Metal Oxide TFTs and Their Influence on Electrochemical Performance

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Oxide TFT Development History and Objectives

Metal oxide thin-film transistors (TFTs) have evolved significantly since their inception in the late 1960s when the first metal oxide semiconductor devices were developed. The journey began with simple binary oxides like ZnO and SnO2, which demonstrated limited performance characteristics. However, the field remained relatively dormant until the early 2000s, when a breakthrough occurred with the development of amorphous indium gallium zinc oxide (a-IGZO) TFTs by Japanese researchers at Tokyo Institute of Technology.

This pivotal advancement marked the beginning of the modern era for metal oxide TFTs, characterized by superior electron mobility, excellent uniformity, and low-temperature processability compared to conventional amorphous silicon technologies. The subsequent decade witnessed rapid technological evolution, with researchers worldwide focusing on enhancing stability, reducing threshold voltage, and improving carrier mobility through material composition optimization and novel fabrication techniques.

By 2010, metal oxide TFTs had begun transitioning from laboratory curiosities to commercially viable technologies, with early applications in display backplanes for LCDs and OLEDs. Companies like Sharp and Samsung pioneered the industrial implementation, demonstrating the scalability and cost-effectiveness of these devices. This period also saw the expansion of material systems beyond IGZO to include zinc tin oxide (ZTO), indium zinc oxide (IZO), and various other multicomponent oxides tailored for specific performance requirements.

The current technological objectives for metal oxide TFTs center around several key areas. First, enhancing operational stability under various environmental conditions remains crucial for widespread adoption. Second, researchers aim to further improve carrier mobility while maintaining the advantageous transparency and amorphous structure. Third, developing low-temperature processes compatible with flexible substrates represents a significant goal for enabling next-generation flexible and wearable electronics.

Most recently, an emerging research direction has focused on the intersection of metal oxide TFTs with electrochemical systems. This novel approach explores how the unique electronic properties of metal oxide semiconductors can influence and enhance electrochemical performance in applications ranging from sensors to energy storage devices. The semiconductor-electrolyte interface presents fascinating opportunities for controlling charge transfer processes, with metal oxide TFTs serving as active components rather than merely passive circuit elements.

Looking forward, the field aims to achieve fully transparent, flexible, and environmentally stable devices with performance metrics approaching those of conventional silicon technologies. Additionally, integration with other emerging technologies such as neuromorphic computing and bioelectronics represents exciting frontiers that could potentially revolutionize how we interact with electronic devices in daily life.

This pivotal advancement marked the beginning of the modern era for metal oxide TFTs, characterized by superior electron mobility, excellent uniformity, and low-temperature processability compared to conventional amorphous silicon technologies. The subsequent decade witnessed rapid technological evolution, with researchers worldwide focusing on enhancing stability, reducing threshold voltage, and improving carrier mobility through material composition optimization and novel fabrication techniques.

By 2010, metal oxide TFTs had begun transitioning from laboratory curiosities to commercially viable technologies, with early applications in display backplanes for LCDs and OLEDs. Companies like Sharp and Samsung pioneered the industrial implementation, demonstrating the scalability and cost-effectiveness of these devices. This period also saw the expansion of material systems beyond IGZO to include zinc tin oxide (ZTO), indium zinc oxide (IZO), and various other multicomponent oxides tailored for specific performance requirements.

The current technological objectives for metal oxide TFTs center around several key areas. First, enhancing operational stability under various environmental conditions remains crucial for widespread adoption. Second, researchers aim to further improve carrier mobility while maintaining the advantageous transparency and amorphous structure. Third, developing low-temperature processes compatible with flexible substrates represents a significant goal for enabling next-generation flexible and wearable electronics.

Most recently, an emerging research direction has focused on the intersection of metal oxide TFTs with electrochemical systems. This novel approach explores how the unique electronic properties of metal oxide semiconductors can influence and enhance electrochemical performance in applications ranging from sensors to energy storage devices. The semiconductor-electrolyte interface presents fascinating opportunities for controlling charge transfer processes, with metal oxide TFTs serving as active components rather than merely passive circuit elements.

Looking forward, the field aims to achieve fully transparent, flexible, and environmentally stable devices with performance metrics approaching those of conventional silicon technologies. Additionally, integration with other emerging technologies such as neuromorphic computing and bioelectronics represents exciting frontiers that could potentially revolutionize how we interact with electronic devices in daily life.

Market Analysis for Metal Oxide TFT Applications

The global market for Metal Oxide Thin-Film Transistors (TFTs) has experienced significant growth over the past decade, driven primarily by their superior performance characteristics compared to traditional amorphous silicon (a-Si) TFTs. The market value reached approximately $3.2 billion in 2022 and is projected to grow at a CAGR of 9.7% through 2028, potentially reaching $5.6 billion by the end of the forecast period.

Display technologies represent the largest application segment for metal oxide TFTs, accounting for over 65% of the total market share. This dominance stems from the exceptional electron mobility, transparency, and stability that metal oxide semiconductors like IGZO (Indium Gallium Zinc Oxide) offer. Major display manufacturers including Samsung, LG Display, and BOE Technology have increasingly adopted these technologies for high-resolution OLED and LCD panels.

The consumer electronics sector remains the primary end-user of metal oxide TFT technology, with applications in smartphones, tablets, and televisions driving demand. However, emerging applications in healthcare monitoring devices, automotive displays, and industrial control systems are creating new market opportunities. The healthcare segment specifically is expected to witness the fastest growth rate of 12.3% annually through 2028.

Regionally, East Asia dominates the metal oxide TFT market with approximately 58% market share, led by manufacturing powerhouses in South Korea, Japan, and Taiwan. North America and Europe follow with 18% and 15% respectively, while emerging economies in Southeast Asia and India are showing accelerated adoption rates.

The electrochemical performance aspects of metal oxide TFTs are opening entirely new market segments beyond traditional display applications. Their integration into biosensors and electrochemical detection systems has created a specialized market niche estimated at $420 million in 2022, with projections to reach $780 million by 2028. This growth is fueled by increasing demand for point-of-care diagnostic devices and environmental monitoring systems.

Supply chain challenges remain a significant market factor, particularly regarding the availability of indium and other rare earth elements essential for high-performance metal oxide semiconductors. This has prompted research into alternative material compositions, creating potential market disruptions and opportunities for new entrants with innovative material solutions.

Price sensitivity varies significantly across application segments. While consumer electronics manufacturers remain highly cost-conscious, specialized applications in medical diagnostics and industrial sensing demonstrate greater willingness to pay premium prices for enhanced electrochemical performance and reliability.

Display technologies represent the largest application segment for metal oxide TFTs, accounting for over 65% of the total market share. This dominance stems from the exceptional electron mobility, transparency, and stability that metal oxide semiconductors like IGZO (Indium Gallium Zinc Oxide) offer. Major display manufacturers including Samsung, LG Display, and BOE Technology have increasingly adopted these technologies for high-resolution OLED and LCD panels.

The consumer electronics sector remains the primary end-user of metal oxide TFT technology, with applications in smartphones, tablets, and televisions driving demand. However, emerging applications in healthcare monitoring devices, automotive displays, and industrial control systems are creating new market opportunities. The healthcare segment specifically is expected to witness the fastest growth rate of 12.3% annually through 2028.

Regionally, East Asia dominates the metal oxide TFT market with approximately 58% market share, led by manufacturing powerhouses in South Korea, Japan, and Taiwan. North America and Europe follow with 18% and 15% respectively, while emerging economies in Southeast Asia and India are showing accelerated adoption rates.

The electrochemical performance aspects of metal oxide TFTs are opening entirely new market segments beyond traditional display applications. Their integration into biosensors and electrochemical detection systems has created a specialized market niche estimated at $420 million in 2022, with projections to reach $780 million by 2028. This growth is fueled by increasing demand for point-of-care diagnostic devices and environmental monitoring systems.

Supply chain challenges remain a significant market factor, particularly regarding the availability of indium and other rare earth elements essential for high-performance metal oxide semiconductors. This has prompted research into alternative material compositions, creating potential market disruptions and opportunities for new entrants with innovative material solutions.

Price sensitivity varies significantly across application segments. While consumer electronics manufacturers remain highly cost-conscious, specialized applications in medical diagnostics and industrial sensing demonstrate greater willingness to pay premium prices for enhanced electrochemical performance and reliability.

Technical Challenges in Metal Oxide TFT Electrochemistry

Metal oxide thin-film transistors (TFTs) face several significant technical challenges when integrated with electrochemical systems. The interface between the metal oxide semiconductor and the electrolyte presents complex electrochemical interactions that can compromise device performance and stability. Charge transfer mechanisms at this interface remain incompletely understood, particularly regarding how ion migration affects the semiconductor's electronic properties during operation.

A primary challenge lies in achieving stable operation in aqueous environments. Metal oxide TFTs typically experience threshold voltage shifts and mobility degradation when exposed to electrolytes, as water molecules and ions penetrate the semiconductor layer. This phenomenon is particularly problematic for biosensing applications where long-term stability in physiological conditions is essential.

The choice of metal oxide material presents another significant hurdle. While indium gallium zinc oxide (IGZO) has emerged as a leading candidate due to its high mobility and low-temperature processability, it exhibits varying degrees of electrochemical stability. Alternative materials such as zinc tin oxide (ZTO) and aluminum zinc oxide (AZO) show promising electrochemical resistance but often at the cost of reduced electrical performance or increased fabrication complexity.

Passivation layers represent a critical technical challenge in protecting the active semiconductor while maintaining sensitivity to target analytes. Current approaches using Al2O3, SiO2, or organic polymers often result in trade-offs between device protection and sensing capability. The development of selective ion-permeable barriers remains an active research area with significant technical obstacles.

Contact resistance issues are exacerbated in electrochemical environments, as metal electrodes may undergo oxidation or reduction reactions at the interface. This leads to unstable device characteristics and potential failure mechanisms that are difficult to predict and mitigate. Novel electrode materials and contact engineering approaches are needed to address these challenges.

Process integration presents substantial difficulties, particularly in maintaining TFT performance while incorporating electrochemical sensing elements. Conventional microfabrication techniques may require modification to accommodate both electronic and electrochemical components on the same substrate without cross-contamination or performance degradation.

Temperature sensitivity poses another challenge, as electrochemical reactions are highly temperature-dependent while TFT characteristics also vary with thermal conditions. Developing compensation mechanisms for these thermal effects remains technically challenging, especially for point-of-care applications where environmental conditions cannot be tightly controlled.

Finally, signal-to-noise ratio optimization represents a significant hurdle in metal oxide TFT electrochemical sensors. Distinguishing small electrochemical signals from background electrical noise requires sophisticated circuit design and signal processing techniques that must be compatible with the inherent limitations of metal oxide semiconductor technology.

A primary challenge lies in achieving stable operation in aqueous environments. Metal oxide TFTs typically experience threshold voltage shifts and mobility degradation when exposed to electrolytes, as water molecules and ions penetrate the semiconductor layer. This phenomenon is particularly problematic for biosensing applications where long-term stability in physiological conditions is essential.

The choice of metal oxide material presents another significant hurdle. While indium gallium zinc oxide (IGZO) has emerged as a leading candidate due to its high mobility and low-temperature processability, it exhibits varying degrees of electrochemical stability. Alternative materials such as zinc tin oxide (ZTO) and aluminum zinc oxide (AZO) show promising electrochemical resistance but often at the cost of reduced electrical performance or increased fabrication complexity.

Passivation layers represent a critical technical challenge in protecting the active semiconductor while maintaining sensitivity to target analytes. Current approaches using Al2O3, SiO2, or organic polymers often result in trade-offs between device protection and sensing capability. The development of selective ion-permeable barriers remains an active research area with significant technical obstacles.

Contact resistance issues are exacerbated in electrochemical environments, as metal electrodes may undergo oxidation or reduction reactions at the interface. This leads to unstable device characteristics and potential failure mechanisms that are difficult to predict and mitigate. Novel electrode materials and contact engineering approaches are needed to address these challenges.

Process integration presents substantial difficulties, particularly in maintaining TFT performance while incorporating electrochemical sensing elements. Conventional microfabrication techniques may require modification to accommodate both electronic and electrochemical components on the same substrate without cross-contamination or performance degradation.

Temperature sensitivity poses another challenge, as electrochemical reactions are highly temperature-dependent while TFT characteristics also vary with thermal conditions. Developing compensation mechanisms for these thermal effects remains technically challenging, especially for point-of-care applications where environmental conditions cannot be tightly controlled.

Finally, signal-to-noise ratio optimization represents a significant hurdle in metal oxide TFT electrochemical sensors. Distinguishing small electrochemical signals from background electrical noise requires sophisticated circuit design and signal processing techniques that must be compatible with the inherent limitations of metal oxide semiconductor technology.

Current Electrochemical Performance Enhancement Solutions

01 Metal oxide semiconductor materials for TFT fabrication

Various metal oxide semiconductor materials are used in the fabrication of thin-film transistors (TFTs) to enhance electrochemical performance. These materials include zinc oxide, indium gallium zinc oxide (IGZO), and other metal oxide combinations that offer high electron mobility, good stability, and transparency. The selection of appropriate metal oxide materials is crucial for achieving optimal TFT performance in various applications including displays and sensors.- Metal oxide semiconductor materials for TFT fabrication: Various metal oxide semiconductor materials are used in the fabrication of thin-film transistors (TFTs) to enhance electrochemical performance. These materials include zinc oxide, indium gallium zinc oxide (IGZO), and other metal oxide combinations that offer advantages such as high electron mobility, good stability, and transparency. The selection and composition of these metal oxides significantly impact the electrical characteristics and overall performance of the TFTs in electronic applications.

- Electrode materials and interfaces in metal oxide TFTs: The electrochemical performance of metal oxide TFTs is heavily influenced by the electrode materials and the interfaces between electrodes and the semiconductor layer. Research focuses on optimizing source/drain and gate electrode materials, interface engineering, and contact resistance reduction techniques. Proper selection of electrode materials and treatment of interfaces can significantly improve charge carrier injection, reduce parasitic resistances, and enhance overall device performance and reliability.

- Processing techniques for enhanced electrochemical performance: Various processing techniques are employed to enhance the electrochemical performance of metal oxide TFTs. These include annealing treatments, plasma processing, solution-based deposition methods, and other fabrication approaches that optimize the microstructure and composition of the metal oxide layers. These techniques can control oxygen vacancy concentration, crystallinity, and defect states, which are critical factors affecting carrier transport properties and device stability under operational conditions.

- Stability and reliability improvements in metal oxide TFTs: Improving the stability and reliability of metal oxide TFTs under various environmental and operational conditions is crucial for their practical applications. Research addresses bias stress stability, temperature effects, humidity resistance, and long-term operational reliability. Approaches include passivation layers, compositional optimization, multilayer structures, and interface engineering to mitigate degradation mechanisms and enhance device lifetime in electrochemical applications.

- Novel applications leveraging electrochemical properties of metal oxide TFTs: Metal oxide TFTs with enhanced electrochemical performance enable novel applications beyond conventional electronics. These include biosensors, chemical sensors, electrochemical transistors for biological interfaces, energy storage integration, and neuromorphic computing elements. The unique combination of electrical switching capabilities and electrochemical sensing properties of metal oxide TFTs allows for multifunctional devices that can interact with both electronic circuits and chemical/biological environments.

02 Electrode configuration and interface engineering in metal oxide TFTs

The electrochemical performance of metal oxide TFTs is significantly influenced by electrode configuration and interface engineering. Optimizing the source/drain electrodes, gate electrode materials, and the interfaces between different layers can reduce contact resistance and improve charge transfer efficiency. Interface engineering techniques such as surface treatments and buffer layers help minimize defects and enhance the overall electrochemical performance of the devices.Expand Specific Solutions03 Doping strategies to enhance conductivity and stability

Doping metal oxide semiconductors with various elements can significantly improve their electrochemical performance in TFT applications. Strategic doping with elements such as aluminum, gallium, or nitrogen can enhance conductivity, stability, and carrier concentration. These doping strategies help in controlling the threshold voltage, reducing off-state current, and improving the overall reliability of metal oxide TFTs under various operating conditions.Expand Specific Solutions04 Deposition techniques and post-treatment processes

Various deposition techniques and post-treatment processes significantly impact the electrochemical performance of metal oxide TFTs. Methods such as sputtering, atomic layer deposition, solution processing, and chemical vapor deposition are used to create high-quality metal oxide films. Post-deposition treatments including annealing, plasma treatment, and passivation layers help reduce defects, improve crystallinity, and enhance the overall electrochemical stability and performance of the devices.Expand Specific Solutions05 Novel device architectures for improved electrochemical sensing

Innovative device architectures are being developed to enhance the electrochemical sensing capabilities of metal oxide TFTs. These include dual-gate structures, vertical channel configurations, and integrated sensor platforms that combine TFTs with electrochemical detection elements. Such novel architectures enable improved sensitivity, selectivity, and response time for applications in chemical and biological sensing, environmental monitoring, and medical diagnostics.Expand Specific Solutions

Leading Companies and Research Institutions in Metal Oxide TFTs

Metal Oxide TFTs technology is currently in a growth phase, with increasing adoption in display and electrochemical applications. The market is expanding rapidly, projected to reach significant scale as these transistors offer advantages in performance and power efficiency. Technologically, the field shows moderate maturity with established players like BOE Technology, Samsung Display, and Sharp leading commercial implementation, while companies such as Applied Materials provide essential manufacturing equipment. Research-focused entities including Semiconductor Energy Laboratory and academic institutions like Northwestern University and South China University of Technology are advancing fundamental innovations. Chinese manufacturers (TCL China Star, Tianma Microelectronics) are rapidly gaining market share, while specialized players like Guangzhou New Vision focus on integrating metal oxide TFTs with emerging technologies such as flexible AMOLED displays, indicating a competitive landscape transitioning from development to broader commercialization.

BOE Technology Group Co., Ltd.

Technical Solution: BOE Technology has developed proprietary metal oxide TFT technologies optimized for both display applications and emerging electrochemical sensing platforms. Their advanced oxide semiconductor formulations incorporate carefully controlled dopants to enhance stability in aqueous environments while maintaining high carrier mobility (>15 cm²/Vs). BOE has pioneered multi-component oxide systems beyond traditional IGZO, including hafnium-indium-zinc-oxide (HIZO) compositions that demonstrate superior resistance to electrochemical degradation. Their research shows that specialized annealing processes in controlled atmospheres can significantly reduce oxygen vacancy concentration fluctuations, a critical factor affecting electrochemical stability. For sensing applications, BOE has developed integrated metal oxide TFT arrays with specialized passivation schemes that selectively expose sensing regions while protecting critical device components from ionic contamination. Their latest generation of metal oxide TFT sensors demonstrates stable operation in physiological solutions for over 1000 hours with minimal threshold voltage shift (<0.2V), enabling reliable long-term electrochemical measurements for biomedical applications.

Strengths: Large-scale manufacturing capability enabling cost-effective production; extensive experience in oxide semiconductor optimization; strong integration with display technologies providing economic advantages. Weaknesses: Primary focus on display applications may limit optimization for specialized electrochemical sensing; proprietary nature of some technologies may restrict academic collaboration and broader development.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed comprehensive manufacturing solutions specifically for metal oxide TFT production with direct implications for electrochemical performance. Their AKT-PiVot™ DT PVD system enables precise deposition of indium-gallium-zinc-oxide (IGZO) and other metal oxide semiconductor materials with controlled stoichiometry and oxygen incorporation, critical factors affecting carrier concentration and electrochemical stability. Applied Materials' process technologies include specialized annealing methods that optimize the metal-oxide microstructure to enhance mobility while maintaining low off-state current. For electrochemical applications, they've developed specialized encapsulation technologies that protect metal oxide TFTs from degradation in ionic environments while maintaining electrochemical sensing capabilities at designated sites. Their research demonstrates that controlled oxygen vacancy management in metal oxide films significantly impacts both electrical performance and electrochemical stability. Applied Materials' integrated manufacturing approach addresses the entire TFT stack, including specialized contact materials and barrier layers that minimize interfacial electrochemical reactions that could degrade device performance in sensing applications.

Strengths: Comprehensive end-to-end manufacturing solutions; precise control over material composition and microstructure; extensive process knowledge enabling customization for specific electrochemical requirements. Weaknesses: Focus primarily on manufacturing equipment rather than end applications; solutions may require significant capital investment; dependence on customer implementation for final application development.

Key Patents and Breakthroughs in Metal Oxide TFT Design

Thin film transistor

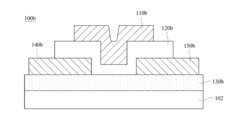

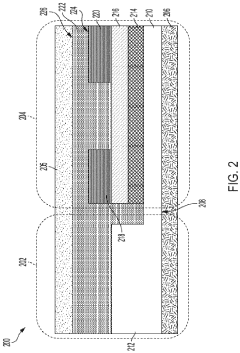

PatentActiveUS20150069379A1

Innovation

- A thin film transistor with an indium gallium zinc oxide (IGZO) semiconductor layer, where the atomic ratios of gallium to indium and zinc are optimized between 1.5 to 2, enhancing the stability and reliability by maintaining mobility greater than 10 cm2/Vs and reducing threshold voltage variation to less than 1.3 V, and subthreshold swing to less than 0.6 V/dec.

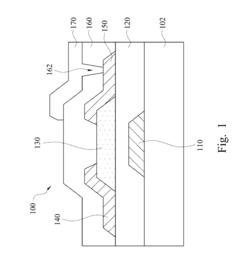

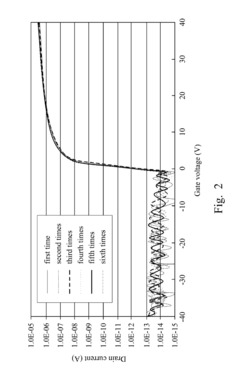

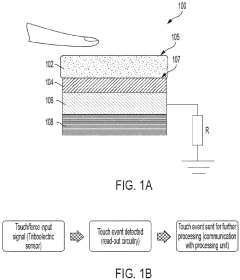

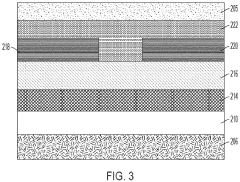

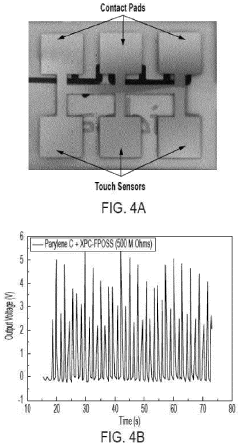

Thin-film transistor integrated with triboelectric layer

PatentInactiveEP3789857A1

Innovation

- An integrated device comprising a passivated thin-film transistor interfaced with a triboelectric driven tactile sensor, utilizing a parylene layer for protection and a triboelectric layer made of a photoactive thermoplastic copolymer and trifluoropropyl polyhedral oligomeric silsesquioxane blend, which generates a voltage pulse upon contact, enabling high triboelectric performance and environmental stability.

Material Science Advancements Supporting Metal Oxide TFTs

Recent advancements in material science have significantly propelled the development of metal oxide thin-film transistors (TFTs). The evolution of these materials has been characterized by a shift from traditional silicon-based semiconductors to metal oxide alternatives, offering superior electron mobility, transparency, and stability. Indium gallium zinc oxide (IGZO) has emerged as a frontrunner, demonstrating exceptional performance characteristics while maintaining compatibility with existing manufacturing processes.

The crystalline structure of metal oxides plays a crucial role in their electrical properties. Research has revealed that amorphous configurations often outperform their crystalline counterparts in TFT applications due to their uniform electron transport pathways and reduced grain boundary effects. This understanding has led to tailored deposition techniques that optimize the amorphous state while maintaining high carrier mobility.

Innovations in deposition methodologies have further enhanced metal oxide TFT performance. Atomic layer deposition (ALD) enables precise control over film thickness and composition, while solution-based processes offer cost-effective alternatives for large-area applications. These techniques have collectively reduced defect densities and improved interface quality, directly impacting electrochemical stability and performance.

Doping strategies represent another significant advancement, with researchers successfully incorporating various elements to modulate carrier concentration and mobility. Hafnium and aluminum doping have shown particular promise in enhancing stability under bias stress conditions, while maintaining high on/off current ratios essential for practical applications.

Interface engineering between the semiconductor and dielectric layers has proven critical for electrochemical performance. Novel passivation techniques and buffer layers have effectively reduced trap states and interface defects, minimizing hysteresis effects and threshold voltage shifts during operation. These improvements directly translate to enhanced electrochemical sensing capabilities when metal oxide TFTs are integrated into sensing platforms.

Nanoscale structuring of metal oxide materials has opened new avenues for performance enhancement. One-dimensional nanostructures such as nanowires and two-dimensional configurations have demonstrated exceptional surface-to-volume ratios, beneficial for electrochemical applications requiring high sensitivity. These structures provide increased active sites for electrochemical reactions while maintaining the electrical advantages of metal oxide semiconductors.

The development of flexible and stretchable metal oxide TFTs represents perhaps the most transformative material science advancement. Through innovative substrate engineering and low-temperature processing techniques, researchers have created devices that maintain performance integrity under mechanical deformation, enabling integration into wearable electrochemical sensors and biomedical monitoring systems.

The crystalline structure of metal oxides plays a crucial role in their electrical properties. Research has revealed that amorphous configurations often outperform their crystalline counterparts in TFT applications due to their uniform electron transport pathways and reduced grain boundary effects. This understanding has led to tailored deposition techniques that optimize the amorphous state while maintaining high carrier mobility.

Innovations in deposition methodologies have further enhanced metal oxide TFT performance. Atomic layer deposition (ALD) enables precise control over film thickness and composition, while solution-based processes offer cost-effective alternatives for large-area applications. These techniques have collectively reduced defect densities and improved interface quality, directly impacting electrochemical stability and performance.

Doping strategies represent another significant advancement, with researchers successfully incorporating various elements to modulate carrier concentration and mobility. Hafnium and aluminum doping have shown particular promise in enhancing stability under bias stress conditions, while maintaining high on/off current ratios essential for practical applications.

Interface engineering between the semiconductor and dielectric layers has proven critical for electrochemical performance. Novel passivation techniques and buffer layers have effectively reduced trap states and interface defects, minimizing hysteresis effects and threshold voltage shifts during operation. These improvements directly translate to enhanced electrochemical sensing capabilities when metal oxide TFTs are integrated into sensing platforms.

Nanoscale structuring of metal oxide materials has opened new avenues for performance enhancement. One-dimensional nanostructures such as nanowires and two-dimensional configurations have demonstrated exceptional surface-to-volume ratios, beneficial for electrochemical applications requiring high sensitivity. These structures provide increased active sites for electrochemical reactions while maintaining the electrical advantages of metal oxide semiconductors.

The development of flexible and stretchable metal oxide TFTs represents perhaps the most transformative material science advancement. Through innovative substrate engineering and low-temperature processing techniques, researchers have created devices that maintain performance integrity under mechanical deformation, enabling integration into wearable electrochemical sensors and biomedical monitoring systems.

Sustainability and Environmental Impact of Metal Oxide TFT Production

The production of metal oxide thin-film transistors (TFTs) presents significant sustainability challenges and environmental implications that warrant careful consideration. The manufacturing processes involve resource-intensive extraction of rare metals, high-temperature deposition techniques, and potentially hazardous chemical treatments, all of which contribute to environmental degradation and resource depletion.

Energy consumption represents one of the most critical environmental concerns in metal oxide TFT production. The high-temperature annealing processes required for crystallization and activation of metal oxide semiconductors typically operate at 300-500°C, demanding substantial energy inputs. Solution-based methods have emerged as more energy-efficient alternatives, potentially reducing energy requirements by 30-40% compared to conventional vacuum-based deposition techniques.

Water usage and contamination constitute another significant environmental challenge. The fabrication of metal oxide TFTs requires ultra-pure water for cleaning and processing, with estimates suggesting that producing a single square meter of display incorporating these TFTs may consume up to 1,500 liters of water. Furthermore, effluent from these processes often contains heavy metals and chemical residues that require specialized treatment before discharge.

Material efficiency and waste generation also impact the sustainability profile of metal oxide TFT production. Current manufacturing techniques typically utilize only 10-15% of input materials effectively, with the remainder becoming waste. Particularly concerning is the incorporation of indium, a scarce element with limited global reserves, in many high-performance metal oxide TFT formulations such as IGZO (indium-gallium-zinc oxide).

Recent advancements in green manufacturing approaches show promise for mitigating these environmental impacts. Low-temperature processing techniques using UV-assisted annealing have demonstrated the ability to reduce processing temperatures to below 200°C while maintaining comparable device performance. Additionally, research into abundant and non-toxic alternative materials such as zinc tin oxide (ZTO) offers pathways to reduce dependence on scarce elements.

Life cycle assessment (LCA) studies indicate that the environmental footprint of metal oxide TFTs extends beyond manufacturing to include end-of-life considerations. The complex multi-layer structure of these devices complicates recycling efforts, with current recovery rates for valuable metals remaining below 20%. Emerging design-for-recycling approaches aim to address this challenge by simplifying device architectures and incorporating more readily separable components.

The electrochemical performance of metal oxide TFTs is intrinsically linked to their environmental impact, as more efficient devices require less power during operation, potentially offsetting manufacturing impacts over product lifetimes. Balancing performance requirements with sustainability considerations represents a key challenge for future development in this field.

Energy consumption represents one of the most critical environmental concerns in metal oxide TFT production. The high-temperature annealing processes required for crystallization and activation of metal oxide semiconductors typically operate at 300-500°C, demanding substantial energy inputs. Solution-based methods have emerged as more energy-efficient alternatives, potentially reducing energy requirements by 30-40% compared to conventional vacuum-based deposition techniques.

Water usage and contamination constitute another significant environmental challenge. The fabrication of metal oxide TFTs requires ultra-pure water for cleaning and processing, with estimates suggesting that producing a single square meter of display incorporating these TFTs may consume up to 1,500 liters of water. Furthermore, effluent from these processes often contains heavy metals and chemical residues that require specialized treatment before discharge.

Material efficiency and waste generation also impact the sustainability profile of metal oxide TFT production. Current manufacturing techniques typically utilize only 10-15% of input materials effectively, with the remainder becoming waste. Particularly concerning is the incorporation of indium, a scarce element with limited global reserves, in many high-performance metal oxide TFT formulations such as IGZO (indium-gallium-zinc oxide).

Recent advancements in green manufacturing approaches show promise for mitigating these environmental impacts. Low-temperature processing techniques using UV-assisted annealing have demonstrated the ability to reduce processing temperatures to below 200°C while maintaining comparable device performance. Additionally, research into abundant and non-toxic alternative materials such as zinc tin oxide (ZTO) offers pathways to reduce dependence on scarce elements.

Life cycle assessment (LCA) studies indicate that the environmental footprint of metal oxide TFTs extends beyond manufacturing to include end-of-life considerations. The complex multi-layer structure of these devices complicates recycling efforts, with current recovery rates for valuable metals remaining below 20%. Emerging design-for-recycling approaches aim to address this challenge by simplifying device architectures and incorporating more readily separable components.

The electrochemical performance of metal oxide TFTs is intrinsically linked to their environmental impact, as more efficient devices require less power during operation, potentially offsetting manufacturing impacts over product lifetimes. Balancing performance requirements with sustainability considerations represents a key challenge for future development in this field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!