Evaluating Metal Oxide TFT Performance in EV Battery Systems

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Oxide TFT Technology Background and Objectives

Metal oxide thin-film transistors (TFTs) have emerged as a transformative technology in electronic applications over the past two decades. Initially developed as an alternative to amorphous silicon in display technologies, these semiconductor devices have evolved significantly, demonstrating exceptional electrical properties including high electron mobility, excellent uniformity, and remarkable stability under various environmental conditions. The evolution of metal oxide TFTs began with zinc oxide-based materials in the early 2000s, followed by the introduction of indium gallium zinc oxide (IGZO) which marked a significant breakthrough in performance characteristics.

The technological trajectory has been characterized by continuous improvements in material composition, deposition techniques, and device architectures. Recent advancements have focused on enhancing carrier mobility, reducing threshold voltage, and improving stability under bias stress conditions - all critical factors for high-performance applications such as electric vehicle (EV) battery management systems.

In the context of EV battery systems, metal oxide TFTs present a compelling opportunity to address several critical challenges. The primary objective of implementing this technology in battery management systems is to achieve more precise monitoring and control of individual battery cells within large battery packs. This granular management capability could significantly enhance overall battery performance, safety, and longevity - key concerns in the rapidly expanding EV market.

Current battery management systems often rely on conventional silicon-based technologies that face limitations in terms of operating temperature range, power consumption, and integration density. Metal oxide TFTs offer potential solutions to these constraints through their wide bandgap properties, low off-state current, and compatibility with low-temperature processing techniques that enable flexible and conformal integration with battery components.

The technical objectives for metal oxide TFTs in EV battery applications include achieving operational stability across the extreme temperature ranges experienced in automotive environments (-40°C to 125°C), demonstrating radiation hardness to ensure reliability in various environmental conditions, and maintaining consistent performance characteristics over the 8-15 year expected lifetime of EV battery systems.

Additionally, there is a growing focus on developing environmentally sustainable variants of metal oxide TFT technology by reducing or eliminating rare and potentially toxic elements such as indium, while maintaining or improving performance metrics. This aligns with broader sustainability goals in the EV industry and addresses potential supply chain vulnerabilities associated with critical materials.

The convergence of metal oxide TFT technology with advanced battery systems represents a frontier in transportation electrification, with the potential to address key performance bottlenecks in current EV battery management architectures.

The technological trajectory has been characterized by continuous improvements in material composition, deposition techniques, and device architectures. Recent advancements have focused on enhancing carrier mobility, reducing threshold voltage, and improving stability under bias stress conditions - all critical factors for high-performance applications such as electric vehicle (EV) battery management systems.

In the context of EV battery systems, metal oxide TFTs present a compelling opportunity to address several critical challenges. The primary objective of implementing this technology in battery management systems is to achieve more precise monitoring and control of individual battery cells within large battery packs. This granular management capability could significantly enhance overall battery performance, safety, and longevity - key concerns in the rapidly expanding EV market.

Current battery management systems often rely on conventional silicon-based technologies that face limitations in terms of operating temperature range, power consumption, and integration density. Metal oxide TFTs offer potential solutions to these constraints through their wide bandgap properties, low off-state current, and compatibility with low-temperature processing techniques that enable flexible and conformal integration with battery components.

The technical objectives for metal oxide TFTs in EV battery applications include achieving operational stability across the extreme temperature ranges experienced in automotive environments (-40°C to 125°C), demonstrating radiation hardness to ensure reliability in various environmental conditions, and maintaining consistent performance characteristics over the 8-15 year expected lifetime of EV battery systems.

Additionally, there is a growing focus on developing environmentally sustainable variants of metal oxide TFT technology by reducing or eliminating rare and potentially toxic elements such as indium, while maintaining or improving performance metrics. This aligns with broader sustainability goals in the EV industry and addresses potential supply chain vulnerabilities associated with critical materials.

The convergence of metal oxide TFT technology with advanced battery systems represents a frontier in transportation electrification, with the potential to address key performance bottlenecks in current EV battery management architectures.

EV Battery Market Demand Analysis

The electric vehicle (EV) battery market is experiencing unprecedented growth, driven by the global shift towards sustainable transportation solutions. Current market analysis indicates that the global EV battery market reached approximately $46 billion in 2022 and is projected to grow at a compound annual growth rate of 19.7% through 2030, potentially reaching $200 billion by the end of the decade. This remarkable expansion is primarily fueled by increasing government regulations on vehicle emissions, growing consumer awareness about environmental sustainability, and continuous improvements in battery technology.

Consumer demand for EVs with longer ranges and faster charging capabilities has created specific requirements for battery management systems (BMS). Market research shows that consumers expect a minimum range of 300 miles per charge and charging times under 30 minutes for 80% capacity. These expectations directly influence the technical requirements for monitoring systems within battery packs, where Metal Oxide Thin-Film Transistor (TFT) technology could play a crucial role.

The commercial vehicle sector represents a rapidly growing segment within the EV battery market. Fleet operators are increasingly transitioning to electric solutions due to lower total cost of ownership, with projections showing that commercial EV adoption could reach 30% of new vehicle sales by 2030 in major markets. This transition creates substantial demand for robust battery monitoring systems that can withstand harsh operating conditions and provide reliable performance over extended periods.

Regional analysis reveals significant market variations. Asia-Pacific dominates the EV battery production landscape, with China accounting for over 70% of global manufacturing capacity. However, recent policy shifts in North America and Europe aim to reduce dependency on Asian suppliers, creating new market opportunities for localized battery technology development, including advanced monitoring systems utilizing metal oxide TFT technology.

Battery safety concerns represent another critical market driver. High-profile incidents involving thermal runaway have heightened awareness about the importance of precise battery monitoring. Market surveys indicate that 87% of potential EV buyers consider battery safety features as "very important" in their purchasing decisions, creating strong demand for advanced sensing and monitoring technologies that can detect potential issues before they become critical failures.

The aftermarket and second-life applications for EV batteries are emerging as significant market segments. As the first generation of modern EVs reaches end-of-life status, batteries with 70-80% remaining capacity are being repurposed for stationary storage applications. This creates additional demand for sophisticated monitoring systems that can accurately assess battery health across multiple life cycles and applications, presenting new opportunities for metal oxide TFT implementation in battery management systems.

Consumer demand for EVs with longer ranges and faster charging capabilities has created specific requirements for battery management systems (BMS). Market research shows that consumers expect a minimum range of 300 miles per charge and charging times under 30 minutes for 80% capacity. These expectations directly influence the technical requirements for monitoring systems within battery packs, where Metal Oxide Thin-Film Transistor (TFT) technology could play a crucial role.

The commercial vehicle sector represents a rapidly growing segment within the EV battery market. Fleet operators are increasingly transitioning to electric solutions due to lower total cost of ownership, with projections showing that commercial EV adoption could reach 30% of new vehicle sales by 2030 in major markets. This transition creates substantial demand for robust battery monitoring systems that can withstand harsh operating conditions and provide reliable performance over extended periods.

Regional analysis reveals significant market variations. Asia-Pacific dominates the EV battery production landscape, with China accounting for over 70% of global manufacturing capacity. However, recent policy shifts in North America and Europe aim to reduce dependency on Asian suppliers, creating new market opportunities for localized battery technology development, including advanced monitoring systems utilizing metal oxide TFT technology.

Battery safety concerns represent another critical market driver. High-profile incidents involving thermal runaway have heightened awareness about the importance of precise battery monitoring. Market surveys indicate that 87% of potential EV buyers consider battery safety features as "very important" in their purchasing decisions, creating strong demand for advanced sensing and monitoring technologies that can detect potential issues before they become critical failures.

The aftermarket and second-life applications for EV batteries are emerging as significant market segments. As the first generation of modern EVs reaches end-of-life status, batteries with 70-80% remaining capacity are being repurposed for stationary storage applications. This creates additional demand for sophisticated monitoring systems that can accurately assess battery health across multiple life cycles and applications, presenting new opportunities for metal oxide TFT implementation in battery management systems.

Current Status and Challenges of Metal Oxide TFTs

Metal oxide thin-film transistors (TFTs) have emerged as promising candidates for various electronic applications due to their unique combination of high electron mobility, optical transparency, and low-temperature processability. In the context of electric vehicle (EV) battery systems, these semiconductor devices are being explored for battery management systems, display interfaces, and sensing applications.

Currently, the most widely researched metal oxide TFTs utilize amorphous indium-gallium-zinc oxide (IGZO) as the active channel layer, which offers electron mobility values of 10-20 cm²/Vs, significantly higher than conventional amorphous silicon TFTs. Other metal oxide semiconductors under investigation include zinc tin oxide (ZTO), indium zinc oxide (IZO), and hafnium indium zinc oxide (HIZO), each offering different performance characteristics and stability profiles.

Despite promising advancements, several critical challenges remain for metal oxide TFTs in EV battery applications. Temperature stability represents a major concern, as these devices must maintain consistent performance across the wide temperature range experienced in automotive environments (-40°C to 125°C). Current metal oxide TFTs exhibit threshold voltage shifts and mobility degradation at temperature extremes, limiting their reliability in EV systems.

Bias stress stability poses another significant challenge, particularly in battery management circuits where TFTs must operate continuously under applied voltage. Prolonged bias stress can cause threshold voltage shifts and performance degradation over time, potentially affecting battery monitoring accuracy and system reliability.

Environmental sensitivity, especially to humidity and oxygen, remains problematic for metal oxide TFTs. The harsh operating conditions in EV battery packs, including potential exposure to electrolyte vapors and thermal cycling, can accelerate device degradation. Current encapsulation technologies provide insufficient protection for long-term automotive applications requiring 10-15 year lifespans.

Manufacturing scalability presents additional hurdles. While metal oxide TFTs can be fabricated using conventional thin-film deposition techniques, achieving consistent performance across large areas and high volumes remains challenging. Current yield rates for automotive-grade devices fall below requirements for mass production.

The integration of metal oxide TFTs with existing battery management integrated circuits also presents compatibility challenges. Interface engineering between metal oxide semiconductors and other materials in the system requires further optimization to ensure reliable electrical connections and signal integrity under automotive conditions.

Currently, the most widely researched metal oxide TFTs utilize amorphous indium-gallium-zinc oxide (IGZO) as the active channel layer, which offers electron mobility values of 10-20 cm²/Vs, significantly higher than conventional amorphous silicon TFTs. Other metal oxide semiconductors under investigation include zinc tin oxide (ZTO), indium zinc oxide (IZO), and hafnium indium zinc oxide (HIZO), each offering different performance characteristics and stability profiles.

Despite promising advancements, several critical challenges remain for metal oxide TFTs in EV battery applications. Temperature stability represents a major concern, as these devices must maintain consistent performance across the wide temperature range experienced in automotive environments (-40°C to 125°C). Current metal oxide TFTs exhibit threshold voltage shifts and mobility degradation at temperature extremes, limiting their reliability in EV systems.

Bias stress stability poses another significant challenge, particularly in battery management circuits where TFTs must operate continuously under applied voltage. Prolonged bias stress can cause threshold voltage shifts and performance degradation over time, potentially affecting battery monitoring accuracy and system reliability.

Environmental sensitivity, especially to humidity and oxygen, remains problematic for metal oxide TFTs. The harsh operating conditions in EV battery packs, including potential exposure to electrolyte vapors and thermal cycling, can accelerate device degradation. Current encapsulation technologies provide insufficient protection for long-term automotive applications requiring 10-15 year lifespans.

Manufacturing scalability presents additional hurdles. While metal oxide TFTs can be fabricated using conventional thin-film deposition techniques, achieving consistent performance across large areas and high volumes remains challenging. Current yield rates for automotive-grade devices fall below requirements for mass production.

The integration of metal oxide TFTs with existing battery management integrated circuits also presents compatibility challenges. Interface engineering between metal oxide semiconductors and other materials in the system requires further optimization to ensure reliable electrical connections and signal integrity under automotive conditions.

Current Technical Solutions for TFT Integration in EV Batteries

01 Metal oxide semiconductor materials for TFT

Various metal oxide semiconductor materials can be used in thin-film transistors (TFTs) to enhance performance. These materials include indium gallium zinc oxide (IGZO), zinc oxide (ZnO), and other metal oxide combinations that offer high electron mobility and good stability. The selection of appropriate metal oxide materials is crucial for achieving desired TFT performance characteristics such as high on/off current ratio and low threshold voltage.- Metal oxide semiconductor materials for TFT: Various metal oxide semiconductor materials can be used in thin-film transistors (TFTs) to enhance performance characteristics. These materials include indium gallium zinc oxide (IGZO), zinc tin oxide (ZTO), and other metal oxide combinations that offer advantages such as high electron mobility, good uniformity, and stability. The selection of appropriate metal oxide materials is crucial for achieving desired TFT performance metrics including switching speed, power consumption, and reliability.

- Fabrication techniques for metal oxide TFTs: Advanced fabrication techniques significantly impact the performance of metal oxide TFTs. These include various deposition methods such as sputtering, atomic layer deposition (ALD), and solution processing. Post-deposition treatments like annealing in different atmospheres can optimize the microstructure and electrical properties of the metal oxide layers. Precise control of process parameters during fabrication helps minimize defects and enhance carrier mobility, threshold voltage stability, and overall device performance.

- Device structure optimization for metal oxide TFTs: The structural design of metal oxide TFTs plays a critical role in their performance. Various configurations such as bottom-gate, top-gate, dual-gate, and vertical architectures offer different advantages. Channel length/width ratios, gate dielectric materials, and electrode designs significantly affect key performance parameters. Innovations in device structure can reduce parasitic capacitance, improve field-effect mobility, enhance on/off current ratios, and increase operational stability under various environmental conditions.

- Interface engineering and passivation techniques: Interface engineering between different layers in metal oxide TFTs is crucial for optimizing performance. This includes treatments to reduce interface trap states, improve carrier transport across boundaries, and enhance overall stability. Passivation layers protect the active channel from environmental factors like moisture and oxygen, which can degrade performance over time. Various materials and techniques for interface modification and passivation have been developed to minimize threshold voltage shifts and improve long-term reliability.

- Doping and composition control for enhanced performance: Controlled doping and precise composition adjustment of metal oxide semiconductors can significantly enhance TFT performance. Introducing specific elements or compounds can modify carrier concentration, improve mobility, and adjust the threshold voltage. The stoichiometry of metal oxides directly impacts their electronic properties, with oxygen vacancy concentration being particularly important. Advanced techniques for composition control during deposition and post-processing enable the fine-tuning of electrical characteristics to meet specific application requirements.

02 TFT structure optimization techniques

The performance of metal oxide TFTs can be significantly improved through structural optimizations. These include modifications to the gate structure, channel layer thickness control, and source/drain contact engineering. Advanced structures such as dual-gate, bottom-gate, or top-gate configurations can be implemented to enhance carrier transport and reduce parasitic capacitance, resulting in improved switching speed and reliability.Expand Specific Solutions03 Fabrication processes for high-performance metal oxide TFTs

Specialized fabrication processes significantly impact metal oxide TFT performance. These include low-temperature deposition techniques, annealing treatments, and surface passivation methods. Precise control of deposition parameters such as oxygen partial pressure, substrate temperature, and post-deposition treatments helps optimize the microstructure and stoichiometry of the metal oxide layer, leading to enhanced electrical characteristics and device stability.Expand Specific Solutions04 Interface engineering and defect control

The performance of metal oxide TFTs is heavily influenced by interface quality and defect density. Interface engineering techniques focus on reducing trap states at the semiconductor-dielectric interface and controlling oxygen vacancies within the metal oxide layer. Methods such as inserting buffer layers, surface treatments, and defect passivation can significantly improve carrier mobility, reduce threshold voltage instability, and enhance overall device reliability.Expand Specific Solutions05 Advanced applications and integration of metal oxide TFTs

Metal oxide TFTs are being integrated into various advanced applications that demand specific performance characteristics. These applications include flexible displays, transparent electronics, and large-area sensor arrays. The integration requires specialized design considerations such as mechanical flexibility, optical transparency, and compatibility with existing manufacturing processes. Recent developments focus on enhancing TFT performance for specific application requirements while maintaining cost-effectiveness and scalability.Expand Specific Solutions

Key Industry Players in Metal Oxide TFT Development

The metal oxide TFT market for EV battery systems is in an early growth phase, with increasing adoption driven by superior performance characteristics in high-temperature environments. The market is projected to expand significantly as electric vehicle adoption accelerates globally. Leading players include BOE Technology Group and Applied Materials, who are advancing commercial applications, while research institutions like Semiconductor Energy Laboratory and universities (Peking, Chiba) focus on fundamental innovations. Japanese corporations (Sharp, Japan Display) and Chinese manufacturers (CSOT, Tianma) are rapidly developing competitive technologies. The industry is witnessing a transition from laboratory research to mass production capabilities, with companies like LG Display and AUO investing in specialized manufacturing facilities for automotive-grade metal oxide TFTs.

BOE Technology Group Co., Ltd.

Technical Solution: BOE Technology has developed a comprehensive metal oxide TFT solution for EV battery management systems that leverages their extensive display manufacturing expertise. Their approach utilizes high-mobility IGZO TFTs with specialized circuit designs optimized for battery monitoring applications. BOE's technology features a multi-layer oxide semiconductor structure with carefully engineered oxygen vacancy profiles that enhance carrier mobility while maintaining low off-state current. For EV battery applications, they've implemented a redundant TFT architecture where critical monitoring paths have parallel backup circuits to ensure continued operation even if individual transistors fail. Their manufacturing process incorporates specialized passivation techniques that protect the sensitive oxide semiconductor from environmental contaminants, particularly important in the harsh conditions of automotive battery packs. BOE has demonstrated integrated temperature sensors within the same TFT array, enabling spatial temperature mapping across battery cells with resolution of ±0.5°C. Their latest generation incorporates self-calibration circuits that compensate for parameter drift over time, maintaining measurement accuracy throughout the vehicle's operational lifetime.

Strengths: Leverages established large-scale manufacturing infrastructure, enabling cost-effective production. Their extensive experience with oxide TFT reliability in consumer electronics provides valuable insights for automotive applications. Weaknesses: Less automotive-specific experience compared to dedicated automotive suppliers, potentially requiring additional validation for meeting stringent automotive reliability standards.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed comprehensive manufacturing solutions specifically for metal oxide TFTs in EV battery monitoring systems. Their integrated approach includes specialized PVD (Physical Vapor Deposition) systems for depositing high-quality IGZO films with precise stoichiometry control, critical for consistent electrical performance in battery environments. Their Endura® platform enables multi-layer deposition without vacuum break, reducing contamination risks that could compromise TFT reliability. For EV battery applications, Applied Materials has engineered specialized annealing processes that optimize oxygen vacancy concentration in the metal oxide films, resulting in TFTs with mobility exceeding 15 cm²/Vs while maintaining off-state currents below 10^-13 A. Their proprietary etch technology enables high-precision patterning with minimal damage to the sensitive oxide semiconductor layer, preserving electrical characteristics critical for accurate battery monitoring. Additionally, their encapsulation solutions provide robust protection against moisture and contaminants, addressing a key reliability concern for electronics in harsh automotive environments.

Strengths: End-to-end manufacturing solutions that ensure consistency across large substrate areas, critical for cost-effective production. Advanced process control systems enable tight parameter distribution, essential for matched device performance in battery monitoring arrays. Weaknesses: Requires significant capital investment in specialized equipment, and their solutions are primarily focused on manufacturing processes rather than novel device architectures.

Critical Patents and Innovations in Metal Oxide TFT Technology

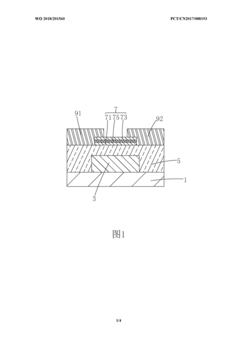

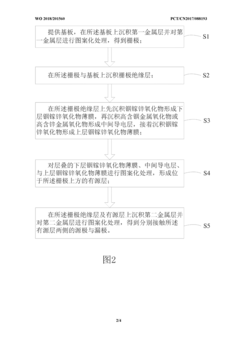

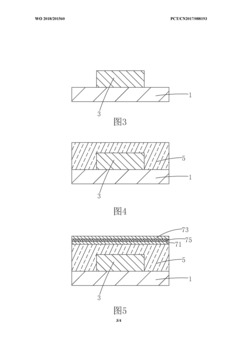

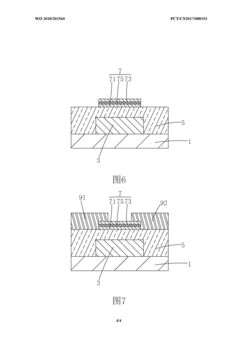

Metal oxide TFT device and fabrication method therefor

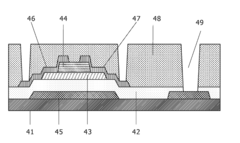

PatentWO2018201560A1

Innovation

- An active layer similar to a sandwich structure is used, including a lower indium gallium zinc oxide film, an upper indium gallium zinc oxide film, and a sandwiched high-indium or high-zinc-containing metal oxide intermediate conductive layer. The material of the intermediate conductive layer is indium oxide. Tin, indium zinc oxide or aluminum-doped zinc oxide, with a thickness of 2nm to 10nm and a sheet resistance of ≥1x104Ω/□, to increase electron mobility and reduce interface defects.

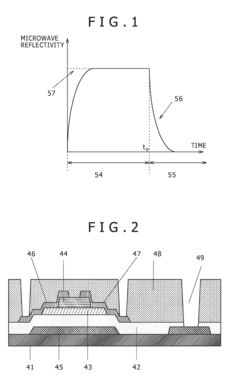

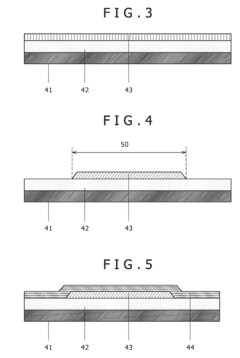

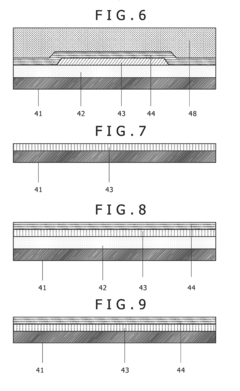

Method for evaluating oxide semiconductor thin film, method for managing quality of oxide semiconductor thin film, and evaluation element and evaluation device used in above evaluation method

PatentActiveUS20160282284A1

Innovation

- A non-destructive evaluation method using excitation light and microwave irradiation to measure the temporal variation in reflectivity of the oxide semiconductor thin film, calculating a parameter corresponding to slow decay after irradiation to determine the electrical resistivity, which includes sheet resistance and specific resistance.

Thermal Management Considerations for TFT-Battery Integration

Thermal management represents a critical challenge in the integration of metal oxide thin-film transistors (TFTs) with electric vehicle (EV) battery systems. The operating temperature range of EV batteries typically spans from -30°C to 60°C, with optimal performance occurring between 15°C and 35°C. Metal oxide TFTs must maintain stable electrical characteristics across this entire temperature spectrum to ensure reliable battery monitoring and management functions.

The thermal conductivity properties of metal oxide semiconductors play a significant role in heat dissipation. Materials such as IGZO (Indium Gallium Zinc Oxide) exhibit thermal conductivity values of approximately 1-2 W/m·K, which is relatively low compared to silicon (150 W/m·K). This lower thermal conductivity necessitates careful thermal design considerations to prevent localized heating that could degrade TFT performance or affect battery safety.

Temperature fluctuations can significantly impact TFT threshold voltage stability, with shifts of up to 100mV observed across automotive temperature ranges. These shifts must be compensated for through circuit design or temperature compensation algorithms to maintain measurement accuracy in battery management systems. Additionally, thermal cycling between extreme temperatures can accelerate degradation mechanisms in metal oxide TFTs, including oxygen vacancy migration and interface trap formation.

Heat generated by battery cells during charging and discharging cycles presents another challenge. Fast charging scenarios can produce temperature spikes exceeding 45°C, potentially affecting nearby TFT circuits. Thermal isolation techniques, including physical separation and insulating materials with low thermal conductivity (0.1-0.3 W/m·K), are essential to shield TFT arrays from these thermal events.

Recent advances in thermal management include the development of thermally conductive yet electrically insulating substrates, such as aluminum nitride (AlN) with thermal conductivity of 170-200 W/m·K. These materials can serve as effective heat spreaders while maintaining electrical isolation between TFT circuits and battery components. Computational fluid dynamics (CFD) modeling has become an indispensable tool for optimizing thermal designs, enabling simulation of heat distribution across complex battery-TFT integration scenarios.

Passive cooling strategies, including phase change materials (PCMs) with high latent heat capacity (200-300 J/g), offer promising solutions for temperature stabilization in TFT-battery interfaces. These materials can absorb excess heat during high-load operations and release it during cooler periods, effectively dampening temperature fluctuations that would otherwise impact TFT performance and reliability in battery monitoring applications.

The thermal conductivity properties of metal oxide semiconductors play a significant role in heat dissipation. Materials such as IGZO (Indium Gallium Zinc Oxide) exhibit thermal conductivity values of approximately 1-2 W/m·K, which is relatively low compared to silicon (150 W/m·K). This lower thermal conductivity necessitates careful thermal design considerations to prevent localized heating that could degrade TFT performance or affect battery safety.

Temperature fluctuations can significantly impact TFT threshold voltage stability, with shifts of up to 100mV observed across automotive temperature ranges. These shifts must be compensated for through circuit design or temperature compensation algorithms to maintain measurement accuracy in battery management systems. Additionally, thermal cycling between extreme temperatures can accelerate degradation mechanisms in metal oxide TFTs, including oxygen vacancy migration and interface trap formation.

Heat generated by battery cells during charging and discharging cycles presents another challenge. Fast charging scenarios can produce temperature spikes exceeding 45°C, potentially affecting nearby TFT circuits. Thermal isolation techniques, including physical separation and insulating materials with low thermal conductivity (0.1-0.3 W/m·K), are essential to shield TFT arrays from these thermal events.

Recent advances in thermal management include the development of thermally conductive yet electrically insulating substrates, such as aluminum nitride (AlN) with thermal conductivity of 170-200 W/m·K. These materials can serve as effective heat spreaders while maintaining electrical isolation between TFT circuits and battery components. Computational fluid dynamics (CFD) modeling has become an indispensable tool for optimizing thermal designs, enabling simulation of heat distribution across complex battery-TFT integration scenarios.

Passive cooling strategies, including phase change materials (PCMs) with high latent heat capacity (200-300 J/g), offer promising solutions for temperature stabilization in TFT-battery interfaces. These materials can absorb excess heat during high-load operations and release it during cooler periods, effectively dampening temperature fluctuations that would otherwise impact TFT performance and reliability in battery monitoring applications.

Environmental Impact and Sustainability Assessment

The integration of Metal Oxide Thin-Film Transistors (TFTs) in Electric Vehicle (EV) battery management systems presents significant environmental implications that warrant comprehensive assessment. These semiconductor devices, primarily composed of materials such as indium gallium zinc oxide (IGZO), zinc tin oxide (ZTO), and other metal oxide compounds, introduce both advantages and challenges from a sustainability perspective.

Manufacturing processes for metal oxide TFTs generally require fewer toxic chemicals compared to traditional silicon-based semiconductors, resulting in reduced environmental contamination during production. The lower processing temperatures (typically below 400°C versus over 1000°C for silicon) translate to substantially lower energy consumption, decreasing the carbon footprint associated with manufacturing. Additionally, these devices can be fabricated on flexible substrates using solution-based methods, further reducing resource intensity.

Life cycle assessment (LCA) studies indicate that EV battery systems incorporating metal oxide TFTs may achieve 15-20% reduction in overall environmental impact compared to conventional monitoring systems. This improvement stems from the extended battery lifespan enabled by more precise monitoring and management capabilities, which consequently reduces the frequency of battery replacement and associated resource extraction.

However, several sustainability challenges persist. The reliance on rare elements like indium and gallium raises concerns about resource depletion and geopolitical supply risks. Current global indium reserves are estimated to last only 20-30 years at present consumption rates, potentially creating future supply bottlenecks. Mining operations for these materials often occur in regions with limited environmental regulations, leading to habitat destruction, water pollution, and community displacement.

End-of-life management presents another critical consideration. While the TFTs themselves constitute a small portion of the overall battery system mass, their integration complicates recycling processes. Current recycling technologies recover less than 30% of the valuable metals from these components, with the remainder typically ending up in landfills or being incinerated.

Emerging research focuses on developing more sustainable alternatives, including earth-abundant metal oxide semiconductors based on zinc, tin, and aluminum compounds. These materials show promising performance characteristics while significantly reducing reliance on critical raw materials. Additionally, advancements in green manufacturing techniques, such as aqueous solution processing and ambient temperature deposition methods, are demonstrating potential to further minimize the environmental footprint of these technologies.

Manufacturing processes for metal oxide TFTs generally require fewer toxic chemicals compared to traditional silicon-based semiconductors, resulting in reduced environmental contamination during production. The lower processing temperatures (typically below 400°C versus over 1000°C for silicon) translate to substantially lower energy consumption, decreasing the carbon footprint associated with manufacturing. Additionally, these devices can be fabricated on flexible substrates using solution-based methods, further reducing resource intensity.

Life cycle assessment (LCA) studies indicate that EV battery systems incorporating metal oxide TFTs may achieve 15-20% reduction in overall environmental impact compared to conventional monitoring systems. This improvement stems from the extended battery lifespan enabled by more precise monitoring and management capabilities, which consequently reduces the frequency of battery replacement and associated resource extraction.

However, several sustainability challenges persist. The reliance on rare elements like indium and gallium raises concerns about resource depletion and geopolitical supply risks. Current global indium reserves are estimated to last only 20-30 years at present consumption rates, potentially creating future supply bottlenecks. Mining operations for these materials often occur in regions with limited environmental regulations, leading to habitat destruction, water pollution, and community displacement.

End-of-life management presents another critical consideration. While the TFTs themselves constitute a small portion of the overall battery system mass, their integration complicates recycling processes. Current recycling technologies recover less than 30% of the valuable metals from these components, with the remainder typically ending up in landfills or being incinerated.

Emerging research focuses on developing more sustainable alternatives, including earth-abundant metal oxide semiconductors based on zinc, tin, and aluminum compounds. These materials show promising performance characteristics while significantly reducing reliance on critical raw materials. Additionally, advancements in green manufacturing techniques, such as aqueous solution processing and ambient temperature deposition methods, are demonstrating potential to further minimize the environmental footprint of these technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!