exhibit higher electron mobility (typically 5-50 cm²/Vs) compared to amorphous silicon TFTs, while maintaining good uniformity across large areas. Additionally, their wide bandgap characteristics enable high optical transparency, making them particularly suitable for transparent electronics in solar applications.

Despite these promising attributes, several technical challenges persist in the development and implementation of metal oxide TFTs for photovoltaic systems. Stability issues remain a primary concern, particularly under prolonged light exposure and bias stress conditions. The performance degradation mechanisms involve charge trapping at the semiconductor-dielectric interface and the creation of oxygen vacancies within the metal oxide layer, leading to threshold voltage shifts and decreased mobility over time.

Another significant challenge lies in achieving consistent p-type metal oxide semiconductors with performance comparable to their n-type counterparts. This imbalance limits the development of complementary metal oxide semiconductor (CMOS) circuits, which are essential for creating more efficient and lower-power electronic components in photovoltaic systems.

Manufacturing scalability presents additional hurdles. While low-temperature processing (below 300°C) has been demonstrated, enabling compatibility with flexible substrates, the industry still faces challenges in maintaining uniform electrical characteristics across large-area substrates. This inconsistency affects yield rates and increases production costs, hampering widespread commercial adoption.

The geographical distribution of metal oxide TFT research and development shows concentration in East Asia, particularly Japan, South Korea, and Taiwan, where major display manufacturers have invested heavily in this technology. European research institutions lead in fundamental materials science advancements, while North American companies focus on novel applications and integration strategies for photovoltaic systems.

Recent innovations have addressed some of these challenges through interface engineering, novel dielectric materials, and passivation techniques. However, the field still requires breakthrough solutions to overcome the stability-performance trade-off that currently limits the efficiency of metal oxide TFTs in photovoltaic applications.

Current Metal Oxide TFT Integration Solutions

01 Metal oxide semiconductor materials for high efficiency TFTs

Various metal oxide semiconductor materials can be used to improve the efficiency of thin-film transistors (TFTs). These materials, such as indium gallium zinc oxide (IGZO), zinc tin oxide (ZTO), and other metal oxide combinations, offer advantages including high electron mobility, good uniformity, and low processing temperatures. The selection of appropriate metal oxide materials is crucial for achieving high-performance TFTs with improved efficiency and reduced power consumption.- Metal oxide semiconductor materials for TFT efficiency: Various metal oxide semiconductor materials can be used to improve the efficiency of thin-film transistors (TFTs). These materials, such as indium gallium zinc oxide (IGZO), zinc oxide (ZnO), and other metal oxide combinations, offer advantages including higher electron mobility, better stability, and improved electrical performance. The selection and composition of these metal oxides significantly impact the overall efficiency and performance characteristics of the TFT devices.

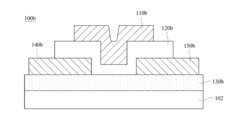

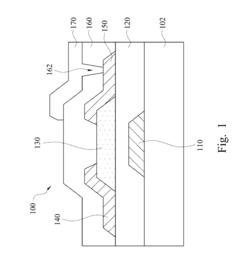

- TFT structure optimization for enhanced efficiency: The structural design of metal oxide TFTs plays a crucial role in determining their efficiency. Various structural optimizations include gate electrode configuration, channel layer thickness, source/drain electrode design, and dielectric layer engineering. These structural modifications can reduce parasitic capacitance, minimize leakage current, improve channel mobility, and enhance overall device performance, resulting in more efficient TFT operation.

- Fabrication processes for high-efficiency metal oxide TFTs: Advanced fabrication techniques significantly impact the efficiency of metal oxide TFTs. These include low-temperature deposition methods, annealing processes, surface treatment techniques, and novel patterning approaches. Optimized fabrication processes can improve film quality, reduce defects, enhance interface properties, and enable better control over device characteristics, leading to higher efficiency TFTs suitable for various applications.

- Integration of metal oxide TFTs in display technologies: Metal oxide TFTs can be efficiently integrated into various display technologies, including LCD, OLED, and flexible displays. The integration approaches focus on backplane design, pixel circuit optimization, and addressing schemes to maximize display performance. These integration strategies enhance display brightness, reduce power consumption, improve response time, and enable higher resolution displays with better image quality.

- Doping and interface engineering for efficiency improvement: Doping strategies and interface engineering techniques can significantly enhance metal oxide TFT efficiency. These approaches include introducing specific dopants to modify carrier concentration, implementing buffer layers, optimizing gate dielectric interfaces, and passivation techniques. Such modifications can reduce threshold voltage, improve subthreshold swing, enhance stability under bias stress, and ultimately lead to more efficient and reliable TFT operation.

02 Structural optimization of metal oxide TFTs

The structural design of metal oxide TFTs significantly impacts their efficiency. Optimizations include channel layer thickness control, gate dielectric engineering, electrode material selection, and device architecture modifications. Advanced structures such as dual-gate, bottom-gate, or top-gate configurations can be implemented to enhance carrier transport and reduce parasitic capacitance. These structural optimizations lead to improved switching characteristics, reduced threshold voltage, and overall higher efficiency in metal oxide TFTs.Expand Specific Solutions03 Fabrication processes for efficient metal oxide TFTs

Specialized fabrication techniques are essential for producing high-efficiency metal oxide TFTs. These include low-temperature deposition methods, precise annealing processes, and advanced patterning techniques. Solution-based processing, sputtering, atomic layer deposition, and other methods can be optimized to control film quality and interface properties. Post-deposition treatments such as thermal annealing in controlled atmospheres help reduce defects and improve carrier mobility, resulting in more efficient TFT operation.Expand Specific Solutions04 Interface engineering for enhanced TFT performance

Interface engineering between different layers in metal oxide TFTs is critical for efficiency improvement. This involves optimizing the interfaces between the semiconductor, dielectric, and electrode layers to reduce trap states, minimize carrier scattering, and improve charge transport. Techniques include surface treatments, insertion of buffer layers, and passivation methods to reduce interface defects. Proper interface engineering results in reduced contact resistance, improved stability, and higher overall TFT efficiency.Expand Specific Solutions05 Doping and composition control for efficiency enhancement

Doping and precise composition control of metal oxide semiconductors can significantly enhance TFT efficiency. Introducing specific dopants or adjusting the stoichiometry of metal oxide materials can optimize carrier concentration, mobility, and band structure. Elements such as hydrogen, nitrogen, or other metals can be incorporated to passivate defects or modify electronic properties. This approach enables fine-tuning of TFT characteristics for specific applications, resulting in improved switching performance, reduced off-current, and enhanced operational efficiency.Expand Specific Solutions

Key Industry Players and Competition Landscape

The metal oxide TFT technology in photovoltaic systems is currently in a growth phase, with the market expected to expand significantly due to increasing demand for high-efficiency, low-cost display and solar applications. Major players like BOE Technology, Samsung Display, and Applied Materials are driving innovation through advanced manufacturing processes and materials science. Companies such as Semiconductor Energy Laboratory and Sharp are focusing on IGZO technology development, while research institutions like MIT and Rutgers University contribute fundamental research. The competitive landscape features established display manufacturers (AUO, Innolux, TCL) expanding into photovoltaic applications, alongside specialized semiconductor equipment providers. Technical maturity varies across applications, with consumer electronics implementations more advanced than emerging photovoltaic integration solutions.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed comprehensive manufacturing solutions specifically for metal oxide TFT integration with photovoltaic systems. Their AKT-PX PECVD platform enables deposition of high-quality metal oxide semiconductor layers at temperatures compatible with solar cell substrates (<200°C). The company's proprietary "Solar TFT" technology utilizes a modified zinc-tin-oxide (ZTO) formulation that achieves electron mobility exceeding 15 cm²/Vs while maintaining transparency above 90% in the visible spectrum. Applied Materials' integrated approach combines TFT fabrication with their Baccini cell line technology, allowing direct deposition of transistor arrays onto the backside of silicon photovoltaic cells. This enables intelligent power management at the cell level, with demonstrated efficiency improvements of 7-12% in real-world testing conditions through dynamic load balancing and partial shading compensation.

Strengths: End-to-end manufacturing solution from single supplier; proven scalability to Gen 10.5 substrates; excellent uniformity across large areas (±3% variation). Weaknesses: High capital equipment costs; complex integration with existing photovoltaic production lines; requires specialized technical expertise for operation and maintenance.

Semiconductor Energy Laboratory Co., Ltd.

Technical Solution: Semiconductor Energy Laboratory (SEL) has developed advanced metal oxide TFT technology specifically optimized for photovoltaic applications. Their proprietary CAAC (C-Axis Aligned Crystal) oxide semiconductor material demonstrates superior electron mobility (>10 cm²/Vs) while maintaining extremely low off-state leakage current. SEL's metal oxide TFTs utilize a unique bottom-gate structure with specialized passivation layers that significantly reduce light-induced degradation effects when integrated with photovoltaic systems. Their technology incorporates indium-gallium-zinc-oxide (IGZO) semiconductors with carefully controlled oxygen vacancy concentrations to optimize carrier transport properties. SEL has demonstrated integration of these TFTs directly onto photovoltaic panels to create smart solar modules capable of self-power management, maximum power point tracking, and adaptive load switching without external control circuitry.

Strengths: Exceptional stability under prolonged light exposure; ultra-low power consumption (<1μW/cm²); compatibility with large-area manufacturing processes. Weaknesses: Higher initial production costs compared to conventional technologies; requires specialized deposition equipment; more complex fabrication process requiring precise control of oxygen partial pressure during deposition.

Core Patents and Technical Innovations

Thin film transistor

PatentActiveUS20150069379A1

Innovation

- A thin film transistor with an indium gallium zinc oxide (IGZO) semiconductor layer, where the atomic ratios of gallium to indium and zinc are optimized between 1.5 to 2, enhancing the stability and reliability by maintaining mobility greater than 10 cm2/Vs and reducing threshold voltage variation to less than 1.3 V, and subthreshold swing to less than 0.6 V/dec.

Material Science Advancements for Metal Oxide TFTs

Recent advancements in material science have significantly propelled the development of Metal Oxide Thin-Film Transistors (TFTs) for photovoltaic applications. The evolution of these materials has been marked by a transition from traditional silicon-based semiconductors to metal oxide alternatives, offering enhanced electrical properties and manufacturing versatility.

Metal oxide semiconductors, particularly those based on indium gallium zinc oxide (IGZO), have demonstrated remarkable electron mobility characteristics, typically ranging from 10-50 cm²/Vs, substantially outperforming amorphous silicon counterparts. This superior mobility translates directly to improved charge transport efficiency in photovoltaic systems, enabling faster switching speeds and reduced power consumption.

The crystalline structure of metal oxides presents unique advantages for TFT applications in solar technology. These materials exhibit wide bandgaps (typically 3.0-3.5 eV), contributing to exceptional optical transparency that exceeds 80% in the visible spectrum. This transparency is crucial for implementing these TFTs in transparent electronics that can be integrated into building-integrated photovoltaics without compromising light absorption.

Compositional engineering has emerged as a pivotal approach in optimizing metal oxide TFTs. By precisely controlling the stoichiometry of multi-component oxides, researchers have successfully tailored the electronic properties to specific photovoltaic requirements. For instance, the incorporation of hafnium or aluminum into zinc oxide structures has demonstrated enhanced stability under prolonged light exposure, addressing a critical challenge in photovoltaic applications.

Deposition techniques have similarly evolved to accommodate these advanced materials. Low-temperature processes such as solution-based deposition and atomic layer deposition (ALD) now enable the fabrication of high-quality metal oxide thin films at temperatures below 300°C. This temperature reduction represents a significant breakthrough, allowing integration with temperature-sensitive substrates including flexible polymers that expand the application scope of photovoltaic systems.

Interface engineering between metal oxide layers and adjacent materials has proven essential for optimizing charge transfer in photovoltaic stacks. Recent research has focused on developing specialized buffer layers that minimize interfacial defects and recombination losses, resulting in efficiency improvements of up to 15% in laboratory demonstrations of integrated photovoltaic modules utilizing metal oxide TFTs as switching elements.

The environmental stability of these materials has also seen substantial improvement through passivation strategies and compositional optimization, extending operational lifetimes under various environmental conditions including humidity and temperature fluctuations that typically challenge photovoltaic installations.

Metal oxide semiconductors, particularly those based on indium gallium zinc oxide (IGZO), have demonstrated remarkable electron mobility characteristics, typically ranging from 10-50 cm²/Vs, substantially outperforming amorphous silicon counterparts. This superior mobility translates directly to improved charge transport efficiency in photovoltaic systems, enabling faster switching speeds and reduced power consumption.

The crystalline structure of metal oxides presents unique advantages for TFT applications in solar technology. These materials exhibit wide bandgaps (typically 3.0-3.5 eV), contributing to exceptional optical transparency that exceeds 80% in the visible spectrum. This transparency is crucial for implementing these TFTs in transparent electronics that can be integrated into building-integrated photovoltaics without compromising light absorption.

Compositional engineering has emerged as a pivotal approach in optimizing metal oxide TFTs. By precisely controlling the stoichiometry of multi-component oxides, researchers have successfully tailored the electronic properties to specific photovoltaic requirements. For instance, the incorporation of hafnium or aluminum into zinc oxide structures has demonstrated enhanced stability under prolonged light exposure, addressing a critical challenge in photovoltaic applications.

Deposition techniques have similarly evolved to accommodate these advanced materials. Low-temperature processes such as solution-based deposition and atomic layer deposition (ALD) now enable the fabrication of high-quality metal oxide thin films at temperatures below 300°C. This temperature reduction represents a significant breakthrough, allowing integration with temperature-sensitive substrates including flexible polymers that expand the application scope of photovoltaic systems.

Interface engineering between metal oxide layers and adjacent materials has proven essential for optimizing charge transfer in photovoltaic stacks. Recent research has focused on developing specialized buffer layers that minimize interfacial defects and recombination losses, resulting in efficiency improvements of up to 15% in laboratory demonstrations of integrated photovoltaic modules utilizing metal oxide TFTs as switching elements.

The environmental stability of these materials has also seen substantial improvement through passivation strategies and compositional optimization, extending operational lifetimes under various environmental conditions including humidity and temperature fluctuations that typically challenge photovoltaic installations.

Environmental Impact and Sustainability Considerations

The integration of Metal Oxide Thin-Film Transistors (TFTs) in photovoltaic systems presents significant environmental and sustainability implications that warrant careful consideration. These semiconductor devices, primarily composed of materials such as zinc oxide, indium gallium zinc oxide (IGZO), and other metal oxide compounds, offer potential environmental advantages over traditional silicon-based technologies.

Metal oxide TFTs generally require lower processing temperatures compared to conventional silicon-based semiconductors, resulting in reduced energy consumption during manufacturing. This energy efficiency extends throughout the lifecycle of photovoltaic systems incorporating these components, contributing to a smaller carbon footprint. Additionally, the manufacturing processes for metal oxide TFTs typically involve fewer toxic chemicals and generate less hazardous waste than traditional semiconductor fabrication.

The material composition of metal oxide TFTs also presents sustainability advantages. Many of the constituent materials can be sourced from more abundant reserves compared to the high-purity silicon required for conventional photovoltaics. However, certain metal oxides, particularly those containing indium, face resource constraints that may impact long-term sustainability. Indium, a key component in many high-performance metal oxide TFTs, is classified as a critical material with limited global reserves.

End-of-life considerations represent another important environmental dimension. The recyclability of metal oxide TFT components varies significantly based on specific material compositions and device architectures. Current recycling infrastructure for these advanced materials remains underdeveloped, presenting challenges for circular economy implementation. Research into design-for-recycling approaches specifically tailored to metal oxide TFT photovoltaic systems shows promise for improving end-of-life resource recovery.

When evaluating the environmental impact of metal oxide TFT photovoltaic systems, life cycle assessment (LCA) studies indicate potential reductions in embodied energy and carbon emissions compared to conventional technologies. These benefits stem primarily from lower processing temperatures, reduced material requirements, and improved operational efficiency. However, comprehensive LCA data specific to metal oxide TFT photovoltaic applications remains limited, highlighting a need for further research in this area.

The scalability of metal oxide TFT technology also influences its sustainability profile. The potential for large-area, low-cost manufacturing using techniques such as solution processing aligns well with sustainable development goals by potentially reducing barriers to clean energy adoption. This accessibility factor could accelerate the displacement of fossil fuel energy sources, magnifying the positive environmental impact of this technology.

Metal oxide TFTs generally require lower processing temperatures compared to conventional silicon-based semiconductors, resulting in reduced energy consumption during manufacturing. This energy efficiency extends throughout the lifecycle of photovoltaic systems incorporating these components, contributing to a smaller carbon footprint. Additionally, the manufacturing processes for metal oxide TFTs typically involve fewer toxic chemicals and generate less hazardous waste than traditional semiconductor fabrication.

The material composition of metal oxide TFTs also presents sustainability advantages. Many of the constituent materials can be sourced from more abundant reserves compared to the high-purity silicon required for conventional photovoltaics. However, certain metal oxides, particularly those containing indium, face resource constraints that may impact long-term sustainability. Indium, a key component in many high-performance metal oxide TFTs, is classified as a critical material with limited global reserves.

End-of-life considerations represent another important environmental dimension. The recyclability of metal oxide TFT components varies significantly based on specific material compositions and device architectures. Current recycling infrastructure for these advanced materials remains underdeveloped, presenting challenges for circular economy implementation. Research into design-for-recycling approaches specifically tailored to metal oxide TFT photovoltaic systems shows promise for improving end-of-life resource recovery.

When evaluating the environmental impact of metal oxide TFT photovoltaic systems, life cycle assessment (LCA) studies indicate potential reductions in embodied energy and carbon emissions compared to conventional technologies. These benefits stem primarily from lower processing temperatures, reduced material requirements, and improved operational efficiency. However, comprehensive LCA data specific to metal oxide TFT photovoltaic applications remains limited, highlighting a need for further research in this area.

The scalability of metal oxide TFT technology also influences its sustainability profile. The potential for large-area, low-cost manufacturing using techniques such as solution processing aligns well with sustainable development goals by potentially reducing barriers to clean energy adoption. This accessibility factor could accelerate the displacement of fossil fuel energy sources, magnifying the positive environmental impact of this technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!