How Metal Oxide TFT Enhances Thermal Stability in Electronics

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Oxide TFT Evolution and Objectives

Metal oxide thin-film transistors (TFTs) have evolved significantly since their inception in the early 2000s, transforming from laboratory curiosities to essential components in modern display technologies. The journey began with amorphous silicon (a-Si) TFTs dominating the market, which offered limited electron mobility and thermal stability. The breakthrough came with the development of amorphous oxide semiconductors (AOS), particularly indium gallium zinc oxide (IGZO), which demonstrated superior electron mobility exceeding 10 cm²/Vs compared to a-Si's typical 0.5-1 cm²/Vs.

The evolution of metal oxide TFTs has been driven by the increasing demands of the electronics industry for higher performance, lower power consumption, and enhanced durability under varying environmental conditions. A significant milestone was reached in 2004 when Hosono and colleagues demonstrated room-temperature fabrication of transparent IGZO TFTs, opening new possibilities for flexible and transparent electronics applications.

Throughout the 2010s, research focused on optimizing material compositions and processing techniques to enhance thermal stability, a critical factor limiting widespread adoption. The incorporation of hafnium, zirconium, and aluminum into oxide semiconductor matrices has progressively improved temperature resilience, allowing devices to maintain performance integrity at temperatures exceeding 300°C in some formulations.

The technical objectives in metal oxide TFT development have evolved from simply achieving functionality to optimizing specific performance metrics critical for next-generation electronics. Current research aims to develop TFTs that maintain stable threshold voltage and mobility across a wide temperature range (-40°C to 125°C) to meet automotive and industrial electronics standards.

Another key objective is reducing the activation energy for carrier generation in metal oxide semiconductors, which directly correlates with improved thermal stability. By engineering band structures and controlling oxygen vacancy concentrations, researchers have progressively lowered activation energies from approximately 0.7 eV in early formulations to below 0.3 eV in advanced compositions.

The trajectory of metal oxide TFT development is now focused on achieving thermal stability without compromising other performance parameters such as switching speed, transparency, and mechanical flexibility. This balanced approach aims to create versatile semiconductor platforms suitable for diverse applications ranging from high-resolution displays to wearable electronics and IoT sensors.

Looking forward, the field is targeting the development of metal oxide TFTs with negligible performance degradation after 1000 hours of operation at 85°C and 85% relative humidity, a benchmark that would enable their integration into mission-critical systems and expand their application scope beyond consumer electronics.

The evolution of metal oxide TFTs has been driven by the increasing demands of the electronics industry for higher performance, lower power consumption, and enhanced durability under varying environmental conditions. A significant milestone was reached in 2004 when Hosono and colleagues demonstrated room-temperature fabrication of transparent IGZO TFTs, opening new possibilities for flexible and transparent electronics applications.

Throughout the 2010s, research focused on optimizing material compositions and processing techniques to enhance thermal stability, a critical factor limiting widespread adoption. The incorporation of hafnium, zirconium, and aluminum into oxide semiconductor matrices has progressively improved temperature resilience, allowing devices to maintain performance integrity at temperatures exceeding 300°C in some formulations.

The technical objectives in metal oxide TFT development have evolved from simply achieving functionality to optimizing specific performance metrics critical for next-generation electronics. Current research aims to develop TFTs that maintain stable threshold voltage and mobility across a wide temperature range (-40°C to 125°C) to meet automotive and industrial electronics standards.

Another key objective is reducing the activation energy for carrier generation in metal oxide semiconductors, which directly correlates with improved thermal stability. By engineering band structures and controlling oxygen vacancy concentrations, researchers have progressively lowered activation energies from approximately 0.7 eV in early formulations to below 0.3 eV in advanced compositions.

The trajectory of metal oxide TFT development is now focused on achieving thermal stability without compromising other performance parameters such as switching speed, transparency, and mechanical flexibility. This balanced approach aims to create versatile semiconductor platforms suitable for diverse applications ranging from high-resolution displays to wearable electronics and IoT sensors.

Looking forward, the field is targeting the development of metal oxide TFTs with negligible performance degradation after 1000 hours of operation at 85°C and 85% relative humidity, a benchmark that would enable their integration into mission-critical systems and expand their application scope beyond consumer electronics.

Market Analysis for Thermally Stable Electronics

The thermally stable electronics market is experiencing robust growth driven by increasing demand across multiple sectors including automotive, aerospace, industrial automation, and consumer electronics. As operating temperatures in modern electronic devices continue to rise due to higher processing power and miniaturization, the need for components that can maintain performance under thermal stress has become critical.

Current market valuations indicate that the thermally stable electronics segment represents approximately 18% of the specialty electronics market, with annual growth rates exceeding the broader semiconductor industry by 3-4 percentage points. This accelerated growth trajectory is expected to continue as applications in extreme environments proliferate.

Metal oxide thin-film transistor (TFT) technology has emerged as a key enabler in this market due to its superior thermal stability compared to conventional silicon-based alternatives. The automotive sector currently represents the largest market share at 34%, where under-hood electronics must withstand temperatures exceeding 150°C. Aerospace applications follow at 27%, with industrial automation at 21%, and consumer electronics comprising 18% of market demand.

Regional analysis reveals Asia-Pacific as the dominant manufacturing hub, accounting for 52% of production capacity, followed by North America (24%) and Europe (19%). However, research and development activities remain more evenly distributed, with significant innovation clusters in Japan, South Korea, Taiwan, Germany, and the United States.

Market forecasts project a compound annual growth rate of 12.7% for thermally stable electronics incorporating metal oxide TFT technology over the next five years. This growth is substantially driven by the electric vehicle market, where battery management systems require exceptional thermal performance. The renewable energy sector is also emerging as a significant growth vector, particularly in solar inverter applications.

Customer requirements analysis indicates that reliability under thermal cycling conditions remains the primary purchasing consideration (cited by 78% of procurement specialists), followed by long-term stability (65%), and cost-effectiveness (57%). Metal oxide TFT solutions are increasingly preferred due to their ability to address these priorities while offering additional benefits in terms of transparency and flexibility.

Pricing trends show gradual cost reduction as manufacturing processes mature, with premium pricing still sustainable in high-reliability applications. The average price premium for thermally enhanced components has decreased from 45% to 32% over the past three years, indicating improving cost competitiveness against conventional alternatives.

Current market valuations indicate that the thermally stable electronics segment represents approximately 18% of the specialty electronics market, with annual growth rates exceeding the broader semiconductor industry by 3-4 percentage points. This accelerated growth trajectory is expected to continue as applications in extreme environments proliferate.

Metal oxide thin-film transistor (TFT) technology has emerged as a key enabler in this market due to its superior thermal stability compared to conventional silicon-based alternatives. The automotive sector currently represents the largest market share at 34%, where under-hood electronics must withstand temperatures exceeding 150°C. Aerospace applications follow at 27%, with industrial automation at 21%, and consumer electronics comprising 18% of market demand.

Regional analysis reveals Asia-Pacific as the dominant manufacturing hub, accounting for 52% of production capacity, followed by North America (24%) and Europe (19%). However, research and development activities remain more evenly distributed, with significant innovation clusters in Japan, South Korea, Taiwan, Germany, and the United States.

Market forecasts project a compound annual growth rate of 12.7% for thermally stable electronics incorporating metal oxide TFT technology over the next five years. This growth is substantially driven by the electric vehicle market, where battery management systems require exceptional thermal performance. The renewable energy sector is also emerging as a significant growth vector, particularly in solar inverter applications.

Customer requirements analysis indicates that reliability under thermal cycling conditions remains the primary purchasing consideration (cited by 78% of procurement specialists), followed by long-term stability (65%), and cost-effectiveness (57%). Metal oxide TFT solutions are increasingly preferred due to their ability to address these priorities while offering additional benefits in terms of transparency and flexibility.

Pricing trends show gradual cost reduction as manufacturing processes mature, with premium pricing still sustainable in high-reliability applications. The average price premium for thermally enhanced components has decreased from 45% to 32% over the past three years, indicating improving cost competitiveness against conventional alternatives.

Current Challenges in Metal Oxide TFT Thermal Stability

Despite the promising advantages of metal oxide thin-film transistors (TFTs) in electronic applications, several significant thermal stability challenges persist that limit their widespread adoption. The primary issue involves the degradation of electrical performance at elevated temperatures, where carrier mobility decreases and threshold voltage shifts occur. This instability manifests particularly in amorphous oxide semiconductors like IGZO (Indium Gallium Zinc Oxide), where oxygen vacancies can migrate under thermal stress, altering the fundamental electrical characteristics of the device.

Another critical challenge is the interface instability between the metal oxide semiconductor layer and the gate dielectric. At higher temperatures, interfacial defects can form or existing defects can be activated, leading to charge trapping phenomena that significantly impact device reliability. These interface states contribute to hysteresis effects and time-dependent threshold voltage shifts that compromise long-term operational stability.

The structural integrity of metal oxide TFTs under thermal cycling represents a substantial hurdle for applications requiring temperature resilience. Repeated heating and cooling cycles induce mechanical stress at material interfaces due to thermal expansion coefficient mismatches, potentially causing delamination or crack formation. This mechanical degradation accelerates device failure and reduces operational lifespan in real-world applications.

Manufacturing consistency presents another significant challenge, as process temperature variations during fabrication can lead to non-uniform electrical properties across devices. The sensitivity of metal oxide semiconductors to deposition and annealing temperatures means that precise thermal control is essential for achieving consistent performance metrics, particularly for large-area electronics and display applications.

Environmental factors further complicate thermal stability issues, as humidity and atmospheric conditions can interact with temperature effects to accelerate degradation mechanisms. Moisture ingress at elevated temperatures can catalyze chemical reactions at interfaces or within the metal oxide layer itself, introducing additional instability factors that are difficult to predict and mitigate in practical device designs.

Current passivation techniques and encapsulation methods provide only partial solutions to these thermal stability challenges. While they can extend device lifetime under moderate conditions, they often fail to provide comprehensive protection against the combined effects of temperature, humidity, and operational stress. This limitation is particularly problematic for emerging applications in wearable electronics, automotive displays, and industrial sensors that must function reliably in harsh environmental conditions.

The trade-off between thermal stability and other desirable properties such as transparency, flexibility, and low-temperature processability further complicates the development of optimized metal oxide TFT technologies. Enhancing thermal stability often requires higher processing temperatures or additional material layers that may compromise other performance metrics or increase manufacturing complexity and cost.

Another critical challenge is the interface instability between the metal oxide semiconductor layer and the gate dielectric. At higher temperatures, interfacial defects can form or existing defects can be activated, leading to charge trapping phenomena that significantly impact device reliability. These interface states contribute to hysteresis effects and time-dependent threshold voltage shifts that compromise long-term operational stability.

The structural integrity of metal oxide TFTs under thermal cycling represents a substantial hurdle for applications requiring temperature resilience. Repeated heating and cooling cycles induce mechanical stress at material interfaces due to thermal expansion coefficient mismatches, potentially causing delamination or crack formation. This mechanical degradation accelerates device failure and reduces operational lifespan in real-world applications.

Manufacturing consistency presents another significant challenge, as process temperature variations during fabrication can lead to non-uniform electrical properties across devices. The sensitivity of metal oxide semiconductors to deposition and annealing temperatures means that precise thermal control is essential for achieving consistent performance metrics, particularly for large-area electronics and display applications.

Environmental factors further complicate thermal stability issues, as humidity and atmospheric conditions can interact with temperature effects to accelerate degradation mechanisms. Moisture ingress at elevated temperatures can catalyze chemical reactions at interfaces or within the metal oxide layer itself, introducing additional instability factors that are difficult to predict and mitigate in practical device designs.

Current passivation techniques and encapsulation methods provide only partial solutions to these thermal stability challenges. While they can extend device lifetime under moderate conditions, they often fail to provide comprehensive protection against the combined effects of temperature, humidity, and operational stress. This limitation is particularly problematic for emerging applications in wearable electronics, automotive displays, and industrial sensors that must function reliably in harsh environmental conditions.

The trade-off between thermal stability and other desirable properties such as transparency, flexibility, and low-temperature processability further complicates the development of optimized metal oxide TFT technologies. Enhancing thermal stability often requires higher processing temperatures or additional material layers that may compromise other performance metrics or increase manufacturing complexity and cost.

Contemporary Thermal Stability Enhancement Solutions

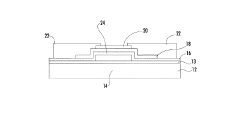

01 Metal oxide composition for improved thermal stability

Various metal oxide compositions can be engineered to enhance the thermal stability of thin-film transistors (TFTs). These compositions typically include combinations of indium, gallium, zinc, and other metals that form amorphous or crystalline structures with high temperature resistance. The specific ratio and selection of metal elements significantly impact the thermal stability of the resulting TFT, with certain compositions demonstrating superior performance under thermal stress conditions.- Metal oxide composition for improved thermal stability: Various metal oxide compositions can be engineered to enhance the thermal stability of thin-film transistors (TFTs). Specific combinations of metal oxides such as indium-gallium-zinc oxide (IGZO), zinc-tin oxide, or hafnium-indium-zinc oxide demonstrate superior resistance to performance degradation under elevated temperatures. The composition can be optimized by adjusting the ratio of constituent metals to minimize carrier concentration fluctuations during thermal stress.

- Annealing processes to enhance thermal stability: Specific annealing processes can significantly improve the thermal stability of metal oxide TFTs. Post-deposition thermal treatments at controlled temperatures and atmospheres help to reduce oxygen vacancies and stabilize the microstructure of the metal oxide semiconductor layer. These processes can include multi-step annealing, atmosphere-controlled annealing, or rapid thermal annealing, which effectively reduce threshold voltage shifts and mobility degradation under thermal stress conditions.

- Passivation and encapsulation techniques: Implementing effective passivation and encapsulation layers can protect metal oxide TFTs from thermal degradation. These protective layers prevent the diffusion of atmospheric gases and moisture into the metal oxide semiconductor, which can cause instability at elevated temperatures. Materials such as silicon nitride, aluminum oxide, or specialized polymer composites can serve as effective barriers, maintaining device performance even after prolonged exposure to high temperatures.

- Interface engineering for thermal robustness: The thermal stability of metal oxide TFTs can be significantly enhanced through interface engineering between the semiconductor and adjacent layers. Introducing buffer layers, modifying the gate dielectric interface, or implementing specific surface treatments can reduce interface trap states that are sensitive to thermal activation. These techniques minimize carrier scattering and threshold voltage shifts that typically occur during thermal cycling, resulting in more stable device operation at elevated temperatures.

- Doping strategies for temperature-resistant TFTs: Strategic doping of metal oxide semiconductors can enhance their thermal stability in TFT applications. Incorporating specific dopants such as nitrogen, hydrogen, or rare earth elements can passivate oxygen vacancies and stabilize the electronic structure of the metal oxide. These dopants can suppress thermally-induced carrier generation and reduce activation energy for defect formation, resulting in TFTs that maintain consistent electrical characteristics across a wider temperature range.

02 Annealing processes to enhance thermal stability

Thermal annealing processes play a crucial role in improving the stability of metal oxide TFTs. Post-deposition annealing at controlled temperatures helps to reduce defects, optimize the metal oxide structure, and enhance carrier mobility. Different annealing methods, including rapid thermal annealing, furnace annealing, and atmosphere-controlled annealing, can be employed to achieve specific thermal stability characteristics in the final device.Expand Specific Solutions03 Passivation layers for thermal protection

Implementing passivation layers is an effective approach to protect metal oxide TFTs from thermal degradation. These layers, typically composed of silicon oxide, silicon nitride, or aluminum oxide, serve as barriers against environmental factors and thermal stress. The passivation layer thickness and deposition method significantly influence the thermal stability of the TFT structure, with optimized layers preventing diffusion of impurities and maintaining device performance at elevated temperatures.Expand Specific Solutions04 Gate insulator materials for thermal stability

The selection of gate insulator materials significantly impacts the thermal stability of metal oxide TFTs. High-k dielectric materials such as hafnium oxide, aluminum oxide, and zirconium oxide provide superior thermal resistance compared to conventional silicon dioxide. These materials maintain their insulating properties at elevated temperatures and reduce leakage current, thereby enhancing the overall thermal stability of the TFT structure.Expand Specific Solutions05 Multi-layer channel structures for enhanced stability

Implementing multi-layer channel structures can significantly improve the thermal stability of metal oxide TFTs. These structures typically consist of alternating layers of different metal oxide compositions or doping profiles, creating interfaces that suppress carrier degradation at high temperatures. The strategic design of these multi-layer channels helps to maintain consistent electrical characteristics and threshold voltage stability under thermal stress conditions.Expand Specific Solutions

Leading Companies in Metal Oxide TFT Development

Metal oxide TFT technology is advancing rapidly in the electronics thermal stability landscape, currently transitioning from early adoption to mainstream implementation. The market is projected to grow significantly as demand increases for high-performance displays in extreme environments. Leading companies like BOE Technology, Sharp, and LG Display have achieved notable technological maturity, developing proprietary metal oxide semiconductor formulations that withstand temperatures exceeding 200°C. Applied Materials and Semiconductor Energy Laboratory are pioneering advanced manufacturing processes, while academic institutions like South China University of Technology and Peking University contribute fundamental research. The competitive landscape features established display manufacturers expanding their portfolios alongside specialized newcomers focusing on niche applications where thermal stability provides critical advantages in automotive, industrial, and medical electronics.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed proprietary metal oxide TFT technology branded as "HOXE" (High-performance Oxide Electronics) that specifically addresses thermal stability challenges in display and sensor applications. Their approach utilizes a multi-component oxide semiconductor system that incorporates hafnium and titanium dopants into traditional IGZO structures, creating more robust bonds that resist thermal degradation. BOE's metal oxide TFTs feature specialized passivation layers that prevent oxygen vacancy formation during thermal cycling, which is typically the primary degradation mechanism. Their research demonstrates stable threshold voltage characteristics even after 1000 hours at temperatures up to 120°C. BOE has also implemented a unique "thermal stress distribution layer" between the gate insulator and channel layer that absorbs and redistributes thermal energy, preventing localized hot spots that accelerate degradation. This technology enables their displays to maintain consistent performance in automotive applications where temperatures can fluctuate dramatically. Additionally, BOE utilizes specialized annealing techniques during fabrication that create more ordered semiconductor microstructures with fewer defect states susceptible to thermal activation.

Strengths: Excellent thermal stability suitable for automotive and industrial environments; maintains consistent electrical characteristics across wide temperature ranges; compatible with flexible substrate applications. Weaknesses: More complex manufacturing process than conventional a-Si; requires specialized deposition equipment; some compositions rely on relatively scarce elements.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed comprehensive metal oxide TFT manufacturing solutions that specifically address thermal stability challenges in advanced display and electronics applications. Their AKT PECVD systems enable the deposition of high-quality metal oxide semiconductor layers with precisely controlled stoichiometry and minimal defect states, which is critical for thermal stability. Applied Materials' proprietary "Thermal Shield" technology incorporates specialized buffer layers between the substrate and active semiconductor regions that effectively distribute and dissipate heat, preventing localized thermal stress that typically accelerates degradation. Their research demonstrates that metal oxide TFTs manufactured using their process technology maintain stable threshold voltage characteristics with shifts of less than 0.1V even after 2000 hours at 85°C with 85% humidity. Applied Materials has also developed specialized annealing techniques that create more ordered semiconductor microstructures with significantly reduced grain boundaries and defect states that are typically vulnerable to thermal activation. Their latest generation of equipment enables the fabrication of metal oxide TFTs that maintain mobility values above 20 cm²/Vs even after extended thermal cycling between -20°C and 100°C.

Strengths: Comprehensive manufacturing solutions that address the entire TFT fabrication process; equipment capable of high-volume production with excellent uniformity; advanced process control systems that ensure consistent thermal performance. Weaknesses: Requires significant capital investment in specialized equipment; some processes have higher energy consumption than conventional TFT manufacturing; optimization required for different metal oxide compositions.

Key Patents in Metal Oxide TFT Thermal Performance

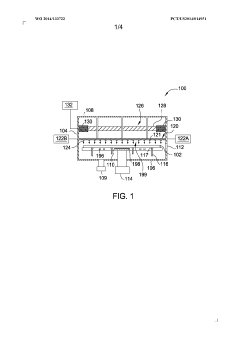

Metal oxide thin film transistor with excellent temperature stability

PatentInactiveJP2016502278A

Innovation

- Implementing a passivation material with a conduction band at least 0.5 eV higher than the metal oxide semiconductor's conduction band to transfer electrons away from the interface, reducing oxygen loss and improving stability by selecting materials like Ta2O5, TiO2, or other insulating oxides that are less susceptible to reduction.

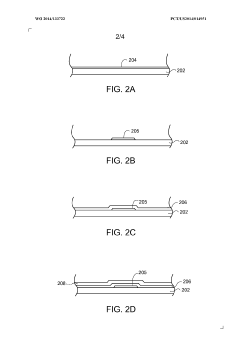

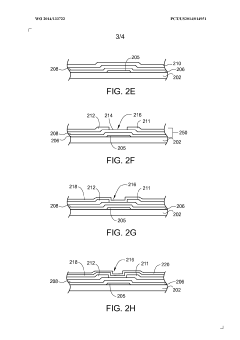

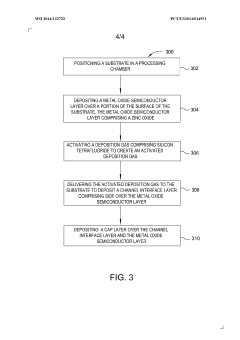

Metal oxide TFT stability improvement

PatentWO2014133722A1

Innovation

- The use of microwave PECVD (MW-PECVD) to deposit hydrogen-free silicon oxyfluoride (SiOF) channel interface layers and subsequent silicon-containing cap layers, reducing hydrogen incorporation and enhancing film stability.

Environmental Impact of Metal Oxide TFT Manufacturing

The manufacturing processes of Metal Oxide Thin-Film Transistors (TFTs) present significant environmental considerations that must be evaluated alongside their technical advantages in thermal stability. The production of these advanced electronic components involves several resource-intensive processes, including material extraction, chemical processing, and energy consumption, all of which contribute to their environmental footprint.

Raw material extraction for metal oxide semiconductors such as indium, gallium, zinc, and tin requires substantial mining operations that can lead to habitat disruption, soil erosion, and water contamination. Particularly concerning is the extraction of rare elements like indium, which is becoming increasingly scarce and environmentally costly to obtain. The refining processes for these materials further compound environmental impacts through energy-intensive purification methods.

Manufacturing facilities for metal oxide TFTs consume considerable electrical power, primarily for the vacuum deposition systems, annealing processes, and clean room operations. These energy demands translate directly to carbon emissions, though the exact impact varies significantly based on regional energy sources. Facilities powered by renewable energy demonstrate substantially lower carbon footprints compared to those reliant on fossil fuels.

Chemical usage represents another critical environmental concern. The fabrication process employs various solvents, etchants, and precursor materials that may contain toxic compounds. While many modern facilities implement closed-loop systems to minimize waste, the potential for environmental contamination through improper disposal or accidental release remains a legitimate concern for surrounding ecosystems and communities.

Water consumption in metal oxide TFT production is substantial, primarily for cleaning and cooling purposes. A single manufacturing facility may require millions of gallons annually, placing pressure on local water resources. Advanced facilities have begun implementing water recycling systems, though complete closed-loop water management remains challenging.

Encouragingly, the industry has made significant strides toward more sustainable manufacturing practices. Low-temperature processing techniques have reduced energy requirements, while solution-based deposition methods minimize chemical waste compared to traditional vacuum deposition. Additionally, the extended lifespan and enhanced efficiency of metal oxide TFT-based devices may partially offset their manufacturing impacts through reduced replacement frequency and lower operational energy consumption.

End-of-life considerations for metal oxide TFTs present both challenges and opportunities. While these components contain valuable materials that could be recovered through recycling, current electronic waste processing infrastructure is often inadequate for efficient material recovery. Developing more effective recycling pathways for these advanced materials represents a crucial area for environmental improvement in the industry's overall lifecycle assessment.

Raw material extraction for metal oxide semiconductors such as indium, gallium, zinc, and tin requires substantial mining operations that can lead to habitat disruption, soil erosion, and water contamination. Particularly concerning is the extraction of rare elements like indium, which is becoming increasingly scarce and environmentally costly to obtain. The refining processes for these materials further compound environmental impacts through energy-intensive purification methods.

Manufacturing facilities for metal oxide TFTs consume considerable electrical power, primarily for the vacuum deposition systems, annealing processes, and clean room operations. These energy demands translate directly to carbon emissions, though the exact impact varies significantly based on regional energy sources. Facilities powered by renewable energy demonstrate substantially lower carbon footprints compared to those reliant on fossil fuels.

Chemical usage represents another critical environmental concern. The fabrication process employs various solvents, etchants, and precursor materials that may contain toxic compounds. While many modern facilities implement closed-loop systems to minimize waste, the potential for environmental contamination through improper disposal or accidental release remains a legitimate concern for surrounding ecosystems and communities.

Water consumption in metal oxide TFT production is substantial, primarily for cleaning and cooling purposes. A single manufacturing facility may require millions of gallons annually, placing pressure on local water resources. Advanced facilities have begun implementing water recycling systems, though complete closed-loop water management remains challenging.

Encouragingly, the industry has made significant strides toward more sustainable manufacturing practices. Low-temperature processing techniques have reduced energy requirements, while solution-based deposition methods minimize chemical waste compared to traditional vacuum deposition. Additionally, the extended lifespan and enhanced efficiency of metal oxide TFT-based devices may partially offset their manufacturing impacts through reduced replacement frequency and lower operational energy consumption.

End-of-life considerations for metal oxide TFTs present both challenges and opportunities. While these components contain valuable materials that could be recovered through recycling, current electronic waste processing infrastructure is often inadequate for efficient material recovery. Developing more effective recycling pathways for these advanced materials represents a crucial area for environmental improvement in the industry's overall lifecycle assessment.

Material Science Advancements for Next-Gen TFTs

Material science has undergone significant transformations in recent years, particularly in the field of thin-film transistors (TFTs). The evolution from traditional silicon-based technologies to metal oxide semiconductors represents a paradigm shift in electronic materials engineering. Metal oxide TFTs, especially those based on amorphous oxide semiconductors (AOS) like indium-gallium-zinc oxide (IGZO), have emerged as promising candidates for next-generation display technologies and flexible electronics.

The fundamental advantage of metal oxide materials lies in their unique electronic structure. Unlike conventional amorphous silicon, metal oxides feature spherically symmetric s-orbitals that form the conduction band minimum, resulting in significantly higher electron mobility even in amorphous states. This characteristic enables high-performance TFTs without requiring crystalline perfection, dramatically simplifying manufacturing processes while enhancing device performance.

Recent advancements in deposition techniques have further accelerated the development of metal oxide TFTs. Low-temperature processes such as solution-based deposition and atomic layer deposition (ALD) have enabled the fabrication of high-quality metal oxide films on temperature-sensitive substrates. These techniques allow precise control over film composition, thickness, and interface properties, which are critical factors affecting thermal stability.

The incorporation of additional elements into metal oxide systems has proven effective in enhancing thermal stability. For instance, hafnium and zirconium doping in IGZO has demonstrated remarkable improvements in device reliability under elevated temperature conditions. These dopants modify the oxygen vacancy formation energy, suppressing thermally-induced carrier generation that typically leads to threshold voltage shifts and performance degradation.

Nanocomposite approaches represent another frontier in material science for TFTs. By creating heterogeneous structures combining metal oxides with other materials such as nanoparticles or 2D materials, researchers have developed systems with enhanced thermal boundaries that effectively dissipate heat and maintain structural integrity at high temperatures. These composite materials often exhibit self-healing properties that can mitigate thermal stress-induced defects.

Interface engineering has emerged as a critical aspect of thermal stability enhancement. Advanced surface treatments and buffer layers have been developed to minimize interfacial defects between the semiconductor and dielectric layers. These innovations reduce charge trapping and interface state generation during thermal cycling, significantly improving the long-term reliability of metal oxide TFTs in harsh environmental conditions.

The pursuit of environmentally friendly and abundant materials has also driven research toward earth-abundant metal oxide systems. Zinc-tin oxide and aluminum-doped zinc oxide have shown promising thermal stability characteristics while reducing dependence on scarce elements like indium. These sustainable material systems align with global efforts toward greener electronics manufacturing while maintaining the performance advantages of metal oxide semiconductors.

The fundamental advantage of metal oxide materials lies in their unique electronic structure. Unlike conventional amorphous silicon, metal oxides feature spherically symmetric s-orbitals that form the conduction band minimum, resulting in significantly higher electron mobility even in amorphous states. This characteristic enables high-performance TFTs without requiring crystalline perfection, dramatically simplifying manufacturing processes while enhancing device performance.

Recent advancements in deposition techniques have further accelerated the development of metal oxide TFTs. Low-temperature processes such as solution-based deposition and atomic layer deposition (ALD) have enabled the fabrication of high-quality metal oxide films on temperature-sensitive substrates. These techniques allow precise control over film composition, thickness, and interface properties, which are critical factors affecting thermal stability.

The incorporation of additional elements into metal oxide systems has proven effective in enhancing thermal stability. For instance, hafnium and zirconium doping in IGZO has demonstrated remarkable improvements in device reliability under elevated temperature conditions. These dopants modify the oxygen vacancy formation energy, suppressing thermally-induced carrier generation that typically leads to threshold voltage shifts and performance degradation.

Nanocomposite approaches represent another frontier in material science for TFTs. By creating heterogeneous structures combining metal oxides with other materials such as nanoparticles or 2D materials, researchers have developed systems with enhanced thermal boundaries that effectively dissipate heat and maintain structural integrity at high temperatures. These composite materials often exhibit self-healing properties that can mitigate thermal stress-induced defects.

Interface engineering has emerged as a critical aspect of thermal stability enhancement. Advanced surface treatments and buffer layers have been developed to minimize interfacial defects between the semiconductor and dielectric layers. These innovations reduce charge trapping and interface state generation during thermal cycling, significantly improving the long-term reliability of metal oxide TFTs in harsh environmental conditions.

The pursuit of environmentally friendly and abundant materials has also driven research toward earth-abundant metal oxide systems. Zinc-tin oxide and aluminum-doped zinc oxide have shown promising thermal stability characteristics while reducing dependence on scarce elements like indium. These sustainable material systems align with global efforts toward greener electronics manufacturing while maintaining the performance advantages of metal oxide semiconductors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!